Content Menu

● Understanding SMT PCB Mini Cyclic Loaders

>> Key Features of SMT PCB Mini Cyclic Loaders

● Why Choose an SMT PCB Mini Cyclic Loader?

>> 1. Enhanced Production Efficiency

>> 2. Improved Precision and Reduced Defects

>> 3. Flexibility and Adaptability

>> 4. Space-Saving Design

>> 5. Seamless Integration

● How to Choose the Right SMT PCB Mini Cyclic Loader for Your Business

>> 1. Assess Your PCB Specifications

>> 2. Evaluate Production Volume and Speed Requirements

>> 3. Consider Machine Stability and Build Quality

>> 4. Control System and User Interface

>> 5. Compatibility and Integration

>> 6. Maintenance and Support

● Additional Considerations When Choosing an SMT PCB Mini Cyclic Loader

>> Automation Level and Customization

>> Environmental and Safety Features

>> Cost vs. Return on Investment (ROI)

● Benefits of Investing in an SMT PCB Mini Cyclic Loader

● Conclusion

● FAQ

>> 1. What is an SMT PCB Mini Cyclic Loader?

>> 2. How does the mini cyclic loader prevent PCB breakage?

>> 3. Can the SMT PCB Mini Cyclic Loader handle different PCB sizes?

>> 4. Is the loader compatible with existing SMT production lines?

>> 5. What kind of maintenance does the mini cyclic loader require?

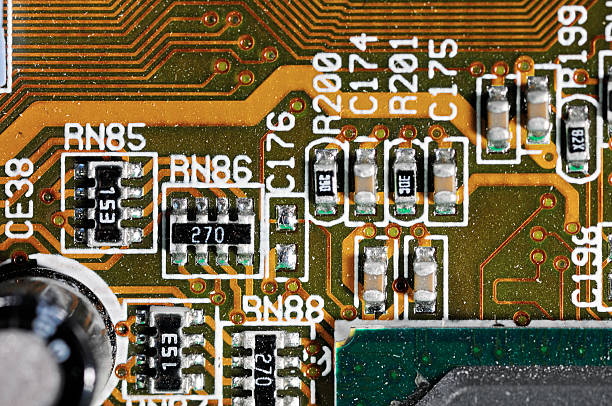

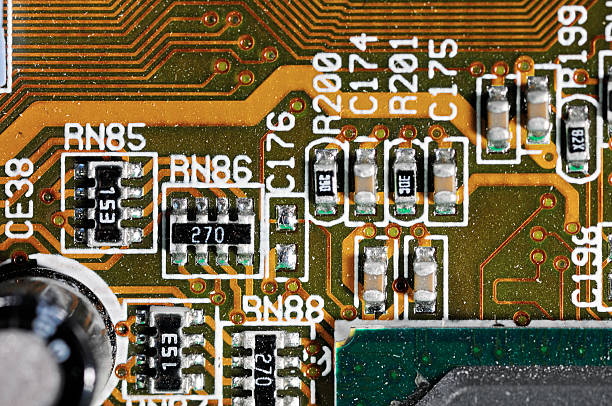

In the fast-evolving world of electronics manufacturing, Surface Mount Technology (SMT) plays a crucial role in assembling printed circuit boards (PCBs). One of the key components that enhance efficiency and precision in SMT assembly lines is the SMT PCB Mini Cyclic Loader. This article provides a comprehensive guide on how to select the right mini cyclic loader tailored to your business requirements, highlighting its features, benefits, and integration considerations.

Understanding SMT PCB Mini Cyclic Loaders

An SMT PCB Mini Cyclic Loader is an automated machine designed to load PCBs onto the SMT production line efficiently and precisely. It automates the process of transferring PCBs from magazines to conveyors, reducing manual labor, minimizing PCB damage, and increasing throughput.

Key Features of SMT PCB Mini Cyclic Loaders

- Strong, firm, and stable design: Ensures durability and consistent operation without shifting during use.

- Aluminum structure with bottom weight design: Enhances stability and prevents movement.

- Effective design to prevent PCB breakage: Special pneumatic clamps and pressure regulation protect delicate PCBs.

- Programmable Logic Controller (PLC) control system: Allows customization and automation of loading cycles.

- Touch screen or LED membrane switch control panel: User-friendly interfaces for easy operation.

- SMEMA compatibility: Ensures seamless integration with other SMT equipment.

- Self-diagnostic error code display: Facilitates quick troubleshooting and maintenance.

- Compact footprint: Saves valuable floor space in production facilities.

- Adjustable loading speed and width: Accommodates various PCB sizes and production speeds.

Why Choose an SMT PCB Mini Cyclic Loader?

1. Enhanced Production Efficiency

The mini cyclic loader automates the PCB loading process, significantly speeding up production lines compared to manual loading. It can load PCBs approximately every 6 seconds, maintaining a steady flow and reducing bottlenecks. This automation not only increases throughput but also ensures consistent timing, which is critical for synchronizing with other SMT line equipment such as pick-and-place machines and reflow ovens.

2. Improved Precision and Reduced Defects

Manual loading of PCBs can lead to misalignment, damage, or contamination, all of which affect product quality. The SMT PCB Mini Cyclic Loader uses pneumatic clamps with adjustable pressure to securely hold PCBs without causing damage. This precision reduces the risk of PCB breakage, warping, or contamination, which in turn lowers defect rates and improves yield.

3. Flexibility and Adaptability

Modern SMT production lines often handle a variety of PCB sizes and types. The mini cyclic loader's programmable settings allow operators to quickly adjust loading parameters such as speed, clamp pressure, and PCB dimensions. This flexibility is essential for manufacturers who produce multiple product lines or prototypes, enabling rapid changeovers and minimizing downtime.

4. Space-Saving Design

Manufacturing floors are often constrained by space, especially in high-volume electronics factories. The compact design of the SMT PCB Mini Cyclic Loader allows it to fit into tight spaces without compromising functionality. Its modular construction also means it can be easily integrated or relocated as production needs evolve.

5. Seamless Integration

The loader's compliance with SMEMA (Surface Mount Equipment Manufacturers Association) standards ensures it can communicate and synchronize with other SMT equipment. This compatibility is vital for maintaining a smooth production flow, preventing jams, and enabling automated line stoppage in case of errors.

How to Choose the Right SMT PCB Mini Cyclic Loader for Your Business

Selecting the right SMT PCB Mini Cyclic Loader requires a thorough understanding of your production needs and the loader's capabilities. Here are the key factors to consider:

1. Assess Your PCB Specifications

- PCB Size Range: Ensure the loader supports your PCB dimensions. Typical loaders handle PCBs from 50x50 mm up to 460x330 mm or larger depending on the model. If your production involves unusually large or small PCBs, verify that the loader can accommodate these sizes.

- PCB Thickness: Confirm the loader can accommodate your PCB thickness, usually starting from 0.4 mm upwards. Some loaders offer adjustable clamps to handle varying thicknesses without manual intervention.

2. Evaluate Production Volume and Speed Requirements

- Determine your required loading speed (e.g., loading time around 6 seconds per PCB). High-volume manufacturers may need faster loaders or multiple units to keep pace with pick-and-place machines.

- Consider the magazine capacity and changeover time to match your production volume. Larger magazines reduce the frequency of reloads, improving uptime.

3. Consider Machine Stability and Build Quality

- Look for loaders with a solid aluminum or steel frame and bottom weight design to ensure stability during operation. A stable machine reduces vibrations and misfeeds.

- Check for features that prevent PCB breakage, such as pneumatic clamps and pressure regulation. Some loaders include sensors to detect PCB presence and prevent loading errors.

4. Control System and User Interface

- Choose loaders with PLC control systems for programmability and automation. PLCs allow integration with factory automation systems and enable complex loading sequences.

- User-friendly interfaces like touch screens or LED membrane switches simplify operation and reduce training time. Some loaders offer multilingual support and customizable menus.

5. Compatibility and Integration

- Verify SMEMA interface compatibility to ensure the loader integrates smoothly with your existing SMT line.

- Confirm the loader supports your conveyor height and direction requirements. Adjustable conveyor height and direction options help align the loader with upstream and downstream equipment.

6. Maintenance and Support

- Opt for loaders with self-diagnostic features to facilitate maintenance. Error code displays and alarms help operators quickly identify and resolve issues.

- Consider manufacturers offering comprehensive after-sales support, including manuals, videos, and on-site service. Reliable support minimizes downtime and extends machine life.

Additional Considerations When Choosing an SMT PCB Mini Cyclic Loader

Automation Level and Customization

Some SMT PCB Mini Cyclic Loaders come with advanced automation features such as automatic magazine feeding, barcode scanning for PCB tracking, and integration with Manufacturing Execution Systems (MES). These features can further enhance production efficiency and traceability.

Environmental and Safety Features

Look for loaders with safety guards, emergency stop buttons, and compliance with local safety standards. Additionally, consider machines designed to operate in cleanroom environments if your production requires strict contamination control.

Cost vs. Return on Investment (ROI)

While initial investment cost is important, consider the long-term ROI. A high-quality loader that reduces defects, labor costs, and downtime can pay for itself quickly. Evaluate total cost of ownership including maintenance, consumables, and energy consumption.

Benefits of Investing in an SMT PCB Mini Cyclic Loader

| Benefit | Description |

| Increased Throughput | Automates loading, reducing cycle time and increasing production capacity. |

| Reduced Labor Costs | Minimizes manual handling, lowering labor expenses and human error. |

| Enhanced PCB Protection | Pneumatic clamps and pressure control prevent PCB damage during loading. |

| Flexibility | Programmable settings allow adaptation to various PCB sizes and production needs. |

| Space Efficiency | Compact design fits into tight production spaces without compromising functionality. |

| Easy Integration | SMEMA compatibility ensures smooth communication with other SMT equipment. |

| User-Friendly Operation | Touch screen and LED controls simplify machine operation and reduce training requirements. |

| Improved Traceability | Optional barcode scanning and MES integration enhance production tracking and quality control. |

Conclusion

Choosing the right SMT PCB Mini Cyclic Loader is a strategic decision that can significantly impact your SMT production line's efficiency, precision, and overall output quality. By carefully evaluating your PCB specifications, production volume, machine stability, control systems, and integration needs, you can select a loader that not only fits your current requirements but also adapts to future demands. Investing in a high-quality mini cyclic loader ensures reduced PCB damage, faster throughput, and a streamlined assembly process, ultimately enhancing your business competitiveness in the electronics manufacturing industry.

FAQ

1. What is an SMT PCB Mini Cyclic Loader?

An SMT PCB Mini Cyclic Loader is an automated machine used in SMT assembly lines to load printed circuit boards from magazines onto conveyors, improving loading speed and precision while reducing manual labor and PCB damage.

2. How does the mini cyclic loader prevent PCB breakage?

The loader uses top and bottom pneumatic clamps with regulated pressure to securely hold PCBs during loading, preventing breakage and damage caused by mechanical stress.

3. Can the SMT PCB Mini Cyclic Loader handle different PCB sizes?

Yes, most mini cyclic loaders support a wide range of PCB sizes, typically from 50x50 mm up to 460x330 mm or more, with adjustable width and loading parameters to accommodate various board dimensions.

4. Is the loader compatible with existing SMT production lines?

Most SMT PCB Mini Cyclic Loaders are designed with SMEMA interface compatibility, allowing seamless integration with upstream and downstream SMT equipment for synchronized operation.

5. What kind of maintenance does the mini cyclic loader require?

Loaders often feature self-diagnostic error code displays to facilitate troubleshooting. Regular maintenance includes checking pneumatic systems, cleaning sensors, and ensuring mechanical parts are lubricated and functioning properly.