Content Menu

>> I. What is Prototype SMT Assembly?

>> II. The Prototype SMT Assembly Process

>>> 1. Material Preparation and Testing

>>> 2. Design and Schematic Capture

>>> 3. BOM (Bill of Materials) Generation

>>> 4. PCB Fabrication

>>> 5. Solder Paste Stenciling

>>> 6. Component Placement (Pick and Place)

>>> 7. Reflow Soldering

>>> 8. Cleaning and Washing

>>> 9. Inspection

>>> 10. Testing

>> III. Benefits of Prototype SMT Assembly

>> IV. Key Considerations for Prototype SMT Assembly

>> V. Choosing a Prototype SMT Assembly Manufacturer

>> VI. Common Challenges in Prototype SMT Assembly

>> VII. Cost Considerations

>> VIII. The Future of Prototype SMT Assembly

>> IX. Case Studies

● FAQ: Frequently Asked Questions About Prototype SMT Assembly

>>> Q1: What are the main advantages of prototype SMT assembly?

>>> Q2: What are the key steps in the prototype SMT assembly process?

>>> Q3: How to assemble a prototype PCB?

>>> Q4: What are the key considerations in the prototype SMT assembly?

>>> Q5: How does SMT assembly reduce cost?

Prototype SMT (Surface Mount Technology) Assembly is the process of creating a small batch of electronic circuit boards for testing and validation *before* full-scale production[7]. It involves assembling electronic components onto a printed circuit board (PCB) using automated pick-and-place machines and reflow ovens[7].

This process is essential for validating the design and functionality of a circuit board[7]. It allows engineers to test the board's performance, identify any issues, and make necessary changes before mass production[7]. This saves time, money, and resources by preventing costly mistakes in large-scale manufacturing.

II. The Prototype SMT Assembly Process

The prototype SMT assembly process typically involves the following steps:

1. Material Preparation and Testing

SMT assembly process flow mainly includes the following steps: material preparation and testing[1]. Prepare SMT machine, SMT PCB, SMD components and check for any defects[1]. PCB usually has flat, usually tin lead, silver or gold plated, non porous copper pads, called pads[1].

2. Design and Schematic Capture

A well-defined design and schematic are the foundation of any successful PCB assembly.

3. BOM (Bill of Materials) Generation

A comprehensive BOM lists all the components required for the assembly.

4. PCB Fabrication

This involves creating the physical PCB based on the design files[2]. Fabrication includes creating photo films, printing layers, fusing, drilling, and plating[2].

5. Solder Paste Stenciling

Solder paste is applied to the PCB using a stencil, ensuring precise and controlled application to the pads where components will be placed[2][4]. In this step, solder paste is applied uniformly using stencils[4]. Solder paste is a combination of powdered metal solder like tin, silver, and copper and a flux medium[4]. We can provide a fixed position for solder paste printing on the template, which is produced according to the design position of the bonding pad on the PCB[1].

6. Component Placement (Pick and Place)

Surface mount components are accurately placed onto the PCB using automated pick and place machines[4][12]. The position of the components will correspond to the design files[12]. Pick and place utilize advanced machines for a precise component population[2]. Components of one type is loaded on each feeder[13]. The orientation, location, and pad size for the SMT components will be programmed on the machine from the picking place files[9].

7. Reflow Soldering

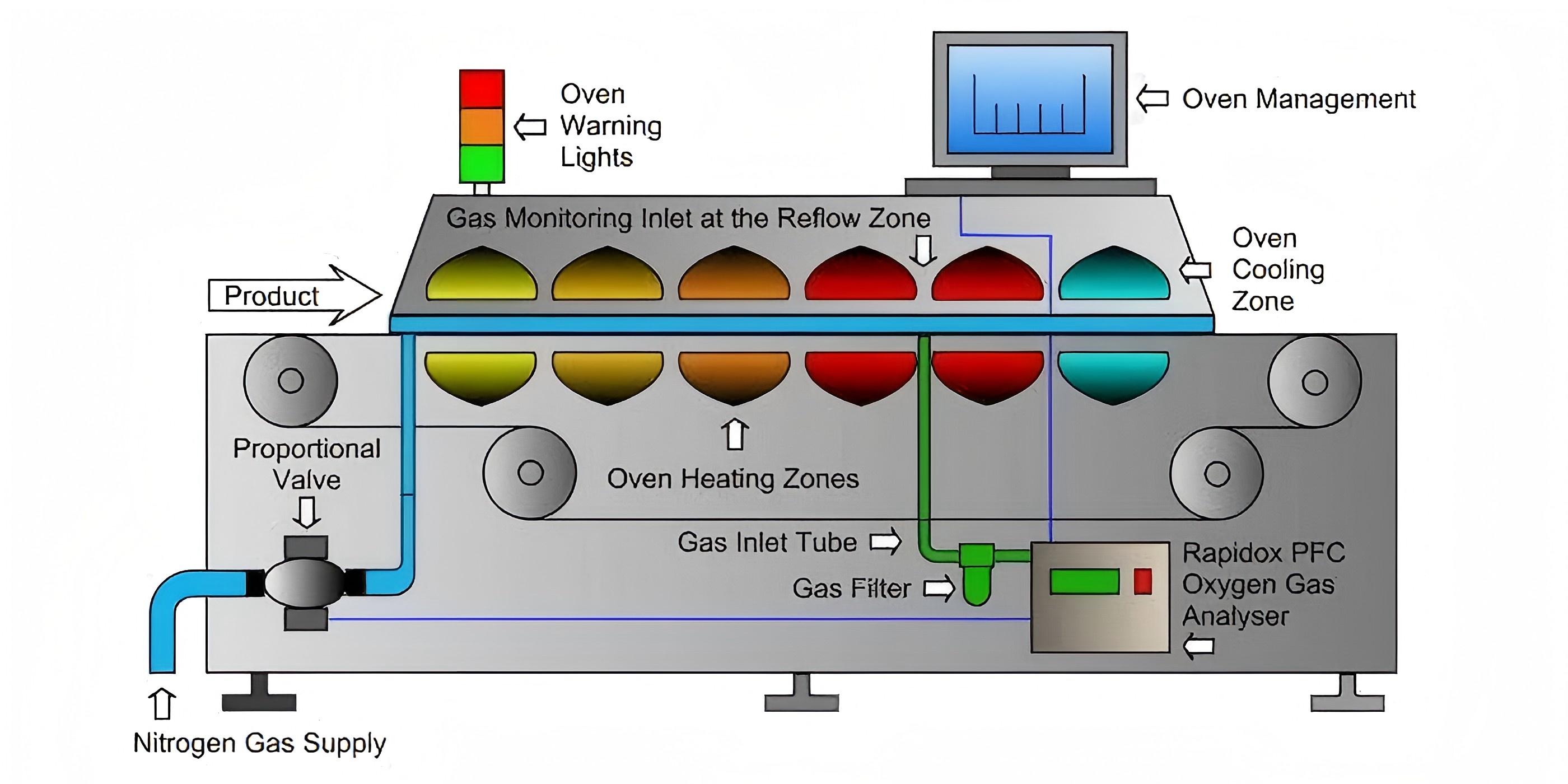

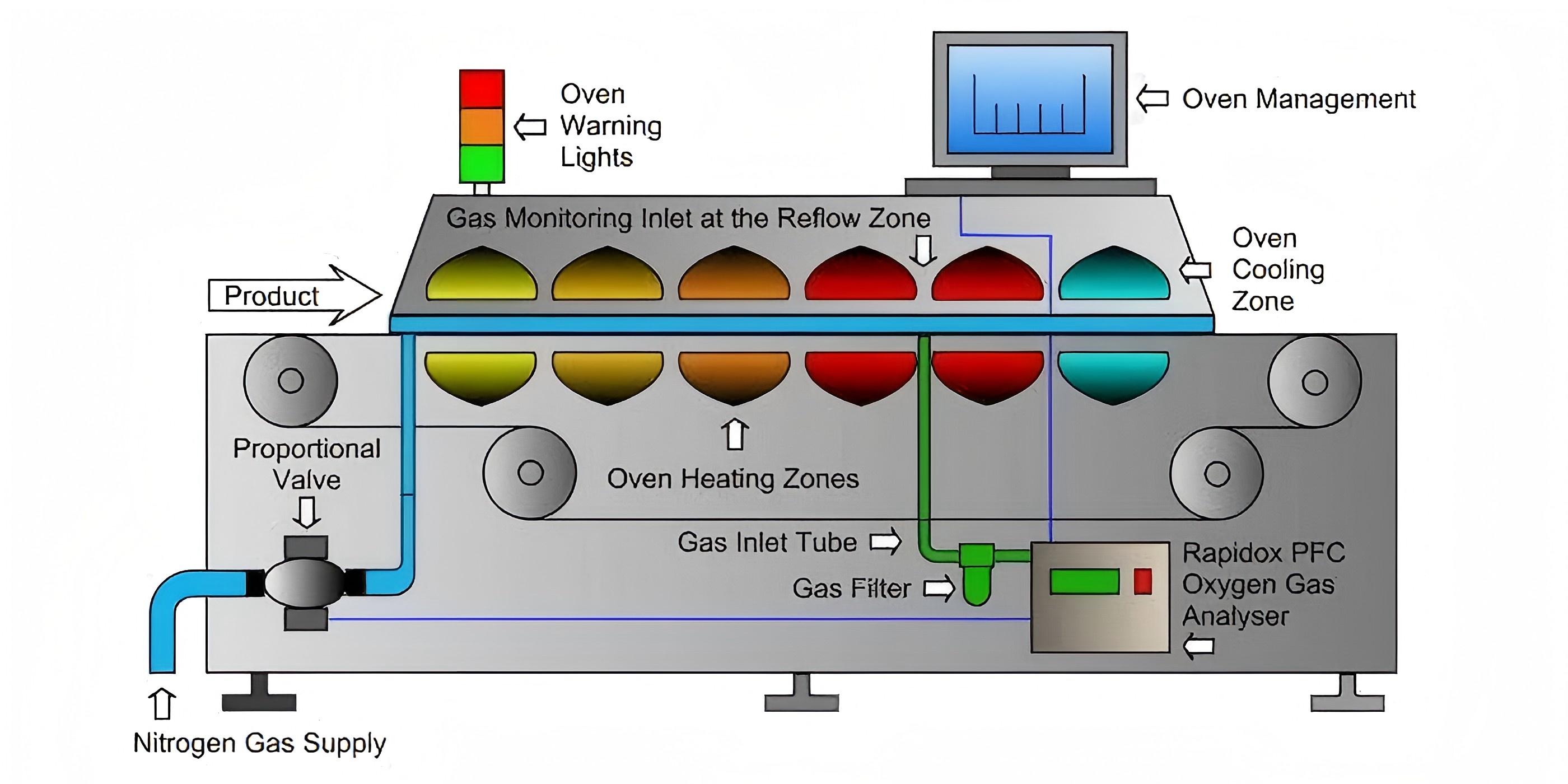

The assembled PCB is then passed through a reflow oven, where the solder paste melts, creating permanent solder joints between the components and the PCB[2][5]. After accurate component positioning, boards pass through industrial reflow ovens.

8. Cleaning and Washing

After reflow soldering, the PCB may require cleaning to remove any flux residue. Cleaning is performed using a PCB machine[2].

9. Inspection

After soldering, the board is inspected to ensure the solder joints meet requirements, and all components are properly placed[2][8]. After that a lot of different things could happen to finish the assembly. It might go through the SMT process again for the second side. It will be cleaned if needed, de-paneled, maybe have through-hole components added by machine or by hand, go through burn-in, get a protective conformal coating, and be packaged in custom trays for shipment[11].

10. Testing

The assembled PCB undergoes functional testing to ensure it performs as designed[2]. This process utilizes an eco-friendly PCB machine[2].

III. Benefits of Prototype SMT Assembly

Prototype SMT assembly offers several key advantages:

* Design Validation: It allows for thorough testing and validation of the PCB design before mass production[7].

* Cost Savings: Identifying and fixing design flaws early on prevents costly rework and scrapped boards in mass production[7].

* Faster Time to Market: By identifying issues early, prototype assembly accelerates the development process, reducing time to market.

* Improved Reliability: Allows for optimization of the assembly process, leading to more reliable end products[7].

* Flexibility: Prototype SMT assembly offers the flexibility to experiment with different components and assembly techniques[6].

* Component Density: SMT assembly allows for higher component density, reduced board size, and lower cost[7].

IV. Key Considerations for Prototype SMT Assembly

* Component Selection:

* Design for Manufacturability (DFM):

* Assembly Process: The assembly process is the final factor to consider in prototype SMT assembly[7].

* Equipment and tools: The right equipment and tools should be used for the assembly process, to ensure efficiency and accuracy[7].

* Soldering technique: The soldering technique used can affect the quality and reliability of the final product[7].

* Quality control: Quality control measures should be put in place to ensure that the final product meets the required specifications and standards[7].

V. Choosing a Prototype SMT Assembly Manufacturer

Selecting the right prototype SMT assembly manufacturer is crucial for the success of your project. Consider the following factors:

* Experience: Look for a manufacturer with proven experience in prototype SMT assembly.

* Capabilities: Ensure the manufacturer has the necessary equipment and expertise to handle your project's complexity.

* Turnaround Time: Check the manufacturer's turnaround time and ensure it meets your project's timeline.

* Quality Control: Inquire about the manufacturer's quality control processes to ensure reliable assembly.

* Communication: Opt for a manufacturer with clear and responsive communication.

* Pricing: Compare pricing from different manufacturers, but don't sacrifice quality for cost.

VI. Common Challenges in Prototype SMT Assembly

* Component Availability: Sourcing components in small quantities for prototypes can be challenging.

* Fine-Pitch Components: Handling and assembling fine-pitch components requires specialized equipment and expertise.

* Double-Sided Assembly: SMT assembly can combine tiny chips with SMT parts and allow hybrid assembly on double-sided boards[2].

* Rework and Repair: Making changes or repairs on assembled prototypes can be complex and time-consuming.

VII. Cost Considerations

* NRE (Non-Recurring Engineering) Costs: These are one-time costs associated with setting up the assembly process.

* Component Costs: The cost of components will depend on their type, quantity, and availability.

* Labor Costs: The cost of labor will depend on the complexity of the assembly and the manufacturer's rates.

* Testing Costs: The cost of functional testing will depend on the complexity of the test procedures.

VIII. The Future of Prototype SMT Assembly

The future of prototype SMT assembly is driven by increasing automation, miniaturization, and demand for faster turnaround times.

FAQ: Frequently Asked Questions About Prototype SMT Assembly

Q1: What are the main advantages of prototype SMT assembly?

A: Design validation, cost savings, faster time to market, and improved reliability[7].

Q2: What are the key steps in the prototype SMT assembly process?

A: Material preparation, design, BOM generation, PCB fabrication, solder paste stenciling, component placement, reflow soldering, cleaning, inspection, and testing [1, 2, 4, 5].

Q3: How to assemble a prototype PCB?

A: The PCB prototype assembly involves following steps: design, routing, generating BOM, stencil, pick & place, reflow soldering, inspection, functionality tests, and thorough checks[2].

Q4: What are the key considerations in the prototype SMT assembly?

A: Equipment, soldering techniques and the quality controls[7].

Q5: How does SMT assembly reduce cost?

A: By higher component density, reduced board size, and lower cost[7].