Content Menu

● Understanding SMT Equipment

● Key Considerations When Selecting SMT Equipment

>> 1. Production Volume and Flexibility

>> 2. Component Compatibility

>> 3. Placement Speed

>> 4. Placement Accuracy

>> 5. Machine Repeatability

>> 6. Software Integration

>> 7. Budget and Total Cost of Ownership

>> 8. Support and Maintenance

● Types of SMT Machines

● Future-Proofing Your Investment

● The Role of Automation in SMT

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How do I determine my production volume needs?

>> 3. What is placement accuracy in SMT?

>> 4. Why is machine repeatability important?

>> 5. How can I ensure my SMT equipment is future-proof?

Selecting the right Surface Mount Technology (SMT) equipment is crucial for any electronics manufacturing facility. The choice of equipment can significantly impact production efficiency, quality, and overall operational costs. This guide will walk you through the essential factors to consider when choosing the best SMT equipment for your factory.

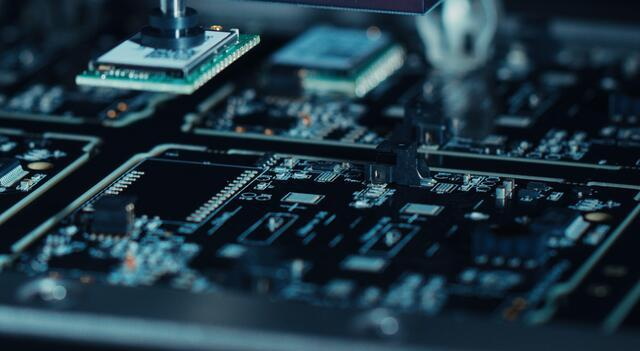

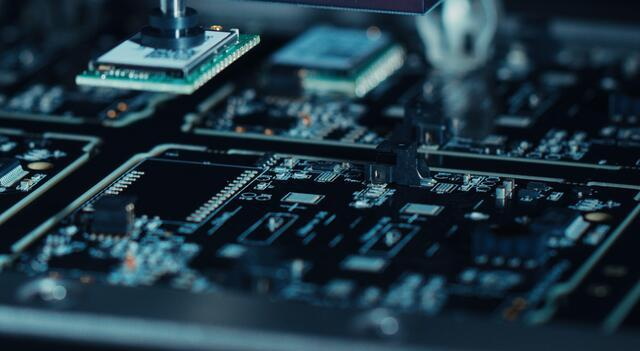

Understanding SMT Equipment

SMT equipment encompasses a variety of machines used in the assembly of electronic components onto printed circuit boards (PCBs). The primary types of SMT equipment include:

- Pick and Place Machines: These machines are responsible for accurately placing components onto the PCB.

- Reflow Ovens: After components are placed, PCBs pass through reflow ovens where solder paste is melted to bond components to the board.

- Stencil Printers: Used for applying solder paste to PCBs before component placement.

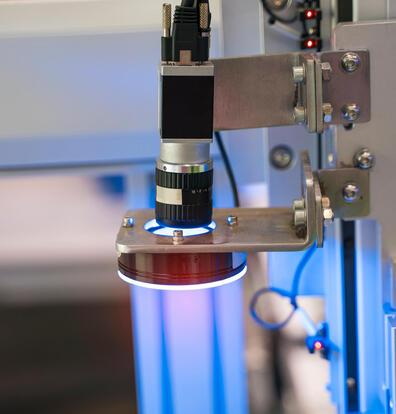

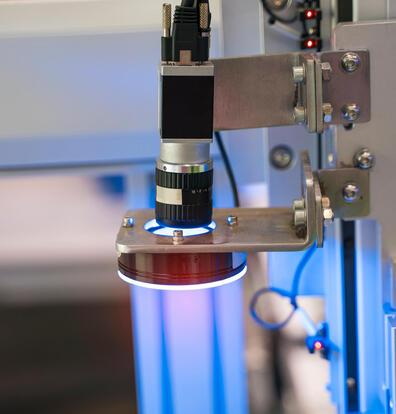

- Inspection Systems: These systems check the quality of assembled PCBs, ensuring that defects are caught early in the process.

Key Considerations When Selecting SMT Equipment

Choosing the right SMT equipment involves evaluating several critical factors:

1. Production Volume and Flexibility

Assess your current and future production volumes. High-volume production lines may require faster, automated machines, while lower volume operations might benefit from more flexible, multi-purpose machines. Consider:

- Throughput rates: Understand how many components your pick-and-place machine can handle per hour (CPH).

- Changeover time: Evaluate how quickly the machine can switch between different product runs.

Flexibility is particularly important in today's fast-paced manufacturing environment, where product lifecycles are shorter and customer demands can change rapidly. Machines that can easily adapt to different product types and sizes will save time and reduce costs associated with retooling.

2. Component Compatibility

Ensure that the SMT equipment can handle the types and sizes of components you will be using. This includes:

- Component sizes: From large integrated circuits to tiny 01005 components.

- Mixed technology requirements: Ability to handle both surface mount and through-hole components.

As technology advances, new component types are continually being introduced. Therefore, it's beneficial to invest in equipment that can accommodate future component innovations.

3. Placement Speed

Placement speed is a crucial factor when selecting an SMT machine. Different machines offer varying speeds, so it's essential to choose one that fits your production needs and budget. The IPC 9850 standard can be a reference point for evaluating speed capabilities.

High-speed machines can significantly increase productivity, but they must also maintain accuracy and reliability. It's important to strike a balance between speed and quality to avoid costly defects and rework.

4. Placement Accuracy

High placement accuracy is vital for achieving quality yields. Look for machines with:

- High precision: Ideally, machines should have an accuracy of ±0.05 mm or better, especially for fine-pitch components.

- Advanced vision systems: These systems help ensure correct component alignment during placement.

Utilizing advanced camera systems allows for real-time adjustments during the placement process, further enhancing accuracy and reducing waste.

5. Machine Repeatability

Repeatability refers to a machine's ability to consistently produce the same results over time. This is particularly important in high-speed production environments where precision is critical.

Investing in machines with high repeatability ratings will contribute to lower defect rates and improved overall product quality.

6. Software Integration

Modern SMT equipment should integrate seamlessly with existing systems, supporting:

- Manufacturing Execution Systems (MES): For better tracking and management of production processes.

- Data collection capabilities: To analyze performance metrics and improve efficiency.

Software that allows for easy data analysis can provide insights into production bottlenecks and areas for improvement, leading to more informed decision-making.

7. Budget and Total Cost of Ownership

Investing in SMT equipment is a significant financial decision. It's important to balance your budget with the need for high-quality and reliable machinery. Consider not only the initial purchase price but also ongoing maintenance costs and potential downtime.

The total cost of ownership (TCO) includes:

- Initial acquisition costs

- Operating costs: Energy consumption, labor costs associated with operation and maintenance.

- Maintenance costs: Regular servicing, spare parts replacement, etc.

By analyzing TCO, you can make a more informed decision about which equipment offers the best long-term value.

8. Support and Maintenance

Evaluate the level of support provided by manufacturers. Reliable after-sales service can significantly reduce downtime and keep your production line running smoothly.

Consider factors such as:

- Availability of spare parts: Ensure that parts are readily available to minimize downtime during repairs.

- Technical support response times: Quick responses from technical support teams can help resolve issues faster.

A strong relationship with your equipment supplier can lead to better service and support throughout the lifespan of your machinery.

Types of SMT Machines

When considering specific types of SMT machines, here are some popular options:

- Panasonic NPM-W2: Known for its speed (77,000 CPH) and precision (25 μm), suitable for medium-sized PCBs.

- Yamaha YSM10: Offers high reliability with speeds up to 50,000 CPH and accuracy of ±0.03 mm.

- JUKI FX-3: A versatile option with high-speed capabilities (90,000 CPH) and ease of use.

- Fuji NXT III: Features modular design allowing flexibility in production setups with speeds up to 37,500 CPH.

Each machine has its unique strengths; thus, it's essential to evaluate them based on your specific needs rather than opting for a one-size-fits-all solution.

Future-Proofing Your Investment

As technology evolves, so do production needs. When selecting SMT equipment, consider future expansions or upgrades that may be necessary as your business grows or as new technologies emerge.

Investing in modular systems or those that allow easy upgrades will help ensure that your factory remains competitive as market demands change. Additionally, keeping an eye on emerging technologies such as automation advancements or artificial intelligence integration can provide insights into future-proofing strategies.

The Role of Automation in SMT

The trend towards automation in manufacturing is undeniable. Automated SMT lines offer numerous advantages including:

- Increased efficiency: Automation reduces human error and speeds up processes.

- Cost savings: While initial investments may be higher, automation often leads to lower labor costs over time.

- Improved safety: Reducing human involvement in potentially hazardous tasks enhances workplace safety.

When selecting SMT equipment, consider how automation features could enhance your operations while aligning with your budgetary constraints.

Conclusion

Selecting the best SMT equipment for your factory involves careful consideration of various factors including production volume, component compatibility, placement speed, accuracy, repeatability, software integration, budget constraints, support services, and future-proofing strategies. By thoroughly evaluating these aspects along with considering automation trends in manufacturing, you can ensure that your investment will enhance productivity and quality in your manufacturing processes while positioning your factory for future growth.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of PCBs rather than through holes.

2. How do I determine my production volume needs?

Assess your current output levels and future growth projections based on market demand and product lifecycle expectations.

3. What is placement accuracy in SMT?

Placement accuracy refers to how precisely a machine can position components on a PCB during assembly; higher accuracy leads to better quality products.

4. Why is machine repeatability important?

Machine repeatability ensures consistent performance over time, which is crucial for maintaining product quality in high-speed manufacturing environments.

5. How can I ensure my SMT equipment is future-proof?

Select machines that offer modular designs or upgradeable features to accommodate changing production needs or advancements in technology.