Content Menu

● Understanding SMD Placement Machine Price

>> Price Range Breakdown

>> Factors Influencing SMD Placement Machine Price

● Advantages of High-End SMD Placement Machines

>> 1. Unmatched Precision and Quality Control

>> 2. Exceptional Speed and Throughput

>> 3. Wide Component Compatibility and Automation

>> 4. Long-Term Cost Savings and ROI

● Considerations Before Investing in a High-End SMD Placement Machine

>> Capital Investment vs. Production Volume

>> Maintenance and Operating Costs

>> Training and Workforce Adaptation

>> Compatibility with Existing Production Lines

● Case Studies: Real-World Impact of High-End SMD Placement Machines

>> Case Study 1: Large Electronics Manufacturer

>> Case Study 2: Small to Medium Enterprise (SME)

● Technological Innovations Driving High-End SMD Placement Machines

● Conlusion

● FAQ

>> 1. What is the typical price range for SMD placement machines?

>> 2. How does machine speed affect the price?

>> 3. Can smaller manufacturers benefit from high-end SMD machines?

>> 4. What operational savings do high-end machines provide?

>> 5. How important is machine accuracy in SMD placement?

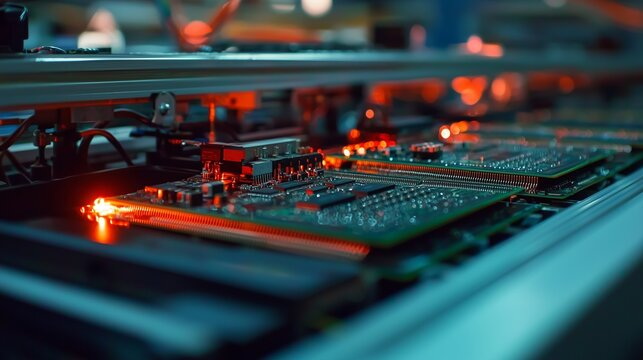

Surface Mount Device (SMD) placement machines are the backbone of modern electronics manufacturing. They enable the precise, rapid, and automated assembly of printed circuit boards (PCBs), which are essential components in virtually all electronic devices today. However, the decision to invest in a high-end SMD placement machine is not straightforward. These machines come with a significant price tag, and manufacturers must carefully evaluate whether the benefits justify the cost.

In this comprehensive article, we will explore the SMD placement machine price spectrum, analyze the advantages of high-end machines, discuss operational considerations, and provide actionable insights to help manufacturers make informed investment decisions.

Understanding SMD Placement Machine Price

The SMD placement machine price varies dramatically depending on the machine's capabilities, brand reputation, and technological sophistication. Understanding this price range is fundamental to evaluating the worth of investing in a high-end model.

Price Range Breakdown

- Entry-Level Machines: These machines are typically priced between USD 5,000 and USD 30,000. They are suitable for small-scale production, prototyping, or educational purposes. While affordable, these machines often have limited speed, accuracy, and component handling capabilities.

- Mid-Range Machines: Costing between USD 30,000 and USD 100,000, mid-range machines offer better speed, improved accuracy, and more flexibility in component sizes. They are ideal for small to medium-sized manufacturers looking to scale production without a massive initial investment.

- High-End Machines: These are premium models designed for large-scale, high-speed, and high-precision production. Their price typically ranges from USD 100,000 to over USD 500,000, with some ultra-high-speed machines exceeding USD 1 million. These machines incorporate advanced technologies such as multi-head placement, AI-driven vision systems, and ultra-precise feeders.

Factors Influencing SMD Placement Machine Price

Several key factors contribute to the price of an SMD placement machine:

- Speed and Throughput: Machines capable of placing tens of thousands of components per hour require sophisticated mechanics and control systems, driving up costs.

- Placement Accuracy: High-end machines offer placement accuracy within a few microns, essential for fine-pitch components and complex PCBs, which increases manufacturing quality but also the price.

- Component Range: The ability to handle a wide variety of component sizes, from tiny 01005 packages to large connectors, requires versatile feeders and nozzles, adding complexity and cost.

- Automation and Software: Advanced automation features, including automated feeder loading, intelligent vision systems, and real-time error detection, contribute significantly to the price.

- Brand and Support: Premium brands often charge more but provide better after-sales support, training, and software updates, which can be crucial for long-term operation.

Advantages of High-End SMD Placement Machines

Investing in a high-end SMD placement machine offers numerous advantages that can significantly impact manufacturing efficiency, product quality, and overall profitability.

1. Unmatched Precision and Quality Control

High-end machines boast placement accuracy often better than ±10 microns. This precision is vital for modern electronics, where components are densely packed on PCBs with fine-pitch leads. Accurate placement reduces soldering defects such as tombstoning, bridging, and misalignment, which can cause costly rework or product failure.

Additionally, advanced vision systems integrated into high-end machines perform real-time inspection of component orientation and placement accuracy, ensuring quality control during production rather than after.

2. Exceptional Speed and Throughput

High-end SMD placement machines can place upwards of 50,000 components per hour, dramatically accelerating production cycles. This speed is essential for manufacturers fulfilling large orders or operating just-in-time (JIT) production lines.

Faster throughput reduces lead times, enabling quicker delivery to customers and the ability to respond rapidly to market demands. This competitive advantage can justify the higher SMD placement machine price.

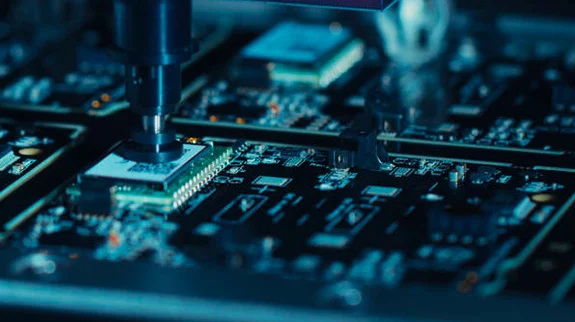

3. Wide Component Compatibility and Automation

High-end machines support a vast range of component sizes and types, including 01005 resistors, BGAs (Ball Grid Arrays), QFNs (Quad Flat No-leads), and connectors. This versatility reduces the need for multiple machines or manual intervention, streamlining the production line.

Automation features such as automatic feeder loading, nozzle changing, and intelligent error recovery reduce labor costs and minimize human error. This automation also improves uptime and consistency, critical for high-volume manufacturing.

4. Long-Term Cost Savings and ROI

While the initial SMD placement machine price is high, the long-term savings can be substantial:

- Reduced Defects and Rework: Higher placement accuracy and quality control minimize costly defects, saving materials and labor.

- Lower Labor Costs: Automation reduces the need for manual operators, lowering payroll expenses.

- Material Efficiency: Precise placement reduces component waste and solder paste usage.

- Improved Customer Satisfaction: Consistent product quality reduces warranty claims and strengthens brand reputation.

Over time, these factors contribute to a favorable return on investment (ROI), often within a few years depending on production volume.

Considerations Before Investing in a High-End SMD Placement Machine

Despite the clear benefits, several practical considerations must be evaluated before committing to a high-end SMD placement machine.

Capital Investment vs. Production Volume

High-end machines often represent about 40-60% of the total capital investment for a medium to large SMT line. For manufacturers with low or variable production volumes, this upfront cost can be prohibitive.

Smaller manufacturers or startups may find it more economical to purchase mid-range or refurbished machines, which offer a balance between cost and capability. Leasing options or contract manufacturing partnerships can also be alternatives to outright purchase.

Maintenance and Operating Costs

Premium machines require regular maintenance, including calibration, cleaning, and parts replacement, to maintain peak performance. These maintenance activities involve skilled technicians and can incur significant costs.

Operating costs such as power consumption, software licensing, and consumables (nozzles, feeders) should also be factored into the total cost of ownership.

Training and Workforce Adaptation

High-end machines often come with complex software and require trained operators and programmers. Investing in workforce training is essential to fully leverage the machine's capabilities and avoid underutilization.

Manufacturers must also consider the learning curve and potential production downtime during the transition period.

Compatibility with Existing Production Lines

Integrating a new high-end SMD placement machine into an existing production line requires compatibility checks with other equipment such as solder paste printers, reflow ovens, and inspection systems.

Ensuring smooth data flow and communication between machines is crucial for maintaining line efficiency.

Case Studies: Real-World Impact of High-End SMD Placement Machines

Case Study 1: Large Electronics Manufacturer

A multinational electronics company invested USD 450,000 in a high-end SMD placement machine capable of placing 60,000 components per hour with ±5 micron accuracy. Within one year, the company reported:

- 30% reduction in defect rates

- 25% increase in throughput

- 20% reduction in labor costs

- ROI achieved within 18 months

This investment enabled the company to meet growing demand while maintaining high quality standards.

Case Study 2: Small to Medium Enterprise (SME)

An SME specializing in custom PCB assemblies opted for a mid-range machine priced at USD 75,000. While the machine did not match the speed of high-end models, it improved placement accuracy and reduced manual labor. The company plans to upgrade to a high-end machine once production volume increases.

Technological Innovations Driving High-End SMD Placement Machines

Recent advancements have further enhanced the value of high-end machines:

- Artificial Intelligence (AI) and Machine Learning: AI algorithms optimize placement sequences and detect anomalies in real-time, reducing errors and downtime.

- Multi-Head Placement: Machines with multiple placement heads can place several components simultaneously, multiplying throughput.

- 3D Vision Systems: These systems provide precise height and orientation measurements, improving placement of complex components like BGAs.

- Flexible Feeders: Automated feeders that can handle a variety of component packaging without manual changeover increase flexibility and reduce setup time.

These innovations justify the higher SMD placement machine price by delivering superior performance and adaptability.

Conlusion

Investing in a high-end SMD placement machine is a strategic decision that depends on:

- Production Volume: High volumes justify the investment due to economies of scale.

- Product Complexity: Complex PCBs with fine-pitch components require high precision.

- Quality Requirements: Industries such as aerospace, medical devices, and automotive demand the highest quality standards.

- Budget and Capital Availability: Sufficient capital or financing options are necessary to afford the upfront cost.

- Long-Term Vision: Commitment to automation and continuous improvement supports the investment.

For manufacturers meeting these criteria, the benefits in speed, quality, and cost savings make the investment worthwhile. For others, mid-range or refurbished machines may offer a more balanced approach.

FAQ

1. What is the typical price range for SMD placement machines?

Answer: The price ranges from about USD 5,000 for entry-level machines to over USD 500,000 for high-end models. Ultra-high-speed machines can exceed USD 1 million depending on features.

2. How does machine speed affect the price?

Answer: Higher placement speeds require advanced mechanics, control systems, and multi-head configurations, which increase the SMD placement machine price significantly.

3. Can smaller manufacturers benefit from high-end SMD machines?

Answer: Smaller manufacturers may find the high upfront cost challenging. They often opt for mid-range or refurbished machines that balance cost and capability, or consider contract manufacturing.

4. What operational savings do high-end machines provide?

Answer: They reduce labor costs through automation, lower defect rates and rework, improve material efficiency, and enhance production consistency, leading to long-term savings.

5. How important is machine accuracy in SMD placement?

Answer: Accuracy is critical, especially for complex PCBs with fine-pitch components. High precision reduces defects, improves product reliability, and ensures compliance with industry standards.