Content Menu

● Introduction to Multifunctional SMD Soldering Machines

>> Key Components of Multifunctional SMD Soldering Machines

● Maintenance Practices for Multifunctional SMD Soldering Machines

>> 1. Cleaning and Dust Removal

>> 2. Regular Checkups and Calibration

>> 3. Conveyor Belt Maintenance

>> 4. Temperature and Humidity Monitoring

>> 5. Use of Quality Materials

● Advanced Features and Technologies

>> Integration with Existing Workflow

● Training and Operator Safety

● Environmental Considerations

● Troubleshooting Common Issues

● Conclusion

● Frequently Asked Questions

>> 1. What are the key components of a multifunctional SMD soldering machine?

>> 2. How often should I clean my multifunctional SMD soldering machine?

>> 3. What are the benefits of using high-quality solder paste and flux?

>> 4. Can I use a multifunctional SMD soldering machine for both high-volume and low-volume production?

>> 5. How does temperature control impact the soldering process?

● Citations:

Maintaining an OEM multifunctional SMD soldering machine is crucial for ensuring its longevity and optimal performance in electronics manufacturing. These machines are designed to handle a wide range of surface mount devices (SMDs) efficiently, making them indispensable in high-volume production environments. In this article, we will explore the essential steps and practices for maintaining these sophisticated machines.

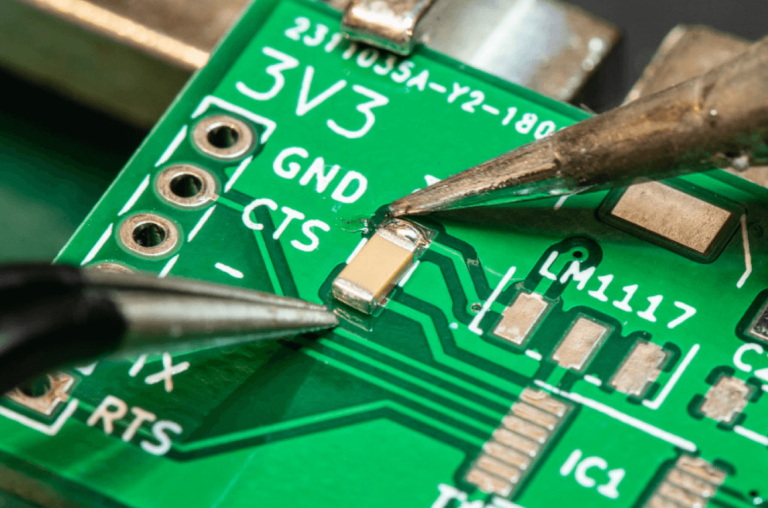

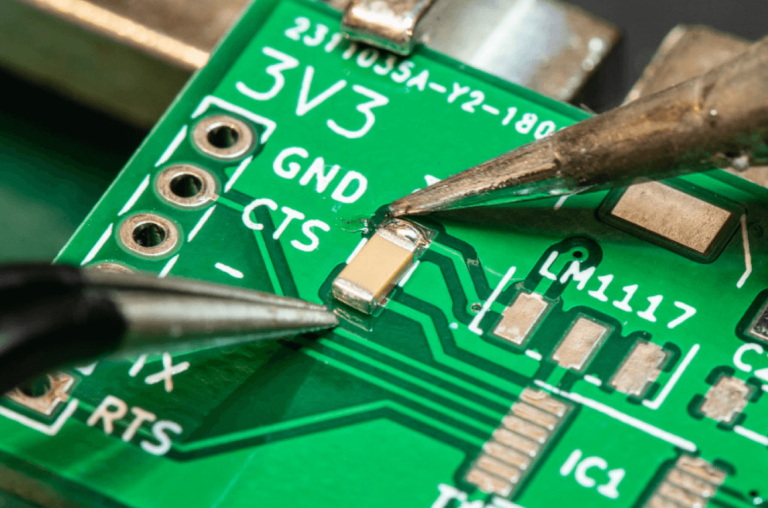

Introduction to Multifunctional SMD Soldering Machines

Multifunctional SMD soldering machines are advanced systems that integrate various technologies to solder SMD components onto printed circuit boards (PCBs). They typically include features like automatic solder paste application, component placement, and reflow soldering under controlled temperature conditions. These machines are equipped with motors, controllers, and heating elements that work together to ensure precise temperature and placement control. Some models also incorporate vision systems for solder joint inspection, enhancing the quality and reliability of the soldering process.

Key Components of Multifunctional SMD Soldering Machines

1. Conveyor System: This is responsible for moving the PCBs through the machine, ensuring smooth and consistent soldering.

2. Heating Elements: These are critical for the reflow process, providing the necessary heat to melt and solidify solder paste.

3. Control Systems: Advanced controllers manage temperature, timing, and component placement to achieve high-quality solder joints.

4. Vision Inspection Systems: Some machines include optical inspection systems to verify the quality of solder joints post-soldering.

Maintenance Practices for Multifunctional SMD Soldering Machines

1. Cleaning and Dust Removal

Keeping the machine clean is essential to prevent dust and debris from accumulating and causing malfunctions. Regular cleaning with a soft brush or vacuum can help maintain the machine's performance and longevity. Pay particular attention to areas around the conveyor belt and heating elements. It's also important to clean the machine's exterior to prevent dust from entering the internal mechanisms.

2. Regular Checkups and Calibration

Scheduling regular checkups by a qualified technician is vital. These checkups help identify potential issues early, preventing major repairs and downtime. Calibration according to the manufacturer's specifications ensures that the machine operates within optimal parameters. Regular calibration also helps maintain the precision required for high-quality soldering.

3. Conveyor Belt Maintenance

The conveyor belt is a critical component, ensuring PCBs move smoothly through the machine. Regularly clean the belt with a soft cloth, lubricate it as needed, and tighten it if it becomes loose. Proper belt maintenance prevents misalignment and ensures consistent soldering quality. Additionally, inspect the belt for signs of wear and replace it when necessary to avoid disruptions in production.

4. Temperature and Humidity Monitoring

Temperature and humidity levels significantly impact the soldering process. Excessive humidity can lead to oxidation on PCBs and components, while high temperatures can cause uneven soldering. Monitoring and regulating these conditions are crucial for achieving consistent results. Many modern machines include built-in environmental control systems, but it's important to ensure these systems are functioning correctly.

5. Use of Quality Materials

Using high-quality solder paste and flux is essential for efficient and reliable soldering. Ensure that these materials are certified and meet the required standards to avoid defects in the soldering process. High-quality materials also help reduce waste and improve overall product quality.

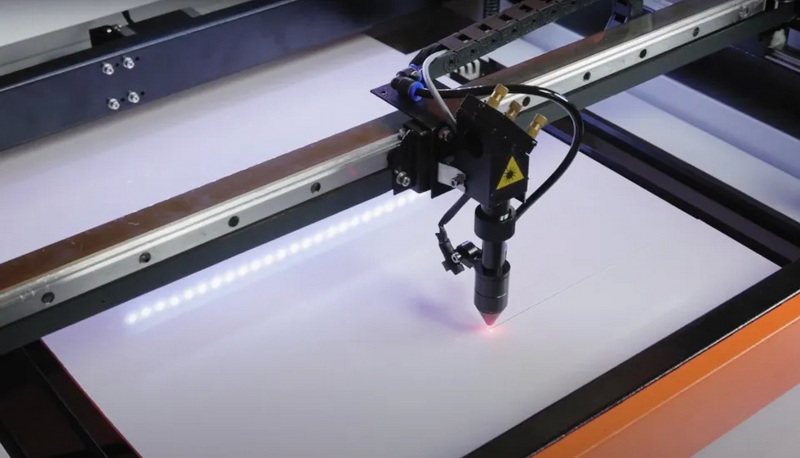

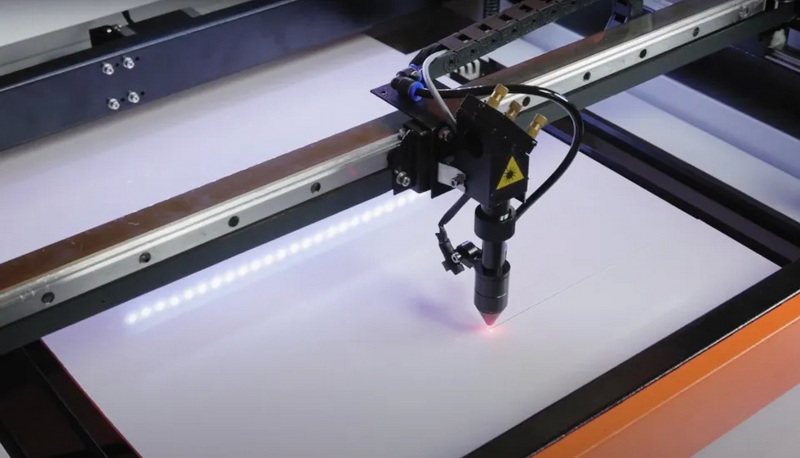

Advanced Features and Technologies

Modern multifunctional SMD soldering machines often incorporate advanced technologies such as robotics and artificial intelligence (AI) to enhance precision and productivity. These systems can handle complex tasks with ease, making them ideal for high-volume manufacturing environments. AI can also help in predictive maintenance by analyzing machine performance data to anticipate potential issues before they occur.

Integration with Existing Workflow

When selecting an OEM multifunctional SMD soldering machine, it's important to ensure that it integrates well with your existing manufacturing workflow. This includes compatibility with your preferred soldering methods (reflow, wave, or hand soldering) and support for the specific types of SMD components used in your production. Integration with other machinery, such as pick-and-place machines and inspection systems, is also crucial for streamlined production.

Training and Operator Safety

Proper training of operators is crucial for the safe and efficient operation of multifunctional SMD soldering machines. Training programs should cover machine operation, maintenance procedures, and safety protocols to prevent accidents and ensure high-quality output. Operators should be aware of potential hazards such as electrical shock and burns from hot components. Regular safety drills and updates on new technologies can enhance operator skills and confidence.

Environmental Considerations

In addition to maintaining the machine itself, it's important to consider the environmental impact of soldering operations. This includes managing waste, reducing energy consumption, and ensuring compliance with environmental regulations. Many modern machines are designed with energy efficiency in mind, offering features like automatic shutdown when not in use and optimized heating systems.

Troubleshooting Common Issues

Troubleshooting is an essential part of maintaining multifunctional SMD soldering machines. Common issues include uneven soldering, component misalignment, and machine downtime due to overheating. Identifying these problems early can help prevent costly repairs and minimize production delays. Regular maintenance and operator training can significantly reduce the occurrence of these issues.

Conclusion

Maintaining an OEM multifunctional SMD soldering machine requires a comprehensive approach that includes regular cleaning, checkups, conveyor belt maintenance, temperature and humidity control, and the use of quality materials. By following these guidelines and leveraging advanced technologies, manufacturers can ensure optimal performance, longevity, and safety of their equipment, leading to high-quality products and satisfied customers.

Frequently Asked Questions

1. What are the key components of a multifunctional SMD soldering machine?

- Answer: The key components include the conveyor system, heating elements, control systems, and vision inspection systems. These work together to ensure precise soldering of SMD components onto PCBs.

2. How often should I clean my multifunctional SMD soldering machine?

- Answer: Cleaning should be done regularly, ideally after each production cycle or at least once a week, depending on usage. This prevents dust buildup and maintains machine performance.

3. What are the benefits of using high-quality solder paste and flux?

- Answer: High-quality solder paste and flux ensure efficient and reliable soldering by providing better heat flow and reducing oxidation, leading to stronger solder joints and fewer defects.

4. Can I use a multifunctional SMD soldering machine for both high-volume and low-volume production?

- Answer: Yes, these machines are versatile and can be used for both high-volume and low-volume production. However, for very low-volume production, manual or semi-automatic methods might be more cost-effective.

5. How does temperature control impact the soldering process?

- Answer: Temperature control is critical as it affects the melting and solidification of solder paste. Incorrect temperatures can lead to uneven soldering, oxidation, or damage to components, so precise control is essential for achieving high-quality solder joints.

Citations:

[1] https://www.zjyingxing.com/info/what-is-the-maintenance-of-reflow-soldering-93138481.html

[2] https://www.chiefdelphi.com/t/smd-soldering/139351

[3] https://www.alibaba.com/showroom/automatic-smd-soldering-machine.html

[4] https://whadda.com/product/multifunctional-smd-repair-station-vtss210/

[5] https://forum.arduino.cc/t/smd-soldering-do-i-need-hot-air-soldering-station/212692

[6] https://t.me/s/researchmfg?before=211

[7] https://www.howardelectronics.com/safe-and-sane-smd-repair/

[8] https://www.reddit.com/r/soldering/comments/1hbbeg5/newbie_practicing_smd_hand_soldering_how_am_i/

[9] https://www.instructables.com/Intro-into-SMD-Soldering/