Content Menu

● Understanding SMT Components

>> Types of SMT Components

>> Advantages of SMT Components

● Essential Tools for Soldering SMT Parts

● Preparing the Workspace

● Soldering Techniques for SMT Parts

>> 1. Tinning the Soldering Iron

>> 2. Applying Flux

>> 3. Positioning the Component

>> 4. Soldering One Pin First

>> 5. Soldering Remaining Pins

>> 6. Inspecting Solder Joints

>> 7. Cleaning Up

● Advanced Techniques

>> Reflow Soldering

>> Hot Air Soldering

>> Using Solder Paste Stencils

● Common Mistakes to Avoid

● Tips for Successful Soldering

● Troubleshooting Common Issues

>> Cold Joints

>> Bridges Between Pins

>> Lifted Pads

● Conclusion

● FAQ

>> 1. What is the best temperature setting for soldering SMT parts?

>> 2. Can I use leaded solder for SMT components?

>> 3. How do I remove excess solder from an SMT joint?

>> 4. Is it necessary to use flux when soldering?

>> 5. What should I do if I accidentally bridge two pins together?

Soldering Surface Mount Technology (SMT) parts is a crucial skill for anyone involved in electronics, whether you are a hobbyist or a professional. SMT components have become prevalent in modern electronic devices due to their compact size and efficiency. This guide will provide you with a comprehensive understanding of how to solder SMT parts like a pro, covering essential tools, techniques, and tips to ensure successful soldering.

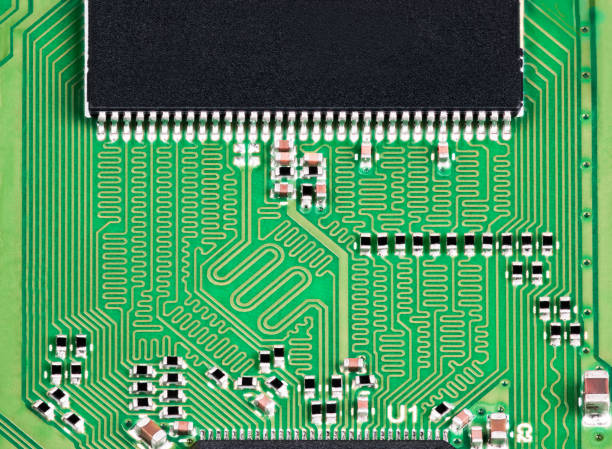

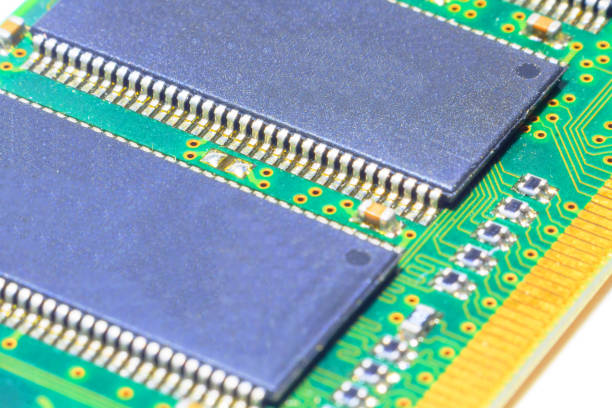

Understanding SMT Components

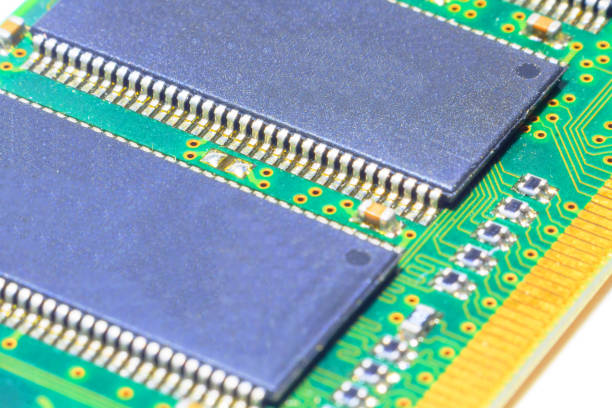

Before diving into the soldering process, it's important to understand what SMT components are. Unlike traditional through-hole components that have leads passing through the PCB, SMT components are mounted directly onto the surface of the PCB. This allows for more compact designs and higher circuit density.

Types of SMT Components

- Resistors: Used to limit current flow.

- Capacitors: Store electrical energy temporarily.

- Integrated Circuits: Combine multiple functions in a single package.

- Diodes: Allow current to flow in one direction.

- Transistors: Act as switches or amplifiers.

Each type of component has its specific characteristics and requires different soldering techniques.

Advantages of SMT Components

SMT components offer several advantages over traditional through-hole components:

- Space Efficiency: SMT allows for more compact designs, which is crucial for modern electronics where space is at a premium.

- Higher Performance: The shorter leads and smaller sizes reduce parasitic inductance and capacitance, improving performance at high frequencies.

- Automated Assembly: SMT components are easier to handle in automated assembly processes, making mass production more efficient.

Essential Tools for Soldering SMT Parts

To achieve professional results when soldering SMT parts, having the right tools is essential. Here's a list of the necessary tools:

- Soldering Iron: A fine-tipped soldering iron is ideal for precision work on small components. Temperature-controlled soldering irons can help maintain consistent heat.

- Solder: Use lead-free solder for environmental safety; however, leaded solder is easier to work with for beginners. A diameter of 0.5mm or smaller is recommended for SMT work.

- Flux: Flux helps improve the flow of solder and prevents oxidation. There are various types, including liquid flux and flux pens, which can be applied precisely.

- Tweezers: Fine-tipped tweezers are essential for handling small SMT components without damaging them.

- Solder Wick: Useful for removing excess solder or correcting mistakes. It absorbs melted solder when heated.

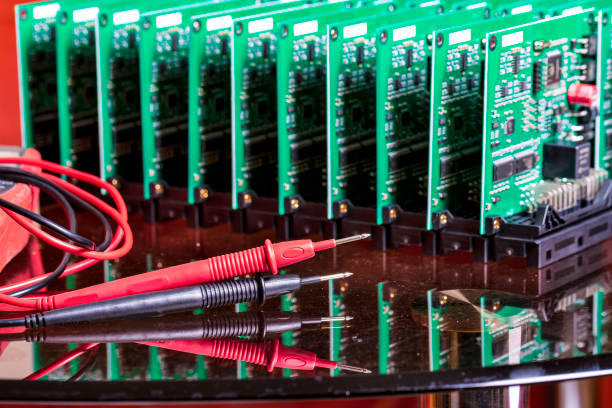

- Hot Air Rework Station: Ideal for reflow soldering and desoldering SMT parts without damaging them. This tool is particularly useful for larger components or when working with multi-lead devices.

- Magnifying Glass or Microscope: Helps in inspecting small components and solder joints to ensure quality work.

Preparing the Workspace

A clean and organized workspace is vital for effective soldering. Follow these steps to prepare your workspace:

1. Clean the Surface: Ensure your work surface is free from dust and debris. A clutter-free area reduces the risk of losing small components.

2. Good Lighting: Ensure adequate lighting to see small components clearly. Consider using a desk lamp with a magnifying lens for better visibility.

3. Static-Free Environment: Use an anti-static mat and wrist strap to prevent damage to sensitive electronic components. This is especially important when working with integrated circuits (ICs).

4. Ventilation: Ensure proper ventilation when soldering, as fumes from solder can be harmful if inhaled over prolonged periods.

Soldering Techniques for SMT Parts

Now that you have your tools ready and workspace prepared, it's time to learn some effective soldering techniques.

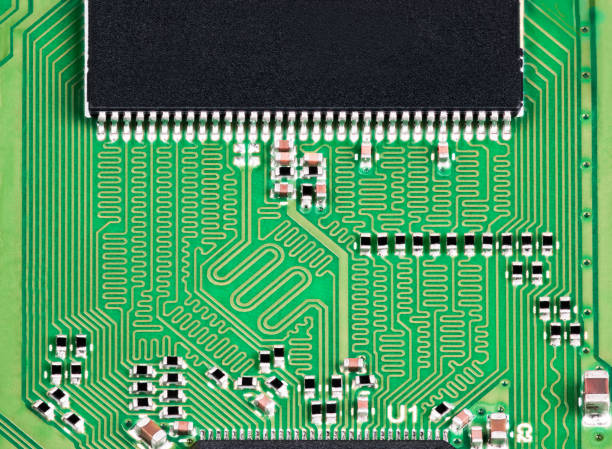

1. Tinning the Soldering Iron

Before starting, tin your soldering iron tip by melting a small amount of solder on it. This helps with heat transfer and prevents oxidation, ensuring better performance during soldering.

2. Applying Flux

Apply a small amount of flux on the pads where you will place the SMT components. Flux improves solder flow and adhesion, making it easier to create strong connections.

3. Positioning the Component

Using tweezers, carefully place the SMT component onto the PCB pads. Ensure it is aligned correctly before proceeding; misalignment can lead to functional issues later on.

4. Soldering One Pin First

Heat one pad with the soldering iron while simultaneously feeding in a small amount of solder until it flows around the pin of the component. Remove the iron and allow it to cool slightly before moving on to other pins.

5. Soldering Remaining Pins

Repeat the process for each remaining pin on the component. Make sure to keep your iron tip clean by wiping it on a damp sponge regularly; this ensures optimal heat transfer and prevents contamination of your joints.

6. Inspecting Solder Joints

After soldering all pins, inspect each joint closely using a magnifying glass or microscope. Look for cold joints (dull or grainy appearance) or bridges (unintentional connections between adjacent pins). Proper inspection is crucial as faulty connections can lead to device malfunction.

7. Cleaning Up

Once satisfied with your work, clean any excess flux residue using isopropyl alcohol and a brush or cloth. This step not only improves aesthetics but also prevents corrosion over time.

Advanced Techniques

For those looking to enhance their skills further, consider these advanced techniques:

Reflow Soldering

Reflow soldering involves applying solder paste to PCB pads before placing components and then heating them using a hot air rework station or oven until the paste melts and solidifies around the component leads. This method is particularly effective for assembling multiple components simultaneously and ensures uniform heating across all joints.

Hot Air Soldering

Using a hot air rework station allows you to heat multiple pins simultaneously, making it easier to solder larger components or multiple parts on densely populated boards without risking damage from direct contact with a hot iron.

Using Solder Paste Stencils

For precise application of solder paste in reflow processes, consider using stencils that align perfectly with your PCB design. This ensures that only the required amount of paste is applied, minimizing waste and improving joint quality.

Common Mistakes to Avoid

While learning how to solder SMT parts like a pro, be aware of these common pitfalls:

- Overheating Components: Excessive heat can damage sensitive parts; always use appropriate temperature settings tailored to your specific components.

- Insufficient Flux Application: Not using enough flux can lead to poor solder joints that may fail under stress.

- Poor Alignment: Misaligned components can cause functional issues; take your time during placement to ensure everything lines up correctly.

- Neglecting Cleanliness: Failing to clean your workspace or tools can lead to contamination that affects joint quality.

Tips for Successful Soldering

To further improve your soldering skills, consider these helpful tips:

- Practice on scrap PCBs before working on actual projects; this builds confidence without risking valuable materials.

- Use a microscope for detailed work on very small components; this will help you avoid mistakes caused by poor visibility.

- Keep your workspace organized; having everything within reach minimizes distractions during critical tasks.

- Experiment with different types of solder and flux; finding what works best for you can significantly improve your efficiency.

- Take breaks during long sessions; fatigue can lead to mistakes that compromise quality.

Troubleshooting Common Issues

Even experienced technicians encounter problems while soldering SMT parts. Here are some common issues and how to troubleshoot them:

Cold Joints

Cold joints appear dull or grainy rather than shiny and smooth. They indicate insufficient heat during the soldering process. To fix this issue:

1. Heat the joint again with your iron.

2. Add more solder if necessary.

3. Allow it to cool properly before moving on.

Bridges Between Pins

Solder bridges occur when excess solder connects two adjacent pins unintentionally:

1. Use desoldering braid or a desolder pump while heating the bridge gently with your iron.

2. Remove excess solder until you have clear separation between pins.

3. Inspect again after cleaning up any residue.

Lifted Pads

If a pad lifts from the PCB during desoldering or excessive heat application:

1. Assess whether there's enough pad left for re-soldering.

2. If not, use wire jumpers from nearby traces as an alternative connection method.

3. Apply adhesive if necessary to secure loose pads before re-soldering.

Conclusion

Soldering SMT parts like a pro requires practice, patience, and attention to detail. By understanding the types of components, using the right tools, employing effective techniques, avoiding common mistakes, and troubleshooting issues as they arise, anyone can master this essential skill in electronics assembly. With time and experience, you will find yourself becoming more confident in your ability to create reliable electronic circuits that meet modern demands for efficiency and performance.

FAQ

1. What is the best temperature setting for soldering SMT parts?

The ideal temperature setting typically ranges from 350°C to 400°C (662°F to 752°F). However, this may vary depending on the type of solder used.

2. Can I use leaded solder for SMT components?

Yes, leaded solder is often easier to work with due to its lower melting point compared to lead-free options; however, consider environmental regulations when choosing your materials.

3. How do I remove excess solder from an SMT joint?

You can use solder wick or desoldering pumps to absorb excess solder from joints effectively by placing them over heated areas until they absorb unwanted material.

4. Is it necessary to use flux when soldering?

While not strictly necessary, using flux significantly improves the quality of your joints by enhancing wetting properties and preventing oxidation during assembly processes.

5. What should I do if I accidentally bridge two pins together?

If you create a bridge between two pins, heat both sides with your iron until the bridge melts away or use desoldering braid to absorb excess material effectively without damaging surrounding areas.