Content Menu

● Understanding the SMT Stencil Adapter

● Best Practices for Handling SMT Stencil Adapters

● Proper Cleaning Techniques for SMT Stencil Adapters

>> Cleaning Methods

>> Cleaning Frequency

>> Cleaning Solutions

● Proper Storage of SMT Stencil Adapters

● Inspection and Maintenance

● Optimizing SMT Printing with Stencil Adapter Maintenance

● Advanced Tips for Extending SMT Stencil Adapter Life

● Conclusion

● FAQ

>> 1. How often should I clean my SMT stencil adapter?

>> 2. What cleaning methods are best for SMT stencil adapters?

>> 3. How should I store SMT stencil adapters to avoid damage?

>> 4. What are signs that my SMT stencil adapter needs replacement?

>> 5. Can improper squeegee use damage the stencil adapter?

Maintaining your SMT stencil adapter properly is crucial for ensuring high-quality surface mount technology (SMT) printing, reducing defects, and extending the life of your stencil equipment. The SMT stencil adapter plays a vital role in aligning and securing the stencil during the solder paste printing process. Proper care and maintenance not only enhance print quality but also reduce downtime and replacement costs. This comprehensive guide covers best practices for handling, cleaning, storing, and inspecting your SMT stencil adapter to maximize its longevity.

Understanding the SMT Stencil Adapter

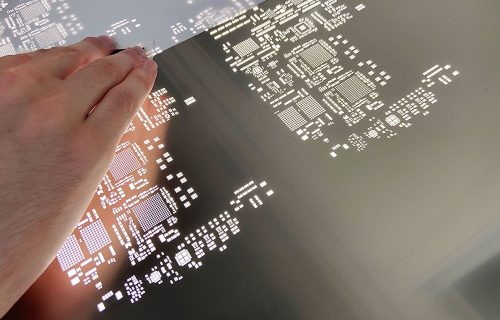

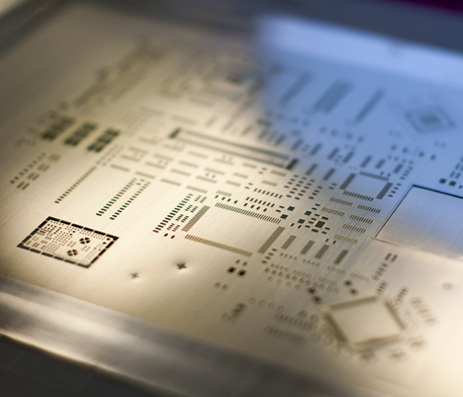

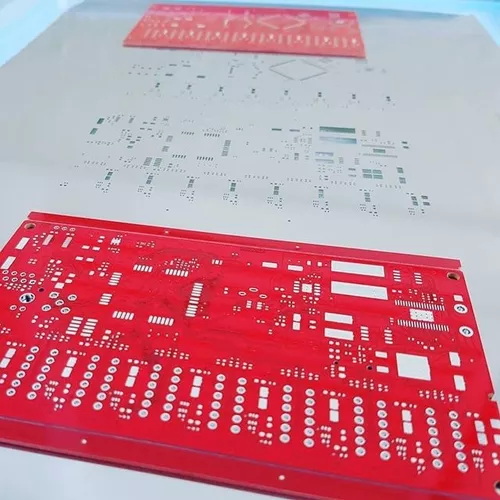

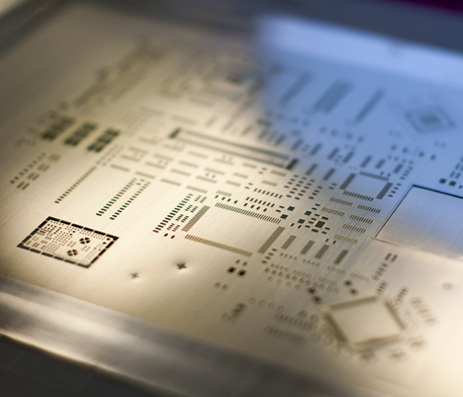

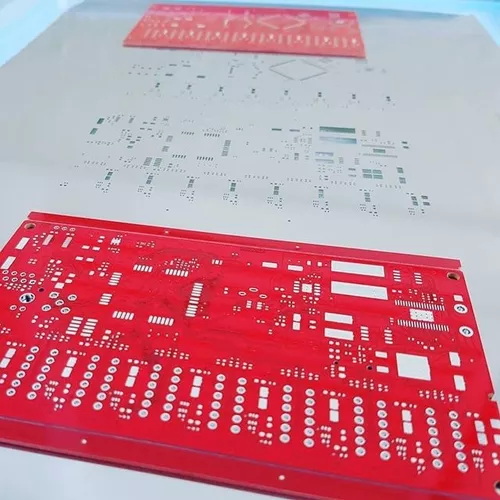

The SMT stencil adapter is an essential tool that holds the stencil securely in place during the solder paste application process on printed circuit boards (PCBs). It ensures precise alignment between the stencil apertures and PCB pads, which is critical for accurate solder paste deposition. Due to its delicate nature and the precision required, the stencil adapter must be handled carefully and maintained regularly.

Typically, SMT stencil adapters are made from thin stainless steel or nickel alloys with fine apertures that correspond to the pads on the PCB. The adapter frames the stencil foil and provides mechanical support, preventing deformation during printing. Because the stencil adapter directly affects the accuracy of solder paste application, any damage or contamination can cause defects such as insufficient solder, bridging, or misalignment.

Best Practices for Handling SMT Stencil Adapters

Proper handling of your SMT stencil adapter is the first step to ensuring its longevity and maintaining print quality.

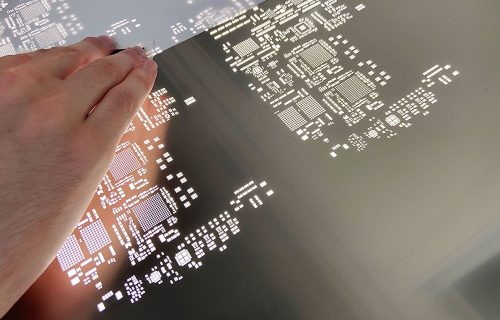

- Handle with Care: Always handle the stencil adapter gently to avoid bending or warping. Most SMT stencil foils and adapters are thin and fragile, typically only 4 to 5 mils thick, making them susceptible to damage from rough handling or accidental drops. Even slight warping can cause misalignment during printing, resulting in defective solder joints.

- Use Gloves: Wear gloves when handling the stencil adapter to prevent contamination from skin oils and dirt, which can affect print quality and cause stencil corrosion. Fingerprints and oils can cause solder paste to stick unevenly or clog apertures.

- Avoid Abrasion: Keep the adapter away from abrasive surfaces and sharp objects. Nanocoatings on adapters can be damaged by abrasion, reducing their lifespan and print quality. When transporting or storing, use protective covers or sleeves designed for stencil adapters.

- Use Proper Tools: When mounting or removing the stencil adapter from the printer, use designated tools or fixtures. This prevents accidental bending or scratching caused by improper force or handling.

Proper Cleaning Techniques for SMT Stencil Adapters

Regular cleaning is paramount to maintaining the SMT stencil adapter's functionality and longevity. Residual solder paste and contaminants can clog apertures and degrade print quality.

Cleaning Methods

1. Manual Cleaning

- Spray a suitable cleaning agent or soak the adapter if solder paste has hardened.

- Use a lint-free cloth or duster with gloves to gently wipe the surface.

- For stubborn paste residues, use a soft brush with gentle strokes to avoid damaging apertures.

- Dry thoroughly with compressed air or lint-free wipes.

- Inspect the adapter for cleanliness and damage after cleaning.

2. Pneumatic Spray Cleaning

- Use a pneumatic stencil cleaning machine with an appropriate cleaning solution.

- This method is efficient and reduces manual labor.

- It is suitable for most stencil adapters but may not be effective for oversized or very thick adapters.

3. Ultrasonic Cleaning

- Place the adapter in an ultrasonic cleaner with a compatible cleaning solution.

- This method provides deep cleaning, especially for clogged apertures.

- It requires specialized equipment and is generally more costly.

- Ultrasonic cleaning is highly effective for removing residual flux and solder paste from fine apertures without damaging the stencil adapter.

Cleaning Frequency

- Clean the stencil adapter immediately after each production run or at least daily in high-volume operations.

- For low-volume or prototype runs, clean after each use or when switching solder paste types.

- Frequent cleaning prevents solder paste buildup, which can clog apertures and cause printing defects.

Cleaning Solutions

- Use isopropyl alcohol (IPA) or specialized stencil cleaning solutions recommended by manufacturers.

- Avoid harsh chemicals or abrasive materials that can damage the stencil adapter surface or nanocoatings.

- Some cleaning solutions contain additives that help protect the stencil surface and improve cleaning efficiency.

Proper Storage of SMT Stencil Adapters

Proper storage is essential to prevent physical damage and contamination when the stencil adapter is not in use.

- Store stencil adapters vertically in dedicated stencil racks to prevent bending or warping. Vertical storage ensures even support and minimizes pressure points.

- Keep them in a clean, dry, and temperature-controlled environment to avoid corrosion and contamination.

- Avoid stacking adapters horizontally or placing them on abrasive surfaces, which can damage the foil and coatings.

- Use protective sleeves or covers to shield adapters from dust and physical damage during storage.

- Label each stencil adapter clearly to avoid confusion and mishandling.

- Maintain a controlled humidity environment if possible, as moisture can accelerate corrosion on metal stencil adapters.

Inspection and Maintenance

Routine inspection and maintenance are critical for identifying issues early and preventing costly defects or downtime.

- Regular Inspection: Use a microscope or magnifying glass to inspect apertures and surfaces for wear, damage, or clogging. Look for signs of aperture deformation, corrosion, or residue buildup.

- Check Tension: Ensure proper tension when mounting the stencil adapter to prevent warping or misalignment during printing. Incorrect tension can cause the stencil foil to sag or stretch, resulting in inconsistent solder paste deposition.

- Replace Damaged Parts: Replace adapters showing visible damage, deformation, or print quality issues that persist after cleaning. Continuing to use a damaged stencil adapter can lead to increased defects and rework.

- Maintain Printer Components: Clean and inspect squeegees, alignment pins, clamps, and the printer frame regularly to ensure proper function and avoid damage to the stencil adapter. Dirty or worn printer parts can cause misalignment or physical damage to the stencil adapter.

Optimizing SMT Printing with Stencil Adapter Maintenance

Proper stencil adapter maintenance goes hand-in-hand with optimizing the entire SMT printing process.

- Use squeegees with sharp, clean edges and replace damaged blades promptly to avoid scratching the stencil adapter. Dull or damaged squeegees require more force, which can damage the stencil foil and adapter.

- Maintain optimal squeegee pressure (no more than 1.25 lbs/in or 0.22 kg/cm of blade length) to prevent excessive wear on the adapter. Excessive pressure can cause stencil deformation and reduce its lifespan.

- Remove excess solder paste from squeegees and stencil adapters before removing the stencil to minimize contamination and damage.

- Follow manufacturer-recommended printer settings and adjust based on test prints to maintain print quality and extend stencil adapter life.

- Conduct periodic test prints to verify stencil adapter condition and print quality.

- Train operators on proper stencil adapter handling and maintenance procedures to ensure consistent care.

Advanced Tips for Extending SMT Stencil Adapter Life

- Nanocoating Protection: Many modern SMT stencil adapters come with nanocoatings that reduce solder paste adhesion and facilitate cleaning. Avoid abrasive cleaning methods that can strip these coatings.

- Environmental Controls: Maintain a stable temperature and humidity in the production area to prevent thermal expansion or corrosion of the stencil adapter.

- Use of Automated Cleaning Systems: Investing in automated stencil cleaning systems can improve cleaning consistency and reduce human error.

- Documentation: Keep maintenance logs for each stencil adapter, recording cleaning schedules, inspections, and any repairs or replacements. This helps track lifespan and identify recurring issues.

Conclusion

Proper maintenance of your SMT stencil adapter is essential for achieving consistent print quality and prolonging the life of your equipment. Handling with care, regular cleaning using appropriate methods and solutions, proper storage, and routine inspection are key to avoiding damage and wear. Additionally, maintaining the entire printing system, including squeegees and printer components, complements stencil adapter care. By implementing these best practices, manufacturers can reduce downtime, improve PCB assembly quality, and save costs associated with frequent stencil adapter replacements. Investing time and resources into stencil adapter maintenance ultimately leads to higher yields, lower defect rates, and a more efficient SMT production process.

FAQ

1. How often should I clean my SMT stencil adapter?

You should clean your SMT stencil adapter immediately after each production run or at least daily for high-volume operations. For low-volume or prototype runs, clean after each use or when changing solder paste types.

2. What cleaning methods are best for SMT stencil adapters?

Manual cleaning with appropriate solvents, pneumatic spray cleaning, and ultrasonic cleaning are common methods. Pneumatic and ultrasonic cleaning offer higher efficiency and effectiveness but require specialized equipment.

3. How should I store SMT stencil adapters to avoid damage?

Store them vertically in stencil racks in a clean, dry, and temperature-controlled environment. Avoid stacking horizontally or placing them on abrasive surfaces.

4. What are signs that my SMT stencil adapter needs replacement?

Visible damage such as warping, deformation, consistent print quality issues after cleaning, clogged or damaged apertures, and difficulty maintaining proper tension indicate the need for replacement.

5. Can improper squeegee use damage the stencil adapter?

Yes, dull or damaged squeegee blades and excessive print pressure can scratch or deform the stencil adapter, reducing its lifespan and print quality.