Content Menu

● Understanding SMT Components

● Why Use Hot Air for Desoldering?

● Tools and Materials Needed

● Step-by-Step Guide to Removing SMT Components with Hot Air

>> Step 1: Prepare Your Workspace

>> Step 2: Set Up the Hot Air Rework Station

>> Step 3: Apply Flux

>> Step 4: Heat the Component

>> Step 5: Remove the Component

>> Step 6: Clean Up

● Tips for Successful Desoldering

● Common Challenges When Using Hot Air

● Advanced Techniques for Hot Air Desoldering

>> Use of Preheating

>> Controlled Cooling

>> Solder Paste Application

● Conclusion

● FAQ

>> 1. What temperature should I set my hot air rework station?

>> 2. How do I know when the solder has melted?

>> 3. Can I use a regular hair dryer instead of a hot air rework station?

>> 4. What should I do if I accidentally overheat my PCB?

>> 5. Is it necessary to use flux when desoldering?

● Citations:

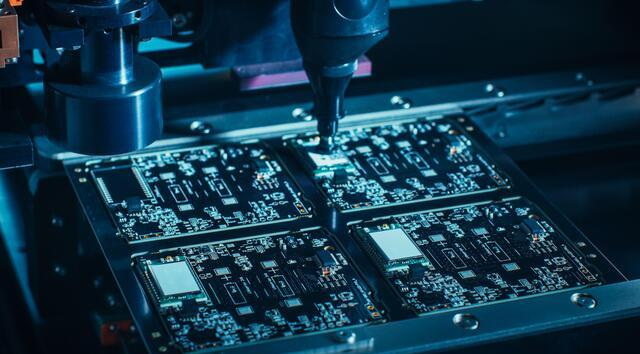

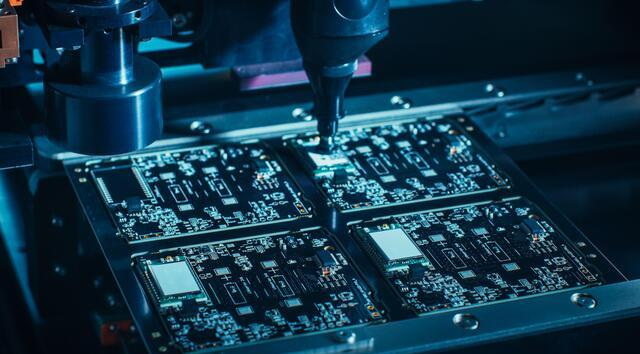

Removing Surface Mount Technology (SMT) components from a printed circuit board (PCB) can be a challenging task, especially if you're inexperienced. However, using a hot air rework station simplifies this process significantly. This article will guide you through the steps necessary to effectively and safely desolder SMT components using hot air, ensuring minimal damage to the surrounding circuitry.

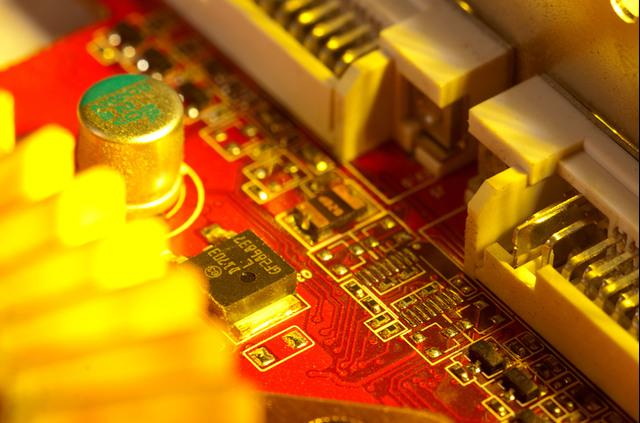

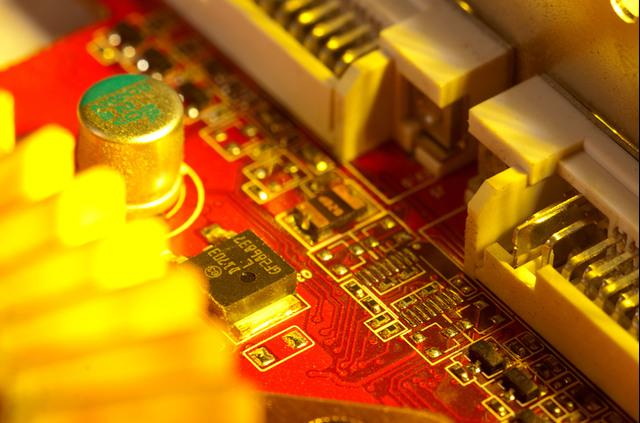

Understanding SMT Components

Surface Mount Technology (SMT) components are electronic devices mounted directly onto the surface of PCBs. Unlike traditional through-hole components, SMT components do not have leads that pass through the board. This design allows for more compact and efficient circuit layouts but poses unique challenges when it comes to repairs and modifications.

SMT components come in various shapes and sizes, including:

- Resistors: These limit current flow in circuits.

- Capacitors: Used for storing electrical energy temporarily.

- Integrated Circuits (ICs): Complex components that can perform various functions.

- Diodes: Allow current to flow in one direction only.

Understanding the specific type of SMT component you are working with is crucial for effective removal and replacement.

Why Use Hot Air for Desoldering?

Hot air rework stations are favored for desoldering SMT components because they provide a controlled way to heat solder joints without direct contact. This method minimizes the risk of damaging nearby components or the PCB itself. The hot air melts the solder, allowing the component to be lifted off easily.

Using hot air also has several advantages:

- Precision: You can target specific areas without affecting the entire board.

- Versatility: Suitable for various component types and sizes.

- Reduced Risk of Damage: Less likely to lift pads or traces compared to other methods.

Tools and Materials Needed

Before starting the desoldering process, gather the following tools and materials:

- Hot Air Rework Station: A quality station with adjustable temperature and airflow settings.

- Tweezers: For handling small components.

- Flux: To enhance solder flow and improve heat distribution.

- Solder Wick or Desoldering Pump: For removing excess solder if needed.

- Isopropyl Alcohol: For cleaning the PCB after desoldering.

- Anti-static Mat and Wrist Strap: To prevent static damage to sensitive components.

- Magnifying Glass or Microscope: To inspect small components and solder joints closely.

- Soldering Iron (optional): For additional solder removal if necessary.

Step-by-Step Guide to Removing SMT Components with Hot Air

Step 1: Prepare Your Workspace

Ensure your workspace is clean, organized, and well-lit. An anti-static mat can help protect sensitive electronic components from static electricity.

Step 2: Set Up the Hot Air Rework Station

Follow these guidelines to set up your hot air rework station:

- Choose the Nozzle: Select an appropriate nozzle size based on the component you are working with; smaller nozzles are better for precise work.

- Adjust Temperature and Airflow: Set the temperature slightly above the melting point of the solder (typically around 250°C for lead-free solder). Adjust airflow to avoid blowing other components off the board.

Step 3: Apply Flux

Using a flux pen or brush, apply a small amount of flux around the solder joints of the component you wish to remove. Flux helps improve solder flow and allows for even heating.

Step 4: Heat the Component

Hold the hot air nozzle approximately 3-5 cm above the component. Move it in circular motions to evenly distribute heat without concentrating it in one spot, which could damage the PCB.

- Monitor Solder Melting: Watch for signs that the solder has melted; it will appear shiny and liquid.

Step 5: Remove the Component

Once you see that the solder has melted, use tweezers to gently lift the component off the board. If it does not come off easily, reapply heat while gently nudging it until it releases.

Step 6: Clean Up

After removing the component, inspect the area for any remaining solder. Use solder wick or a desoldering pump to remove excess solder from pads. Clean any flux residue with isopropyl alcohol and a soft brush or cloth.

Tips for Successful Desoldering

- Practice on Scrap Boards: If you're new to this technique, practice on old or scrap boards before working on valuable equipment.

- Be Patient: Allow adequate time for heating; rushing can lead to mistakes or damage.

- Use Proper Technique: Always keep moving the hot air nozzle; holding it in one place too long can cause overheating.

Common Challenges When Using Hot Air

While using a hot air rework station is generally straightforward, several challenges may arise:

- Component Movement: If too much airflow is used, smaller components may blow away. Adjust airflow settings accordingly.

- Solder Not Melting Evenly: This may occur if there is insufficient flux or uneven heating. Ensure adequate flux application and maintain consistent movement of the hot air nozzle.

- Damage to PCB Pads: If excessive heat is applied, PCB pads may lift off with components. Always monitor temperature closely and avoid prolonged exposure.

Advanced Techniques for Hot Air Desoldering

For those looking to refine their skills further, consider these advanced techniques:

Use of Preheating

Preheating your PCB can help reduce thermal shock and ensure even heating across larger areas. Preheating mats or plates can be used for this purpose.

Controlled Cooling

After removing a component, allow it to cool gradually rather than exposing it to sudden temperature changes. This helps prevent thermal stress on both new and existing components.

Solder Paste Application

When replacing removed components, applying fresh solder paste can enhance adhesion and improve electrical connections. Use a stencil for precise application if necessary.

Conclusion

Removing SMT components with hot air is an effective method that requires careful preparation and execution. By following this guide, you can successfully desolder components while minimizing risks to your PCB and surrounding parts. Remember that practice makes perfect; take your time to master this technique for better results in your electronics projects.

FAQ

1. What temperature should I set my hot air rework station?

For lead-free solder, set your hot air rework station between 250°C and 350°C depending on your specific application and component sensitivity.

2. How do I know when the solder has melted?

The solder will appear shiny and liquid when it reaches its melting point. You can also gently nudge the component with tweezers; if it moves easily, it's likely melted.

3. Can I use a regular hair dryer instead of a hot air rework station?

While a hair dryer can produce heat, it lacks precise temperature control and airflow settings necessary for safe desoldering of SMT components.

4. What should I do if I accidentally overheat my PCB?

If you notice discoloration or warping, stop immediately and allow it to cool down. Assess any damage before proceeding further; you may need to repair traces or pads.

5. Is it necessary to use flux when desoldering?

Yes, applying flux improves heat distribution and helps melt solder more effectively, making removal easier and cleaner.

Citations:

[1] https://www.aixuntech.com/newsinfo/how-to-desoldering-smd-components-with-hot-air-station/

[2] https://www.youtube.com/watch?v=v2onF_h7GnY

[3] https://www.youtube.com/watch?v=kYBxA9zJybE

[4] https://hakko.com.sg/blogs/tune-in-with-hakko/rework-everything-you-need-to-know

[5] https://www.raypcb.com/remove-smd-chip-with-hot-air/

[6] https://mansfield-devine.com/speculatrix/2018/05/adventures-in-smd-soldering-part-2-hot-air/

[7] https://www.circuitrework.com/guides/8-3-2.html

[8] https://learn.sparkfun.com/tutorials/how-to-use-a-hot-air-rework-station/how-to-use-a-hot-air-rework-station

[9] https://www.ti.com/lit/an/slva439a/slva439a.pdf?ts=1703656404004

[10] https://www.youtube.com/watch?v=v58m-S35s24