Content Menu

● Understanding SMT PCB Assembly

● Key Advantages of SMT PCB Assembly

● Optimizing SMT PCB Assembly for High-Volume Production

>> 1. Streamline Component Selection

>> 2. Implement Advanced Automation

>> 3. Optimize Solder Paste Application

>> 4. Enhance Reflow Soldering Process

>> 5. Implement Robust Quality Control Measures

>> 6. Optimize Factory Layout and Material Flow

>> 7. Invest in Employee Training and Development

>> 8. Implement Effective Data Management and Analysis

>> 9. Optimize Supply Chain Management

>> 10. Embrace Flexibility and Scalability

● Conclusion

● FAQ

>> 1. What is the difference between SMT and through-hole PCB assembly?

>> 2. How does SMT PCB assembly contribute to miniaturization in electronics?

>> 3. What are the key challenges in high-volume SMT PCB assembly?

>> 4. How can manufacturers ensure quality in high-volume SMT PCB assembly?

>> 5. What role does automation play in optimizing SMT PCB assembly for high-volume production?

● Citations:

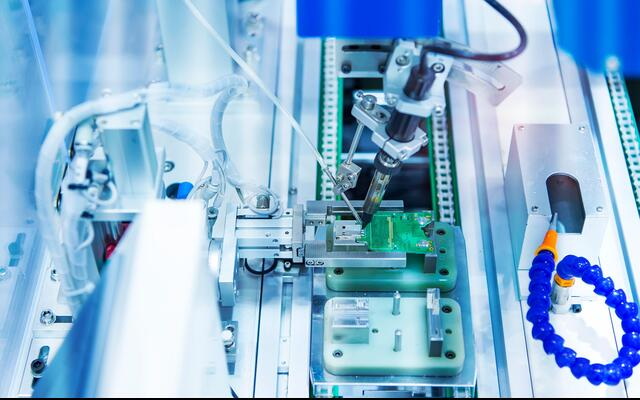

In today's rapidly evolving electronics industry, the demand for high-volume production of printed circuit boards (PCBs) continues to grow. Surface Mount Technology (SMT) has revolutionized the PCB assembly process, offering numerous advantages over traditional through-hole assembly methods. This article will explore various strategies and techniques to optimize SMT PCB assembly for high-volume production, ensuring efficiency, cost-effectiveness, and consistent quality.

Understanding SMT PCB Assembly

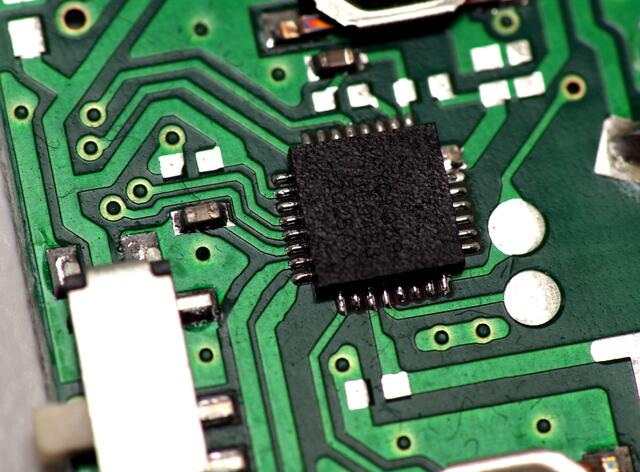

Surface Mount Technology (SMT) is a method of electronic component assembly where components are mounted directly onto the surface of a printed circuit board (PCB)[1]. This technique has become the industry standard for high-volume PCB assembly due to its numerous benefits, including increased component density, improved performance, and faster production times[2].

Key Advantages of SMT PCB Assembly

Before delving into optimization strategies, it's essential to understand the advantages of SMT PCB assembly for high-volume production:

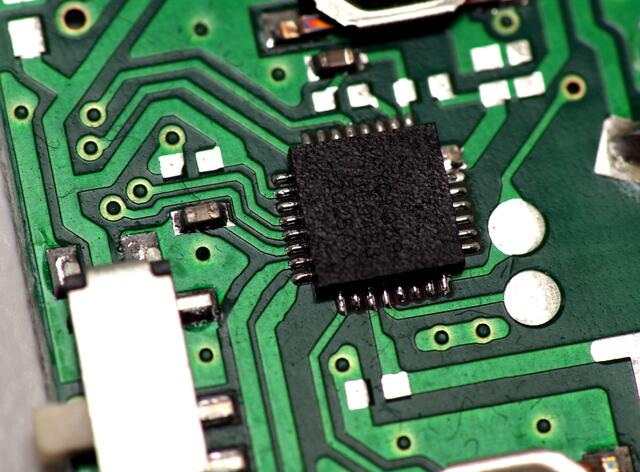

1. Increased Component Density: SMT allows for higher component density on PCBs, enabling the creation of smaller and more compact electronic devices[5].

2. Improved Performance: The shorter leads and direct surface mounting of components result in better electrical performance and reduced signal interference[3].

3. Faster Production: SMT assembly processes are highly automated, leading to significantly faster production times compared to through-hole assembly[2].

4. Cost-Effectiveness: While initial setup costs may be higher, SMT assembly becomes more cost-effective for high-volume production due to reduced labor costs and material usage[2].

5. Enhanced Reliability: SMT components are generally more resistant to shock and vibration, resulting in more reliable electronic products[3].

Optimizing SMT PCB Assembly for High-Volume Production

To maximize the benefits of SMT PCB assembly in high-volume production scenarios, consider implementing the following optimization strategies:

1. Streamline Component Selection

Effective component selection is crucial for optimizing SMT PCB assembly. Consider the following approaches:

- Standardize Components: Use standardized components across multiple product lines to reduce inventory complexity and improve purchasing power[1].

- Design for Manufacturability (DFM): Collaborate closely with design teams to ensure PCB layouts are optimized for efficient assembly processes[1].

- Component Placement Optimization: Arrange components to minimize pick-and-place machine movements and reduce assembly time[5].

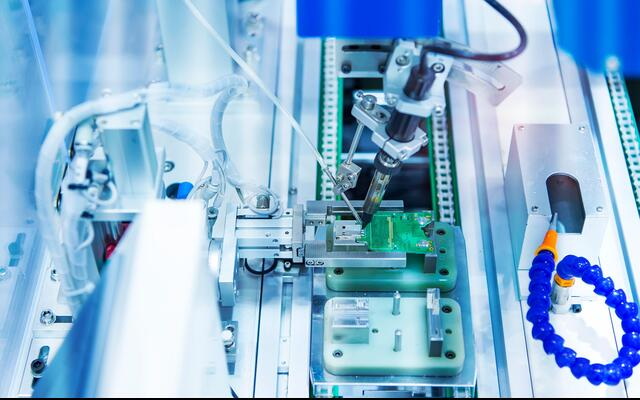

2. Implement Advanced Automation

Automation is key to achieving high-volume production efficiency in SMT PCB assembly:

- High-Speed Pick-and-Place Machines: Invest in advanced pick-and-place machines capable of handling high component placement speeds with precision[2].

- Automated Optical Inspection (AOI): Implement AOI systems to detect defects early in the assembly process, reducing rework and improving overall quality[7].

- Automated Material Handling: Use automated systems for component feeding, board handling, and inventory management to minimize human intervention and errors[4].

3. Optimize Solder Paste Application

Proper solder paste application is critical for ensuring reliable connections in SMT assembly:

- Stencil Design: Use high-quality stencils designed specifically for your PCB layout to ensure precise solder paste deposition[6].

- Solder Paste Inspection: Implement automated solder paste inspection systems to detect issues before component placement[7].

- Climate Control: Maintain a controlled environment for solder paste storage and application to ensure consistent viscosity and performance[3].

4. Enhance Reflow Soldering Process

Reflow soldering is a crucial step in SMT PCB assembly. Optimize this process for high-volume production:

- Profiling: Develop and maintain accurate reflow profiles for different board types and component mixes[4].

- Nitrogen Atmosphere: Consider using a nitrogen atmosphere in reflow ovens to improve solder joint quality and reduce oxidation[3].

- Continuous Monitoring: Implement real-time monitoring systems to ensure consistent reflow temperatures and detect any deviations[7].

5. Implement Robust Quality Control Measures

Maintaining high quality in high-volume production requires comprehensive quality control:

- In-Line Inspection: Integrate automated optical inspection (AOI) and X-ray inspection systems at key points in the assembly process[7].

- Statistical Process Control (SPC): Use SPC techniques to monitor and control process variations, ensuring consistent quality[4].

- Functional Testing: Implement automated functional testing systems to verify the performance of assembled PCBs[9].

6. Optimize Factory Layout and Material Flow

Efficient factory layout and material flow are essential for high-volume SMT PCB assembly:

- Lean Manufacturing Principles: Apply lean manufacturing concepts to minimize waste and optimize production flow[4].

- Just-in-Time (JIT) Inventory: Implement JIT inventory systems to reduce storage costs and improve cash flow[2].

- Smart Factory Integration: Leverage Industry 4.0 technologies to create a connected and intelligent production environment[5].

7. Invest in Employee Training and Development

Well-trained staff is crucial for maintaining efficiency and quality in high-volume production:

- Continuous Training: Provide ongoing training to keep staff updated on the latest SMT assembly techniques and technologies[4].

- Cross-Training: Develop a multi-skilled workforce capable of handling various aspects of the SMT assembly process[9].

- Process Improvement Teams: Establish teams dedicated to identifying and implementing process improvements[1].

8. Implement Effective Data Management and Analysis

Leveraging data is key to optimizing high-volume SMT PCB assembly:

- Manufacturing Execution Systems (MES): Implement MES to collect and analyze real-time production data[5].

- Predictive Maintenance: Use data analytics to predict and prevent equipment failures, minimizing downtime[7].

- Continuous Improvement: Analyze production data to identify bottlenecks and opportunities for process optimization[4].

9. Optimize Supply Chain Management

Efficient supply chain management is crucial for maintaining high-volume production:

- Supplier Partnerships: Develop strong relationships with key suppliers to ensure reliable component sourcing[2].

- Inventory Optimization: Use advanced forecasting techniques to optimize inventory levels and reduce carrying costs[9].

- Risk Management: Implement strategies to mitigate supply chain disruptions and ensure production continuity[4].

10. Embrace Flexibility and Scalability

Design your SMT PCB assembly process to be flexible and scalable:

- Modular Production Lines: Use modular assembly line configurations that can be easily reconfigured for different product types[5].

- Scalable Automation: Implement automation solutions that can be scaled up or down based on production volume requirements[2].

- Rapid Changeover: Develop efficient changeover procedures to minimize downtime between different product runs[4].

Conclusion

Optimizing SMT PCB assembly for high-volume production requires a comprehensive approach that addresses various aspects of the manufacturing process. By implementing advanced automation, streamlining component selection, enhancing quality control measures, and leveraging data-driven insights, manufacturers can significantly improve efficiency, reduce costs, and maintain consistent quality in their high-volume PCB assembly operations.

As the electronics industry continues to evolve, staying ahead of the curve in SMT PCB assembly optimization will be crucial for maintaining competitiveness in the global market. By continuously evaluating and improving assembly processes, investing in cutting-edge technologies, and fostering a culture of innovation, manufacturers can position themselves for success in the dynamic world of high-volume electronic PCB SMT assembly.

FAQ

1. What is the difference between SMT and through-hole PCB assembly?

SMT (Surface Mount Technology) involves mounting components directly onto the surface of the PCB, while through-hole assembly requires components to be inserted through holes in the board. SMT allows for higher component density, faster assembly, and improved performance, making it ideal for high-volume production[3].

2. How does SMT PCB assembly contribute to miniaturization in electronics?

SMT enables the use of smaller components and allows for higher component density on PCBs. This results in more compact circuit designs, facilitating the development of smaller and lighter electronic devices without compromising functionality[5].

3. What are the key challenges in high-volume SMT PCB assembly?

Some key challenges include maintaining consistent quality, managing complex supply chains, optimizing production efficiency, and keeping up with rapidly evolving technology. Addressing these challenges requires continuous improvement in processes, investment in advanced equipment, and effective workforce training[4].

4. How can manufacturers ensure quality in high-volume SMT PCB assembly?

Quality in high-volume SMT PCB assembly can be ensured through a combination of strategies, including implementing robust inspection systems (AOI, X-ray), using statistical process control, conducting thorough functional testing, and maintaining strict quality control protocols throughout the production process[7].

5. What role does automation play in optimizing SMT PCB assembly for high-volume production?

Automation is crucial in high-volume SMT PCB assembly, enabling faster production speeds, improved accuracy, and consistent quality. Advanced pick-and-place machines, automated inspection systems, and automated material handling solutions all contribute to optimizing the assembly process for high-volume production[2].

Citations:

[1] https://www.thinksemiinfotech.com/pcb-assembly/pcb-smt-assembly-process-helping-you-reduce-production-costs/

[2] https://www.linkedin.com/pulse/high-volume-pcb-assembly-accelerating-manufacturing-efficiency-b

[3] https://www.fs-pcba.com/smt-pcba/

[4] https://www.elepcb.com/blog/a-complete-guide-to-high-volume-pcb-assembly/

[5] https://jlcpcb.com/blog/the-ultimate-guide-to-pcba

[6] https://www.viasion.com/smt-assembly/

[7] https://blog.matric.com/smt-production-for-pcbs-matric

[8] https://www.viasion.com/blog/guide-to-smt-and-pcb-assembly-techniques/

[9] https://morepcb.com/assembly-pcb/high-volume-pcb-assembly/

[10] https://swimbi.com/high-volume-pcb-manufacturing-everything-you-need-to-know/

[11] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[12] https://mermarinc.com/high-volume-pcb-assembly/