Content Menu

● Introduction to Automatic SMD LED Placement Machines

>> Key Components of Automatic SMD LED Placement Machines

● Maintenance Strategies for Optimal Performance

>> Daily Maintenance

>> Weekly Maintenance

>> Monthly Maintenance

● Calibration and Adjustment

● Software Updates

● Training and Operator Knowledge

● Storage and Environmental Conditions

● Common Issues and Troubleshooting

>> Component Placement Errors

>> Component Damage

>> Inaccurate Fiducial Recognition

>> Component Pick-up and Release Issues

● Advanced Maintenance Techniques

>> Predictive Maintenance

>> Use of Quality Components

>> Environmental Considerations

● Future Trends in SMD LED Placement Machines

● Conclusion

● FAQ

>> 1. What are the key components of an automatic SMD LED placement machine?

>> 2. Why is regular lubrication important for the machine?

>> 3. How often should the vision system be calibrated?

>> 4. What are the benefits of keeping the machine's software up to date?

>> 5. Why is operator training important for machine maintenance?

● Citations:

Maintaining an automatic SMD LED placement machine is crucial for ensuring optimal performance, reducing downtime, and improving overall production efficiency. These machines are integral to the electronics manufacturing process, particularly in the production of LED-based products. In this article, we will delve into the essential maintenance strategies and best practices for sustaining the peak performance of your automatic SMD LED placement machine.

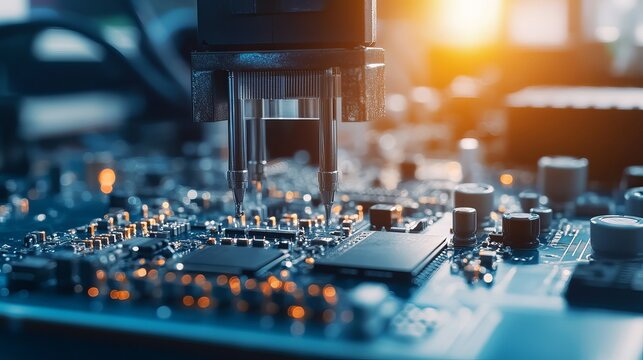

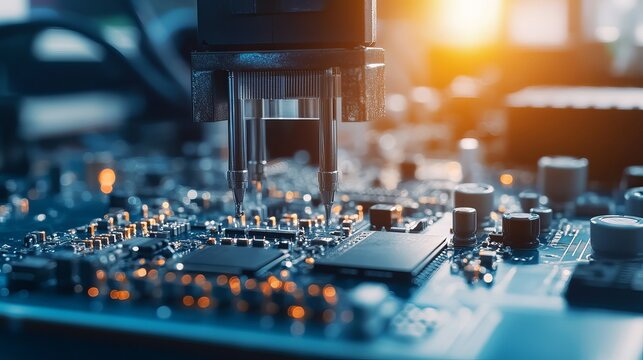

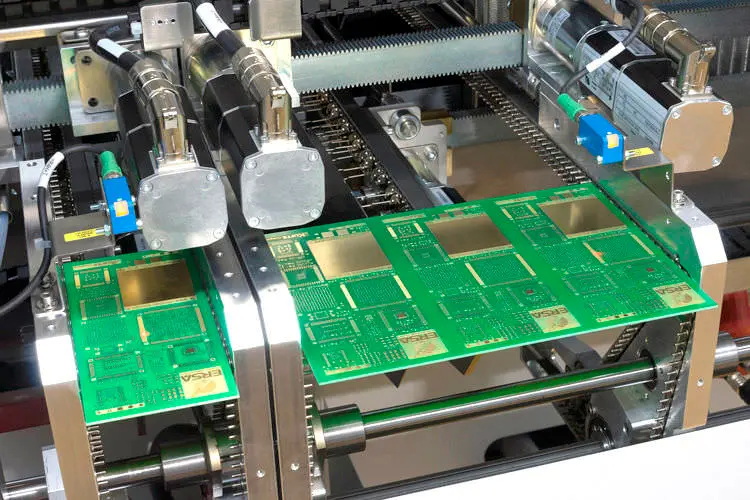

Introduction to Automatic SMD LED Placement Machines

Automatic SMD LED placement machines are sophisticated devices used in the Surface Mount Technology (SMT) process. They are designed to accurately place Surface Mount Devices (SMDs), including LEDs, onto printed circuit boards (PCBs). The precision and speed of these machines make them indispensable in modern electronics manufacturing.

Key Components of Automatic SMD LED Placement Machines

1. Placement Head: This is the core component responsible for picking and placing SMDs onto the PCB. It includes nozzles that handle the components.

2. Feeders: These supply the SMDs to the placement head. Proper feeder maintenance is essential to prevent component misfeeds.

3. Vision System: This system ensures accurate placement by identifying and aligning components with their designated positions on the PCB.

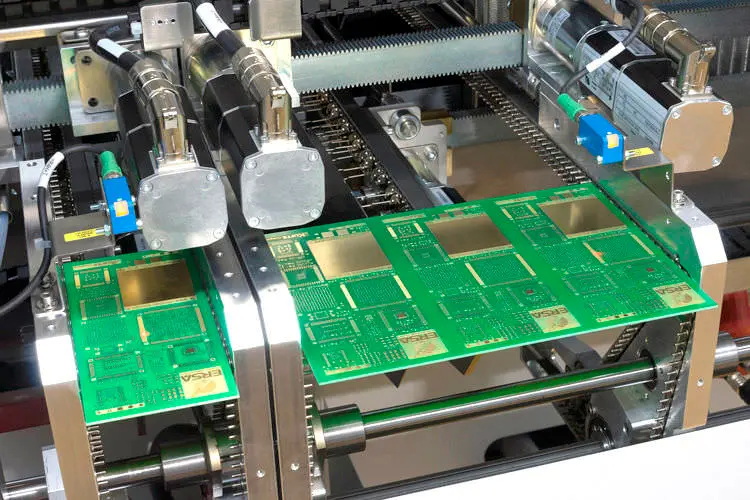

4. Conveyor Belts: These transport the PCBs through the machine during the placement process.

Maintenance Strategies for Optimal Performance

Daily Maintenance

Daily maintenance is crucial for preventing issues that could lead to downtime or reduced performance. Key tasks include:

- Cleaning Feeders and Nozzles: Use a soft brush or compressed air to remove dust and debris. This prevents misfeeds and ensures smooth component pickup.

- Inspecting Conveyor Belts: Check for wear or misalignment. Properly aligned belts ensure PCBs move smoothly through the machine.

- Verifying Vision System Operation: Ensure the vision system is calibrated and functioning correctly to maintain accurate component placement.

Weekly Maintenance

- Lubrication of Moving Parts: Apply machine-specific lubricants to moving parts like linear guides and bearings. This reduces friction and prevents premature wear.

- Thorough Inspection: Check all components for signs of damage or deterioration.

Monthly Maintenance

- In-Depth Cleaning: Perform more thorough cleaning of feeders, nozzles, and vision systems.

- Performance Tests: Evaluate machine accuracy and identify potential issues.

- Review Maintenance Logs: Adjust maintenance schedules based on observed trends.

Calibration and Adjustment

Regular calibration is vital for maintaining the accuracy of your automatic SMD LED placement machine. This involves adjusting parameters such as nozzle heights and component pickup settings. Calibration should be performed in a controlled environment with consistent lighting conditions to ensure reliable results.

Software Updates

Keeping the machine's software up to date is essential for optimizing performance. Updates can improve efficiency, add new features, and fix bugs. Regularly check for updates and follow the manufacturer's instructions for installation.

Training and Operator Knowledge

Operators should be well-trained in the operation, maintenance, and troubleshooting of the machine. Continuous training ensures that operators can handle the machine correctly, reducing the risk of misuse and extending its lifespan.

Storage and Environmental Conditions

When not in use, store the machine in a clean, dry environment. Cover it with a dust cover to prevent dust accumulation. Maintain optimal temperature and humidity levels to prevent component degradation.

Common Issues and Troubleshooting

Component Placement Errors

- Causes: Incorrect component calibration, damaged feeders, inadequate maintenance.

- Solutions: Ensure proper calibration, replace damaged feeders, and perform regular maintenance.

Component Damage

- Causes: Malfunction or incorrect operation of the machine, overworked machine, poor-quality components.

- Solutions: Proper operation, regular maintenance, use of high-quality components.

Inaccurate Fiducial Recognition

- Causes: Damaged or dirty camera lens, inaccurate calibration, software malfunctions.

- Solutions: Clean the camera lens regularly, perform calibration checks, and service the machine as needed.

Component Pick-up and Release Issues

- Causes: Inadequate vacuum or nozzle pressure, worn-out nozzles, ineffective vibration.

- Solutions: Adjust vacuum and nozzle pressures, replace worn nozzles, verify vibration process.

Advanced Maintenance Techniques

Predictive Maintenance

Implementing predictive maintenance involves using data analytics and sensors to predict when maintenance is required. This proactive approach can significantly reduce downtime by identifying potential issues before they occur.

Use of Quality Components

Using high-quality components is crucial for maintaining machine performance. Poor-quality components can lead to increased maintenance needs and reduced machine lifespan.

Environmental Considerations

Maintaining a clean and controlled environment is essential for the longevity of your automatic SMD LED placement machine. Dust, moisture, and static electricity can all impact machine performance and component quality.

Future Trends in SMD LED Placement Machines

As technology advances, automatic SMD LED placement machines are expected to incorporate more advanced automation features, such as artificial intelligence (AI), to enhance efficiency and adaptability. These advancements will enable machines to better handle diverse PCB types and assembly conditions, further improving production efficiency.

Conclusion

Maintaining an automatic SMD LED placement machine requires a comprehensive approach that includes daily, weekly, and monthly maintenance tasks. By implementing these strategies, you can ensure optimal performance, reduce downtime, and improve production efficiency. Regular calibration, software updates, and proper storage are also crucial for extending the machine's lifespan and maintaining its accuracy.

FAQ

1. What are the key components of an automatic SMD LED placement machine?

- The key components include the placement head, feeders, vision system, and conveyor belts. Each plays a crucial role in the accurate placement of SMDs onto PCBs.

2. Why is regular lubrication important for the machine?

- Regular lubrication reduces friction and prevents premature wear of moving parts, ensuring smooth operation and extending the machine's lifespan.

3. How often should the vision system be calibrated?

- The vision system should be calibrated regularly, ideally after any software updates or when changes in lighting conditions occur. This ensures accurate component placement.

4. What are the benefits of keeping the machine's software up to date?

- Keeping the software up to date improves performance, adds new features, and fixes bugs, ensuring the machine operates efficiently and effectively.

5. Why is operator training important for machine maintenance?

- Operator training is crucial as it ensures that the machine is used correctly, reducing the risk of misuse and extending its lifespan. Trained operators can also perform routine maintenance and troubleshooting.

Citations:

[1] https://www.seamarkzm.com/maintaining-and-calibrating-an-smd-reel-counter.html

[2] https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

[3] https://www.hct-smt.com/blog/the-ultimate-guide-to-led-smd-pcb-loaders--everything-you-need-to-know

[4] https://de.hct-smt.com/blog/how-to-masterfully-operate-fully-automatic-led-smt-machines

[5] https://www.circuitinsight.com/pdf/led_pick_place_challenge_ipc.pdf

[6] https://www.zjyingxing.com/info/what-are-smt-related-tips-93976082.html

[7] https://www.zjyingxing.com/info/what-are-the-cleaning-and-maintenance-methods-82799641.html

[8] https://www.anzer-usa.com/resources/smd-led-pcb-assembly/

[9] https://www.hct-smt.com/blog/keep-your-machines-running-smoothly--expert-tips-for-automatic-smt-mounter-pick-and-place-machine-maintenance

[10] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[11] https://www.hobbytalk.com/threads/working-with-smd-leds-tips-and-tricks.475058/

[12] https://www.seamarkzm.com/maintenance-and-calibration-of-smt-inspection-machines.html

[13] https://www.vse.com/blog/2022/03/15/8-common-smt-placement-issues-and-solutions/

[14] https://www.kingbrightusa.com/ApplicationNotes/ApplicationNotesFor_SMD_LEDs.pdf

[15] https://www.neodensmt.com/news/pick-and-place-machine-for-led-32593939.html

[16] https://www.tronstol.com/how-to-solve-the-problems-of-abnormalities-in-the-led-placement-machine-pickup.html

[17] https://www.pcbjhy.com/blog/led-pcb-design-guide/

[18] https://www.zjyingxing.com/info/what-are-the-smt-machine-technical-instruction-83598159.html

[19] https://www.gmleds.com/info/7-common-problems-and-solutions-of-smd-led-chi-63204474.html

[20] https://jhdpcb.com/blog/efficient-smt-assembly/