Content Menu

● Understanding Wholesale SMT Manufacturing

>> The Importance of Efficiency in SMT Manufacturing

● Key Strategies to Maximize Efficiency

>> Invest in Advanced SMT Machinery

>> Implement Lean Manufacturing Principles

>> Utilize Data Analytics and AI

>> Embrace Industry 4.0 Technologies

>> Focus on Quality Control

● Conclusion

● Related Questions

>> 1. What are the benefits of using wholesale SMT manufacturing machines?

>> 2. How can lean manufacturing principles improve SMT production?

>> 3. What role does data analytics play in SMT manufacturing?

>> 4. How does Industry 4.0 impact SMT manufacturing?

>> 5. Why is quality control important in SMT manufacturing?

In the fast-paced world of electronics manufacturing, maximizing efficiency is crucial for staying competitive. Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled, allowing for faster production times and higher quality outputs. This article explores various strategies and solutions to enhance efficiency in wholesale SMT manufacturing, focusing on the integration of advanced machinery, process optimization, and the adoption of Industry 4.0 technologies.

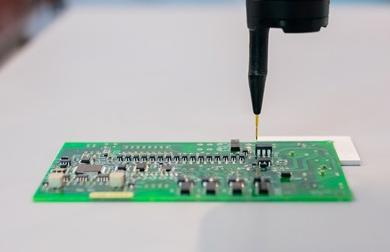

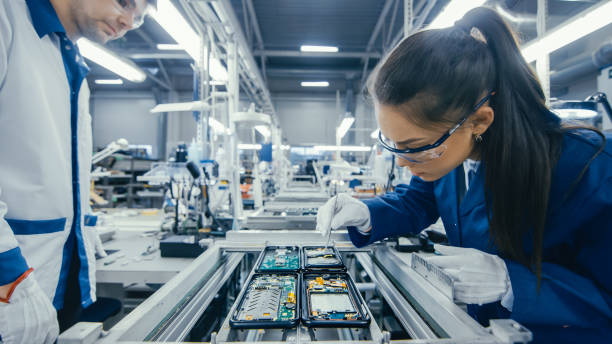

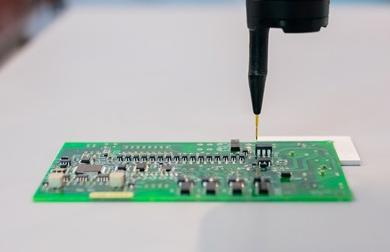

Understanding Wholesale SMT Manufacturing

Wholesale SMT manufacturing involves the mass production of electronic components using surface mount technology. This method allows components to be mounted directly onto the surface of printed circuit boards (PCBs), significantly reducing the size and weight of electronic devices. The efficiency of this process is heavily reliant on the machinery used, including wholesale SMT manufacturing machines that automate various stages of production.

The Importance of Efficiency in SMT Manufacturing

Efficiency in SMT manufacturing is not just about speed; it encompasses quality control, cost reduction, and the ability to meet market demands. As consumer electronics evolve, manufacturers must adapt to shorter product life cycles and increasing complexity in designs. Therefore, optimizing production processes is essential for maintaining profitability and customer satisfaction.

Key Strategies to Maximize Efficiency

Invest in Advanced SMT Machinery

The backbone of efficient SMT manufacturing is the machinery used in the production line. Investing in wholesale SMT manufacturing machines that incorporate the latest technology can lead to significant improvements in speed and accuracy. Features to look for include:

- High-speed placement: Machines that can place components quickly and accurately reduce cycle times.

- Automated inspection systems: These systems help identify defects early in the process, minimizing waste and rework.

- Flexible production capabilities: Machines that can easily switch between different product types enhance versatility and responsiveness to market changes.

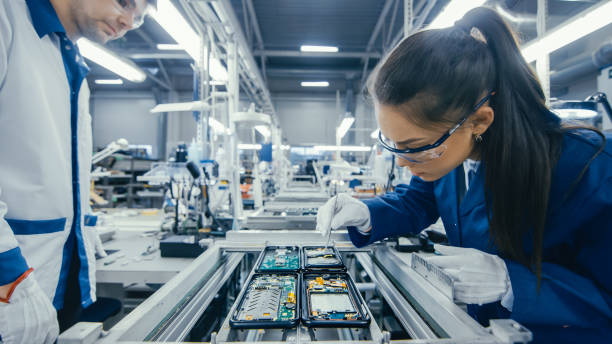

Implement Lean Manufacturing Principles

Lean manufacturing focuses on minimizing waste while maximizing productivity. In the context of SMT manufacturing, this can involve:

- Streamlining workflows: Analyzing and optimizing the flow of materials and information can reduce bottlenecks.

- Just-in-time (JIT) inventory: Maintaining minimal inventory levels can reduce holding costs and improve cash flow.

- Continuous improvement (Kaizen): Encouraging a culture of ongoing improvement among employees can lead to innovative solutions for efficiency challenges.

Utilize Data Analytics and AI

The integration of data analytics and artificial intelligence (AI) into SMT manufacturing processes can provide valuable insights into production efficiency. By analyzing data from various stages of production, manufacturers can:

- Identify trends and patterns: Understanding production metrics can help pinpoint areas for improvement.

- Predict maintenance needs: AI can forecast when machines are likely to require maintenance, reducing downtime.

- Optimize production schedules: Data-driven scheduling can enhance resource allocation and minimize idle time.

Embrace Industry 4.0 Technologies

Industry 4.0 represents the next phase of industrial revolution, characterized by the integration of digital technologies into manufacturing. For SMT manufacturing, this includes:

- Internet of Things (IoT): Connecting machines and devices allows for real-time monitoring and control of production processes.

- Smart factories: Implementing smart technologies can lead to more agile and responsive manufacturing environments.

- Digital twins: Creating virtual models of production processes enables manufacturers to simulate and optimize operations before implementation.

Focus on Quality Control

Quality control is integral to efficient SMT manufacturing. Implementing robust quality assurance processes can help ensure that products meet specifications and reduce the likelihood of defects. Strategies include:

- Automated inspection systems: Utilizing machine vision systems can enhance the accuracy of inspections.

- Statistical process control (SPC): Monitoring production processes using statistical methods can help identify variations and maintain quality standards.

- Employee training: Regular training programs can equip staff with the skills needed to maintain high-quality standards.

Conclusion

Maximizing efficiency in wholesale SMT manufacturing is a multifaceted challenge that requires a strategic approach. By investing in advanced machinery, implementing lean principles, utilizing data analytics, embracing Industry 4.0 technologies, and focusing on quality control, manufacturers can significantly enhance their production processes. As the electronics industry continues to evolve, staying ahead of the curve in efficiency will be essential for success.

Related Questions

1. What are the benefits of using wholesale SMT manufacturing machines?

Wholesale SMT manufacturing machines offer increased speed, accuracy, and flexibility in production, allowing manufacturers to meet market demands more effectively.

2. How can lean manufacturing principles improve SMT production?

Lean manufacturing principles help reduce waste, streamline workflows, and enhance productivity, leading to more efficient SMT production processes.

3. What role does data analytics play in SMT manufacturing?

Data analytics provides insights into production metrics, helping manufacturers identify areas for improvement and optimize their processes.

4. How does Industry 4.0 impact SMT manufacturing?

Industry 4.0 introduces digital technologies that enhance connectivity, automation, and data-driven decision-making, leading to more efficient and agile manufacturing environments.

5. Why is quality control important in SMT manufacturing?

Quality control ensures that products meet specifications and reduces defects, which is crucial for maintaining customer satisfaction and minimizing costs.