Content Menu

● Introduction

● Key Strategies for Improving Efficiency

>> Machine Calibration and Maintenance

>> Process Optimization

>> Automation and Inline Inspection

>> Training and Education

>> Design for Manufacturability (DFM)

>> Scrap Factor Management

● Advanced Techniques and Tools

>> Lean Production and Continuous Improvement

>> Supplier and Material Management

>> Use of Advanced Design Software

>> Advanced PCB Assembly Techniques

>> Automation of Soldering Processes

● Best Practices in PCB Design

>> Effective Component Placement

>> Minimizing Trace Lengths

>> Thermal Management Considerations

>> Utilizing High-Density Interconnects (HDIs)

● The Role of Data Analytics

● Conclusion

● FAQ

>> 1. What is the role of machine calibration in SMT efficiency?

>> 2. How does automation improve the SMT process?

>> 3. What are the benefits of inline inspection systems?

>> 4. Why is operator training important?

>> 5. How does DFM contribute to efficiency?

● Citations:

Introduction

Efficiency in the PCB SMT (Surface Mount Technology) process is critical for manufacturers aiming to stay competitive in the fast-paced electronics industry. By optimizing various aspects of the SMT process, companies can reduce costs, improve product quality, and enhance production speed. This article explores key strategies and advanced techniques to improve efficiency in the PCB SMT process.

Key Strategies for Improving Efficiency

Machine Calibration and Maintenance

Regular calibration and preventive maintenance of SMT machines are essential to ensure they operate at peak efficiency. Properly calibrated machines reduce errors, minimize downtime, and extend the lifespan of equipment. Scheduled maintenance checks can help identify potential issues before they escalate, ensuring that machines run smoothly throughout production.

Process Optimization

Optimizing the SMT process involves fine-tuning machine setups, placement parameters, and production sequences. Grouping similar components, using common feeders, and reducing tooling changes can significantly enhance efficiency. For instance, by organizing components based on their type or size, operators can streamline the setup process and minimize time spent on adjustments.

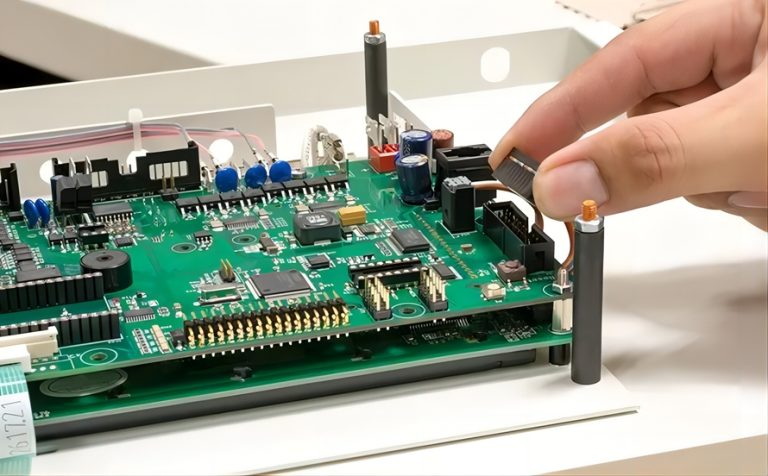

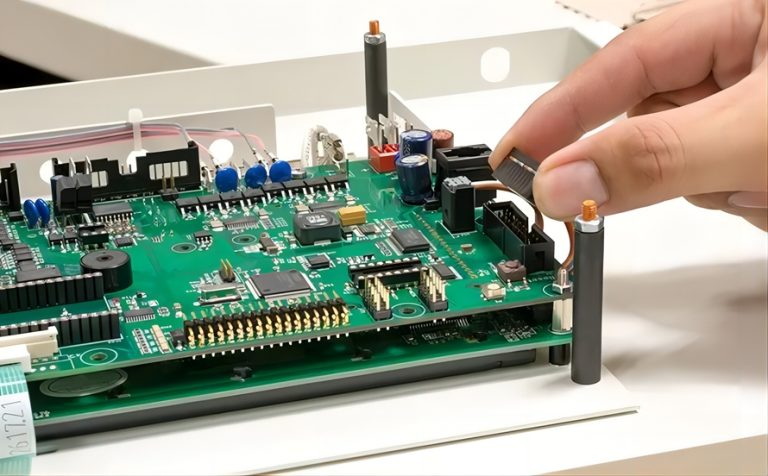

Automation and Inline Inspection

Automation plays a pivotal role in improving efficiency. Automated material handling and inline inspection systems reduce manual intervention, enhance quality control, and minimize rework. Automated Optical Inspection (AOI) systems can quickly detect defects such as misaligned components or insufficient solder paste application, allowing for immediate corrections without halting production.

Training and Education

Well-trained operators are crucial for efficient SMT processes. Comprehensive training programs enable operators to optimize machine settings, troubleshoot issues, and perform minor repairs, reducing downtime and improving productivity. Continuous education on new technologies and processes ensures that staff remains competent in handling advanced machinery.

Design for Manufacturability (DFM)

DFM practices help identify and mitigate potential production challenges during the design phase. Incorporating fiducial marks, aligning components, and using appropriate tooling strips are some ways to ensure a smooth SMT process. By considering manufacturability early in the design stage, companies can avoid costly modifications later on.

Scrap Factor Management

Managing scrap factors is key to optimizing efficiency in PCB assembly. By minimizing scrap through effective design practices and quality control measures, manufacturers can significantly reduce costs while enhancing sustainability. This involves regular analysis of scrap rates to identify areas for improvement[1].

Advanced Techniques and Tools

Lean Production and Continuous Improvement

Implementing lean production techniques and Kaizen methods helps minimize waste and optimize workflows. Continuous improvement fosters innovation and enhances overall efficiency by encouraging teams to regularly assess processes and identify areas for enhancement.

Supplier and Material Management

Reliable supply chains and efficient material handling are vital for uninterrupted production. Building strong supplier relationships ensures timely delivery of high-quality materials. Implementing automated material management systems can also streamline inventory control and reduce lead times.

Use of Advanced Design Software

Advanced design software enables engineers to optimize PCB layouts, prevent errors, and streamline the manufacturing process. Tools like Cadence Allegro and Xpedition Enterprise offer features for design automation that enhance productivity by reducing manual input errors.

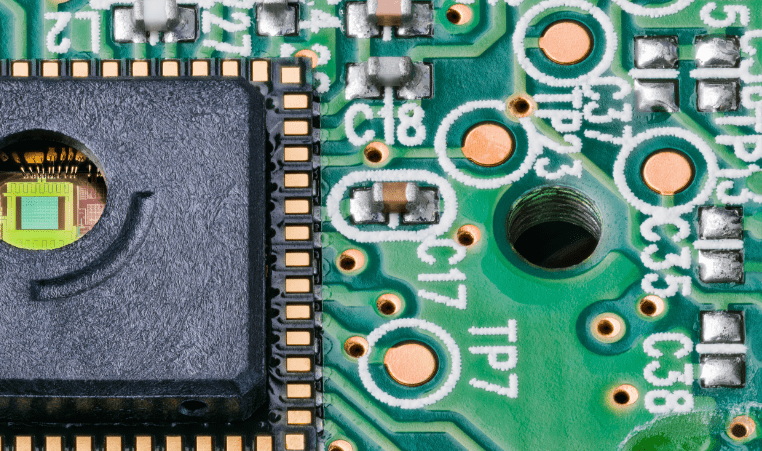

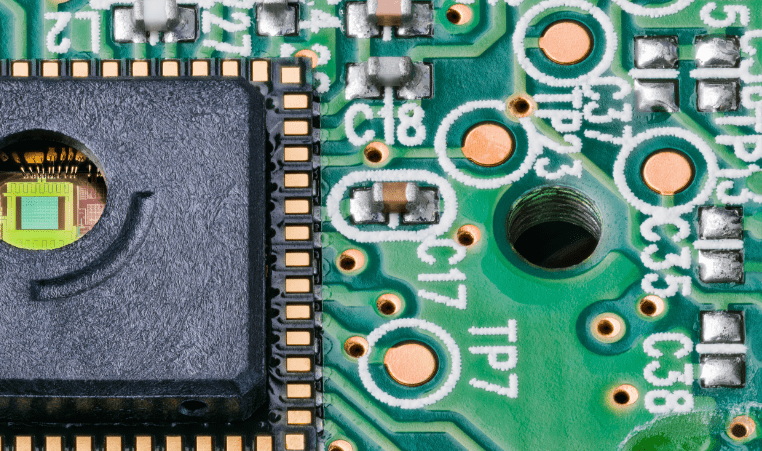

Advanced PCB Assembly Techniques

Incorporating advanced assembly techniques such as microvias technology allows for the creation of complex multilayer circuits with exceptional routing density. Fine-pitch component placement requires high-precision equipment but significantly enhances efficiency by maximizing space utilization[3]. Controlled impedance routing is essential for high-speed circuits to maintain signal integrity while minimizing electromagnetic interference (EMI).

Automation of Soldering Processes

Robotic soldering ensures uniform application of solder to each joint, maintaining consistent quality across all assemblies. This eliminates variability associated with manual soldering processes[4]. Additionally, automated dispensing systems ensure precise application of adhesives or coatings necessary for PCB assembly.

Best Practices in PCB Design

Effective Component Placement

Proper component placement is pivotal in designing an efficient PCB layout. Grouping similar components together simplifies the assembly process by minimizing trace lengths while ensuring effective power distribution[11]. A consistent orientation also aids automated assembly machines by preventing misalignment during production.

Minimizing Trace Lengths

Minimizing trace lengths is a fundamental principle in PCB layout design that reduces signal delay, controlled impedance issues, and electromagnetic interference (EMI). Shorter traces enhance signal integrity while improving overall circuit performance[14].

Thermal Management Considerations

Thermal management is crucial for ensuring reliability in PCBs. Properly designed thermal reliefs help maintain soldering temperatures during assembly processes like wave soldering[5]. Additionally, separating high-power components across different areas of the board can equalize temperature distribution and prevent hotspots.

Utilizing High-Density Interconnects (HDIs)

HDI designs maximize routing density through techniques such as microvias, blind vias, and buried vias. This allows for more intricate routing without sacrificing board real estate or performance[11]. Collaborating closely with fabricators ensures that these advanced techniques align with manufacturing capabilities.

The Role of Data Analytics

Data analytics plays an increasingly important role in optimizing PCB assembly lines. Historical performance data can reveal inefficiencies such as machine downtimes or supply chain delays that need addressing[18]. Implementing real-time monitoring systems can provide alerts for low stock levels or machine malfunctions before they impact production schedules.

Conclusion

Improving efficiency in the PCB SMT process requires a combination of strategic planning, advanced tools, skilled personnel, and continuous evaluation of processes. By implementing the strategies discussed in this article—ranging from machine maintenance to advanced design techniques—manufacturers can achieve higher productivity levels while ensuring product quality. As technology continues to evolve within the electronics industry, staying abreast of these advancements will be crucial for maintaining competitiveness.

FAQ

1. What is the role of machine calibration in SMT efficiency?

Regular calibration ensures machines operate at peak efficiency, reducing errors and downtime.

2. How does automation improve the SMT process?

Automation reduces errors, increases production speed, lowers labor costs, enhancing overall efficiency.

3. What are the benefits of inline inspection systems?

Inline inspection systems enhance quality control by detecting defects early, reducing rework, improving production efficiency.

4. Why is operator training important?

Trained operators can optimize machine settings, troubleshoot issues, perform repairs—minimizing downtime while improving productivity.

5. How does DFM contribute to efficiency?

DFM practices identify potential production challenges during design phases ensuring smoother manufacturing processes.

Citations:

[1] https://riversideintegratedsolutions.com/n/scrap-factor/

[2] https://resources.pcb.cadence.com/blog/2022-pcb-design-for-thermal-performance-solutions-and-best-practices

[3] https://www.rigiflex.com/blog/get-to-know-about-the-advanced-pcb-assembly-techniques-for-complex-circuits/

[4] https://profabelectronics.com/posts/how-automated-pcb-assembly-improves-efficiency/

[5] https://resources.altium.com/p/pcb-layout-guidelines

[6] https://blog.matric.com/robotics-current-pcb-manufacturing-techniques-the-latest

[7] https://eda.sw.siemens.com/en-US/pcb/engineering-productivity-and-efficiency/

[8] https://blogs.sw.siemens.com/electronic-systems-design/2023/03/03/pcb-best-practices-design-automation/

[9] https://www.zuken.com/us/blog/advances-in-pcb-manufacturing-automation/

[10] https://www.sierraassembly.com/blog/impact-of-advanced-pcb-layering-on-electronics-manufacturing/

[11] https://camptechii.com/pcb-design-for-manufacturing-dfm-best-practices-and-optimization-strategies-for-2024/

[12] https://morepcb.com/pcb-v-scoring/

[13] https://resources.pcb.cadence.com/blog/advanced-pcb-design-techniques-orcad-x-routing-and-placement-cadence

[14] https://www.911eda.com/solutions/top-10-tips-for-efficient-pcb-layout-design/

[15] https://www.sierraassembly.com/blog/what-is-pcb-routing-and-how-it-improves-signal-integrity/

[16] https://www.andwinpcb.com/how-to-improve-the-wiring-efficiency-in-pcb-design/

[17] https://www.mclpcb.com/blog/ipc-standards-for-pcbs/

[18] https://cogiscan.com/data-analytics-pcb-assembly-historical-performance-increase