Content Menu

● Understanding SMT Stencil Printers

>> Types of SMT Stencil Printers

● Key Benefits of High-End SMT Stencil Printers

>> Superior Precision and Accuracy

>> Increased Production Efficiency

>> Consistency and Repeatability

>> Flexibility for Complex Designs

>> Long-Term Cost Savings

● Considerations Before Investing

>> Balancing Cost and Production Volume

>> Complexity of PCB Designs

>> Maintenance and Support

>> Integration with Automated Production Lines

● Comparing SMT Stencil Printing to Alternative Technologies

● Conclusion

● FAQ

>> 1. What factors affect the SMT stencil printer price?

>> 2. How does a high-end SMT stencil printer improve solder paste application?

>> 3. Is a high-end SMT stencil printer suitable for small production runs?

>> 4. How does SMT stencil printing compare to jet-based solder paste printing?

>> 5. What maintenance is required for high-end SMT stencil printers?

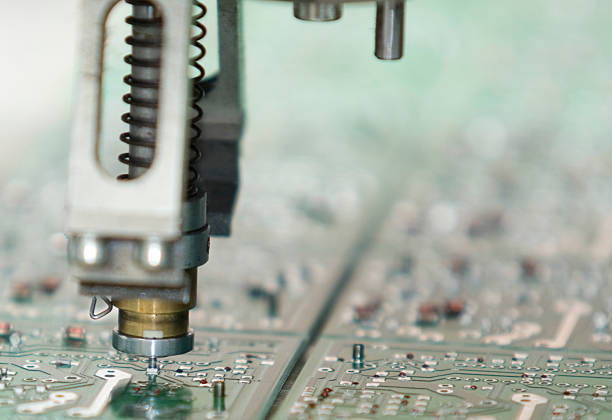

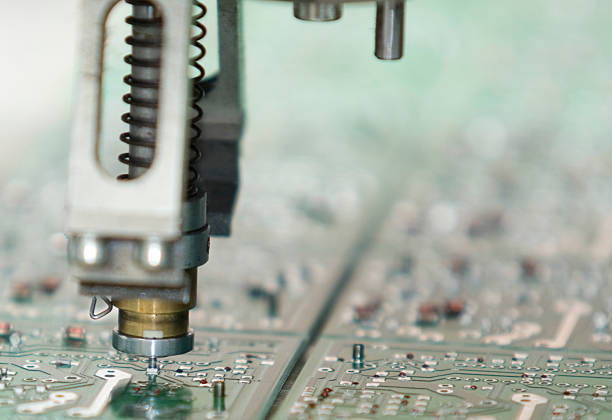

In the fast-evolving electronics manufacturing industry, precision, efficiency, and quality are paramount. Surface Mount Technology (SMT) stencil printers play a critical role in the assembly of printed circuit boards (PCBs) by ensuring accurate application of solder paste. This directly affects the reliability and performance of electronic devices. However, deciding whether to invest in a high-end SMT stencil printer requires careful consideration, especially given the significant smt stencil printer price associated with advanced models. This article will explore the advantages, features, and considerations of high-end SMT stencil printers to help manufacturers determine if such an investment aligns with their production needs.

Understanding SMT Stencil Printers

SMT stencil printers are machines used to apply solder paste onto PCBs through precisely cut apertures in a stencil. The solder paste is deposited exactly where electronic components will be mounted, ensuring strong electrical and mechanical connections. The quality of this step is critical to avoid defects such as solder bridging, insufficient solder, or misalignment, which can compromise the final product.

Types of SMT Stencil Printers

- Manual SMT Stencil Printers: These are basic machines that require manual operation. They are suitable for small-scale production or prototyping but offer limited automation and slower throughput.

- Semi-Automatic SMT Stencil Printers: These printers combine manual and automated features, providing improved control and consistency with moderate production speeds. They are often preferred by manufacturers with medium-volume requirements.

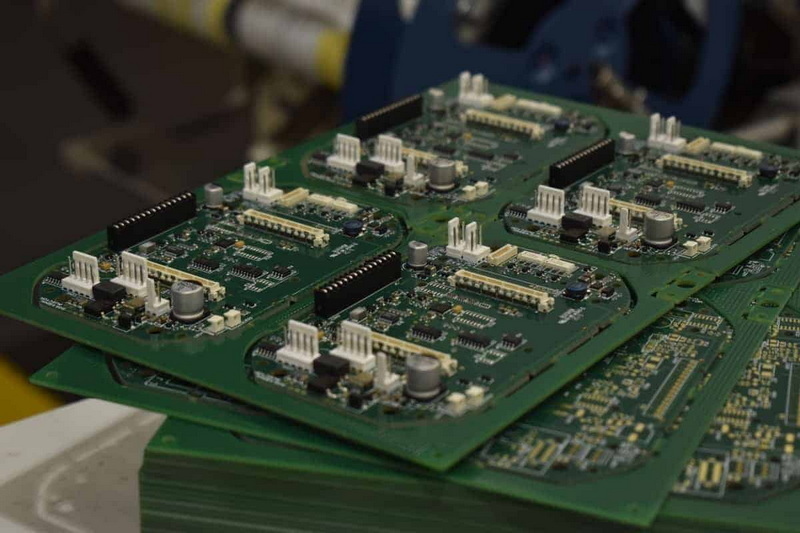

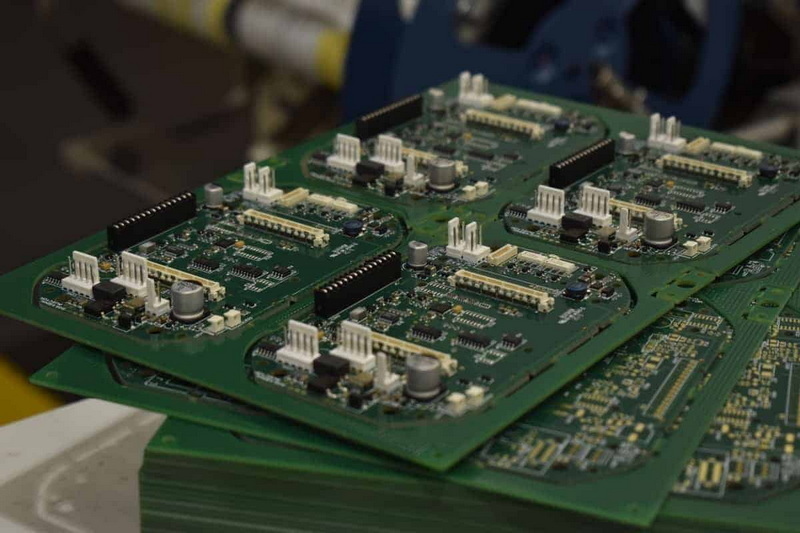

- Fully Automatic SMT Stencil Printers: These high-end machines feature full automation, including automatic stencil alignment, paste printing, and cleaning. They deliver the highest precision, speed, and repeatability, making them ideal for large-scale manufacturing.

The smt stencil printer price varies widely across these categories, with high-end models commanding a premium due to their advanced capabilities.

Key Benefits of High-End SMT Stencil Printers

Superior Precision and Accuracy

High-end SMT stencil printers incorporate advanced technologies such as automatic alignment systems, dual squeegees, and precise pressure controls. These features ensure that solder paste is applied with exceptional accuracy, reducing the risk of defects like solder shorts or open circuits. This precision is especially critical for fine-pitch components and complex PCB designs that demand meticulous solder paste deposition.

Increased Production Efficiency

Automation significantly speeds up the solder paste printing process. Features such as automatic stencil cleaning and parallel stencil lifting reduce downtime between print cycles, enabling manufacturers to achieve higher throughput. This efficiency is vital for meeting tight production schedules and handling large volumes.

Consistency and Repeatability

Maintaining uniform solder paste volume and placement across multiple PCBs is essential for quality control. High-end printers provide consistent application, minimizing variability and reducing the need for rework. This consistency enhances overall yield and reliability of electronic assemblies.

Flexibility for Complex Designs

Advanced SMT stencil printers can accommodate a variety of stencil types and sizes, including frameless stencils and those with specialized coatings. They are also capable of printing on double-sided boards and handling different PCB geometries. This flexibility supports manufacturers dealing with increasingly intricate PCB layouts.

Long-Term Cost Savings

Although the initial smt stencil printer price for high-end models is considerable, the investment can lead to significant long-term savings. Reduced defects, minimized solder paste waste, and lower labor costs contribute to improved profitability. Furthermore, the robustness and reliability of high-end machines help reduce maintenance expenses over time.

Considerations Before Investing

Balancing Cost and Production Volume

The smt stencil printer price for high-end machines is substantial. For manufacturers with low production volumes or limited budgets, such an investment may not be justified. In these cases, semi-automatic or manual printers might provide a better balance between cost and capability.

Complexity of PCB Designs

Manufacturers producing simple PCB designs may not require the advanced features of high-end printers. However, those working with fine-pitch components or high-density boards will benefit greatly from the precision and automation offered by premium stencil printers.

Maintenance and Support

High-end SMT stencil printers often come with comprehensive service packages, including setup assistance, operator training, and ongoing technical support. These services can add value by ensuring optimal machine performance and minimizing downtime.

Integration with Automated Production Lines

For manufacturers operating automated assembly lines, choosing a high-end SMT stencil printer that integrates smoothly with other equipment can enhance overall workflow efficiency and reduce manual intervention.

Comparing SMT Stencil Printing to Alternative Technologies

While SMT stencil printing remains the industry standard for solder paste application, alternative methods such as jet-based solder paste printing are gaining attention. Jet printing offers high precision and flexibility, especially for complex or small-batch production. However, stencil printing remains more cost-effective for mass production and is known for its reliability and repeatability.

Conclusion

Investing in a high-end SMT stencil printer is a strategic decision influenced by production volume, PCB design complexity, and quality requirements. High-end printers offer superior precision, increased efficiency, and consistent solder paste application, which can translate into improved product quality and long-term cost savings. However, the significant smt stencil printer price means that such investments are best suited for medium to large-scale manufacturers or those with demanding assembly needs. Smaller operations or prototyping facilities may find semi-automatic or manual printers more economically viable. Ultimately, understanding your specific production goals and evaluating total cost of ownership will help determine whether a high-end SMT stencil printer is the right choice for your manufacturing process.

FAQ

1. What factors affect the SMT stencil printer price?

The smt stencil printer price depends on automation level, printing area size, precision features, and brand reputation. Fully automatic printers with advanced alignment and cleaning systems are priced higher than manual or semi-automatic models.

2. How does a high-end SMT stencil printer improve solder paste application?

High-end SMT stencil printers provide precise control over solder paste volume and placement, reducing defects such as solder bridging and insufficient solder joints.

3. Is a high-end SMT stencil printer suitable for small production runs?

For small production runs or prototyping, the high cost of advanced printers may not be justified. Manual or semi-automatic printers often provide sufficient quality at a lower price.

4. How does SMT stencil printing compare to jet-based solder paste printing?

Stencil printing is generally more cost-effective and reliable for large-scale production, while jet-based printing offers greater flexibility and precision for complex or small-batch assemblies.

5. What maintenance is required for high-end SMT stencil printers?

Maintenance includes regular cleaning, calibration, stencil inspection, and software updates. Many manufacturers offer support packages to assist with ongoing upkeep.