Content Menu

● Understanding the Importance of PCB Manufacturing Quality

>> The Impact of Quality on PCB Performance

● Key Factors in Identifying a Reliable PCB Manufacturer

>> Certifications and Industry Standards

>> Production Capabilities and Technology

>> Quality Control Processes

>> Experience and Expertise

● The Role of Communication in Ensuring PCB Manufacturing Quality

>> Clear and Consistent Communication

>> Technical Support and Design Assistance

● Quality Assurance Methods in PCB Manufacturing

>> Design Verification

>> Material Selection and Component Sourcing

>> Automated Optical Inspection (AOI)

>> In-Circuit Testing (ICT)

>> X-ray Inspection

>> Environmental and Stress Testing

● The Importance of Continuous Improvement in PCB Manufacturing Quality

● Conclusion

● FAQ

>> 1. What are the most important certifications to look for in a PCB manufacturer?

>> 2. How does automated optical inspection (AOI) contribute to PCB manufacturing quality?

>> 3. Why is environmental and stress testing important in PCB manufacturing?

>> 4. What role does communication play in ensuring PCB manufacturing quality?

>> 5. How does continuous improvement contribute to PCB manufacturing quality?

● Citations:

In today's rapidly evolving electronics industry, printed circuit boards (PCBs) play a crucial role in the functionality and reliability of electronic devices. As such, identifying a reliable PCB manufacturer that prioritizes quality assurance is paramount for businesses seeking to produce high-quality electronic products. This comprehensive guide will explore the key factors to consider when selecting a PCB manufacturer and the importance of quality assurance in PCB manufacturing.

Understanding the Importance of PCB Manufacturing Quality

Before delving into the process of identifying a reliable PCB manufacturer, it's essential to understand why PCB manufacturing quality is so critical. High-quality PCBs are the foundation of reliable electronic devices, ensuring optimal performance and longevity. Poor-quality PCBs can lead to device failures, increased maintenance costs, and damage to a company's reputation.

The Impact of Quality on PCB Performance

PCB manufacturing quality directly affects the performance of the final product. A well-manufactured PCB will have:

- Consistent electrical properties

- Proper component placement and soldering

- Accurate trace widths and spacing

- Reliable connections and vias

These factors contribute to the overall functionality and reliability of the electronic device, making PCB manufacturing quality a top priority for manufacturers and OEMs alike.

Key Factors in Identifying a Reliable PCB Manufacturer

When searching for a reliable PCB manufacturer, several crucial factors should be considered to ensure you partner with a company that prioritizes PCB manufacturing quality.

Certifications and Industry Standards

One of the primary indicators of a reliable PCB manufacturer is their adherence to industry standards and certifications. Look for manufacturers that hold certifications such as:

- ISO 9001:2015 for quality management systems

- IPC-A-600 for PCB acceptability

- IPC-A-610 for electronic assemblies

- ISO 13485:2016 for medical device quality management systems[4]

These certifications demonstrate a manufacturer's commitment to PCB manufacturing quality and their ability to meet stringent industry standards.

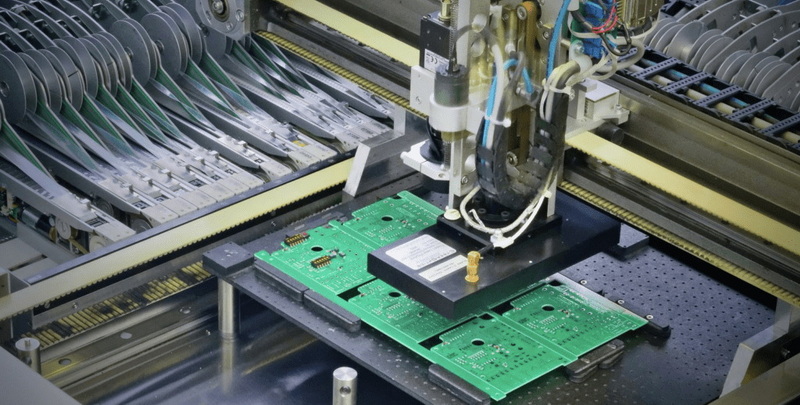

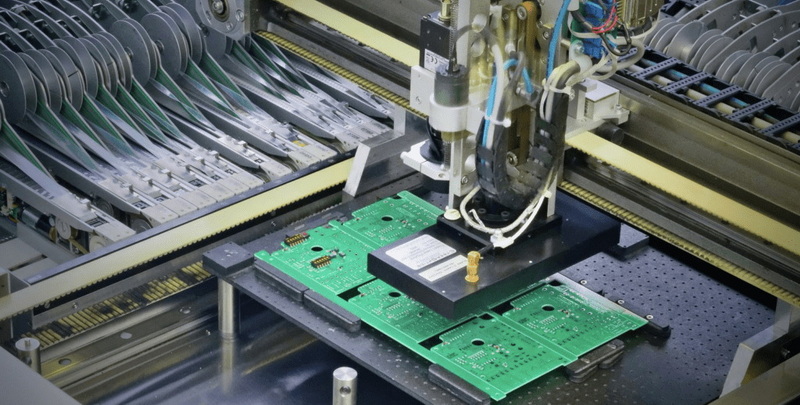

Production Capabilities and Technology

A reliable PCB manufacturer should possess advanced production capabilities and utilize cutting-edge technology to ensure PCB manufacturing quality. Consider the following aspects:

- State-of-the-art equipment for PCB fabrication and assembly

- Automated optical inspection (AOI) systems

- X-ray inspection capabilities

- In-circuit testing (ICT) facilities

- Environmental and stress testing capabilities[2][5]

Advanced production capabilities enable manufacturers to produce high-quality PCBs consistently and efficiently.

Quality Control Processes

A robust quality control process is essential for maintaining PCB manufacturing quality. Look for manufacturers that implement comprehensive quality assurance measures, including:

1. Design verification: Thorough review of design files, schematics, and layouts[2]

2. Material selection and component sourcing: Use of high-quality materials and reliable components[2]

3. Automated optical inspection (AOI): High-resolution camera inspection for defects[2]

4. In-circuit testing (ICT): Verification of individual component integrity and connections[2]

5. X-ray inspection: Detection of hidden defects and soldering issues[2]

6. Environmental and stress testing: Subjecting PCBs to extreme conditions to ensure durability[2]

A manufacturer with a comprehensive quality control process demonstrates their commitment to PCB manufacturing quality and reduces the risk of defects in the final product.

Experience and Expertise

When evaluating PCB manufacturers, consider their experience and expertise in the industry. Look for manufacturers with:

- A proven track record of producing high-quality PCBs

- Experience in your specific industry or application

- Technical expertise in PCB design and manufacturing

- A team of skilled engineers and technicians[6]

Experienced manufacturers are more likely to understand the nuances of PCB manufacturing quality and can provide valuable insights and solutions to potential challenges.

The Role of Communication in Ensuring PCB Manufacturing Quality

Effective communication between the customer and the PCB manufacturer is crucial for achieving optimal PCB manufacturing quality. Consider the following aspects when evaluating a manufacturer's communication capabilities:

Clear and Consistent Communication

Look for manufacturers that prioritize clear and consistent communication throughout the production process. This includes:

- Prompt responses to inquiries and concerns

- Regular updates on project status

- Transparent discussions about potential issues or challenges

- Willingness to collaborate on design improvements[6]

Effective communication ensures that both parties are aligned on quality expectations and can address any issues promptly.

Technical Support and Design Assistance

A reliable PCB manufacturer should offer technical support and design assistance to help optimize PCB manufacturing quality. This may include:

- Design for manufacturability (DFM) reviews

- Suggestions for component placement and routing

- Advice on material selection and stackup design

- Guidance on testing and quality assurance processes[4]

Manufacturers that provide comprehensive technical support demonstrate their commitment to PCB manufacturing quality and can help customers achieve better results.

Quality Assurance Methods in PCB Manufacturing

To ensure consistent PCB manufacturing quality, reliable manufacturers employ a variety of quality assurance methods throughout the production process.

Design Verification

Design verification is a critical step in ensuring PCB manufacturing quality. This process involves:

- Reviewing design files, schematics, and layouts for accuracy

- Checking compliance with industry standards

- Verifying component placement and routing

- Identifying potential manufacturing issues[2]

Thorough design verification helps prevent manufacturing errors and ensures that the final product meets the required specifications.

Material Selection and Component Sourcing

The quality of materials and components used in PCB manufacturing directly impacts the final product's performance and reliability. Reliable manufacturers:

- Source materials and components from reputable suppliers

- Conduct incoming quality control inspections

- Ensure compliance with industry standards and certifications

- Maintain traceability of materials and components[2]

Proper material selection and component sourcing contribute significantly to overall PCB manufacturing quality.

Automated Optical Inspection (AOI)

AOI systems play a crucial role in PCB manufacturing quality control. These systems use high-resolution cameras to inspect PCBs for defects such as:

- Missing components

- Component misalignments

- Solder bridges

- Trace defects

AOI systems enhance reliability and reduce human error in the inspection process, contributing to improved PCB manufacturing quality[2][5].

In-Circuit Testing (ICT)

ICT is an essential quality assurance method that verifies the electrical integrity of PCBs. This process involves:

- Using a bed of nails fixture to contact test points on the PCB

- Powering up the board and measuring electrical properties

- Identifying issues such as short circuits, open circuits, and incorrect component values[5]

ICT ensures that PCBs are free from basic electrical defects before proceeding to more comprehensive testing.

X-ray Inspection

X-ray inspection is particularly valuable for detecting hidden defects in complex PCB assemblies. This method:

- Provides detailed imaging of internal PCB layers

- Detects soldering issues beneath components

- Identifies defects in ball grid array (BGA) packages

- Ensures the integrity of hidden connections[2]

X-ray inspection contributes to PCB manufacturing quality by revealing defects that may not be visible through other inspection methods.

Environmental and Stress Testing

To ensure the long-term reliability of PCBs, manufacturers conduct environmental and stress testing. These tests may include:

- Thermal cycling

- Humidity testing

- Vibration testing

- Accelerated aging tests

Environmental and stress testing help identify potential weaknesses in PCBs and ensure their ability to withstand various operational conditions[2].

The Importance of Continuous Improvement in PCB Manufacturing Quality

Reliable PCB manufacturers understand that maintaining and improving PCB manufacturing quality is an ongoing process. Look for manufacturers that demonstrate a commitment to continuous improvement through:

- Regular staff training and development programs

- Investment in new technologies and equipment

- Participation in industry conferences and workshops

- Collaboration with customers to implement feedback and suggestions

A focus on continuous improvement ensures that the manufacturer stays up-to-date with the latest advancements in PCB manufacturing quality and can adapt to changing industry requirements.

Conclusion

Identifying a reliable PCB manufacturer for quality assurance is crucial for businesses seeking to produce high-quality electronic products. By considering factors such as certifications, production capabilities, quality control processes, and communication, companies can select a manufacturer that prioritizes PCB manufacturing quality.

Remember that PCB manufacturing quality is not just about the final product but also about the entire production process. A reliable manufacturer will demonstrate a commitment to quality at every stage, from design verification to final testing and inspection.

By partnering with a reputable PCB manufacturer that emphasizes quality assurance, businesses can ensure the reliability and performance of their electronic devices, ultimately leading to increased customer satisfaction and success in the competitive electronics market.

FAQ

1. What are the most important certifications to look for in a PCB manufacturer?

The most important certifications to look for in a PCB manufacturer include ISO 9001:2015 for quality management systems, IPC-A-600 for PCB acceptability, IPC-A-610 for electronic assemblies, and ISO 13485:2016 for medical device quality management systems. These certifications demonstrate a manufacturer's commitment to PCB manufacturing quality and adherence to industry standards[4].

2. How does automated optical inspection (AOI) contribute to PCB manufacturing quality?

Automated optical inspection (AOI) contributes to PCB manufacturing quality by using high-resolution cameras to inspect PCBs for defects such as missing components, misalignments, solder bridges, and trace defects. AOI systems enhance reliability and reduce human error in the inspection process, leading to improved overall PCB manufacturing quality[2][5].

3. Why is environmental and stress testing important in PCB manufacturing?

Environmental and stress testing is important in PCB manufacturing because it helps ensure the long-term reliability of PCBs. These tests subject PCBs to extreme conditions such as thermal cycling, humidity, vibration, and accelerated aging. By conducting these tests, manufacturers can identify potential weaknesses in PCBs and ensure their ability to withstand various operational conditions, ultimately contributing to improved PCB manufacturing quality[2].

4. What role does communication play in ensuring PCB manufacturing quality?

Communication plays a crucial role in ensuring PCB manufacturing quality by facilitating clear and consistent information exchange between the customer and the manufacturer. Effective communication ensures that both parties are aligned on quality expectations, enables prompt addressing of issues, and allows for collaboration on design improvements. Good communication also includes technical support and design assistance, which can help optimize PCB manufacturing quality[6].

5. How does continuous improvement contribute to PCB manufacturing quality?

Continuous improvement contributes to PCB manufacturing quality by ensuring that manufacturers stay up-to-date with the latest advancements in technology and industry best practices. This includes regular staff training, investment in new equipment, participation in industry events, and implementing customer feedback. By focusing on continuous improvement, manufacturers can adapt to changing industry requirements and consistently enhance their PCB manufacturing quality over time.

Citations:

[1] https://www.candorind.com/our-company/quality-assurance/

[2] https://en.intretech.com/news/quality-assurance-in-pcb-manufacturing-best-practices-and-cutting-edge-techniques/

[3] https://www.pcbelec.com/finding-the-right-china-pcb-manufacturers.html

[4] https://www.elepcb.com/pcb-quality-control/

[5] https://www.pcbnet.com/blog/6-most-common-pcb-quality-assurance-tests/

[6] https://www.viasion.com/blog/choosing-a-reliable-pcb-supplier-in-china/

[7] https://www.vse.com/blog/2020/05/21/the-top-six-pcb-quality-control-methods-of-the-best-cms/

[8] https://www.protoexpress.com/kb/pcb-quality/

[9] https://www.ablcircuits.co.uk/blog/importance-quality-assurance-oem-pcb-production/

[10] https://jlcpcb.com/blog/pcb-basics-5-pcb-testing-and-quality-assurance