Content Menu

● Understanding the SMD PCB Mounting Machine

● Common Issues in SMD PCB Mounting Machines and How to Troubleshoot Them

>> 1. Component Placement Inaccuracy

>> 2. Component Pick-Up and Release Failures

>> 3. Solder Paste Printing Defects Leading to Mounting Issues

>> 4. Fiducial Recognition Errors

>> 5. Component Damage During Placement

>> 6. Tombstoning and Skewed Components

>> 7. Insufficient or Excessive Solder

>> 8. Solder Bridging

>> 9. Non-Wetting or De-Wetting Issues

● Best Practices for Maintaining SMD PCB Mounting Machines

● Conclusion

● FAQ

>> 1. What causes solder bridging in SMD PCB mounting machines, and how can it be prevented?

>> 2. How often should an SMD PCB mounting machine be calibrated?

>> 3. What are the signs of component damage caused by the pick-and-place machine?

>> 4. How can tombstoning be minimized during SMT assembly?

>> 5. What tools are essential for troubleshooting SMD PCB mounting machines?

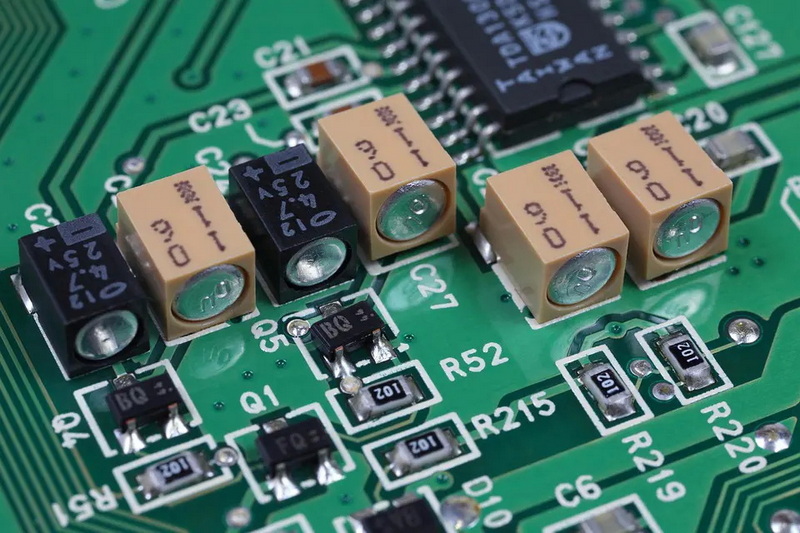

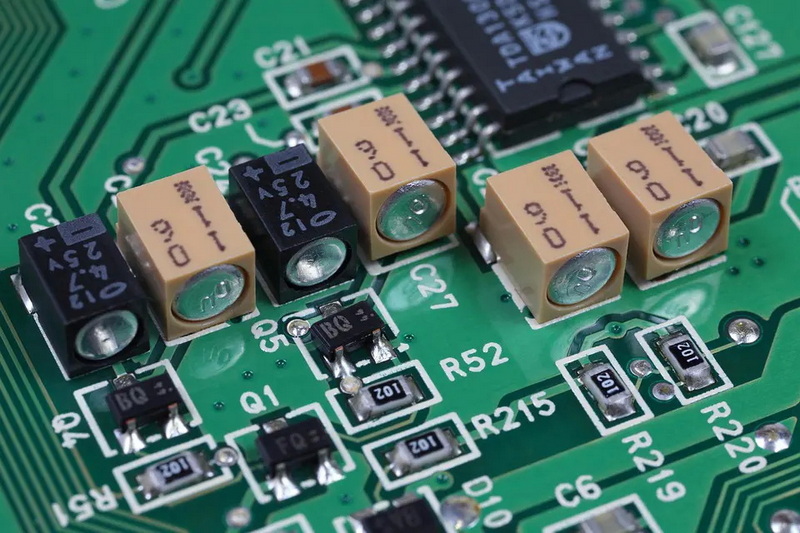

Surface Mount Device (SMD) PCB mounting machines are pivotal in modern electronics manufacturing, enabling the rapid and precise placement of tiny components onto printed circuit boards (PCBs). These machines, often called pick-and-place machines, are the backbone of Surface Mount Technology (SMT) assembly lines, ensuring high throughput and accuracy that manual assembly cannot match. However, despite their advanced design and automation, SMD PCB mounting machines can encounter various issues that degrade production quality, increase downtime, and elevate manufacturing costs. This comprehensive guide delves into the most common problems faced during SMD PCB mounting, their root causes, and step-by-step troubleshooting techniques to maintain optimal machine performance and ensure high-quality PCB assembly.

Understanding the SMD PCB Mounting Machine

An SMD PCB mounting machine automates the placement of surface mount components onto PCBs with extreme precision. It integrates several subsystems including component feeders, vacuum nozzles, vision inspection cameras, and sophisticated software algorithms to pick components from reels, tubes, or trays and place them accurately on the PCB pads. The machine's performance directly impacts product quality, yield rates, and manufacturing efficiency.

Key components of an SMD PCB mounting machine include:

- Feeders: Responsible for supplying components to the pick-up point.

- Pick-and-Place Head: Equipped with vacuum nozzles to pick components.

- Vision System: Cameras and image processing software to detect component orientation and PCB fiducials.

- Control Software: Coordinates movements, placement coordinates, and process parameters.

Understanding how these components interact is essential for effective troubleshooting.

Common Issues in SMD PCB Mounting Machines and How to Troubleshoot Them

1. Component Placement Inaccuracy

Problem: The machine places components off their designated pads, causing misalignment that can lead to electrical shorts, open circuits, or reduced device performance.

Causes:

- Incorrect machine calibration.

- Worn or damaged feeders causing inconsistent feeding.

- Misaligned or dirty vision system cameras.

- Faulty or missing fiducial marks on the PCB.

- Software errors in coordinate mapping.

Troubleshooting Steps:

- Calibrate the Machine: Regularly perform calibration procedures to ensure that the machine's coordinate system aligns with the PCB layout. This includes calibrating the X, Y, and Z axes as well as rotation.

- Inspect Feeders: Check feeders for wear, damage, or misalignment. Replace or repair feeders that cause inconsistent component feeding.

- Clean Vision System: Dust, grease, or scratches on camera lenses can cause vision errors. Clean lenses and ensure cameras are properly focused.

- Verify Fiducials: Ensure fiducial marks on the PCB are clean, visible, and correctly positioned. Recalibrate fiducial recognition if necessary.

- Software Checks: Update or reinstall placement software to fix bugs or errors in coordinate mapping.

Accurate placement is critical; even minor deviations can cause downstream defects, so maintaining machine precision is paramount.

2. Component Pick-Up and Release Failures

Problem: The machine fails to pick up components or drops them before placement, resulting in missing parts or assembly defects.

Causes:

- Insufficient vacuum pressure or vacuum leaks.

- Nozzle damage or clogging.

- Incorrect feeder vibration settings causing components to be misaligned.

- Components sticking to the nozzle due to static or contamination.

Troubleshooting Steps:

- Check Vacuum System: Inspect vacuum pumps, hoses, and seals for leaks or blockages. Adjust vacuum pressure to recommended levels.

- Replace Nozzles: Worn or damaged nozzles lose suction or cause improper release. Replace nozzles regularly based on usage.

- Adjust Feeder Settings: Ensure feeder vibration and alignment are correct to present components properly for pick-up.

- Anti-Static Measures: Use ionizers or anti-static mats to reduce static cling causing components to stick to nozzles.

- Clean Nozzles: Remove dust, solder paste, or flux residues that may cause sticking.

Maintaining the vacuum system and nozzle integrity is essential for reliable component handling.

3. Solder Paste Printing Defects Leading to Mounting Issues

Problem: Poor solder paste application causes defects such as solder bridging, insufficient solder joints, or tombstoning during reflow.

Causes:

- Misaligned or dirty stencils.

- Excessive or insufficient solder paste deposition.

- Incorrect stencil aperture size or thickness.

- Poor solder paste quality or improper storage.

- Inadequate reflow oven temperature profiles.

Troubleshooting Steps:

- Stencil Alignment: Use alignment pins or optical systems to ensure the stencil is perfectly aligned with the PCB pads.

- Stencil Cleaning: Regularly clean stencils to remove dried solder paste and prevent clogging.

- Optimize Aperture Design: Adjust aperture size and shape to control solder paste volume and distribution.

- Solder Paste Quality: Store solder paste under recommended conditions (typically refrigerated) and use within shelf life.

- Reflow Profile Tuning: Adjust oven zones to achieve proper heating curves-preheat, soak, reflow, and cooling-to ensure solder melts and solidifies correctly.

Good solder paste printing is the foundation of reliable solder joints and successful component mounting.

4. Fiducial Recognition Errors

Problem: The machine fails to correctly identify PCB fiducial marks, leading to placement errors.

Causes:

- Dirty or scratched camera lenses.

- Poorly printed or damaged fiducials on PCBs.

- Incorrect vision system calibration.

- Software glitches in fiducial detection algorithms.

Troubleshooting Steps:

- Lens Maintenance: Clean camera lenses regularly to ensure clear images.

- Inspect Fiducials: Verify that fiducials are clearly visible and conform to design standards.

- Recalibrate Vision System: Perform vision calibration routines to align camera coordinates with machine coordinates.

- Software Updates: Keep vision system software up to date to benefit from improved detection algorithms.

Accurate fiducial recognition is critical for aligning the PCB coordinate system with the machine, ensuring precise component placement.

5. Component Damage During Placement

Problem: Components are damaged during pick-and-place, resulting in defective PCBs.

Causes:

- Excessive placement pressure.

- Malfunctioning or misaligned placement heads.

- Poor-quality or fragile components.

- Static discharge damaging sensitive components.

Troubleshooting Steps:

- Adjust Placement Pressure: Set placement force according to component specifications to avoid crushing or cracking.

- Regular Maintenance: Inspect and maintain placement heads and mechanical parts to prevent misalignment or excessive force.

- Use Quality Components: Source components from reputable suppliers with proper packaging and handling.

- Implement ESD Controls: Use grounding straps, ionizers, and ESD-safe workstations to protect sensitive components.

Minimizing component damage improves yield and reduces rework costs.

6. Tombstoning and Skewed Components

Problem: Components stand vertically on one end (tombstoning) or are skewed, leading to unreliable solder joints.

Causes:

- Uneven solder paste volume on component pads.

- Imbalanced heating during reflow.

- Misaligned placement.

- Excessive PCB movement during reflow.

Troubleshooting Steps:

- Control Solder Paste Volume: Ensure stencil apertures are uniform and solder paste printing is consistent.

- Optimize Reflow Profile: Balance heating zones to ensure both sides of the component heat evenly.

- Improve Placement Accuracy: Regularly calibrate the pick-and-place machine to avoid skewed placement.

- Secure PCB During Reflow: Use proper fixtures or conveyors to minimize PCB movement.

Addressing these factors reduces tombstoning and improves assembly reliability.

7. Insufficient or Excessive Solder

Problem: Too little solder causes weak joints or opens; too much solder causes bridging and shorts.

Causes:

- Incorrect stencil design (aperture size or thickness).

- Poor solder paste handling or storage.

- Inadequate reflow temperature profiles.

Troubleshooting Steps:

- Stencil Optimization: Adjust aperture dimensions and stencil thickness to control solder volume.

- Proper Solder Paste Storage: Keep solder paste refrigerated and use it before expiration.

- Reflow Profile Adjustment: Ensure the oven temperature profile supports proper solder melting and wetting without excess spread.

Balanced solder volume is critical for defect-free solder joints.

8. Solder Bridging

Problem: Excess solder creates unintended electrical connections between adjacent pads.

Causes:

- Excessive solder paste deposition.

- Stencil misalignment.

- Improper reflow temperature ramp rates.

- Narrow pad spacing or component misplacement.

Troubleshooting Steps:

- Reduce Solder Paste Volume: Decrease stencil aperture size by about 10% to reduce solder paste volume.

- Improve Stencil Alignment: Use precision alignment tools to ensure stencil and PCB pads match exactly.

- Optimize Reflow Ramp Rates: Adjust heating rates to prevent solder paste from slumping excessively.

- Maintain Placement Accuracy: Regularly calibrate the machine to prevent component misplacement that narrows pad gaps.

Solder bridging is a primary cause of shorts and must be carefully controlled.

9. Non-Wetting or De-Wetting Issues

Problem: Solder fails to wet the component leads or PCB pads, causing weak or open joints.

Causes:

- Poor PCB surface finish or contamination.

- Flux exhaustion due to excessive soak time.

- Insufficient reflow temperature or improper profile.

Troubleshooting Steps:

- Use Proper Surface Finishes: Ensure PCBs have suitable finishes like ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling).

- Adjust Reflow Profile: Prevent excessive soak times that degrade flux activity.

- Maintain Cleanliness: Keep PCBs and components free of oils, dust, and oxidation before assembly.

Proper wetting is essential for strong metallurgical bonds in solder joints.

Best Practices for Maintaining SMD PCB Mounting Machines

To minimize troubleshooting frequency and maintain high-quality output, adopt these best practices:

- Regular Calibration: Schedule weekly or monthly calibration of placement accuracy, vision systems, and fiducial recognition.

- Routine Preventive Maintenance: Clean feeders, nozzles, vacuum systems, and cameras regularly. Replace worn parts proactively.

- Use Quality Consumables: Employ high-quality solder paste, stencils, and components from reputable suppliers.

- Monitor Reflow Profiles: Continuously verify oven temperature zones with thermocouples and adjust profiles to match solder paste and PCB requirements.

- Train Operators Thoroughly: Ensure operators understand machine operation, maintenance, and troubleshooting procedures.

- Implement Automated Inspection: Use solder paste inspection (SPI) and automated optical inspection (AOI) systems to detect defects early in the process.

Conclusion

Troubleshooting common issues in SMD PCB mounting machines requires a comprehensive understanding of the machine's mechanical, optical, and software systems, as well as the SMT process parameters. By systematically addressing problems such as placement inaccuracies, pick-and-place failures, solder paste defects, and reflow-related issues, manufacturers can significantly improve product quality and reduce downtime. Preventive maintenance, regular calibration, process optimization, and operator training are key pillars to sustaining high-performance SMT production lines. With diligent attention to these factors, the reliability and efficiency of SMD PCB mounting machines can be maximized, supporting the production of high-quality electronic devices.

FAQ

1. What causes solder bridging in SMD PCB mounting machines, and how can it be prevented?

Solder bridging mainly results from excessive solder paste deposition, stencil misalignment, and improper reflow profiles. Prevention involves optimizing stencil aperture size, ensuring precise stencil-to-PCB alignment, using solder paste with the correct metal-to-flux ratio, and fine-tuning reflow oven temperature profiles to avoid solder paste slump.

2. How often should an SMD PCB mounting machine be calibrated?

Calibration frequency depends on machine usage and production volume but generally should be performed regularly-weekly or monthly-and after any maintenance or component changes. Frequent calibration ensures placement accuracy and reduces defects caused by misalignment.

3. What are the signs of component damage caused by the pick-and-place machine?

Signs include cracked or broken components, missing parts, and electrical failures after assembly. Causes often include excessive placement pressure, malfunctioning nozzles, or poor-quality components. Adjusting machine settings and using quality parts help mitigate damage.

4. How can tombstoning be minimized during SMT assembly?

Tombstoning can be minimized by balancing the reflow oven temperature profile to ensure even heating, controlling solder paste volume through stencil design, ensuring precise component placement, and minimizing PCB movement during reflow.

5. What tools are essential for troubleshooting SMD PCB mounting machines?

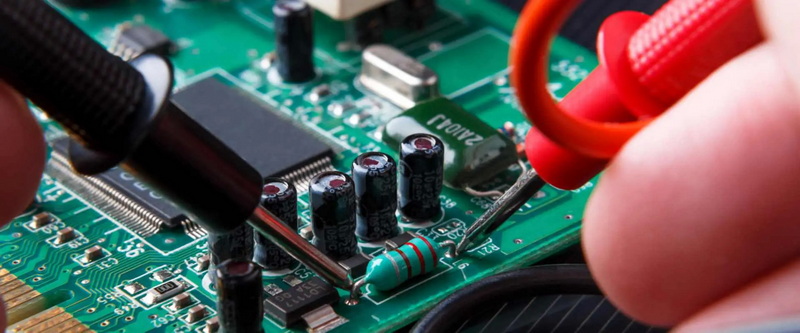

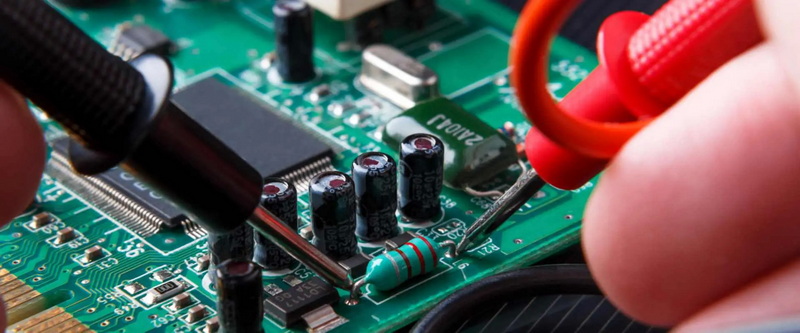

Essential tools include multimeters for electrical testing, oscilloscopes for signal analysis, thermal cameras for hotspot detection, magnification tools for visual inspection, and soldering stations for repairs. Electrostatic discharge (ESD) protection gear is also critical to prevent component damage.