Content Menu

● Introduction to SMD Counter Machines

>> Key Features of SMD Counter Machines

● Benefits of Using an SMD Counter Machine

>> Reduced Labor Costs

>> Improved Accuracy

>> Enhanced Efficiency

>> Cost Savings

>> Quality Improvement

● How SMD Counter Machines Optimize SMT Assembly

>> Precision in Component Counting

>> Real-Time Inventory Management

>> Enhanced Production Flow

● Integrating SMD Counter Machines into Production Lines

>> Collaboration with Other Automated Systems

>> Streamlining Production Processes

● Maintenance and Calibration of SMD Counter Machines

>> Best Practices for Maintenance

● Role of SMD Counter Machines in Quality Control

>> Improved Accuracy and Error Prevention

>> Time Efficiency

>> Integration with AI and Emerging Technologies

● Emerging Trends in SMD Counter Technology

>> Integration of AI and Machine Learning

>> Adoption of 3D X-ray Counters

>> Focus on Automation and Integration

>> Sustainability and Environmental Responsibility

● Case Studies: Implementing SMD Counter Machines

>> Benefits Observed

● Conclusion

● FAQs

>> 1. What is an SMD Counter Machine?

>> 2. How Does an SMD Counter Machine Improve Efficiency?

>> 3. What Features Should I Look for in an SMD Counter Machine?

>> 4. How Often Should I Calibrate My SMD Counter Machine?

>> 5. Can SMD Counter Machines Be Integrated with Other Automated Systems?

● Citations:

In the modern electronics manufacturing industry, efficiency and precision are paramount. One of the key tools that have revolutionized the production process is the SMD counter machine. This device is designed to accurately count Surface Mount Device (SMD) components, which are crucial in Surface Mount Technology (SMT) assembly. By automating the counting process, manufacturers can significantly enhance production efficiency, reduce costs, and improve product quality. In this article, we will explore how an SMD counter machine can improve efficiency in electronics manufacturing.

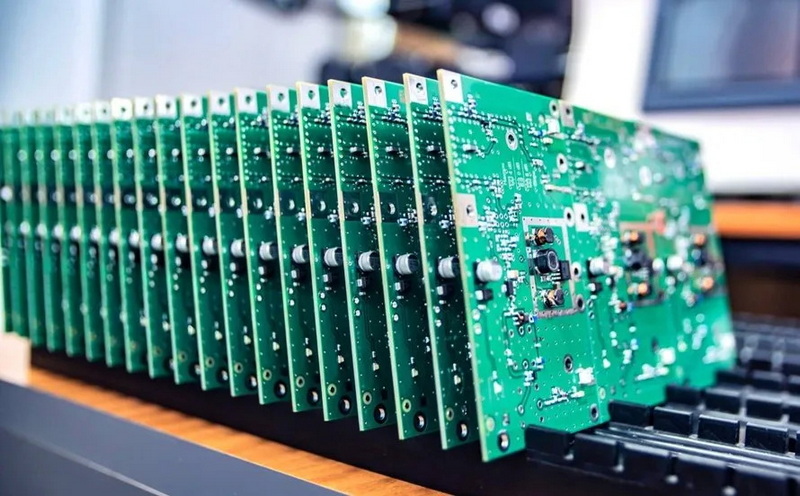

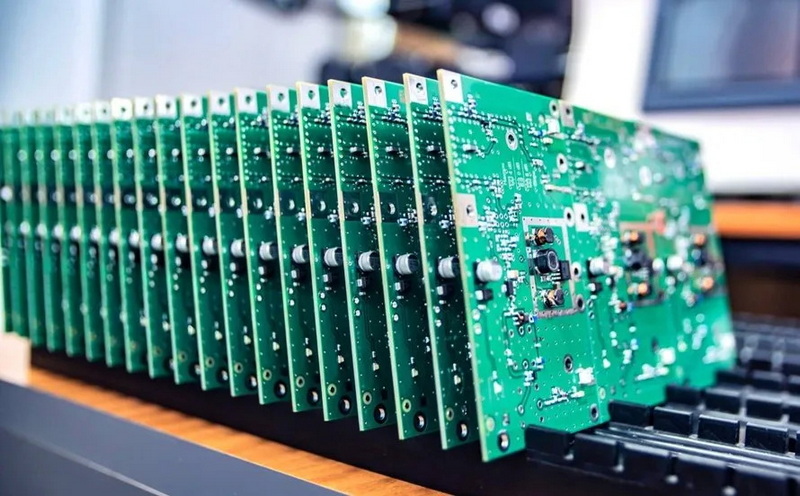

Introduction to SMD Counter Machines

An SMD counter machine is a specialized device used in electronic manufacturing to count small components like capacitors, resistors, and ICs. These machines are equipped with advanced sensors and optical recognition systems that enable precise counting, eliminating the need for manual intervention. By automating the counting process, manufacturers can reduce labor costs, minimize errors, and enhance overall production efficiency.

Key Features of SMD Counter Machines

1. High Accuracy: SMD counter machines use optical sensors to accurately count components, ensuring that the count is precise and reliable.

2. Automation: These machines automate the counting process, significantly reducing manual labor and the potential for human error.

3. Real-Time Data: They provide real-time updates on component quantities, helping manufacturers manage inventory more effectively.

4. Fault Detection: Many models include fault detection capabilities, identifying issues such as missing or duplicate components, which helps in maintaining quality standards.

Benefits of Using an SMD Counter Machine

Reduced Labor Costs

Traditional manual counting methods are time-consuming and labor-intensive. By automating this process with an SMD counter machine, manufacturers can allocate resources more efficiently, reducing labor costs and enhancing productivity.

Improved Accuracy

Manual counting is prone to errors, which can lead to inventory discrepancies and production delays. An SMD counter machine ensures accurate counts, reducing the risk of errors and improving the reliability of the production process.

Enhanced Efficiency

With precise component counts, manufacturers can optimize material usage, avoid shortages or excesses, and streamline the production line. This leads to increased efficiency and reduced downtime.

Cost Savings

By minimizing waste and ensuring accurate material allocation, SMD counter machines help reduce inventory costs and prevent unnecessary purchases.

Quality Improvement

The ability to detect faults and errors in real-time allows for early intervention, reducing the likelihood of defective products and subsequent rework costs.

How SMD Counter Machines Optimize SMT Assembly

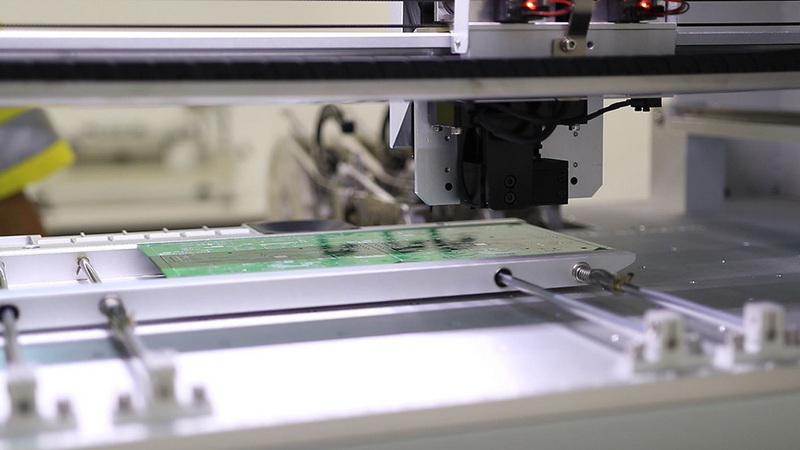

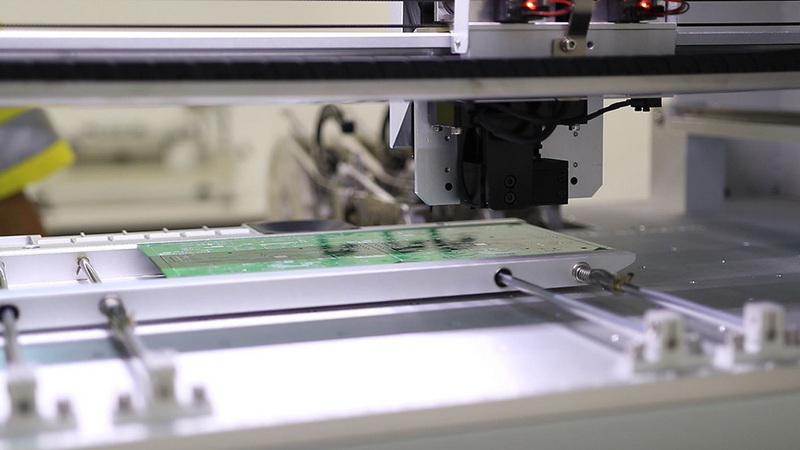

In SMT assembly, precision is critical. Every component must be accurately placed on the circuit board to ensure optimal functionality and reliability. An SMD counter machine plays a crucial role in this process by providing accurate counts of components, which helps in maintaining the precision required for successful assembly.

Precision in Component Counting

By accurately counting components, manufacturers can ensure that the right quantity of parts is available for assembly, reducing the risk of shortages or excesses that could disrupt production.

Real-Time Inventory Management

Real-time data from SMD counter machines helps in managing inventory levels effectively, ensuring that components are available when needed and reducing the likelihood of stockouts.

Enhanced Production Flow

With accurate component counts, the pick-and-place process becomes more efficient, allowing for smoother production flows and increased productivity.

Integrating SMD Counter Machines into Production Lines

To maximize efficiency, SMD counter machines should be integrated with other automated equipment in the production line. This integration ensures seamless data exchange, allowing for real-time inventory updates and optimized material allocation.

Collaboration with Other Automated Systems

By integrating with other machines, SMD counter machines can enhance overall production efficiency. They provide critical data that helps in allocating resources effectively, reducing downtime, and improving production quality.

Streamlining Production Processes

Automated counting and inventory management enable manufacturers to streamline their production processes, focusing on high-value tasks rather than manual counting and inventory tracking.

Maintenance and Calibration of SMD Counter Machines

To ensure optimal performance, regular maintenance and calibration of SMD counter machines are essential. This includes cleaning the machine regularly, inspecting for wear and tear, and calibrating the counting mechanism to maintain accuracy.

Best Practices for Maintenance

1. Regular Cleaning: Use a soft cloth and mild cleaning solution to remove dust and debris.

2. Inspection: Regularly inspect the machine for signs of wear or damage.

3. Calibration: Follow the manufacturer's guidelines for calibration to ensure accurate counts.

4. Storage: Store the machine in a clean, dry environment when not in use.

Role of SMD Counter Machines in Quality Control

SMD counter machines contribute significantly to quality control by ensuring accurate component counts and detecting faults early. This reduces the risk of defective products and enhances the overall reliability of the manufacturing process.

Improved Accuracy and Error Prevention

By automating the counting process, these machines minimize the risk of human errors, ensuring that each batch contains the correct number of components. This accuracy is crucial for maintaining high-quality standards in the final product.

Time Efficiency

SMD counter machines expedite the manufacturing cycle by providing swift component counting, which leads to shorter lead times and improved productivity. This efficiency is particularly beneficial in industries where timely delivery is critical, such as medical device manufacturing.

Integration with AI and Emerging Technologies

The integration of artificial intelligence (AI) and machine learning algorithms in SMD counter machines is a promising trend. AI can enhance defect detection, predict errors, and optimize production processes, further improving efficiency and quality.

Emerging Trends in SMD Counter Technology

Integration of AI and Machine Learning

The use of AI in SMD manufacturing is becoming increasingly prevalent. AI-powered systems can analyze vast amounts of data from various production stages, identifying patterns and predicting potential issues before they occur. This proactive approach enhances quality control and reduces downtime.

Adoption of 3D X-ray Counters

Traditional 2D X-ray counters have limitations in accurately counting components with complex geometries. The adoption of 3D X-ray counters provides a more comprehensive view, allowing for precise counting and inspection of stacked components.

Focus on Automation and Integration

Manufacturers are focusing on integrating SMD counter machines with other automated equipment to create fully automated production lines. This integration reduces manual intervention, enhances efficiency, and improves overall production quality.

Sustainability and Environmental Responsibility

There is a growing emphasis on developing energy-efficient and environmentally friendly SMD counter machines. This trend aligns with the industry's commitment to sustainable manufacturing practices, reducing the carbon footprint of SMD manufacturing processes.

Case Studies: Implementing SMD Counter Machines

Several companies have successfully integrated SMD counter machines into their production lines, achieving significant improvements in efficiency and quality. For instance, Seamark's SMD reel counter machine has been instrumental in optimizing SMT assembly by providing precise component counts and enhancing production flow.

Benefits Observed

- Reduced Labor Costs: By automating the counting process, companies have seen a substantial reduction in labor costs.

- Improved Accuracy: The use of advanced sensors has minimized errors, ensuring accurate component counts.

- Enhanced Efficiency: Real-time inventory management and fault detection have streamlined production processes, reducing downtime.

Conclusion

In conclusion, SMD counter machines are indispensable tools for enhancing efficiency in electronics manufacturing. By automating the counting process, these machines reduce labor costs, improve accuracy, and optimize production flows. Their integration into SMT assembly processes ensures precision and reliability, making them a critical component of modern manufacturing lines.

FAQs

1. What is an SMD Counter Machine?

An SMD counter machine is a device used in electronics manufacturing to accurately count small components like capacitors and resistors. It automates the counting process, reducing manual labor and errors.

2. How Does an SMD Counter Machine Improve Efficiency?

An SMD counter machine improves efficiency by automating the counting process, reducing labor costs, and minimizing errors. It also provides real-time inventory data, helping manufacturers optimize material usage and streamline production.

3. What Features Should I Look for in an SMD Counter Machine?

When selecting an SMD counter machine, look for features like high accuracy, automation, real-time data updates, and fault detection capabilities. Additionally, consider models with user-friendly interfaces and optional features like barcode scanning.

4. How Often Should I Calibrate My SMD Counter Machine?

Calibration of an SMD counter machine should be performed regularly, following the manufacturer's guidelines. This ensures that the machine maintains its accuracy over time.

5. Can SMD Counter Machines Be Integrated with Other Automated Systems?

Yes, SMD counter machines can be integrated with other automated systems in the production line. This integration enhances overall efficiency by providing real-time data for inventory management and material allocation.

Citations:

[1] https://www.seamarkzm.com/reduce-production-costs-with-an-smd-reel-counter-machine.html

[2] https://www.seamarkzm.com/how-smd-reel-counter-machines-optimize-smt-assembly.html

[3] https://www.seamarkzm.com/the-contribution-of-smd-reel-counter-machines-to-quality-control.html

[4] https://pmarketresearch.com/auto/x-ray-smd-counter-market/

[5] https://www.linkedin.com/pulse/revolutionizing-electronics-manufacturing-ai-ramesh-gaha-bh6me

[6] https://www.seamarkzm.com/the-role-of-smd-reel-counter-machines-in-pcb-manufacturing.html

[7] https://www.escatec.com/blog/does-ai-boost-efficiency-in-surface-mount-device-production

[8] https://cnsmtline.com/products/smd-counter-machine/

[9] https://www.manncorp.com/products/smd-counter-with-pocket-check-2000pc

[10] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[11] https://www.seamarkzm.com/application-of-xray-smd-component-counter-in-smt-production.html

[12] https://legacy.crownpolymers.com/new-automatic-smd-parts-counter-components-counting-machine-smt-point-machine-X11SUFdBG1VBWEJY

[13] https://smtnet.com/products/index.cfm?fuseaction=browse_products&cat_id=23

[14] https://www.seamarkzm.com/future-trends-and-innovations-in-pcb-inspection-equipment.html

[15] https://www.asus.com/networking-iot-servers/aiot-industrial-solutions/intelligent-integrated-solutions/aidis-100qc/

[16] https://www.youtube.com/watch?v=iQCXgDnVV-o

[17] https://www.seamarkzm.com/products/x-ray-smd-reel-counter/

[18] https://www.nordson.com/en/products/test-and-inspection-products/cc-assure

[19] https://www.linkedin.com/pulse/north-america-smd-component-counter-market-size-applicationcontact-bdloe/

[20] https://www.seamarkzm.com/smd-components-counting.html