Content Menu

● Understanding Pick and Place Machines

● Importance of Optimization

● Key Strategies for Optimization

>> 1. Regular Maintenance and Calibration

>> 2. Optimize Feeder Setup

>> 3. Implement Advanced Software Solutions

>> 4. Utilize High-Speed Components

>> 5. Enhance Operator Training

>> 6. Streamline Workflow and Layout

>> 7. Optimize Placement Programs

● Conclusion

● FAQ

>> 1. What are pick and place machines used for?

>> 2. How often should pick and place machines be calibrated?

>> 3. What factors affect the efficiency of pick and place machines?

>> 4. How can operator training improve machine performance?

>> 5. What role does software play in optimizing pick and place operations?

● Citations:

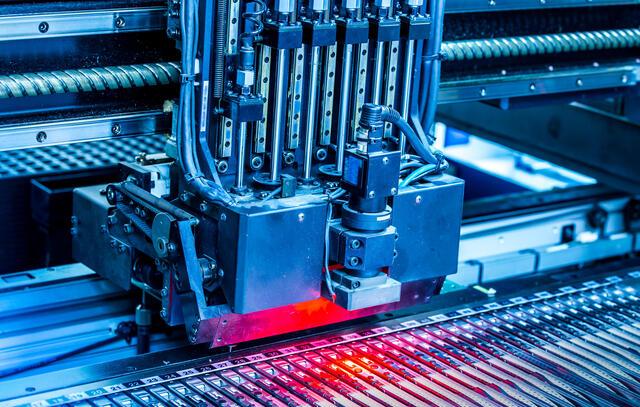

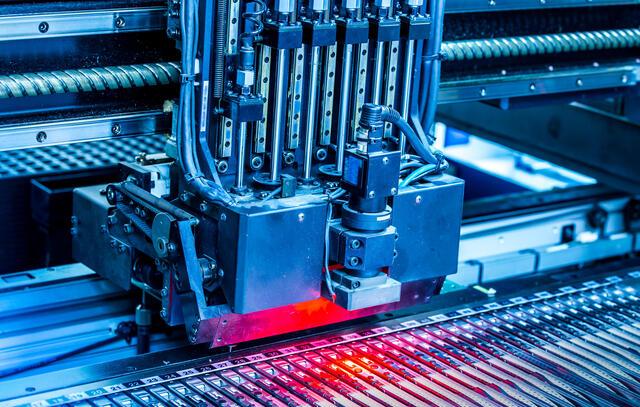

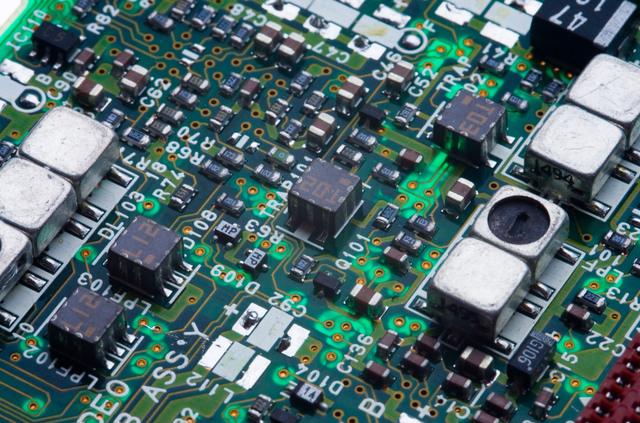

In the fast-paced world of electronics manufacturing, Surface Mount Technology (SMT) plays a crucial role in assembling printed circuit boards (PCBs). At the heart of this process are pick and place machines, which automate the placement of components onto PCBs. Optimizing the performance of multiple pick and place machines in line is essential for enhancing productivity, reducing costs, and ensuring high-quality output. This article delves into various strategies to optimize these machines effectively.

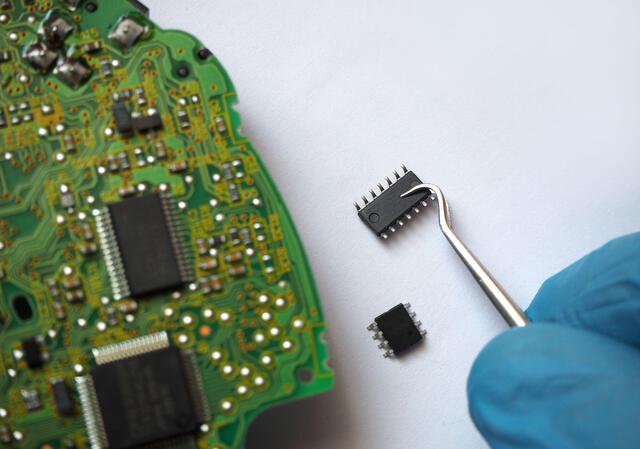

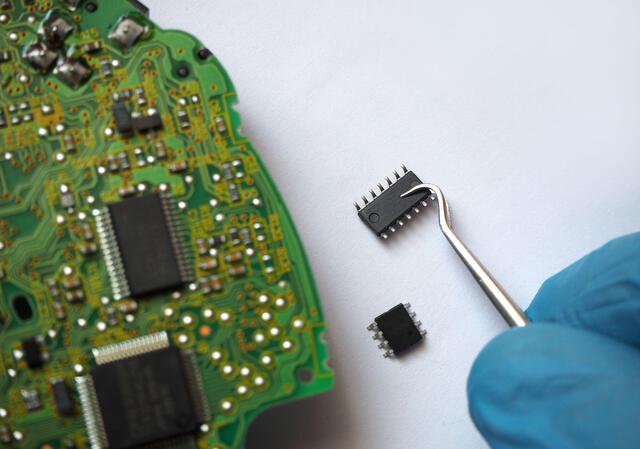

Understanding Pick and Place Machines

Pick and place machines are automated devices used in SMT processes to position electronic components onto PCBs accurately. They utilize robotic arms equipped with suction nozzles to pick components from feeders and place them onto the PCB at high speeds. The efficiency of these machines directly impacts the overall productivity of the SMT line.

Importance of Optimization

Optimizing the performance of multiple pick and place machines is vital for several reasons:

- Increased Throughput: Efficient machines can significantly enhance production rates.

- Cost Reduction: Optimized operations minimize waste and reduce labor costs.

- Quality Assurance: High accuracy in component placement leads to fewer defects.

- Flexibility: Well-optimized machines can adapt to different production requirements quickly.

Key Strategies for Optimization

1. Regular Maintenance and Calibration

Regular maintenance is crucial for ensuring that pick and place machines operate at peak efficiency. This includes:

- Routine Checks: Inspecting critical components such as nozzles, feeders, and vision systems regularly to prevent breakdowns.

- Calibration: Periodically calibrating machines to maintain placement accuracy. This involves adjusting the machine settings based on component specifications and PCB designs.

2. Optimize Feeder Setup

The configuration of feeders plays a significant role in machine efficiency:

- Strategic Arrangement: Organize feeders based on component usage frequency to minimize changeover times during production runs.

- Feeder Maintenance: Keep feeders clean and in good condition to avoid jams that could halt production.

3. Implement Advanced Software Solutions

Utilizing advanced software can greatly enhance the performance of pick and place machines:

- Programming Optimization: Use software that can automatically optimize placement programs based on component types and PCB layouts, reducing manual input errors.

- Real-Time Monitoring: Implement systems that provide real-time data on machine performance, allowing for quick adjustments to improve efficiency.

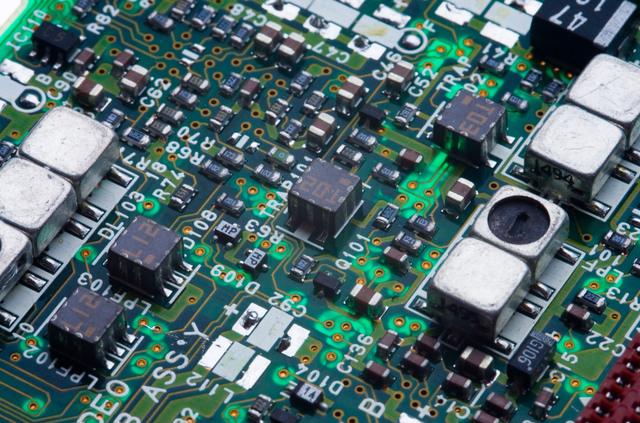

4. Utilize High-Speed Components

Selecting the right components can impact placement speed:

- Standardized Sizes: Use components that are designed for high-speed assembly, which simplifies handling and placement.

- Regular Inventory Evaluation: Ensure that inventory consists of components that align with your production needs, minimizing delays caused by component shortages.

5. Enhance Operator Training

The skill level of operators significantly affects machine performance:

- Comprehensive Training Programs: Invest in training programs that equip operators with the skills necessary to troubleshoot issues quickly and operate machinery efficiently.

- Continuous Learning: Encourage ongoing education about new technologies and techniques in SMT manufacturing.

6. Streamline Workflow and Layout

An efficient factory layout is critical for optimizing production speed:

- Logical Arrangement: Place SMT machines in a sequence that aligns with the production process to minimize material handling time.

- Lean Manufacturing Principles: Implement lean principles to eliminate wasteful practices within the workflow.

7. Optimize Placement Programs

Minimizing the complexity of placement programs can enhance efficiency:

- Reduce Nozzle Changes: Design programs that require fewer nozzle changes by grouping similar components together.

- Shorten Travel Distances: Optimize the path that the machine head travels during operation to reduce cycle times.

Conclusion

Optimizing the performance of multiple pick and place machines in an SMT line is a multifaceted approach that requires attention to detail across various aspects of manufacturing. By focusing on regular maintenance, feeder optimization, advanced software utilization, operator training, streamlined workflows, and effective placement program design, manufacturers can significantly enhance productivity while maintaining high-quality standards. In an industry where speed and precision are paramount, these strategies are not just beneficial but essential for staying competitive in today's market.

FAQ

1. What are pick and place machines used for?

Pick and place machines are used in electronics manufacturing to automate the process of placing surface-mount components onto printed circuit boards (PCBs).

2. How often should pick and place machines be calibrated?

Pick and place machines should be calibrated regularly—ideally every few months or whenever significant changes occur in component types or PCB designs—to ensure accuracy in component placement.

3. What factors affect the efficiency of pick and place machines?

Factors include machine maintenance, feeder setup, software optimization, operator training, workflow design, and the types of components used in production.

4. How can operator training improve machine performance?

Well-trained operators can troubleshoot issues quickly, make necessary adjustments during operation, and ensure optimal use of machine capabilities, leading to improved overall performance.

5. What role does software play in optimizing pick and place operations?

Software helps automate programming tasks, provides real-time monitoring capabilities, optimizes placement paths, reduces manual errors, and enhances overall operational efficiency.

Citations:

[1] https://invsmt.com/optimizing/

[2] https://www.linkedin.com/advice/1/how-can-you-optimize-your-pick-and-place-cwdje

[3] https://www.tronstol.com/ways-to-improve-the-speed-of-the-pick-and-place-machine.html

[4] https://www.tronstol.com/how-to-optimize-smt-mounter-machine-equipment.html

[5] https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

[6] https://www.tronstol.com/how-to-deal-with-the-alarm-of-smt-pick-and-place-machine.html

[7] https://www.smtfactory.com/Optimizing-SMT-Manufacturing-The-Crucial-Contribution-of-Pick-And-Place-Machines-To-Maximize-Productivity-id49783497.html

[8] https://www.tronstol.com/how-to-improve-the-efficiency-of-pick-and-place-ma.html

[9] https://www.globalsmt.net/articles-and-papers/optimizing-pick-and-place-machines/

[10] https://www.zjyingxing.com/info/smt-machine-use-common-problems-and-solutions-79029869.html

[11] https://www.neodensmt.com/news/improve-smt-production-efficiency-48868013.html

[12] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[13] https://interelectronic.com/articles/Make_Your_SMT_Factory_SMART_en

[14] https://www.smtpark.com/how-to-Increase-the-placement-speed-of-surface-mount-machines.html

[15] https://www.smthelp.com/component-programming-tips-for-smt-pick-and-place-machine

[16] https://core-emt.com/blog/smt-news-1/how-to-boost-placement-productivity-87

[17] https://www.tronstol.com/how-to-improve-the-placement-speed-of-the-pick-and-place-machine.html

[18] https://www.ddmnovastar.com/smt-quick-tips-selecting-a-pick-and-place-machine

[19] https://www.globalsmt.net/articles-and-papers/optimizing-pick-and-place-machines/

[20] https://www.circuitinsight.com/pdf/Modeling_SMT_Line_Improve_Throughput_smta.pdf

[21] https://www.hct-smt.com/blog/keep-your-machines-running-smoothly--expert-tips-for-automatic-smt-mounter-pick-and-place-machine-maintenance

[22] https://www.sztech-smt.com/how-to-improve-smt-chip-processing-efficiency/

[23] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[24] https://www.linkedin.com/pulse/rapid-smt-assembly-improving-efficiency-surface-oerzc

[25] https://www.zjyingxing.com/info/how-to-improve-the-place-efficiency-of-smt-mac-66944776.html

[26] https://www.zjyingxing.com/info/what-to-improve-the-production-efficiency-of-s-102748737.html

[27] https://www.surfacemountprocess.com/surface-mount-troubleshooting-guide.html

[28] https://jhdpcb.com/blog/efficient-smt-assembly/

[29] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

[30] https://www.restronics.com/blog/everything-you-need-to-know-about-smt-pick-and-place-machines

[31] https://smtnet.com/library/files/upload/SMT-troubleshooting-guide.pdf

[32] https://www.qhsmt.com/2023/11/29/smt-pick-and-place-most-asked-power-electronics-supply-questions-and-answers/

[33] https://www.vse.com/blog/2022/03/15/8-common-smt-placement-issues-and-solutions/

[34] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[35] https://www.manufacturingtomorrow.com/news/2024/06/24/choosing-the-right-smt-pick-and-place-machine-a-comprehensive-guide-for-different-buyers/22957