Content Menu

● Introduction

● Understanding SMT Manufacturing

● Key Factors Influencing Quality in SMT Manufacturing

>> Component Quality

>> Solder Paste Quality

>> Machine Calibration and Maintenance

>> Process Control

>> Training and Skill Development

● Best Practices for Ensuring Quality in Wholesale SMT Manufacturing

>> Implementing Quality Management Systems (QMS)

>> Utilizing Advanced Inspection Technologies

>> Conducting Regular Audits and Reviews

>> Engaging in Continuous Improvement Initiatives

>> Collaboration with Suppliers

● Conclusion

● Related Questions

>> 1. What are the common defects in SMT manufacturing?

>> 2. How can I improve solder paste printing quality?

>> 3. What role does training play in SMT manufacturing quality?

>> 4. How often should SMT machines be calibrated?

>> 5. What are the benefits of using automated inspection in SMT manufacturing?

Introduction

In the rapidly evolving electronics industry, wholesale SMT (Surface Mount Technology) manufacturing plays a pivotal role in the production of high-quality electronic components. As the demand for electronic devices continues to rise, ensuring consistent quality in SMT manufacturing becomes increasingly critical. This article explores various strategies and best practices to maintain high standards in wholesale SMT manufacturing, focusing on quality assurance, process optimization, and technological advancements.

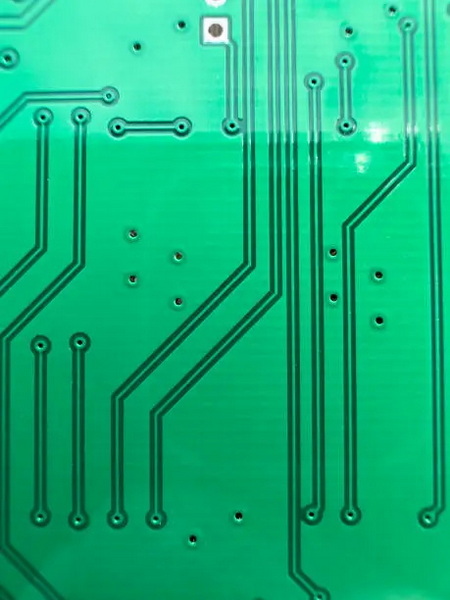

Understanding SMT Manufacturing

SMT manufacturing involves the process of placing electronic components directly onto the surface of printed circuit boards (PCBs). This method has become the standard in the electronics industry due to its efficiency and ability to produce compact and reliable electronic devices. However, the complexity of the process necessitates rigorous quality control measures to ensure that the final products meet the required specifications.

Key Factors Influencing Quality in SMT Manufacturing

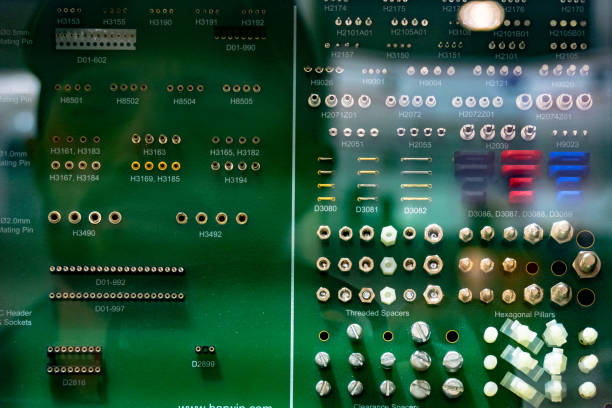

Component Quality

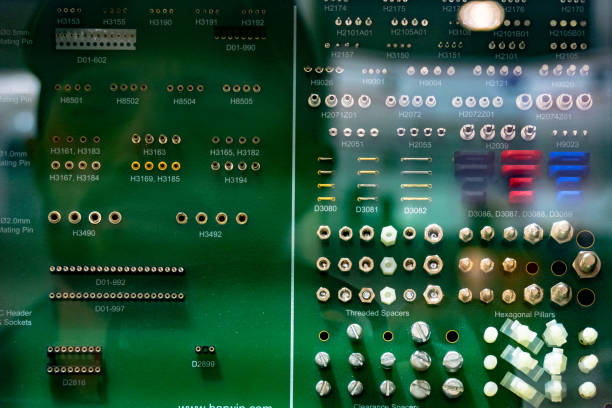

The quality of components used in SMT manufacturing significantly impacts the overall quality of the final product. It is essential to source components from reputable suppliers who adhere to industry standards. Regular audits and inspections of suppliers can help ensure that the components meet the necessary quality criteria.

Solder Paste Quality

Solder paste is a critical element in SMT assembly, as it facilitates the connection between the components and the PCB. The quality of solder paste can affect the reliability of solder joints. Manufacturers should implement strict quality control measures for solder paste, including regular testing for viscosity, particle size, and composition.

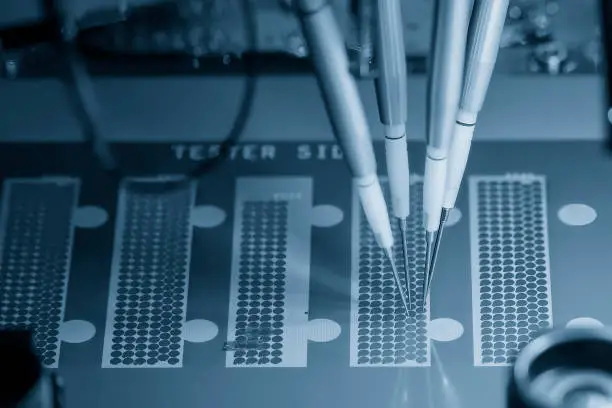

Machine Calibration and Maintenance

Regular calibration and maintenance of SMT machines are vital for ensuring consistent quality. Machines that are not properly calibrated can lead to misalignment and improper placement of components. Establishing a routine maintenance schedule can help prevent machine-related issues and maintain optimal performance.

Process Control

Implementing robust process control measures is essential for maintaining quality in SMT manufacturing. This includes monitoring key parameters such as temperature, humidity, and production speed. Utilizing statistical process control (SPC) techniques can help identify variations in the manufacturing process and enable timely corrective actions.

Training and Skill Development

The skills and knowledge of the workforce play a crucial role in the quality of SMT manufacturing. Continuous training programs should be established to keep employees updated on the latest technologies and best practices. A well-trained workforce is better equipped to identify and address potential quality issues.

Best Practices for Ensuring Quality in Wholesale SMT Manufacturing

Implementing Quality Management Systems (QMS)

A robust Quality Management System (QMS) is essential for ensuring consistent quality in SMT manufacturing. A QMS provides a framework for documenting processes, conducting audits, and implementing corrective actions. It helps organizations maintain compliance with industry standards and continuously improve their manufacturing processes.

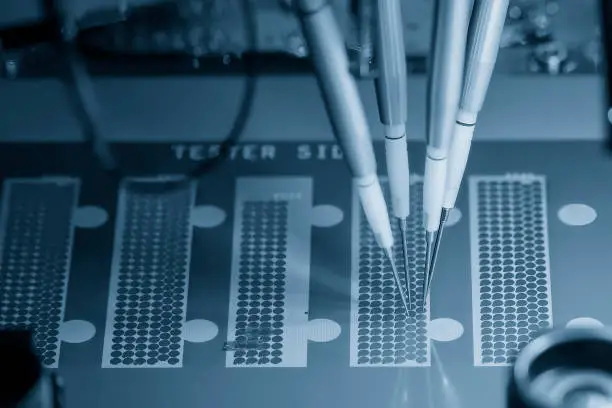

Utilizing Advanced Inspection Technologies

Incorporating advanced inspection technologies, such as Automated Optical Inspection (AOI) and X-ray inspection, can significantly enhance quality control in SMT manufacturing. These technologies allow for real-time monitoring of the assembly process, enabling manufacturers to detect defects early and reduce the risk of faulty products reaching the market.

Conducting Regular Audits and Reviews

Regular audits of the manufacturing process and quality control measures are crucial for identifying areas for improvement. These audits should assess compliance with established standards and identify any deviations from the expected quality levels. Continuous improvement initiatives should be based on the findings of these audits.

Engaging in Continuous Improvement Initiatives

Adopting a culture of continuous improvement is vital for maintaining high-quality standards in SMT manufacturing. Techniques such as Lean Manufacturing and Six Sigma can help identify inefficiencies and reduce waste in the production process. By fostering a culture of innovation and improvement, manufacturers can enhance their overall quality and efficiency.

Collaboration with Suppliers

Building strong relationships with suppliers is essential for ensuring the quality of components used in SMT manufacturing. Manufacturers should engage in regular communication with suppliers to discuss quality expectations and address any issues that may arise. Collaborative efforts can lead to improved quality and reliability of components.

Conclusion

Ensuring consistent quality in wholesale SMT manufacturing is a multifaceted challenge that requires a comprehensive approach. By focusing on key factors such as component quality, solder paste quality, machine maintenance, process control, and workforce training, manufacturers can significantly enhance their quality assurance efforts. Implementing best practices such as Quality Management Systems, advanced inspection technologies, regular audits, continuous improvement initiatives, and supplier collaboration will further strengthen the quality of SMT manufacturing processes. As the electronics industry continues to evolve, maintaining high-quality standards will be crucial for success in the competitive landscape of wholesale SMT manufacturing.

Related Questions

1. What are the common defects in SMT manufacturing?

Common defects in SMT manufacturing include solder bridging, tombstoning, and insufficient solder. These issues can arise from improper solder paste application, incorrect component placement, or inadequate reflow processes.

2. How can I improve solder paste printing quality?

Improving solder paste printing quality can be achieved by optimizing the stencil design, ensuring proper alignment, and maintaining consistent printing speed and pressure. Regular maintenance of printing equipment is also essential.

3. What role does training play in SMT manufacturing quality?

Training plays a crucial role in SMT manufacturing quality by equipping employees with the necessary skills and knowledge to identify and address quality issues. Continuous training helps keep the workforce updated on best practices and technological advancements.

4. How often should SMT machines be calibrated?

SMT machines should be calibrated regularly, typically every few months or after significant maintenance. The frequency may vary based on production volume and the specific requirements of the manufacturing process.

5. What are the benefits of using automated inspection in SMT manufacturing?

Automated inspection, such as AOI and X-ray inspection, provides real-time monitoring of the assembly process, allowing for early detection of defects. This leads to reduced rework, improved product reliability, and enhanced overall quality.