Content Menu

● Understanding Surface Mount Assembly Stencils

>> Key Features of SMT Stencils

● Preparing for Solder Paste Application

● Applying Solder Paste with the Stencil

● Component Placement and Reflow Soldering

● Cleaning and Maintenance

● Conclusion

● FAQs

>> 1. What types of materials are used for SMT stencils?

>> 2. How do I choose the right aperture size for my SMT stencil?

>> 3. Can I reuse SMT stencils?

>> 4. What should I do if my solder paste does not release properly from the stencil?

>> 5. Is it necessary to align my PCB with my SMT stencil?

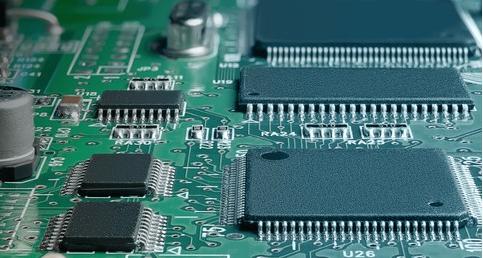

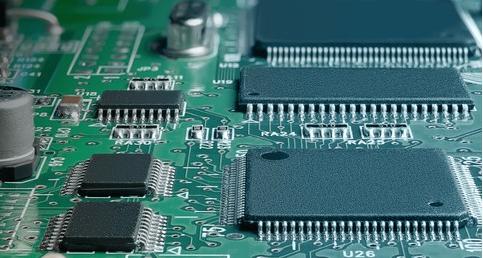

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for the efficient assembly of components onto printed circuit boards (PCBs). A critical component in this process is the *surface mount assembly stencil*, which is essential for applying solder paste accurately. This article will guide you through the proper use of a surface mount assembly stencil for soldering, ensuring high-quality results in your PCB assembly projects.

Understanding Surface Mount Assembly Stencils

A surface mount assembly stencil is typically a thin sheet made from stainless steel or brass, featuring a series of precisely cut apertures that correspond to the solder pads on a PCB. The primary function of this stencil is to facilitate the accurate deposition of solder paste onto the PCB, which is crucial for creating reliable solder joints between the components and the board.

Key Features of SMT Stencils

- Material: Most stencils are made from stainless steel due to its durability and resistance to wear.

- Aperture Design: The shape and size of the apertures can significantly affect solder paste transfer efficiency. Common shapes include squares, rectangles, and circles, but more complex designs like "squircles" can enhance paste transfer.

- Thickness: The thickness of the stencil affects how much solder paste can be deposited. Thicker stencils may provide better control over paste volume but can also lead to challenges in paste release.

Preparing for Solder Paste Application

Before using a surface mount assembly stencil, it is essential to prepare adequately. Here are the steps you should follow:

1. Gather Materials: Ensure you have all necessary materials ready, including:

- A suitable SMT stencil

- Solder paste

- A squeegee or spatula

- A clean and flat working surface

- PCB that needs assembly

- Alignment tools or jigs if necessary

2. Check Compatibility: Verify that the stencil's aperture layout matches the PCB's pad layout. Misalignment can lead to improper soldering.

3. Clean Surfaces: Ensure both the PCB and stencil surfaces are clean and free from contaminants that could affect solder adhesion.

4. Warm Up Solder Paste: If your solder paste has been stored in a refrigerator, allow it to reach room temperature before use to ensure optimal flow characteristics.

Applying Solder Paste with the Stencil

Once preparations are complete, you can proceed with applying solder paste using the stencil:

1. Align the Stencil: Place the stencil over the PCB, ensuring that all apertures align perfectly with their corresponding pads on the board. Use alignment marks if available.

2. Secure the Stencil: Fix the stencil in place using tape or clamps to prevent movement during application.

3. Apply Solder Paste:

- Place a small amount of solder paste at one end of the stencil.

- Using a squeegee or spatula, spread the solder paste across the stencil openings by applying even pressure.

- Ensure that you cover all apertures without excessive force to avoid smearing.

4. Lift the Stencil: Carefully lift the stencil away from the PCB without dragging it across the surface. This action should leave behind an even layer of solder paste on each pad.

5. Inspect Paste Application: Check each pad for proper coverage and consistency. Any discrepancies may require reapplication or adjustment in technique.

Component Placement and Reflow Soldering

After successfully applying solder paste, follow these steps for placing components and completing the soldering process:

1. Place Components: Using tweezers or an automated pick-and-place machine, position each surface mount component onto its respective pad covered with solder paste.

2. Reflow Process: Once all components are placed, heat the PCB using a reflow oven or hot air station to melt the solder paste, creating strong electrical connections between components and pads.

3. Cool Down: Allow the board to cool down after reflowing so that solidified solder joints form securely.

Cleaning and Maintenance

Proper cleaning and maintenance of your SMT stencils are vital for ensuring longevity and consistent performance:

- Cleaning After Use: Remove any residual solder paste from both sides of the stencil using appropriate cleaning solutions or wipes.

- Storage: Store stencils flat in a protective case or holder to prevent warping or damage.

- Regular Inspection: Periodically check stencils for wear or damage, particularly around apertures, as this can affect future applications.

Conclusion

Using a surface mount assembly stencil effectively is crucial for achieving high-quality results in PCB assembly processes. By following proper preparation methods, applying solder paste accurately, and maintaining your stencils diligently, you can enhance your production efficiency while minimizing defects. The precision offered by SMT stencils not only improves reliability but also contributes significantly to overall product quality.

FAQs

1. What types of materials are used for SMT stencils?

SMT stencils are primarily made from stainless steel due to its durability and resistance to wear; however, brass is also used in some cases for specific applications.

2. How do I choose the right aperture size for my SMT stencil?

The aperture size should match closely with the pad size on your PCB; generally, it should be slightly smaller than the pad size to ensure optimal solder paste deposition without excessive overflow.

3. Can I reuse SMT stencils?

Yes, SMT stencils can be reused multiple times; however, they must be cleaned thoroughly after each use to maintain performance and prevent contamination.

4. What should I do if my solder paste does not release properly from the stencil?

If solder paste does not release well from the stencil, check for proper cleaning of both surfaces and ensure that you are applying adequate pressure during application without excessive force that could cause smearing.

5. Is it necessary to align my PCB with my SMT stencil?

Yes, proper alignment between your PCB and SMT stencil is crucial to ensure that each aperture corresponds accurately with its respective pad on the board for effective soldering.