Content Menu

● Understanding Surface Mount Devices (SMDs)

● Common Issues with SMD Circuit Boards

● Troubleshooting Techniques

>> Visual Inspection

>> Mapping Out the Circuit Board

>> Testing Components

>> Identifying Hot Spots

>> Signal Probing

● Common Problems and Solutions

>> Solder Bridging

>> Insufficient Solder Joints

>> Tombstoning

>> Cold Joints

● Conclusion

● FAQ

>> 1. What tools do I need for troubleshooting surface mount device circuit boards?

>> 2. How do I prevent solder bridging during assembly?

>> 3. What causes tombstoning in surface mount devices?

>> 4. How can I check if my solder joints are cold?

>> 5. What steps should I take if I find an open circuit?

Troubleshooting circuit boards equipped with surface mount devices (SMDs) can be a meticulous yet rewarding task. As electronics become increasingly compact and complex, understanding how to diagnose and repair issues on these boards is essential for engineers, technicians, and hobbyists alike. This guide will cover various methods to effectively troubleshoot circuit boards with SMDs, including visual inspections, testing techniques, and practical solutions for common problems.

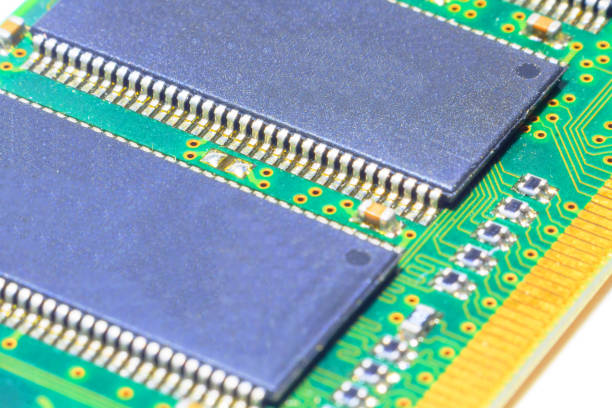

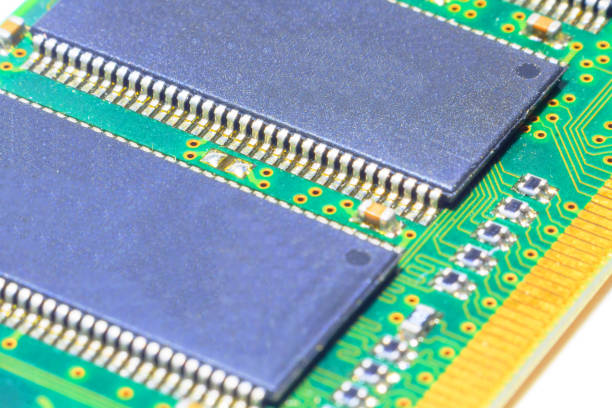

Understanding Surface Mount Devices (SMDs)

Surface mount devices are electronic components that are mounted directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole components, SMDs are designed for automated assembly and offer several advantages:

- Higher component density: SMDs allow for more components to be placed in a smaller area.

- Improved performance: They can enhance high-frequency performance due to shorter lead lengths.

- Ease of automation: The manufacturing process is often more efficient with SMDs.

However, these benefits come with challenges, particularly when it comes to troubleshooting.

Common Issues with SMD Circuit Boards

Before diving into troubleshooting techniques, it's important to recognize common issues that can arise with SMD circuit boards:

- Solder bridging: Excess solder can create unintended connections between pads.

- Insufficient solder joints: Poor solder application can lead to open circuits.

- Tombstoning: Components may lift off the PCB due to uneven heating during soldering.

- Cold joints: Improperly soldered connections can result in intermittent failures.

Understanding these issues will help you identify potential problems during the troubleshooting process.

Troubleshooting Techniques

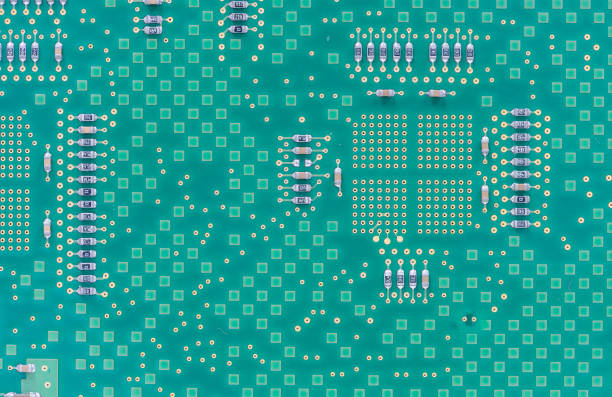

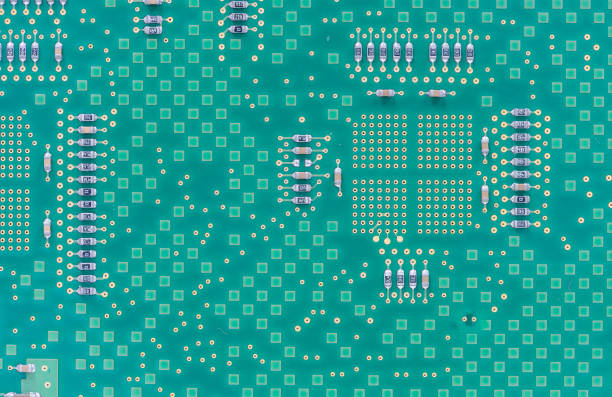

Visual Inspection

A thorough visual inspection is often the first step in troubleshooting a PCB. Use a magnifying glass or microscope to examine the following:

- Component placement: Ensure all components are correctly positioned according to the design.

- Solder joints: Look for cold joints, insufficient solder, or bridging.

- Physical damage: Check for cracks, burns, or lifted pads on the PCB.

Mapping Out the Circuit Board

Creating a map of the circuit board can help you understand its layout and functionality. This includes noting the following:

- Component values and types: Document each component's specifications.

- Connections and traces: Identify how components are interconnected.

Mapping can also assist in comparing faulty boards with functional ones, making it easier to spot discrepancies.

Testing Components

Using a multimeter or an LCR meter is essential for testing individual components on the PCB:

- Resistors: Measure resistance values to ensure they match specifications.

- Capacitors and inductors: Check capacitance and inductance values using an LCR meter.

- Diodes and transistors: Test these components using the diode setting on your multimeter to confirm they are functioning correctly.

Identifying Hot Spots

If visual inspections do not yield results, powering the circuit board can help identify faulty areas:

- Thermal inspection: Use a thermal camera or touch method to locate hot spots that indicate excessive current flow or short circuits.

Signal Probing

Signal probing involves measuring voltages at various points in the circuit while it is powered on:

- Use an oscilloscope to observe waveforms at critical test points.

- Compare measured values against expected values based on the circuit design.

This method helps isolate issues related to signal integrity or power distribution.

Common Problems and Solutions

Solder Bridging

Solder bridging occurs when excess solder connects two adjacent pads, leading to short circuits.

Solution: Adjust solder paste application techniques and ensure proper reflow profiles during assembly.

Insufficient Solder Joints

Insufficient solder can result from improper paste application or component misalignment during assembly.

Solution: Ensure that solder paste stencils are clean and properly designed. Regularly inspect solder joints during assembly processes.

Tombstoning

Tombstoning happens when one end of a component lifts off its pad due to uneven heating during reflow.

Solution: Optimize reflow profiles and ensure adequate thermal contact during the soldering process.

Cold Joints

Cold joints appear grainy or dull and occur when solder does not melt properly during reflow.

Solution: Maintain appropriate temperature settings during reflow and ensure that all connections are adequately heated before solidifying.

Conclusion

Troubleshooting circuit boards with surface mount devices requires a systematic approach that combines visual inspection, testing techniques, and an understanding of common issues. By following these methods, technicians can effectively diagnose problems and implement solutions that restore functionality to faulty PCBs. As technology continues to evolve, staying informed about best practices in SMT troubleshooting will be crucial for anyone involved in electronics design or repair.

FAQ

1. What tools do I need for troubleshooting surface mount device circuit boards?

You will need basic tools such as a multimeter, LCR meter, oscilloscope, magnifying glass or microscope, thermal camera (optional), and soldering equipment for repairs.

2. How do I prevent solder bridging during assembly?

Ensure proper stencil design for solder paste application and monitor reflow profiles closely to avoid excess solder accumulation on pads.

3. What causes tombstoning in surface mount devices?

Tombstoning is typically caused by uneven heating during the reflow process or differences in thermal mass between component leads.

4. How can I check if my solder joints are cold?

Inspect solder joints visually; cold joints often appear dull or grainy instead of shiny. You can also use a multimeter to check continuity across connections.

5. What steps should I take if I find an open circuit?

Identify the section of the board where the open occurs using your mapping technique, then test individual components along that path until you find the faulty connection or component.