Content Menu

● Introduction to Mini SMD Pick and Place Machines

>> Key Considerations for Choosing a Mini SMD Pick and Place Machine

● Types of Buyers and Suitable Mini SMD Pick and Place Machines

>> Hobbyists

>> Small Businesses

>> Original Equipment Manufacturers (OEMs)

● Common Mistakes When Choosing a Mini SMD Pick and Place Machine

● Advanced Features of Mini SMD Pick and Place Machines

● Latest Trends in Mini SMD Pick and Place Technology

● Case Studies of Successful Mini SMD Pick and Place Machine Usage

● Comparison of Top Mini SMD Pick and Place Machines

● User Experiences with Mini SMD Pick and Place Machines

● Setting Up and Operating a Mini SMD Pick and Place Machine

● Common Failure Problems and Fixes

>> Fixes

● Conclusion

● FAQ

>> 1. What are the key factors to consider when choosing a mini SMD pick and place machine?

>> 2. Which mini SMD pick and place machines are suitable for hobbyists?

>> 3. How do I ensure accurate component placement on a mini SMD pick and place machine?

>> 4. What are common failure problems in mini SMD pick and place machines?

>> 5. How do I set up feeders correctly on a mini SMD pick and place machine?

Choosing the right mini SMD pick and place machine is crucial for efficient and cost-effective electronics manufacturing, especially for small-scale production or prototyping. These machines are designed to handle surface mount devices (SMDs) with precision and speed, making them essential for hobbyists, small businesses, and even larger enterprises looking to streamline their production processes.

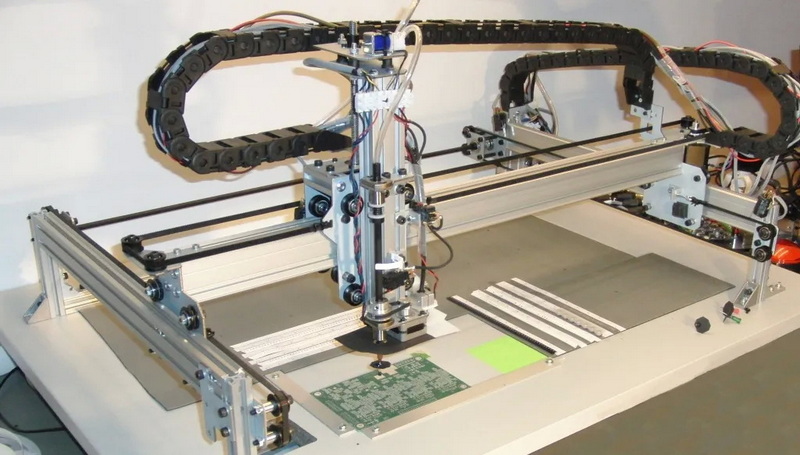

Introduction to Mini SMD Pick and Place Machines

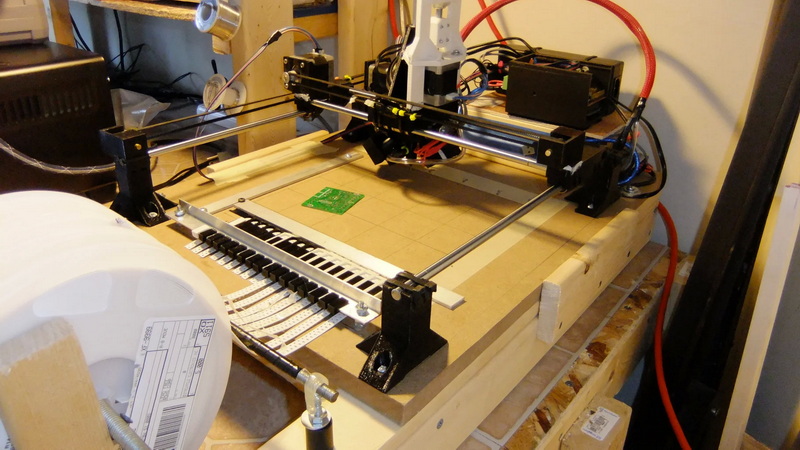

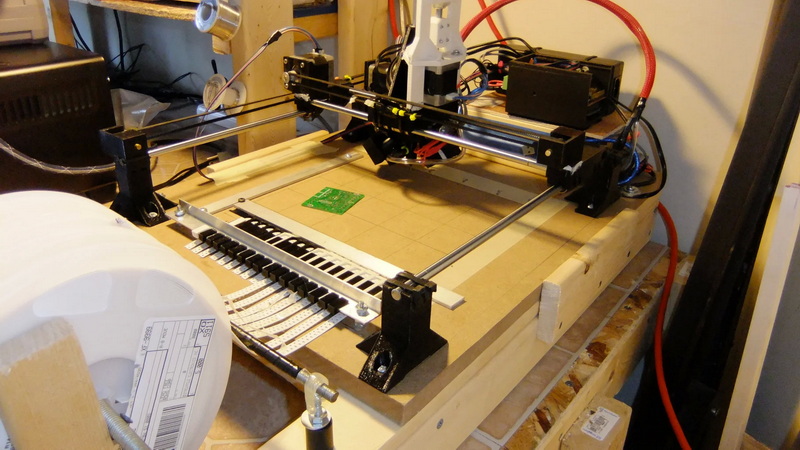

Mini SMD pick and place machines are compact, versatile tools that enable users to assemble electronic components onto printed circuit boards (PCBs) with ease. They are particularly popular among hobbyists and small businesses due to their affordability and ease of use. However, selecting the right machine can be challenging without understanding the key factors involved.

Key Considerations for Choosing a Mini SMD Pick and Place Machine

When selecting a mini SMD pick and place machine, several factors must be considered to ensure that the machine meets your specific needs and enhances your production efficiency.

1. Production Volume: Determine the scale of your production. If you are producing small batches, a compact machine with lower throughput might suffice. However, if you anticipate growth, consider a machine that can handle increased volumes without compromising on speed or accuracy.

2. Component Type and Size: Ensure the machine can handle the types and sizes of components you work with. This includes SMDs like 0402, 0201, and even smaller components if needed.

3. Speed and Accuracy: While speed is important for efficiency, accuracy is crucial for quality. Look for machines with advanced vision systems to ensure precise component placement.

4. Versatility: A versatile machine can handle different types of components and PCBs, allowing you to diversify your product offerings.

5. Ease of Use: Opt for machines with user-friendly interfaces and software that simplify setup and operation.

6. Support and Maintenance: Consider the level of support provided by the manufacturer, including technical assistance and spare parts availability.

Types of Buyers and Suitable Mini SMD Pick and Place Machines

Different buyers have varying needs based on their production scale and requirements.

Hobbyists

For hobbyists, mini SMD pick and place machines like Boarditto and Liteplacer are ideal. These machines are affordable, compact, and easy to use, making them perfect for small-scale projects.

Small Businesses

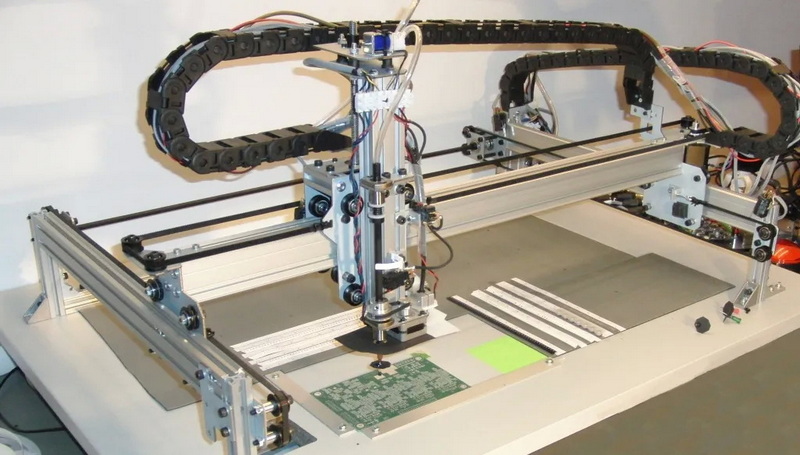

Small businesses may require machines that offer a balance between functionality and cost-effectiveness. Novastar machines are often recommended for this segment due to their versatility and scalability.

Original Equipment Manufacturers (OEMs)

OEMs typically require more advanced machines with high-speed and high-precision capabilities. These machines often include features like automated setup and rapid changeover to meet large production demands.

Common Mistakes When Choosing a Mini SMD Pick and Place Machine

When selecting a machine, it's easy to overlook critical factors. Common mistakes include:

- Underestimating Production Needs: Not considering future growth can lead to investing in a machine that soon becomes inadequate.

- Ignoring Component Variety: Failing to ensure the machine can handle various component sizes and types can limit production flexibility.

- Overlooking Maintenance Costs: Not considering ongoing maintenance and support costs can lead to unexpected expenses.

Advanced Features of Mini SMD Pick and Place Machines

Modern mini SMD pick and place machines often include advanced features that enhance their functionality and efficiency:

- Automated Component Inspection: Some machines come equipped with built-in inspection systems to detect component defects before placement.

- Smart Feeder Systems: These systems allow for automatic feeder detection and adjustment, reducing setup time and increasing throughput.

- Advanced Vision Systems: High-resolution cameras and sophisticated algorithms improve placement accuracy and reduce errors.

Latest Trends in Mini SMD Pick and Place Technology

The field of mini SMD pick and place technology is rapidly evolving, with several trends shaping the industry:

- Increased Use of AI: Artificial intelligence is being integrated into machines to improve component recognition, placement accuracy, and predictive maintenance.

- Modular Design: Machines are being designed with modular components to facilitate easier upgrades and customization.

- Integration with IoT: Machines are increasingly connected to the internet, enabling real-time monitoring and remote control.

Case Studies of Successful Mini SMD Pick and Place Machine Usage

Several companies have successfully integrated mini SMD pick and place machines into their production lines, achieving significant improvements in efficiency and quality:

- Case Study 1: A small electronics manufacturer in Europe increased production capacity by 30% after implementing a Novastar machine, allowing them to meet growing demand without expanding their workforce.

- Case Study 2: A U.S.-based startup reduced production costs by 25% by using a Liteplacer machine for prototyping, enabling them to allocate more resources to product development.

Comparison of Top Mini SMD Pick and Place Machines

Here's a comparison of some top mini SMD pick and place machines:

| Machine Model | Production Speed | Component Range | Ease of Use |

| Boarditto | Medium | 0402 to 1206 | High |

| Liteplacer | High | 0201 to 1206 | Medium |

| Novastar | High | 0402 to 1812 | Medium |

User Experiences with Mini SMD Pick and Place Machines

Users often report positive experiences with mini SMD pick and place machines, citing benefits such as:

- Improved Efficiency: Machines significantly reduce manual labor time, allowing for faster project completion.

- Enhanced Accuracy: Automated placement reduces human error, leading to higher-quality PCBs.

- Cost Savings: By reducing labor costs and improving yield rates, these machines can quickly pay for themselves.

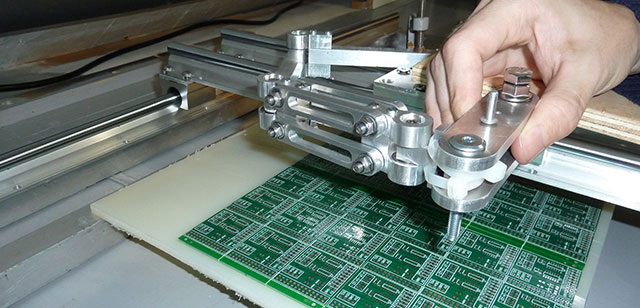

Setting Up and Operating a Mini SMD Pick and Place Machine

Proper setup and operation are crucial for optimal performance.

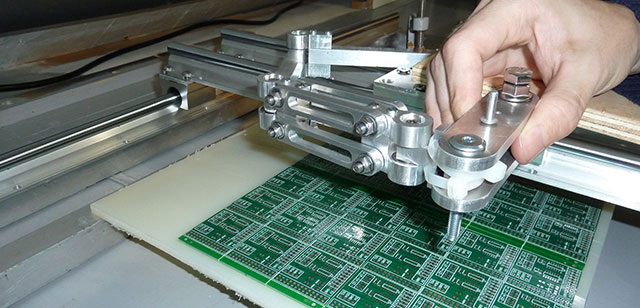

- Feeder Setup: Correctly setting up feeders involves adjusting parameters like part angle, length, width, and height to ensure accurate component pickup and placement.

- Camera Calibration: Regular calibration of the machine's cameras ensures precise fiducial recognition and component placement.

Common Failure Problems and Fixes

Even with proper setup, machines can experience issues. Common problems include:

- Component Placement Errors: Often due to incorrect calibration or damaged feeders.

- Component Damage: Caused by malfunctioning machines or poor-quality components.

- Inaccurate Fiducial Recognition: Resulting from dirty camera lenses or software malfunctions.

Fixes

- Regular maintenance and calibration.

- Prompt replacement of damaged parts.

- Use of high-quality components.

Conclusion

Choosing the right mini SMD pick and place machine requires careful consideration of production volume, component type, speed, accuracy, versatility, ease of use, and support. By understanding these factors and avoiding common mistakes, you can select a machine that enhances your production efficiency and quality, contributing to the success of your business.

FAQ

1. What are the key factors to consider when choosing a mini SMD pick and place machine?

When selecting a mini SMD pick and place machine, consider production volume, component type and size, speed, accuracy, versatility, ease of use, and the level of support provided by the manufacturer.

2. Which mini SMD pick and place machines are suitable for hobbyists?

Hobbyists often prefer machines like Boarditto and Liteplacer due to their affordability and ease of use.

3. How do I ensure accurate component placement on a mini SMD pick and place machine?

Ensure accurate component placement by regularly calibrating the machine, using high-quality components, and maintaining the machine properly.

4. What are common failure problems in mini SMD pick and place machines?

Common issues include component placement errors, component damage, and inaccurate fiducial recognition, often due to incorrect calibration, damaged parts, or poor maintenance.

5. How do I set up feeders correctly on a mini SMD pick and place machine?

Correct feeder setup involves adjusting parameters like part angle, length, width, and height. Regular testing and calibration are essential for optimal performance.