Content Menu

● Understanding SMT Stencils

● Types of SMT Stencils

● Material Selection

● Thickness Considerations

● Design Considerations

● Optimizing Stencil Performance

● Maintenance and Cleaning

● Troubleshooting Common Issues

● Future Trends in SMT Stencil Technology

● Cost Considerations

● Conclusion

● FAQ

>> 1. What factors should I consider when choosing an SMT stencil?

>> 2. How does stencil thickness affect solder paste deposition?

>> 3. What maintenance practices should I follow for SMT stencils?

>> 4. Why is aperture design important in stencil manufacturing?

>> 5. What future trends should I watch in SMT stencil technology?

Selecting the right stencil mask for your Surface Mount Technology (SMT) line is a critical decision that can significantly impact the quality and efficiency of your PCB assembly process. This article explores the various factors to consider when choosing a stencil mask, including types, materials, thickness, design considerations, and maintenance practices.

Understanding SMT Stencils

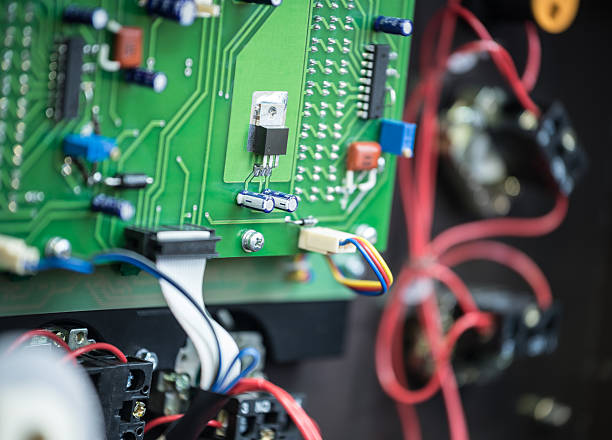

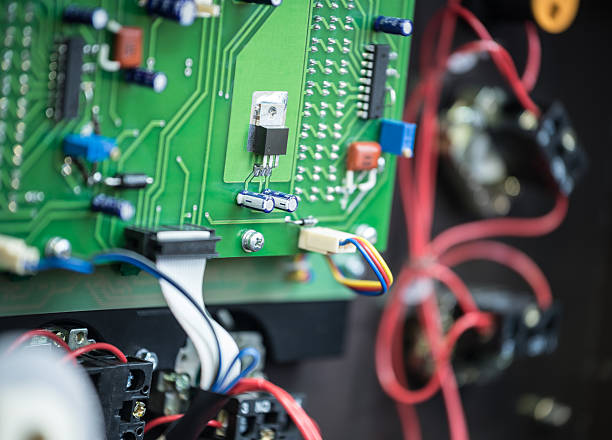

An SMT stencil is a thin metal sheet with apertures that allow for the precise application of solder paste onto the pads of a printed circuit board (PCB). This process is essential for ensuring that the correct amount of solder is deposited, which helps prevent defects during the soldering process.

Types of SMT Stencils

When selecting a stencil mask, it's important to understand the different types available:

- Framed Stencils: These are rigid stencils mounted on a frame, providing stability and ease of alignment. They are ideal for high-volume production due to their durability and reusability.

- Frameless Stencils: These stencils do not have a frame and are typically lighter and less expensive. However, they require careful handling and are more suitable for low to mid-volume production.

- Electroformed Stencils: Known for their high precision and smooth aperture walls, these stencils are best suited for fine-pitch components but come at a higher cost.

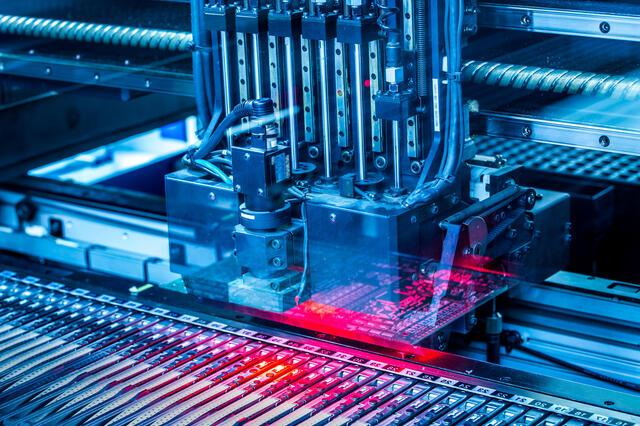

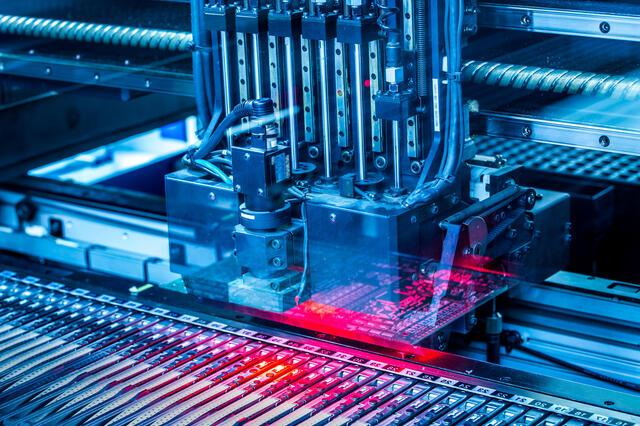

- Laser-Cut Stencils: The most common type, laser-cut stencils provide good precision and are cost-effective for most applications.

Material Selection

The material used to manufacture SMT stencils plays a significant role in their performance:

- Stainless Steel: The most widely used material due to its durability, resistance to wear, and cost-effectiveness. It is suitable for general-purpose applications.

- Nickel: Offers increased hardness and smoother aperture walls, making it ideal for high-precision applications but at a higher cost.

- Composite Materials: Used in specialized applications where unique properties are required, although they are less common.

Thickness Considerations

The thickness of the stencil is crucial in determining the volume of solder paste deposited:

- Standard Thicknesses: Common thicknesses range from 0.05mm to 0.15mm for solder paste stencils. Thicker stencils (up to 0.3mm) may be used for applications requiring more robust deposits.

- Component Type: For fine-pitch components like BGAs (Ball Grid Arrays), thinner stencils are recommended to ensure proper paste release without bridging between pads.

Design Considerations

Proper stencil design is essential for achieving high-quality prints:

- Aperture Size and Shape: The aperture size should match the PCB pads while accounting for solder paste properties. Common shapes include circles, squares, and home plates.

- Area Ratio: The area ratio (the ratio of the aperture opening area to its wall area) should ideally be 0.66 or higher to ensure good paste release.

- Aspect Ratio: Defined as the width of the aperture divided by the stencil thickness, maintaining an appropriate aspect ratio prevents clogging and ensures effective paste transfer.

Optimizing Stencil Performance

To achieve optimal results with SMT stencils, consider these techniques:

- Nano-coating: Applying a nano-coating can improve paste release properties and reduce cleaning frequency. This coating creates a non-stick surface that minimizes residue buildup on the stencil.

- Electropolishing: This process smooths out imperfections on the stencil surface, enhancing paste release quality. A smoother surface reduces friction during paste transfer, leading to better print quality.

- Custom Aperture Designs: For unique PCB layouts or challenging components, custom designs can optimize paste deposition. Utilizing software tools allows engineers to simulate different designs before production.

Maintenance and Cleaning

Regular maintenance of SMT stencils is vital for consistent print quality:

- Cleaning Schedule: Implementing a regular cleaning schedule helps remove residual solder paste and prevents clogging of apertures. Methods include manual cleaning with solvents or using ultrasonic cleaning systems.

- Inspection: Regularly inspect stencils for wear or damage to maintain print quality. Use magnification tools to check apertures for deformation or blockage.

- Proper Storage: Store stencils in a clean environment with protective covers to prevent damage during handling. Avoid stacking heavy items on top of stencils to prevent warping.

Troubleshooting Common Issues

Even with proper selection and maintenance, issues may arise during the printing process:

- Insufficient Paste Volume: If you notice insufficient solder paste on some pads, check if your stencil's aperture size is appropriate or if there's an issue with the printing pressure.

- Bridging Between Pads: This issue often occurs with fine-pitch components when too much solder paste is deposited or when the stencil design does not allow sufficient space between apertures.

- Solder Paste Smearing: If you experience smearing during prints, ensure that your stencil is clean and that you're using appropriate printing speeds and pressures.

Future Trends in SMT Stencil Technology

As technology evolves, so does stencil manufacturing:

- 3D Printing: Additive manufacturing techniques are being explored to create complex multi-level stencils that accommodate various component types on a single PCB. This technology allows for rapid prototyping and customization without significant lead times.

- Smart Stencils: Integrating sensors into stencils could provide real-time feedback on print quality and performance, enabling proactive maintenance strategies. These smart systems could monitor parameters such as paste volume and alignment accuracy during production runs.

Cost Considerations

When choosing an SMT stencil mask, it's essential to consider not only the initial purchase price but also long-term costs associated with maintenance, cleaning processes, and potential downtime due to stencil-related issues:

- Initial Investment vs Long-Term Savings: While high-quality materials may have a higher upfront cost, they often lead to reduced maintenance needs and longer lifespans—resulting in lower costs over time.

- Cost-Benefit Analysis: Conducting a cost-benefit analysis can help determine which type of stencil best fits your production needs while balancing performance with budget constraints.

Conclusion

Choosing the right stencil mask for your SMT line involves careful consideration of various factors including type, material, thickness, design considerations, maintenance practices, troubleshooting strategies, future trends in technology, and cost implications. By understanding these elements and implementing best practices in stencil selection and management, you can significantly enhance the quality and efficiency of your PCB assembly process.

FAQ

1. What factors should I consider when choosing an SMT stencil?

Factors include type (framed vs frameless), material (stainless steel vs nickel), thickness (standard ranges), aperture design (size and shape), area ratio, aspect ratio, maintenance needs, storage requirements, troubleshooting strategies, future technology trends, and overall cost implications.

2. How does stencil thickness affect solder paste deposition?

Thicker stencils generally deposit more solder paste but may hinder release; thinner stencils allow better paste release but may not provide enough volume for larger components. The choice depends on specific component requirements and production volume needs.

3. What maintenance practices should I follow for SMT stencils?

Implement regular cleaning schedules using appropriate methods like ultrasonic cleaning or manual solvent cleaning; inspect frequently for damage or wear; store properly in clean environments with protective covers to prolong their lifespan.

4. Why is aperture design important in stencil manufacturing?

Proper aperture design ensures accurate solder paste deposition on PCB pads while preventing issues such as bridging between pads or insufficient paste volume. It directly affects print quality and reliability in assembly processes.

5. What future trends should I watch in SMT stencil technology?

Look out for advancements in 3D printing techniques for complex designs that accommodate various component types efficiently; also monitor developments in smart stencils equipped with sensors that provide real-time feedback on performance metrics during printing processes.