Content Menu

● Understanding ODM PCB Assembly

>> The Importance of Quality Control in ODM PCB Assembly

● Key Steps in ODM PCB Assembly Quality Control

>> 1. Design for Manufacturing (DFM) Check

>> 2. Component Procurement and Verification

>> 3. Solder Paste Application and Inspection

>> 4. Component Placement

>> 5. Reflow Soldering

>> 6. Automated Optical Inspection (AOI)

>> 7. X-ray Inspection

>> 8. Functional Testing

>> 9. Environmental Stress Testing

● Advanced Quality Control Techniques in ODM PCB Assembly

>> Implementing Statistical Process Control (SPC)

>> Utilizing Machine Learning and AI

>> Implementing Traceability Systems

● Best Practices for Quality Control in ODM PCB Assembly

● Challenges in ODM PCB Assembly Quality Control

● The Future of Quality Control in ODM PCB Assembly

● Conclusion

● FAQ

>> 1. What is the difference between ODM and OEM in PCB assembly?

>> 2. How does SMT improve the quality of PCB assemblies?

>> 3. What are the most common defects in ODM PCB assembly?

>> 4. How often should quality control checks be performed during the ODM PCB assembly process?

>> 5. What certifications are important for ODM PCB assembly manufacturers?

● Citations:

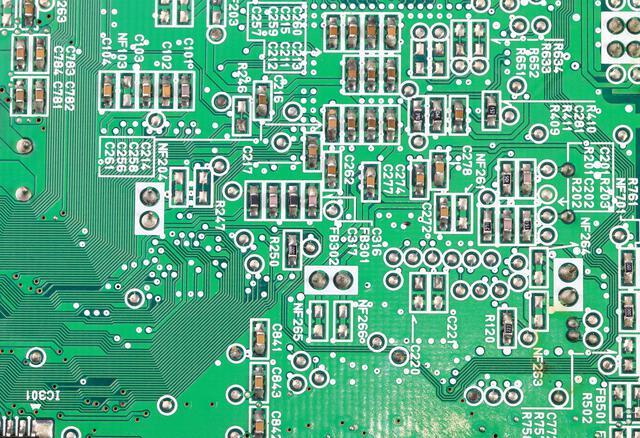

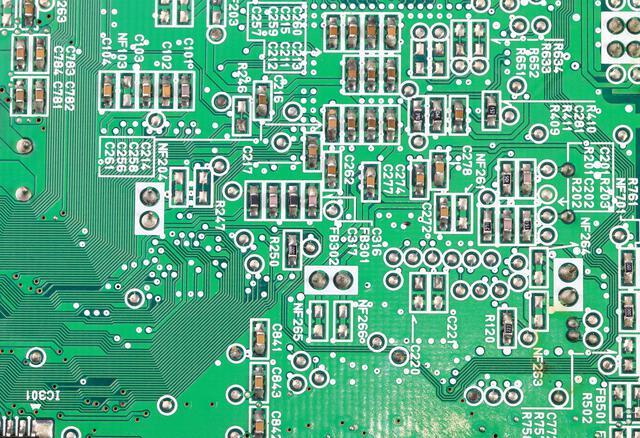

In the world of electronics manufacturing, Original Design Manufacturer (ODM) PCB assembly plays a crucial role in producing high-quality electronic devices. Ensuring quality control throughout the ODM PCB assembly process is essential for delivering reliable and functional products to end-users. This article will explore the various aspects of quality control in ODM PCB assembly processes, focusing on Surface Mount Technology (SMT) and other critical steps involved in creating top-notch printed circuit boards.

Understanding ODM PCB Assembly

ODM PCB assembly refers to the process where a manufacturer designs and produces printed circuit boards based on a client's specifications. This approach allows companies to leverage the expertise of specialized manufacturers while maintaining control over their product designs. The ODM model often incorporates advanced technologies like SMT to create efficient and compact electronic devices.

The Importance of Quality Control in ODM PCB Assembly

Quality control is paramount in ODM PCB assembly processes for several reasons:

1. Ensuring product reliability

2. Reducing manufacturing costs

3. Maintaining brand reputation

4. Meeting industry standards and regulations

5. Improving overall product performance

By implementing robust quality control measures, ODM manufacturers can deliver PCBs that meet or exceed client expectations while minimizing defects and production issues.

Key Steps in ODM PCB Assembly Quality Control

To ensure the highest quality in ODM PCB assembly, manufacturers must implement a comprehensive quality control process that covers every stage of production. Let's explore the critical steps involved in maintaining quality throughout the assembly process.

1. Design for Manufacturing (DFM) Check

The first step in ensuring quality control begins even before the actual assembly process. A thorough Design for Manufacturing (DFM) check is crucial to identify potential issues in the PCB design that could lead to manufacturing problems[8]. This process involves:

- Reviewing component placement and orientation

- Checking minimum component spacing

- Verifying pad sizes and clearances

- Ensuring proper thermal management

By conducting a comprehensive DFM check, manufacturers can prevent costly errors and optimize the design for the SMT assembly process flow[8].

2. Component Procurement and Verification

The quality of components used in ODM PCB assembly directly impacts the final product's performance and reliability. To ensure high-quality components, manufacturers should:

- Validate the Bill of Materials (BOM)

- Verify manufacturer part numbers and reference designators

- Check component manufacturing status

- Ensure MPN-footprint match

- Use trustworthy suppliers to procure genuine components

- Perform visual inspection of components

- Verify solderability and tolerance ranges[9]

3. Solder Paste Application and Inspection

Proper solder paste application is critical for successful SMT assembly. Quality control measures during this stage include:

- Using high-quality solder paste

- Implementing Solder Paste Inspection (SPI) systems

- Verifying solder paste volume and alignment

- Checking for proper stencil design and aperture size[2]

4. Component Placement

Accurate component placement is essential for ensuring proper connections and functionality. Quality control measures during this stage include:

- Implementing Automated Optical Inspection (AOI) systems

- Verifying component polarity and orientation

- Checking for proper component spacing

- Ensuring accurate placement of fine-pitch components[2]

5. Reflow Soldering

The reflow soldering process is critical for creating strong and reliable solder joints. Quality control measures during this stage include:

- Optimizing reflow profile for different component types

- Monitoring temperature and time parameters

- Implementing nitrogen atmosphere for improved solder joint quality

- Performing post-reflow inspection for solder defects[2]

6. Automated Optical Inspection (AOI)

AOI is a crucial step in the quality control process, allowing for rapid and accurate detection of various defects. Key aspects of AOI include:

- Detecting solder joint issues (insufficient solder, excess solder, bridging)

- Identifying component placement errors

- Verifying component polarity and orientation

- Detecting missing or incorrect components[7]

7. X-ray Inspection

X-ray inspection is particularly useful for detecting hidden defects in complex PCB assemblies. This process involves:

- Inspecting Ball Grid Array (BGA) solder joints

- Detecting voids in solder connections

- Identifying internal defects in multi-layer PCBs

- Verifying component placement in densely populated areas

8. Functional Testing

Functional testing ensures that the assembled PCB performs as intended. This stage involves:

- Powering up the PCB and verifying voltage levels

- Testing individual circuit functions

- Simulating real-world operating conditions

- Verifying communication interfaces and protocols

9. Environmental Stress Testing

To ensure the reliability of ODM PCB assemblies in various conditions, manufacturers often perform environmental stress testing, which may include:

- Temperature cycling tests

- Humidity testing

- Vibration and shock testing

- Electromagnetic compatibility (EMC) testing

Advanced Quality Control Techniques in ODM PCB Assembly

To further enhance quality control in ODM PCB assembly processes, manufacturers can implement advanced techniques and technologies.

Implementing Statistical Process Control (SPC)

Statistical Process Control involves using statistical methods to monitor and control the manufacturing process. In ODM PCB assembly, SPC can be applied to:

- Track solder paste volume consistency

- Monitor component placement accuracy

- Analyze reflow profile stability

- Identify trends in defect rates

By implementing SPC, manufacturers can proactively address potential issues before they lead to significant quality problems.

Utilizing Machine Learning and AI

Machine learning and artificial intelligence technologies are increasingly being applied to ODM PCB assembly quality control. These advanced systems can:

- Improve defect detection accuracy in AOI systems

- Optimize reflow profiles based on historical data

- Predict potential failures before they occur

- Enhance overall process efficiency

Implementing Traceability Systems

Traceability is crucial for identifying the root cause of defects and implementing corrective actions. Advanced traceability systems in ODM PCB assembly can:

- Track individual components throughout the assembly process

- Record process parameters for each PCB

- Link assembled PCBs to specific batches of components and materials

- Facilitate rapid recall and corrective action in case of issues

Best Practices for Quality Control in ODM PCB Assembly

To ensure consistent quality in ODM PCB assembly processes, manufacturers should adhere to the following best practices:

1. Establish clear communication channels with clients to understand their requirements and expectations[4].

2. Develop and maintain detailed documentation of assembly processes and quality control procedures.

3. Invest in regular training and skill development for assembly technicians and quality control personnel.

4. Implement a robust supplier evaluation and management system to ensure high-quality components and materials.

5. Regularly calibrate and maintain all assembly and inspection equipment.

6. Conduct periodic audits of the assembly process to identify areas for improvement.

7. Foster a culture of continuous improvement and encourage feedback from all levels of the organization.

Challenges in ODM PCB Assembly Quality Control

While implementing comprehensive quality control measures is essential, ODM PCB assembly manufacturers may face several challenges:

1. Keeping up with rapidly evolving technology and miniaturization trends

2. Balancing quality control requirements with production speed and efficiency

3. Managing the complexity of multi-layer and high-density PCB designs

4. Ensuring consistent quality across different production batches and volumes

5. Addressing the unique quality control requirements of various industries (e.g., automotive, aerospace, medical)

The Future of Quality Control in ODM PCB Assembly

As technology continues to advance, the future of quality control in ODM PCB assembly looks promising. Some emerging trends include:

1. Increased adoption of Industry 4.0 principles and smart manufacturing technologies

2. Greater integration of quality control data across the entire supply chain

3. Development of more sophisticated AI-powered inspection and prediction systems

4. Implementation of augmented reality (AR) for assembly guidance and quality checks

5. Advancements in non-destructive testing methods for complex PCB assemblies

Conclusion

Ensuring quality control in ODM PCB assembly processes is crucial for producing reliable and high-performance electronic devices. By implementing comprehensive quality control measures throughout the assembly process, from design verification to final testing, manufacturers can deliver products that meet or exceed client expectations. Embracing advanced technologies and best practices in quality control will not only improve product quality but also enhance efficiency and competitiveness in the rapidly evolving electronics manufacturing industry.

FAQ

1. What is the difference between ODM and OEM in PCB assembly?

ODM (Original Design Manufacturer) refers to a company that designs and manufactures products based on a client's specifications, while OEM (Original Equipment Manufacturer) typically involves manufacturing products designed by the client. In ODM PCB assembly, the manufacturer has more control over the design process, often leading to more efficient and cost-effective solutions.

2. How does SMT improve the quality of PCB assemblies?

Surface Mount Technology (SMT) improves PCB assembly quality by:

- Allowing for higher component density

- Reducing the size and weight of PCBs

- Improving electrical performance due to shorter connection paths

- Enhancing reliability through more precise component placement

- Facilitating automated assembly processes, reducing human error

3. What are the most common defects in ODM PCB assembly?

Common defects in ODM PCB assembly include:

- Solder bridges (short circuits between adjacent pads)

- Insufficient or excess solder

- Component misalignment or incorrect orientation

- Missing or wrong components

- Cold solder joints

- Voids in solder connections

- PCB warpage or damage

4. How often should quality control checks be performed during the ODM PCB assembly process?

Quality control checks should be performed at multiple stages throughout the ODM PCB assembly process, including:

- After solder paste application (using SPI)

- Following component placement (using AOI)

- Post-reflow soldering (using AOI and X-ray inspection)

- During functional testing

- Before final packaging

Continuous monitoring and in-process checks are also crucial for maintaining consistent quality.

5. What certifications are important for ODM PCB assembly manufacturers?

Important certifications for ODM PCB assembly manufacturers include:

- ISO 9001 (Quality Management System)

- IPC-A-610 (Acceptability of Electronic Assemblies)

- ISO 13485 (for medical device manufacturing)

- AS9100 (for aerospace industry)

- IATF 16949 (for automotive industry)

- UL certification (for safety standards)

These certifications demonstrate a manufacturer's commitment to quality and adherence to industry standards.

Citations:

[1] https://www.7pcb.com/blog/quality-control-measures-in-prototype-assembly

[2] https://www.ednasia.com/top-12-incredible-techniques-to-control-the-quality-of-pcb-smt-assembly/

[3] https://www.pcbway.com/oem/quality-control.html

[4] https://www.electronicdesign.com/markets/automation/article/21176834/technotronix-6-best-practices-for-a-smoother-pcb-assembly-process

[5] https://www.elepcb.com/pcb-quality-control/

[6] https://www.protoexpress.com/kb/pcb-assembly-process-overview/

[7] https://topfastpcba.com/quality-control-in-pcb-manufacturing/

[8] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[9] https://leadsintec.com/how-does-pcb-company-ensure-pcb-quality-control-methods/

[10] https://resources.pcb.cadence.com/blog/2020-how-to-optimize-pcb-design-for-smt-assembly-process-flow