Content Menu

● Inroduction

● Understanding Surface Mount Devices (SMD)

>> Key Types of Surface Mount Components

● Advantages of Using SMD Components

● Disadvantages of Using SMD Components

● Factors to Consider When Choosing SMD Components

>> Application Requirements

>> Component Specifications

>> Availability and Cost

>> Manufacturer Reputation

>> Testing and Validation

● Best Practices for Integrating SMD Components

● Conclusion

● FAQ

>> 1. What are surface mount devices (SMD)?

>> 2. What are the main advantages of using SMT?

>> 3. What challenges do SMDs present in repairability?

>> 4. How do I ensure proper thermal management with SMDs?

>> 5. Why is testing important when using SMDs?

Inroduction

When embarking on an electronics project, one of the most critical decisions you'll face is selecting the right surface mount device (SMD) components. This choice can significantly impact your project's performance, size, and cost. In this article, we will explore the various factors to consider when choosing SMD components, the advantages and disadvantages of surface mount technology (SMT), and tips for ensuring successful integration into your designs.

Understanding Surface Mount Devices (SMD)

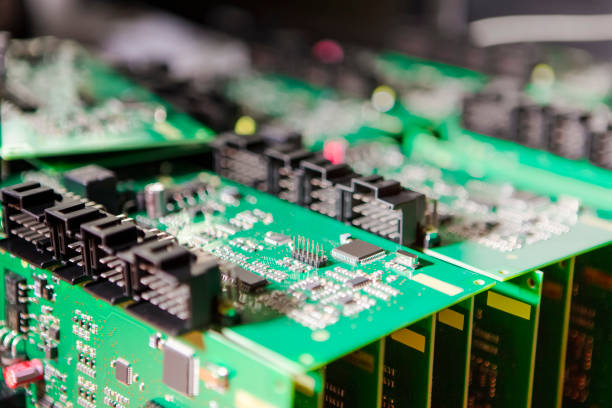

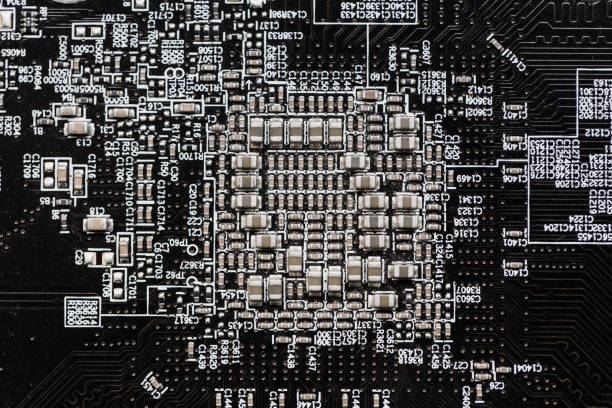

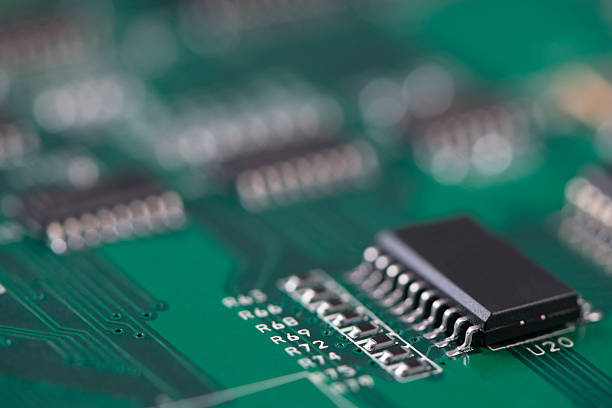

Surface mount devices are electronic components designed to be mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole components, which require holes drilled into the PCB for installation, SMDs are soldered onto pads on the board's surface. This method allows for a more compact design and enables higher component density.

Key Types of Surface Mount Components

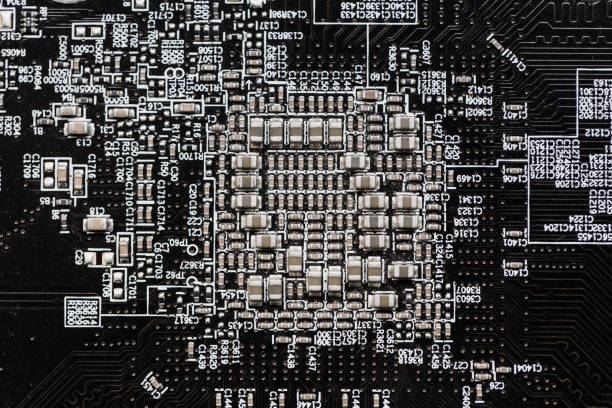

- Resistors: Used to limit current flow.

- Capacitors: Store electrical energy temporarily.

- Inductors: Store energy in a magnetic field.

- Diodes: Allow current to flow in one direction only.

- Transistors: Act as switches or amplifiers.

- Integrated Circuits (ICs): Combine multiple functions into a single package.

Advantages of Using SMD Components

1. Compact Size: SMDs are generally smaller than their through-hole counterparts, allowing for more compact designs.

2. Higher Component Density: More components can fit on a single PCB, which is essential for modern electronic devices that require miniaturization.

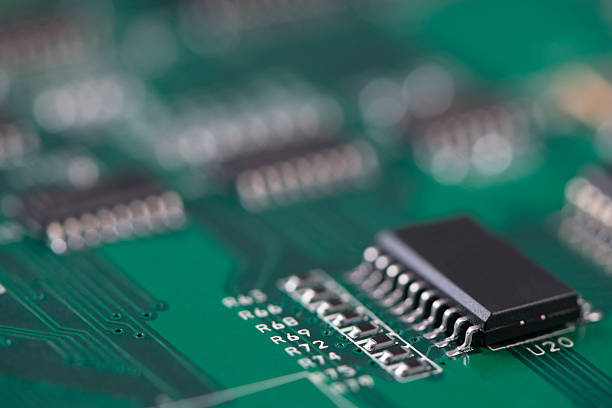

3. Improved Performance: Shorter leads reduce inductance and resistance, enhancing electrical performance and signal integrity.

4. Automated Assembly: SMT allows for automated assembly processes, increasing production speed and reducing manufacturing costs.

5. Dual-Sided Assembly: SMDs can be placed on both sides of the PCB, maximizing space utilization.

Disadvantages of Using SMD Components

1. Repair Challenges: SMDs can be more difficult to replace or repair compared to through-hole components due to their small size and placement on the PCB surface.

2. Thermal Management Issues: The compact nature of SMDs can lead to heat dissipation problems if not adequately managed.

3. Specialized Equipment Needed: SMT requires specific tools and techniques for assembly and soldering, which may not be readily available in all workshops.

Factors to Consider When Choosing SMD Components

When selecting SMD components for your project, consider the following factors:

Application Requirements

Understanding the specific requirements of your application is crucial. Different projects may prioritize size, weight, power consumption, or signal integrity differently.

Component Specifications

Evaluate the specifications of potential SMDs:

- Electrical Ratings: Ensure that voltage and current ratings meet your project's needs.

- Package Type: Choose a package that fits your design constraints (e.g., size, thermal management).

- Tolerance Levels: Select components with appropriate tolerances based on your circuit's sensitivity.

Availability and Cost

Research component availability from suppliers to avoid delays in your project timeline. Additionally, consider the cost-effectiveness of different options; sometimes a more expensive component may offer better performance or reliability.

Manufacturer Reputation

Select components from reputable manufacturers known for quality and reliability. This choice can significantly affect the overall performance and longevity of your project.

Testing and Validation

Always test your selected components in prototype builds before finalizing your design. This process helps identify any potential issues early on.

Best Practices for Integrating SMD Components

1. Design Layout Considerations

- Keep traces short to minimize resistance and inductance.

- Use adequate spacing between components to prevent short circuits.

- Follow recommended layout guidelines from component manufacturers.

2. Soldering Techniques

- Use reflow soldering for most applications; this method provides uniform heating and reduces defects.

- Ensure proper solder paste application using stencils for accuracy.

3. Thermal Management

- Incorporate heat sinks or thermal vias if necessary to manage heat dissipation effectively.

- Consider component placement carefully to enhance airflow around heat-sensitive parts.

4. Inspection and Testing

- Implement automated optical inspection (AOI) systems to catch defects during assembly.

- Conduct functional testing post-assembly to ensure all components operate as intended.

Conclusion

Choosing the right surface mount devices is a pivotal step in any electronics project. By understanding the characteristics of different SMD components, considering application requirements, and adhering to best practices during design and assembly, you can significantly enhance your project's success rate. The transition from traditional through-hole technology to surface mount technology has revolutionized electronics manufacturing, enabling smaller, faster, and more efficient designs.

FAQ

1. What are surface mount devices (SMD)?

Surface mount devices are electronic components designed for mounting directly onto the surface of printed circuit boards (PCBs), allowing for compact designs with higher component density compared to through-hole devices.

2. What are the main advantages of using SMT?

The main advantages include compact size, higher component density, improved electrical performance, automated assembly capabilities, and dual-sided placement on PCBs.

3. What challenges do SMDs present in repairability?

SMDs can be more challenging to replace due to their small size and placement on PCBs; specialized tools may be required for removal and replacement without damaging surrounding components.

4. How do I ensure proper thermal management with SMDs?

To ensure proper thermal management with SMDs, use heat sinks or thermal vias as needed and carefully consider component placement to enhance airflow around heat-sensitive parts.

5. Why is testing important when using SMDs?

Testing is crucial when using SMDs because it helps identify potential issues early in the design process, ensuring that all components function correctly within the circuit before final production.