Content Menu

● Understanding SMT Line Components

● Importance of Regular Maintenance

>> Daily Maintenance Tasks

>> Weekly Maintenance Tasks

>> Monthly Maintenance Tasks

● Implementing Predictive Maintenance

● Optimization Techniques for SMT Lines

>> 1. Line Layout Optimization

>> 2. Automation Integration

>> 3. Staff Training

>> 4. Data Analysis and Control

● Continuous Improvement Practices

● Quality Control Measures

● Environmental Considerations

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are common challenges in optimizing SMT lines?

>> 2. How can automation improve SMT line efficiency?

>> 3. Why is staff training important in SMT production?

>> 4. What role does maintenance play in SMT line optimization?

>> 5. How can lean manufacturing principles benefit an SMT line?

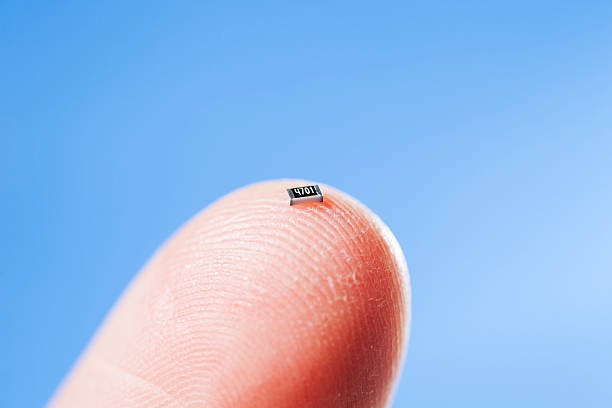

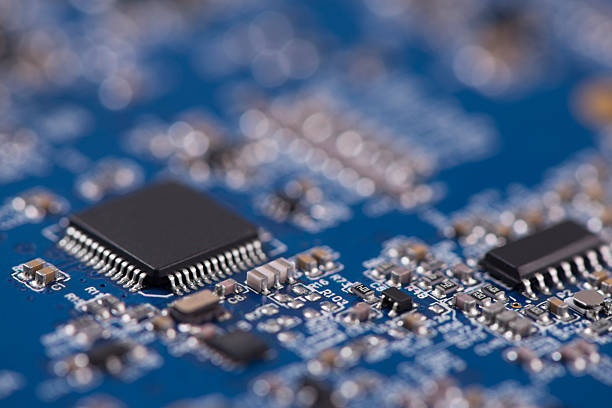

Surface Mount Technology (SMT) has become a cornerstone of modern electronics manufacturing, allowing for the efficient assembly of printed circuit boards (PCBs). However, maintaining and optimizing an SMT line is crucial to ensure high productivity, reduce downtime, and enhance product quality. This article delves into the best practices for maintaining and optimizing your wholesale automatic SMT line, covering everything from equipment maintenance to process optimization.

Understanding SMT Line Components

Before diving into maintenance and optimization strategies, it is essential to understand the key components of an SMT line:

- Solder Paste Printer: Applies solder paste to the PCB.

- Pick-and-Place Machine: Places components onto the PCB with precision.

- Reflow Oven: Melts solder paste to create electrical connections.

- Inspection Systems: Ensure quality by detecting defects.

Each component plays a critical role in the overall efficiency of the SMT line. Understanding how each part functions allows for better maintenance and optimization strategies.

Importance of Regular Maintenance

Regular maintenance of SMT equipment is vital to prevent unexpected downtimes and ensure consistent production quality. Here are some essential maintenance tasks:

Daily Maintenance Tasks

- Cleaning: Dust and debris can accumulate on machinery, leading to component misalignment and defects. Daily cleaning of surfaces, nozzles, and sensors is necessary.

- Lubrication: Ensure that moving parts are adequately lubricated to minimize wear and tear.

- Visual Inspections: Check for signs of wear on critical components such as nozzles and feeders.

Weekly Maintenance Tasks

- Detailed Cleaning: Perform more thorough cleaning of internal components, including filters and sensors.

- Calibration Checks: Regularly calibrate machines according to manufacturer specifications to maintain accuracy.

Monthly Maintenance Tasks

- Replace Worn Parts: Inspect and replace any worn-out parts such as belts, nozzles, and filters.

- System Updates: Ensure that all software controlling the SMT line is up-to-date to avoid operational issues.

Implementing Predictive Maintenance

Predictive maintenance uses data analytics to predict equipment failures before they happen. By integrating sensors into your SMT line, you can monitor key parameters such as temperature and vibration. This data allows for timely interventions that can prevent costly downtimes.

Predictive maintenance not only reduces unplanned downtime but also extends the life of your equipment. By analyzing historical data, manufacturers can identify patterns that signal potential failures. This proactive approach leads to more efficient operations and can significantly reduce maintenance costs over time.

Optimization Techniques for SMT Lines

Optimizing your SMT line involves several strategies aimed at improving efficiency and throughput. Here are some key techniques:

1. Line Layout Optimization

A well-designed layout minimizes material handling and reduces cycle times. Consider these layout strategies:

- Linear Flow Arrangement: Arrange machines in a linear sequence to facilitate smooth movement of PCBs through the production process.

- Minimized Distance Between Machines: Reducing the distance between machines decreases transport time and potential errors.

An optimized layout not only enhances efficiency but also improves safety by reducing clutter and potential hazards on the shop floor.

2. Automation Integration

Automation plays a crucial role in enhancing efficiency. Consider integrating automated systems such as:

- Automated Material Handling: Use conveyors and robotic arms to reduce manual handling and improve speed.

- Real-Time Monitoring Systems: Employ IoT-enabled sensors to monitor machine performance continuously.

Automation can also enhance flexibility in production runs, allowing manufacturers to switch between different products with minimal downtime.

3. Staff Training

A skilled workforce is essential for optimizing your SMT line. Regular training sessions should focus on:

- Proper machine operation

- Preventive maintenance practices

- Troubleshooting techniques

Well-trained personnel can identify potential issues early, handle machinery correctly, and contribute significantly to overall productivity. Investing in staff training not only improves operational efficiency but also boosts employee morale by empowering them with skills that enhance their job performance.

4. Data Analysis and Control

Modern SMT lines feature sophisticated software that collects, analyzes, and applies production data effectively. Key capabilities include:

- Traceability: Barcodes track boards through each process step.

- Data Mining: Statistical tools find trends in production data.

- Closed-Loop Control: Measurements are fed back into the system to adjust parameters automatically for improved performance.

Using data analytics allows manufacturers to make informed decisions based on real-time information rather than relying solely on intuition or past experiences. This data-driven approach can lead to substantial improvements in yield rates and reductions in defects.

Continuous Improvement Practices

Optimization is not a one-time task but an ongoing process. Implementing continuous improvement practices such as Kaizen events can help tap into worker insights for enhancing processes. Regularly assess your SMT line's performance using metrics like throughput, defect rates, and cycle times.

Incorporating feedback loops where employees can suggest improvements fosters a culture of continuous improvement. By regularly reviewing processes and outcomes, manufacturers can adapt quickly to changing market demands or technological advancements.

Quality Control Measures

Quality control is paramount in SMT manufacturing due to the intricate nature of electronic components. Implementing rigorous quality control measures ensures that defects are caught early in the process:

- In-Line Inspection Systems: Utilize automated optical inspection (AOI) systems at various stages of production to detect defects before they escalate downstream.

- Functional Testing: Conduct functional tests post-reflow to ensure that assembled boards meet specifications before they leave the facility.

By integrating quality control throughout the manufacturing process rather than at the end, manufacturers can significantly reduce rework costs and improve customer satisfaction through higher-quality products.

Environmental Considerations

As manufacturers strive for optimization, it is essential not to overlook environmental sustainability. Implementing eco-friendly practices can enhance brand reputation while also reducing costs associated with waste management:

- Waste Reduction Programs: Develop initiatives aimed at minimizing waste generated during production processes.

- Energy Efficiency Measures: Invest in energy-efficient machinery or retrofitting existing equipment with energy-saving technologies.

By adopting sustainable practices within your SMT operations, you not only contribute positively to environmental conservation but also position your company favorably in an increasingly eco-conscious market landscape.

Conclusion

Maintaining and optimizing your wholesale automatic SMT line requires a multifaceted approach that includes regular maintenance, layout optimization, automation integration, staff training, data analysis, continuous improvement practices, quality control measures, and environmental considerations. By focusing on these areas, manufacturers can achieve significant gains in efficiency, product quality, and overall competitiveness in the electronics market.

Frequently Asked Questions (FAQ)

1. What are common challenges in optimizing SMT lines?

Common challenges include long changeover times between product variants, frequent machine jams or crashes, high rework rates after soldering, difficulty balancing throughput with inventory levels, and lack of standardized procedures.

2. How can automation improve SMT line efficiency?

Automation enhances speed by reducing manual handling processes, minimizes errors through consistent operations, lowers labor costs by streamlining tasks, and increases flexibility within production lines.

3. Why is staff training important in SMT production?

Proper training ensures that staff can set up machines correctly, identify potential issues early on, perform preventive maintenance effectively, analyze data for continuous improvement, and ultimately contribute to higher productivity levels.

4. What role does maintenance play in SMT line optimization?

Regular maintenance prevents unexpected breakdowns that can lead to costly downtimes while ensuring that all equipment operates at peak performance levels. It also extends the lifespan of machinery.

5. How can lean manufacturing principles benefit an SMT line?

Lean manufacturing principles help identify wasteful practices within the production process. By minimizing waste through streamlined workflows and continuous improvement initiatives, manufacturers can reduce costs while enhancing overall efficiency.