Content Menu

● Understanding Surface Mount Assembly

● Key Components of a Surface Mount Assembly Line

● Workflow Optimization

● Equipment Selection

● Quality Control Measures

● Employee Training and Engagement

● Conclusion

● FAQ

>> 1. What is surface mount technology (SMT)?

>> 2. How does automation impact surface mount assembly lines?

>> 3. What are some common quality control measures used in SMT?

>> 4. Why is employee training important in SMT?

>> 5. What are lean manufacturing principles?

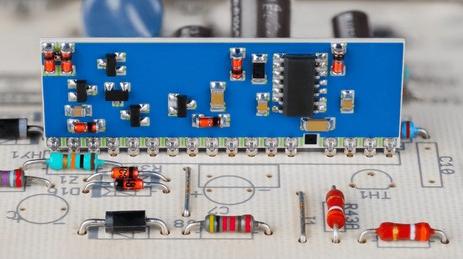

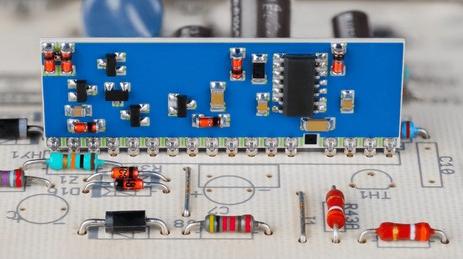

In the fast-paced world of electronics manufacturing, optimizing efficiency in a surface mount assembly line is crucial for maintaining competitiveness and meeting customer demands. Surface mount technology (SMT) has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). This article explores various strategies and methods to enhance the efficiency of a surface mount assembly line, focusing on workflow optimization, equipment selection, quality control, and employee training.

Understanding Surface Mount Assembly

Surface mount assembly involves placing electronic components directly onto the surface of PCBs. Unlike traditional through-hole technology, which requires holes in the PCB for component leads, SMT allows for smaller components to be mounted on both sides of the board. This method not only saves space but also improves performance and reliability.

Key Components of a Surface Mount Assembly Line

To optimize efficiency, it is essential to understand the key components involved in a surface mount assembly line:

- Pick and Place Machines: These machines automate the placement of components onto PCBs. Their speed and precision are critical for maintaining high throughput.

- Solder Paste Printers: These machines apply solder paste to the PCB before component placement. Accurate application is vital for ensuring strong solder joints.

- Reflow Ovens: After components are placed, PCBs pass through reflow ovens where solder paste is melted to create electrical connections.

- Inspection Systems: Automated optical inspection (AOI) systems check for defects in component placement and solder joints.

- Test Equipment: Functional testing equipment verifies that assembled boards meet specifications.

Workflow Optimization

One of the most effective ways to optimize a surface mount assembly line is by streamlining processes. This can be achieved through:

- Value Stream Mapping: Identify each step in the assembly process and eliminate any non-value-added activities. This helps in reducing cycle times and improving overall efficiency.

- Work Cell Design: Organize workstations in a way that minimizes movement and transportation of materials. A well-designed work cell can significantly reduce lead times.

- Batch Size Reduction: Smaller batch sizes can lead to quicker turnaround times and less inventory buildup. Implementing just-in-time (JIT) manufacturing principles can help achieve this.

Implementing Lean Manufacturing Principles

Lean manufacturing focuses on minimizing waste while maximizing productivity. Key lean principles applicable to surface mount assembly include:

- Continuous Improvement (Kaizen): Encourage employees to suggest improvements in processes regularly. Small, incremental changes can lead to significant efficiency gains over time.

- Standardized Work: Develop standardized procedures for each task within the assembly line. This ensures consistency and reduces variability in performance.

- 5S Methodology: Implementing Sort, Set in order, Shine, Standardize, and Sustain (5S) can create an organized workspace that enhances productivity and safety.

Equipment Selection

The choice of machinery plays a significant role in the efficiency of a surface mount assembly line. Considerations include:

- Machine Speed: Select pick and place machines with high placement speeds without compromising accuracy. Faster machines can significantly increase throughput.

- Flexibility: Choose equipment that can handle various component sizes and types. This flexibility allows for quick changeovers between different product lines.

- Maintenance Requirements: Invest in machines that require minimal maintenance downtime. Regular maintenance schedules should be established to prevent unexpected breakdowns.

Automation vs. Manual Processes

While automation is essential for high-volume production, there are scenarios where manual processes may be more efficient:

- Low Volume Production: For low-volume or prototyping runs, manual assembly may be more cost-effective than investing in expensive automated equipment.

- Complex Assemblies: Some complex assemblies may require skilled labor for specific tasks that automated systems cannot perform effectively.

x

x

Quality Control Measures

Quality control is vital in ensuring that assembled products meet industry standards and customer expectations. Effective quality assurance protocols include:

- In-Process Inspection: Conduct inspections at various stages of the assembly process to catch defects early before they escalate into larger issues.

- Final Testing: Implement rigorous final testing procedures to ensure that each assembled board functions correctly before shipping.

- Feedback Loops: Establish feedback mechanisms where defects are analyzed to identify root causes and implement corrective actions promptly.

Utilizing Technology for Quality Control

Modern technology offers various tools that can enhance quality control processes:

- Automated Optical Inspection (AOI): AOI systems can quickly detect defects such as misalignment or insufficient solder joints during production.

- X-ray Inspection: For complex assemblies with hidden solder joints, X-ray inspection provides a non-destructive method to ensure quality.

Employee Training and Engagement

While technology plays a crucial role in optimizing efficiency, skilled labor remains an essential component of a successful surface mount assembly line:

- Training Programs: Regular training programs should be implemented to keep employees updated on new technologies and best practices in SMT assembly.

- Cross-Training Employees: Cross-training employees allows them to perform multiple roles within the assembly line, providing flexibility during peak production periods.

Fostering a Culture of Engagement

Creating an engaging work environment encourages employees to take ownership of their work:

- Incentive Programs: Implement incentive programs that reward employees for meeting or exceeding performance targets.

- Open Communication Channels: Establish open lines of communication where employees can share ideas or concerns about the assembly process without fear of repercussions.

Conclusion

Optimizing efficiency in a surface mount assembly line requires a multifaceted approach that encompasses workflow optimization, equipment selection, quality control measures, and employee training. By implementing lean manufacturing principles, selecting appropriate machinery, maintaining rigorous quality assurance protocols, and fostering an engaged workforce, manufacturers can significantly enhance their production capabilities. As technology continues to evolve, staying ahead of industry trends will further contribute to achieving optimal efficiency in SMT assembly lines.

FAQ

1. What is surface mount technology (SMT)?

Surface mount technology (SMT) is a method used for mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for smaller and more efficient designs compared to traditional through-hole methods.

2. How does automation impact surface mount assembly lines?

Automation enhances speed and precision in surface mount assembly lines by utilizing machines like pick-and-place systems and reflow ovens, which reduce human error and increase overall production rates.

3. What are some common quality control measures used in SMT?

Common quality control measures include automated optical inspection (AOI), in-process inspections at various stages of production, final testing before shipment, and implementing feedback loops for continuous improvement.

4. Why is employee training important in SMT?

Employee training is crucial as it ensures that workers are knowledgeable about new technologies and best practices, leading to higher productivity levels and reduced errors during the assembly process.

5. What are lean manufacturing principles?

Lean manufacturing principles focus on minimizing waste while maximizing productivity through methods such as continuous improvement (Kaizen), standardized work processes, and organizing workspaces using the 5S methodology.

x

x