Content Menu

● Introduction

● Understanding SMT Line Test Equipment

● Steps to Integrate SMT Line Test Equipment

● Best Practices for Seamless Integration

● Importance of Testing in SMT Production Lines

● Common Challenges in Integrating SMT Line Test Equipment

● Enhancing Workflow Efficiency Through Automation

● The Role of Data Analytics in Quality Control

● Conclusion

● FAQ

>> 1. What is SMT line test equipment?

>> 2. Why is integration important?

>> 3. How do I choose the right equipment?

>> 4. What are common challenges in integration?

>> 5. How can I maintain SMT test equipment?

● Citations:

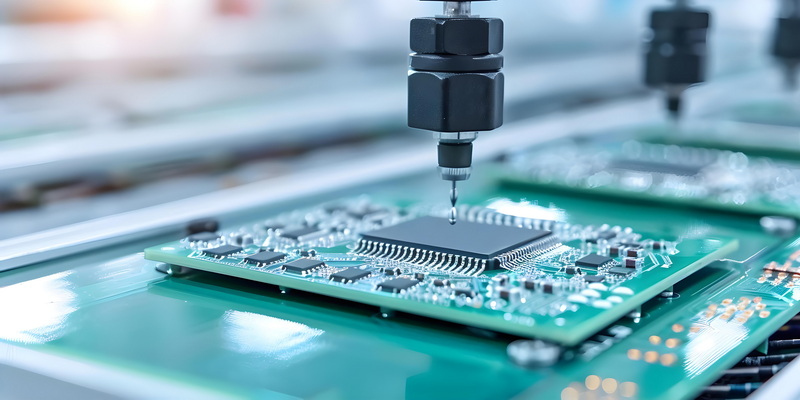

Introduction

Surface Mount Technology (SMT) line test equipment is essential in modern electronics manufacturing, ensuring the quality and reliability of printed circuit boards (PCBs). As electronic devices become increasingly complex, integrating effective testing equipment into manufacturing workflows is critical for maintaining high standards of production efficiency and product quality. This article will explore how to seamlessly integrate SMT line test equipment into your workflow, enhancing both operational effectiveness and product integrity.

Understanding SMT Line Test Equipment

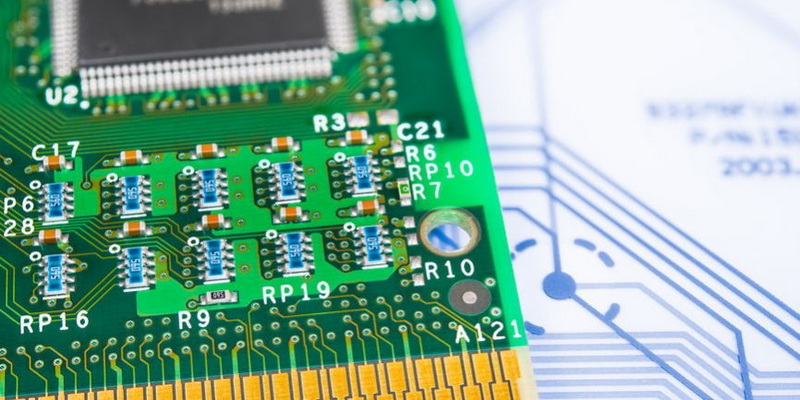

SMT line test equipment includes various tools designed for quality control and inspection throughout the PCB assembly process. Key examples of this equipment are:

- Automated Optical Inspection (AOI): This system utilizes high-resolution cameras and sophisticated software algorithms to detect defects in solder paste application, component placement, and solder joints. AOI is crucial for identifying issues early in the production process, thereby reducing the likelihood of defective products reaching the market.

- X-ray Inspection Systems: These systems are particularly valuable for detecting hidden defects within solder joints, especially in complex assemblies like Ball Grid Arrays (BGAs). X-ray inspection allows manufacturers to ensure that all components are properly soldered, even when they are not visible.

- Functional Test Machines: These machines validate the operational performance of assembled PCBs under real-world conditions. They simulate actual usage scenarios to confirm that all components function as intended before products are shipped to customers.

Integrating these systems into your workflow can significantly enhance quality control measures and streamline production processes.

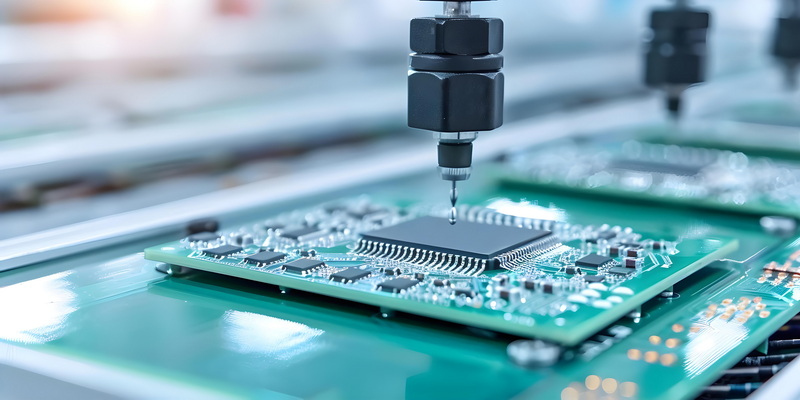

Steps to Integrate SMT Line Test Equipment

Integrating SMT line test equipment requires a structured approach. Here are the key steps to ensure a successful integration:

1. Equipment Selection: Choose testing equipment that aligns with your specific production needs. Consider factors such as compatibility with existing systems, the types of components being assembled, and the expected production volume.

2. Installation: Follow manufacturer guidelines for installing the selected equipment. Proper installation is crucial for ensuring that all systems work together efficiently. Pay special attention to alignment and connections between machines.

3. Debugging and Calibration: After installation, conduct thorough debugging and calibration of each piece of equipment. This step ensures that all machines operate within specified parameters and can accurately detect defects.

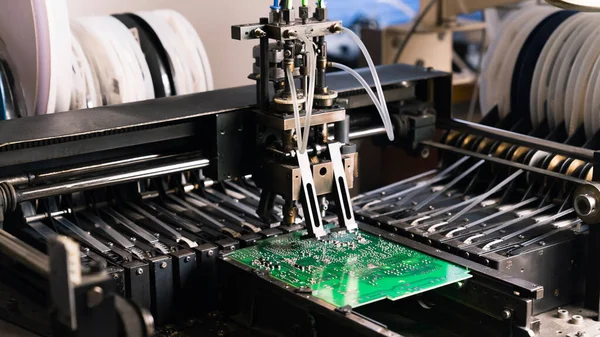

4. Integration: Establish communication protocols between different systems on the SMT line, such as pick-and-place machines, reflow ovens, and inspection systems. This may involve configuring network connections and data exchange protocols to facilitate seamless operation.

5. Training Staff: Ensure that all personnel involved in operating and maintaining the equipment receive adequate training. Well-trained staff can effectively troubleshoot issues and optimize machine performance.

Best Practices for Seamless Integration

To maximize the effectiveness of your SMT line test equipment integration, consider implementing these best practices:

- Workflow Optimization: Arrange equipment in a logical sequence to minimize bottlenecks in production. This arrangement helps maintain a smooth flow of materials through the SMT line.

- Regular Maintenance: Schedule routine maintenance checks to prevent unexpected downtime. Regularly calibrating machines also helps maintain accuracy and reliability over time.

- Data Monitoring: Utilize real-time monitoring systems to track performance metrics across the SMT line. Analyzing this data can help identify trends, potential issues, and areas for improvement.

Importance of Testing in SMT Production Lines

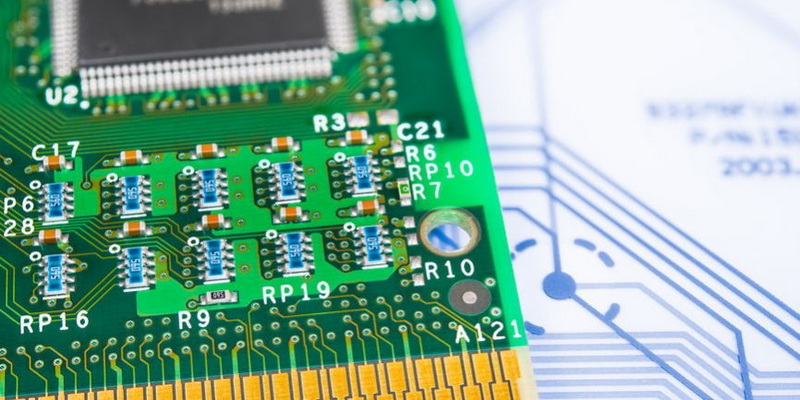

Quality control is paramount in Surface Mount Technology (SMT) production lines, especially concerning PCB assembly and testing processes. Understanding the critical role of testing and quality assurance measures is key to ensuring the reliability and performance of electronic devices manufactured through SMT processes.

Efficient SMT production lines incorporate comprehensive testing protocols at various stages of the assembly process. This includes functional testing, electrical testing, and quality inspections to verify component integrity, circuit connectivity, and overall functionality. By implementing rigorous testing protocols, manufacturers can identify and rectify potential defects early in the production cycle, minimizing rework and enhancing product reliability.

Advanced SMT production lines leverage automated testing systems integrated into full-auto SMT lines. These systems utilize sophisticated testing algorithms and equipment to conduct thorough evaluations of PCBs, ensuring adherence to specifications and industry standards. Automated testing systems not only improve testing accuracy but also accelerate the testing process, enabling faster throughput rates and reduced time-to-market for electronic products.

Effective quality control in SMT production lines involves proactive defect detection and continuous quality assurance measures. Utilizing advanced inspection technologies such as AOI (Automated Optical Inspection) and X-ray inspection enables manufacturers to identify defects such as soldering issues, component misalignment, and PCB layout errors early in the production process.

Common Challenges in Integrating SMT Line Test Equipment

While integrating SMT line test equipment can lead to significant improvements in production efficiency, several challenges may arise:

- Compatibility Issues: Ensure that all selected equipment supports standard communication protocols to avoid integration problems. Choosing compatible systems from reputable manufacturers can mitigate these risks.

- Calibration Errors: Regular calibration is essential for maintaining accurate measurements and performance standards. Implement a schedule for routine checks to ensure all machines remain calibrated according to manufacturer specifications.

- Staff Resistance to Change: Some employees may be resistant to adopting new technologies or processes. To address this, provide comprehensive training and emphasize the benefits of integration on overall productivity and product quality.

By proactively addressing these challenges, manufacturers can facilitate a smoother integration process.

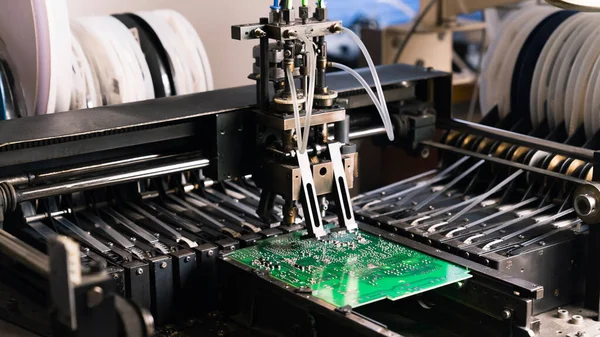

Enhancing Workflow Efficiency Through Automation

Automation plays a pivotal role in optimizing workflow efficiency within an SMT line. The use of automated pick-and-place machines significantly reduces manual labor while increasing precision during component placement on PCBs. These machines are equipped with vision systems that ensure components are placed accurately according to design specifications.

Additionally, reflow ovens automate the soldering process by controlling temperature profiles during soldering cycles, which enhances solder joint quality while reducing human error associated with manual soldering processes.

Implementing automated inspection systems further streamlines workflows by quickly identifying defects without slowing down production rates. For instance:

- Automated Optical Inspection (AOI): This technology inspects every PCB after assembly for defects like misaligned components or insufficient solder joints before they proceed further down the production line.

- X-ray Inspection Systems: These allow for non-destructive evaluation of hidden solder joints on BGA packages or other densely populated areas on PCBs where visual inspection isn't feasible.

By integrating automation at various stages of production—from assembly through inspection—manufacturers can achieve higher throughput rates while maintaining stringent quality control measures.

The Role of Data Analytics in Quality Control

Incorporating data analytics into your SMT workflow can significantly enhance your ability to monitor processes effectively. By collecting data from various stages—such as component placement accuracy or defect rates—manufacturers can analyze trends over time using statistical methods or machine learning algorithms.

This analysis enables companies not only to identify recurring issues but also to predict potential failures before they occur based on historical data patterns. For example:

- If certain components consistently show high defect rates when placed by specific machines or operators, targeted training or machine recalibration can be implemented promptly.

- Real-time dashboards displaying key performance indicators (KPIs) allow managers to make informed decisions quickly regarding resource allocation or process adjustments needed during production runs.

By leveraging data analytics tools integrated with existing SMT line test equipment, manufacturers can ensure continuous improvement across their operations while enhancing overall product quality.

Conclusion

Integrating SMT line test equipment into your workflow is not only a strategic move but also a necessary step toward enhancing production efficiency and product quality in electronics manufacturing. By carefully selecting appropriate testing equipment, following structured integration steps, implementing best practices, addressing potential challenges proactively, automating processes where possible, and utilizing data analytics effectively; manufacturers can significantly improve their operational capabilities.

The successful integration of SMT line test equipment leads to better quality control, reduced defect rates, and ultimately higher customer satisfaction—key factors in today's competitive electronics market. As technology continues evolving within this sector; staying ahead through proactive strategies will be vital for long-term success.

FAQ

1. What is SMT line test equipment?

SMT line test equipment includes tools like AOI and X-ray systems used for quality control in PCB assembly.

2. Why is integration important?

Integration ensures seamless operation across different systems within the SMT line, leading to high-quality production outcomes.

3. How do I choose the right equipment?

Consider your specific production needs, compatibility with existing machinery, budget constraints, and future scalability requirements when selecting testing equipment.

4. What are common challenges in integration?

Common challenges include compatibility issues between different machines and calibration errors which can affect overall production quality.

5. How can I maintain SMT test equipment?

Regular maintenance schedules should include calibration checks, software updates, and routine inspections to ensure optimal performance over time.

Citations:

[1] https://www.smtfactory.com/Maximizing-Quality-Control-Importance-of-Testing-in-SMT-Production-Lines-id40973586.html

[2] https://www.viasion.com/blog/smt-assembly-and-its-advantages/

[3] https://www.vse.com/blog/2022/03/15/8-common-smt-placement-issues-and-solutions/

[4] https://www.electronicspecifier.com/news/surface-mount-technology-best-practice-guide

[5] https://vectorbluehub.com/smt-assembly

[6] https://www.criticalmanufacturing.com/blog/material-optimization-in-the-smt-and-electronics-assembly-industries/

[7] https://www.smithsinterconnect.com/smiths-interconnect-blog/best-practices-in-installation-and-testing-of-board-level-passive-components-for-applications-at-fre/

[8] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[9] https://blog.intraratio.com/revolutionizing-smt-manufacturing-amidst-economic-challenges

[10] https://www.seamarkzm.com/function-and-components-of-smt-inspection-machines.html

[11] https://www.hct-smt.com/blog/the-ultimate-guide-to-universal-smt-equipment

[12] https://quality-line.com/smt-quality/

[13] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

[14] https://blog.intraratio.com/traceability-for-surface-mount-technology-process

[15] https://blog.intraratio.com/machine-integration-for-automated-traceability-and-process-control

[16] https://www.swfuliusmt.com/2024/07/12/understanding-smt-lines-the-backbone-of-modern-electronics-manufacturing/

[17] https://www.linkedin.com/pulse/advantages-smt-manufacturing-practical-cost-effective-nyn3c

[18] https://www.linkedin.com/pulse/inspections-tests-applied-smt-assembly-process-tina-raypcb-jidpf

[19] https://hilelectronic.com/smt-assembly/

[20] https://iconnect007.com/article/98769/addressing-new-testing-inspection-challenges/98772/smt