Content Menu

● Introduction

● Understanding Manual Pick and Place Machines

>> Components and Tools Involved

>> Basic Operation Principles

● Step-by-Step Guide to Using a Manual Pick and Place Machine

>> Preparation of the Workspace

>> Selecting and Placing Components

>> Tips for Accuracy and Efficiency

>> Common Challenges in Manual Placement

● Advantages and Limitations

>> Benefits of Using Manual Machines

>> Challenges and How to Overcome Them

● Advanced Techniques for Manual Pick and Place

>> Using Templates and Jigs

>> Implementing Quality Control Measures

>> Training and Skill Development

● Future of Manual Pick and Place Machines

● Conclusion

● FAQ

>> 1. What are the key components of a manual pick and place machine?

>> 2. How do I maintain a manual pick and place machine?

>> 3. Can manual pick and place machines handle all types of SMT components?

>> 4. What safety precautions should I take when using a manual pick and place machine?

>> 5. How does a manual pick and place machine compare to an automated one?

● Citations:

Introduction

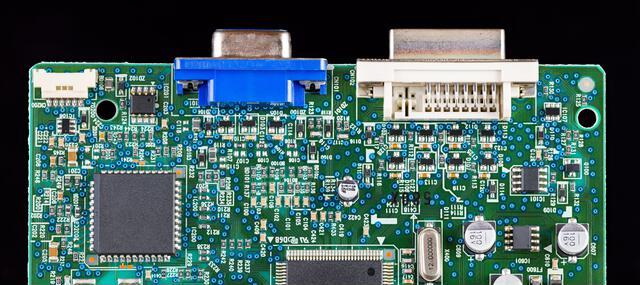

Surface Mount Technology (SMT) has transformed the electronics manufacturing landscape, enabling the miniaturization of components and the automation of assembly processes. Despite the rise of automated systems, manual pick and place machines for SMT components remain essential, particularly for small-scale production, prototyping, and situations where precision is paramount. These machines empower engineers and hobbyists to achieve high-quality results with control over the placement process.

Understanding Manual Pick and Place Machines

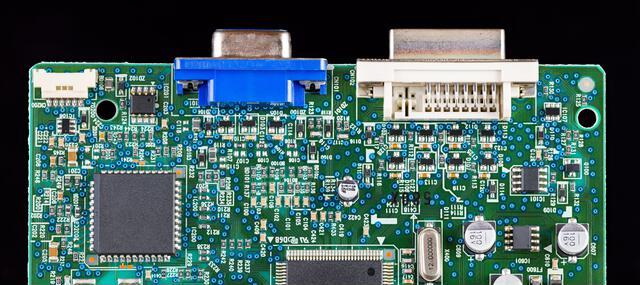

Manual pick and place machines are designed specifically for placing SMT components onto printed circuit boards (PCBs). They consist of several key elements that facilitate the manual operation of component placement.

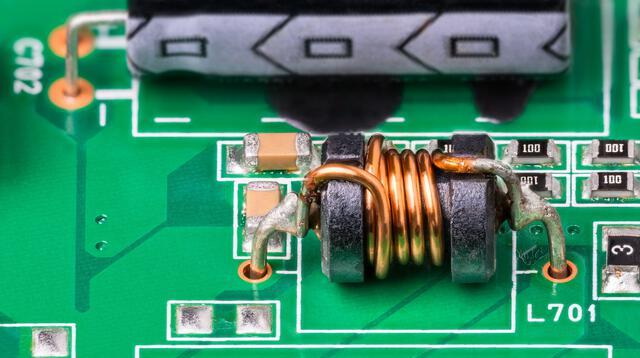

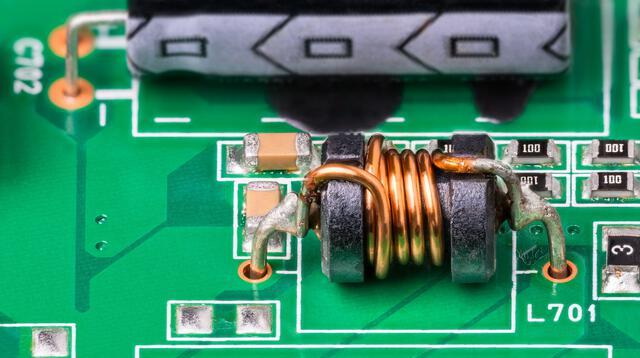

Components and Tools Involved

A typical manual pick and place machine includes:

- Base Platform: Serves as a stable surface for securing the PCB during assembly.

- Component Feeder: Holds and organizes various SMT components, making them easily accessible.

- Placement Head: Equipped with a vacuum nozzle or tweezers to pick up components from the feeder.

- Control Interface: Allows operators to maneuver the placement head accurately.

Basic Operation Principles

The operation of a manual pick and place machine follows a straightforward sequence:

1. Setup: Secure the PCB onto the base platform.

2. Component Loading: Load the required SMT components into the feeder.

3. Placement: Use the control interface to guide the placement head in picking up and placing components on the PCB.

4. Inspection: After placement, inspect for accuracy and make any necessary adjustments.

Step-by-Step Guide to Using a Manual Pick and Place Machine

Preparation of the Workspace

Before beginning any project, ensure your workspace is clean, well-lit, and organized. A clutter-free environment minimizes errors and enhances efficiency.

Selecting and Placing Components

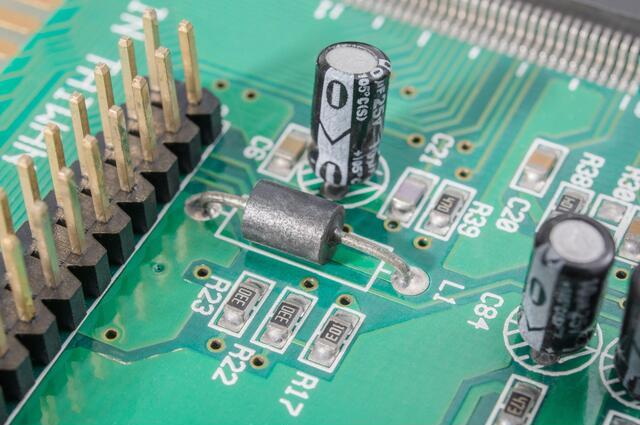

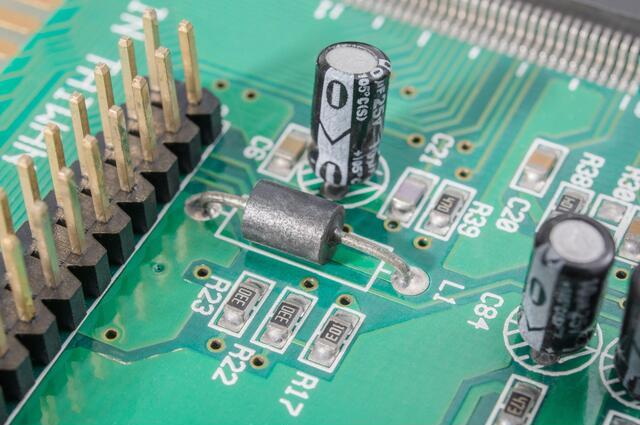

- Select Appropriate Components: Confirm that you have all necessary components according to your PCB design specifications. This includes resistors, capacitors, integrated circuits, and other SMT parts.

- Utilize the Placement Head: Carefully maneuver the placement head to pick up components from their designated feeders. Ensure that you are familiar with how to adjust the vacuum strength if using a vacuum nozzle.

- Accurate Placement: Align each component with its respective location on the PCB before gently placing it down. It is crucial to observe proper orientation for polarized components like diodes or electrolytic capacitors.

Tips for Accuracy and Efficiency

- Steady Hands: Practice maintaining steady hand movements to improve your placement accuracy over time. Consider using both hands for better control if needed.

- Magnification Tools: Utilize magnifying glasses or microscopes to enhance visibility when working with small components. This can help in ensuring that you are placing them correctly without missing details.

- Consistent Pressure: Apply uniform pressure when placing components to prevent damage or misalignment. Avoid pressing too hard, which could displace adjacent components.

Common Challenges in Manual Placement

While manual pick and place machines offer many advantages, users may encounter challenges that can affect performance:

- Component Misalignment: Inaccurate placement can lead to misalignment during soldering. To avoid this, double-check component orientation before placing them on the PCB.

- Fatigue During Long Sessions: Extended use can lead to operator fatigue, affecting precision. Taking regular breaks helps maintain focus and reduces errors.

- Limited Speed Compared to Automation: Manual processes are inherently slower than automated systems. To counter this, practice efficient techniques such as batch processing multiple PCBs at once when possible.

Advantages and Limitations

Benefits of Using Manual Machines

- Cost-Effective Solution: Ideal for small-scale production runs or prototyping where automation may not be justified. This makes it accessible for startups or individual projects without significant financial outlay.

- Flexibility in Design: Easily adapt to different PCB designs and component types without extensive reconfiguration. This flexibility allows users to experiment with various layouts without investing in new machinery.

- Enhanced Precision: Offers greater control over component placement compared to fully automated systems. Operators can make real-time adjustments based on visual feedback during assembly.

Challenges and How to Overcome Them

- Time Consumption: Manual placement can be slower than automated processes. To mitigate this, practice efficient techniques such as grouping similar tasks together (e.g., picking all resistors first).

- Skill Dependency: Achieving high accuracy requires practice. Investing time in skill development through training can significantly enhance performance. Consider participating in workshops or online tutorials focused on SMT assembly techniques.

- Operator Fatigue: Long periods of manual operation can lead to fatigue. Take regular breaks to maintain focus and efficiency; stretching exercises can also help alleviate tension in hands and wrists.

Advanced Techniques for Manual Pick and Place

Using Templates and Jigs

Templates or jigs can significantly improve both accuracy and speed during manual component placement. By creating a custom template that matches your PCB layout, you can ensure each component is placed correctly with minimal effort. This approach also helps in maintaining consistent spacing between components.

Implementing Quality Control Measures

Quality control is vital in SMT assembly to ensure reliability. Regularly inspect placed components for alignment, solder joint quality, and overall integrity. If available, use automated optical inspection (AOI) tools or magnifying lenses after placement to catch errors early in the process.

Training and Skill Development

Investing in training can greatly enhance your efficiency with manual pick and place machines. Workshops or online courses focusing on advanced techniques will equip you with valuable skills that improve both speed and accuracy. Networking with other professionals in forums or local meetups can also provide insights into best practices.

Future of Manual Pick and Place Machines

While automation continues to evolve, manual pick and place machines will retain their relevance for specific applications. Their adaptability makes them ideal for educational purposes, hobbyist projects, small-scale production runs, or rapid prototyping where quick changes are necessary without significant downtime associated with reprogramming automated systems.

As technology advances, we may witness hybrid systems that combine manual precision with automated efficiency—such as machines that allow users to switch between manual control for intricate placements while automating repetitive tasks like solder paste application or inspection processes.

Conclusion

Manual pick and place machines for SMT components are invaluable tools in electronics assembly. They offer a unique blend of precision, flexibility, and cost-effectiveness that makes them essential for hobbyists, engineers, and small manufacturers alike. While they may not match the speed of automated systems, their ability to adapt to various projects ensures they remain relevant in an increasingly automated world. By understanding their operation, advantages, limitations, best practices, advanced techniques, and future trends, users can maximize their potential for achieving high-quality results in electronic assembly.

FAQ

1. What are the key components of a manual pick and place machine?

The key components include a base platform for stability, a component feeder for organization, a placement head equipped with a vacuum nozzle or tweezers for picking up parts, and a control interface for maneuvering these elements effectively.

2. How do I maintain a manual pick and place machine?

Regular maintenance involves cleaning all parts of the machine after use, checking for wear on moving parts, ensuring that no debris obstructs operation, calibrating the placement head regularly, troubleshooting any issues promptly to avoid prolonged downtime.

3. Can manual pick and place machines handle all types of SMT components?

While manual machines are versatile enough to handle many types of SMT components, they may struggle with very small or complex parts due to limitations in precision. It is crucial to assess your machine's capabilities against your project requirements before beginning assembly.

4. What safety precautions should I take when using a manual pick and place machine?

Ensure your workspace is well-lit to avoid accidents while handling small parts. Use protective eyewear if necessary; avoid wearing loose clothing that could get caught in machinery; keep tools organized to prevent tripping hazards; always follow manufacturer guidelines during operation.

5. How does a manual pick and place machine compare to an automated one?

Manual machines provide greater control over component placement at lower costs but require more time than automated systems which excel in speed and consistency for large-scale production runs. The choice between them often depends on project scale, budget constraints, and required precision levels.

Citations:

[1] https://www.ddmnovastar.com/smt-quick-tips-selecting-a-pick-and-place-machine

[2] https://www.elektormagazine.com/review/pixel-pump-pick-and-place-tool-review

[3] https://www.smtfactory.com/introduction-of-smt-pick-and-place-machine

[4] https://www.instructables.com/Pick-and-Place-Machine/

[5] https://resources.pcb.cadence.com/blog/2024-pick-and-place-machine