Content Menu

● Understanding Aqueous SMT PCB Washer Cleaners

>> Key Components of Aqueous SMT PCB Washer Cleaners

>> The Science Behind Aqueous Cleaning

● Preparing for the Cleaning Process

>> Assessing PCB Compatibility

>> Selecting the Right Cleaning Solution

>> Pre-Cleaning Inspection

>> Optimizing Board Placement

● Optimizing the Cleaning Cycle

>> Setting the Appropriate Temperature

>> Adjusting Wash Time

>> Configuring Spray Pressure

>> Optimizing Rinse Cycles

>> Fine-tuning Chemical Concentrations

● Enhancing Cleaning Effectiveness

>> Utilizing Ultrasonic Cleaning

>> Implementing Shadow Areas Cleaning

>> Monitoring Cleaning Solution Quality

>> Implementing Process Controls

● Post-Cleaning Procedures

>> Drying Techniques

>> Quality Control Inspection

>> Proper Handling and Storage

● Maintaining Your Aqueous SMT PCB Washer Cleaner

>> Daily Maintenance Tasks

>> Weekly Maintenance Tasks

>> Monthly Maintenance Tasks

>> Preventive Maintenance Schedule

● Troubleshooting Common Issues

● Environmental Considerations

>> Implementing Sustainable Practices

● Conclusion

● FAQ

>> 1. How often should I change the cleaning solution in my aqueous SMT PCB washer cleaner?

>> 2. Can I use an aqueous SMT PCB washer cleaner for boards with water-sensitive components?

>> 3. What are the advantages of aqueous cleaning over solvent-based cleaning for PCBs?

>> 4. How can I improve the cleaning of hard-to-reach areas on complex PCB assemblies?

>> 5. What are the key factors to consider when selecting an aqueous SMT PCB washer cleaner for my production line?

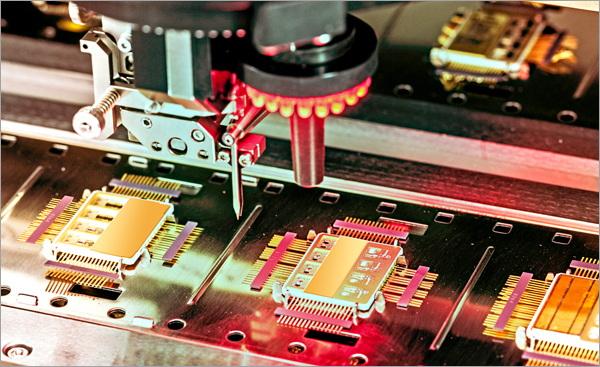

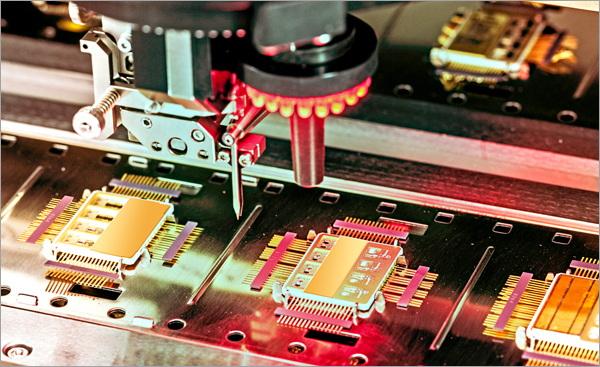

In the world of electronics manufacturing, ensuring the cleanliness of printed circuit boards (PCBs) is crucial for optimal performance and reliability. Aqueous SMT PCB washer cleaners have emerged as an efficient and environmentally friendly solution for removing contaminants from circuit boards. This comprehensive guide will explore the best practices for using aqueous SMT PCB washer cleaners to achieve optimal results in your manufacturing process.

Understanding Aqueous SMT PCB Washer Cleaners

Aqueous SMT PCB washer cleaners are specialized machines designed to clean printed circuit boards using water-based cleaning solutions. These systems offer several advantages over traditional solvent-based cleaning methods, including improved safety, reduced environmental impact, and enhanced cleaning effectiveness.

Key Components of Aqueous SMT PCB Washer Cleaners

1. Cleaning Chamber: The main compartment where the PCBs are cleaned.

2. Spray System: High-pressure nozzles that distribute the cleaning solution.

3. Filtration System: Removes contaminants from the cleaning solution.

4. Drying System: Ensures PCBs are completely dry after cleaning.

5. Control Panel: Allows operators to adjust cleaning parameters.

The Science Behind Aqueous Cleaning

Aqueous cleaning relies on the principles of chemistry and physics to remove contaminants effectively. The water-based cleaning solutions used in these systems typically contain:

- Surfactants: These molecules reduce surface tension, allowing the solution to penetrate tight spaces and lift contaminants.

- Saponifiers: These compounds react with flux residues, converting them into water-soluble soaps that can be easily rinsed away.

- pH Modifiers: Adjusting the pH of the solution can enhance its ability to remove certain types of contaminants.

- Corrosion Inhibitors: These additives protect metal components from oxidation during the cleaning process.

Understanding these components helps operators optimize the cleaning process for different types of contaminants and PCB materials.

Preparing for the Cleaning Process

Before using an aqueous SMT PCB washer cleaner, proper preparation is essential to ensure optimal results.

Assessing PCB Compatibility

Not all PCBs are suitable for aqueous cleaning. Ensure that the boards you intend to clean are compatible with water-based solutions. Most modern PCBs are designed to withstand aqueous cleaning, but it's always best to verify with the manufacturer's specifications.

Selecting the Right Cleaning Solution

Choose a cleaning solution specifically formulated for aqueous SMT PCB cleaning. Consider factors such as:

- Types of flux residues to be removed

- PCB material compatibility

- Environmental regulations in your area

- Cost-effectiveness and concentration ratios

Pre-Cleaning Inspection

Before placing PCBs in the washer cleaner, perform a visual inspection to identify any obvious contaminants or damage. Remove any loose components or debris that could interfere with the cleaning process.

Optimizing Board Placement

Proper board placement within the cleaning chamber is crucial for effective cleaning:

- Use appropriate racks or fixtures to hold PCBs securely

- Ensure adequate spacing between boards to allow proper solution flow

- Orient boards to maximize exposure to spray nozzles

- Consider using shadow boards or custom fixtures for complex assemblies

Optimizing the Cleaning Cycle

To achieve the best results with your aqueous SMT PCB washer cleaner, it's crucial to optimize the cleaning cycle for your specific needs.

Setting the Appropriate Temperature

The cleaning solution's temperature plays a significant role in its effectiveness. Most aqueous cleaning processes operate between 40°C and 60°C (104°F to 140°F). Higher temperatures generally improve cleaning efficiency but may not be suitable for all components.

Adjusting Wash Time

The optimal wash time depends on several factors, including:

- Level of contamination

- PCB complexity

- Type of flux residue

Start with the manufacturer's recommended wash time and adjust as needed based on cleaning results.

Configuring Spray Pressure

Proper spray pressure ensures that the cleaning solution reaches all areas of the PCB, including under components. However, excessive pressure can damage delicate parts. Consult your washer cleaner's manual for recommended pressure settings.

Optimizing Rinse Cycles

Thorough rinsing is crucial to remove all traces of cleaning solution and contaminants. Most aqueous SMT PCB washer cleaners use deionized (DI) water for rinsing. Configure multiple rinse cycles if necessary to achieve optimal cleanliness.

Fine-tuning Chemical Concentrations

The concentration of cleaning chemicals in the solution can significantly impact cleaning effectiveness:

- Too low: Insufficient cleaning power

- Too high: Potential residue issues and increased costs

Regularly test and adjust chemical concentrations to maintain optimal cleaning performance.

Enhancing Cleaning Effectiveness

To further improve the cleaning process, consider implementing these advanced techniques:

Utilizing Ultrasonic Cleaning

Some aqueous SMT PCB washer cleaners incorporate ultrasonic technology to enhance cleaning effectiveness. Ultrasonic waves create microscopic bubbles that implode, dislodging stubborn contaminants. However, be cautious when using ultrasonic cleaning with sensitive components, as it may cause damage.

Implementing Shadow Areas Cleaning

Shadow areas, such as spaces under BGA components, can be challenging to clean. Some washer cleaners offer specialized features to address this issue:

- Oscillating spray nozzles

- Angled spray patterns

- Flipping mechanisms for double-sided cleaning

Monitoring Cleaning Solution Quality

Regularly monitor the quality of your cleaning solution to maintain optimal performance:

- Check pH levels

- Monitor conductivity

- Replace or replenish the solution as needed

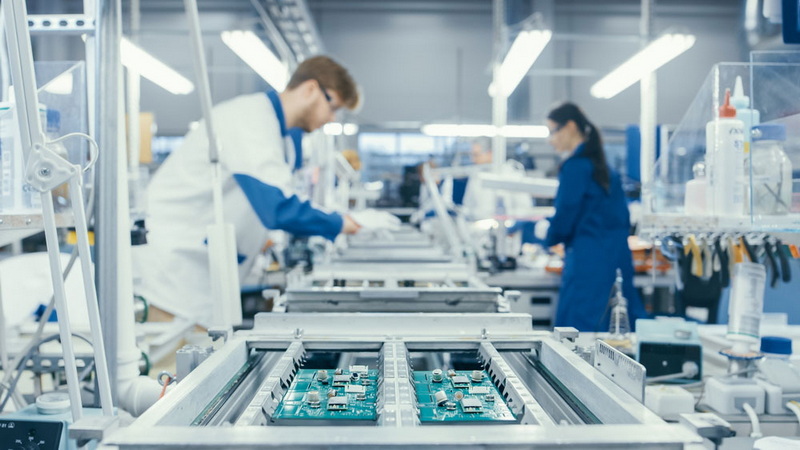

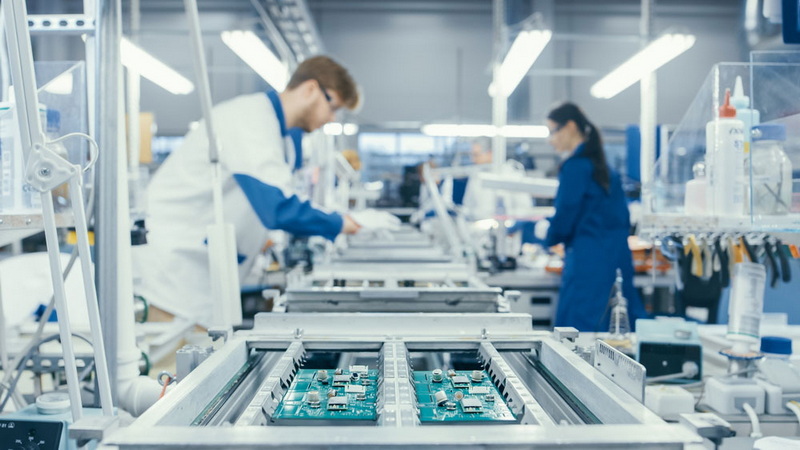

Implementing Process Controls

Establish robust process controls to ensure consistent cleaning results:

- Develop and document standard operating procedures (SOPs)

- Train operators on proper machine usage and maintenance

- Implement regular quality checks and audits

- Use statistical process control (SPC) to track cleaning performance over time

Post-Cleaning Procedures

After the cleaning cycle is complete, proper post-cleaning procedures are essential to ensure the best results.

Drying Techniques

Effective drying is crucial to prevent water spots and ensure the PCB is ready for further processing. Common drying methods include:

- Hot air drying

- Infrared drying

- Centrifugal drying

Choose the method that best suits your production requirements and PCB characteristics.

Quality Control Inspection

Implement a thorough quality control process to verify the effectiveness of your cleaning:

1. Visual Inspection: Check for any remaining visible contaminants.

2. Ionic Contamination Testing: Use an ionic contamination tester to measure residual ionic content.

3. Surface Insulation Resistance (SIR) Testing: Verify the PCB's electrical integrity post-cleaning.

Proper Handling and Storage

After cleaning and drying, handle PCBs with care to prevent recontamination:

- Use lint-free gloves when handling cleaned boards.

- Store cleaned PCBs in a clean, dry environment.

- Consider using moisture-barrier packaging for sensitive components.

Maintaining Your Aqueous SMT PCB Washer Cleaner

Regular maintenance of your washer cleaner is essential for consistent performance and longevity.

Daily Maintenance Tasks

- Clean filters and strainers

- Check and replenish cleaning solution levels

- Inspect spray nozzles for clogs or damage

Weekly Maintenance Tasks

- Clean the washing chamber thoroughly

- Check and clean pumps and valves

- Calibrate temperature and pressure sensors

Monthly Maintenance Tasks

- Perform a deep clean of the entire system

- Replace filters as needed

- Conduct a comprehensive system check

Preventive Maintenance Schedule

Develop a comprehensive preventive maintenance schedule to minimize downtime and extend equipment life:

- Schedule regular inspections of critical components

- Replace wear parts according to manufacturer recommendations

- Keep detailed maintenance logs for troubleshooting and optimization

Troubleshooting Common Issues

Even with proper maintenance, issues may arise. Here are some common problems and their solutions:

1. Inadequate Cleaning: Adjust wash time, temperature, or pressure. Consider changing the cleaning solution.

2. Water Spots: Improve rinsing and drying processes. Check water quality.

3. Component Damage: Reduce spray pressure or adjust nozzle angles. Consider using protective fixtures.

4. Foam Buildup: Use a defoaming agent or adjust the cleaning solution concentration.

Environmental Considerations

Aqueous SMT PCB washer cleaners offer significant environmental benefits compared to solvent-based systems. However, it's essential to consider the following:

- Wastewater Management: Implement proper treatment and disposal methods for used cleaning solutions.

- Energy Efficiency: Optimize cleaning cycles to reduce energy consumption.

- Chemical Selection: Choose environmentally friendly cleaning solutions when possible.

Implementing Sustainable Practices

To further enhance the environmental benefits of aqueous cleaning:

- Implement closed-loop water recycling systems to reduce water consumption

- Explore heat recovery options to improve energy efficiency

- Consider biodegradable cleaning solutions to minimize environmental impact

- Establish a recycling program for used filters and other consumables

Conclusion

Aqueous SMT PCB washer cleaners are powerful tools for maintaining the cleanliness and reliability of printed circuit boards. By following the best practices outlined in this guide, you can optimize your cleaning process, improve product quality, and enhance overall manufacturing efficiency. Remember that each production environment is unique, so it's essential to fine-tune these recommendations to suit your specific needs and equipment.

Continuous improvement and adaptation of your aqueous cleaning process will ensure that you consistently achieve optimal results, meeting the ever-increasing demands of modern electronics manufacturing. By investing time and resources in mastering the use of aqueous SMT PCB washer cleaners, you'll be well-positioned to produce high-quality, reliable electronic products while minimizing environmental impact.

FAQ

1. How often should I change the cleaning solution in my aqueous SMT PCB washer cleaner?

The frequency of cleaning solution changes depends on several factors, including the volume of PCBs cleaned, the level of contamination, and the type of cleaning solution used. Generally, it's recommended to monitor the solution's pH and conductivity regularly. Change the solution when these parameters fall outside the recommended range or when you notice a decrease in cleaning effectiveness. For high-volume production, this might be weekly or bi-weekly, while lower-volume operations may extend to monthly changes.

2. Can I use an aqueous SMT PCB washer cleaner for boards with water-sensitive components?

While many modern PCBs and components are designed to withstand aqueous cleaning, some water-sensitive components may require special consideration. If you have water-sensitive components, consider the following options:

- Use conformal coatings to protect sensitive areas before cleaning

- Employ selective cleaning techniques to avoid exposing sensitive components to water

- Consult with the component manufacturer for specific cleaning recommendations

Always verify component compatibility before using an aqueous cleaning process.

3. What are the advantages of aqueous cleaning over solvent-based cleaning for PCBs?

Aqueous cleaning offers several advantages over solvent-based methods:

- Improved safety: Water-based solutions are generally less hazardous than solvents

- Environmental friendliness: Reduced VOC emissions and easier waste management

- Cost-effectiveness: Water-based solutions are often less expensive than solvents

- Versatility: Effective on a wide range of contaminants and flux types

- Compatibility: Suitable for most modern PCB and component materials

However, the choice between aqueous and solvent-based cleaning depends on your specific application and requirements.

4. How can I improve the cleaning of hard-to-reach areas on complex PCB assemblies?

Cleaning hard-to-reach areas on complex PCB assemblies can be challenging. Here are some strategies to improve cleaning effectiveness:

- Use specialized nozzle configurations that provide angled sprays

- Implement oscillating or rotating spray systems to reach under components

- Consider ultrasonic cleaning for particularly stubborn contaminants

- Employ board rotation or flipping mechanisms to clean from multiple angles

- Use custom fixtures to optimize cleaning angles for specific board designs

Remember to balance aggressive cleaning with the need to protect delicate components.

5. What are the key factors to consider when selecting an aqueous SMT PCB washer cleaner for my production line?

When selecting an aqueous SMT PCB washer cleaner, consider the following factors:

- Production volume: Ensure the machine can handle your required throughput

- PCB size and complexity: Choose a system that accommodates your largest boards and most complex assemblies

- Cleaning requirements: Consider the types of contaminants and flux residues you need to remove

- Footprint and facility integration: Evaluate how the system will fit into your existing production line

- Energy and water efficiency: Look for systems with optimized resource consumption

- Maintenance and support: Consider the availability of local service and spare parts

Carefully assess your specific needs and consult with multiple vendors to find the best fit for your operation.