Content Menu

● Understanding SMT Production Lines

● Key Factors in Choosing SMT Equipment

>> 1. Production Volume and Flexibility

>> 2. PCB Complexity and Component Mix

>> 3. Accuracy and Quality

>> 4. Software Integration

>> 5. Equipment Types

● Choosing Specific Equipment

>> Pick and Place Machines

>> Solder Paste Printers

>> Reflow Ovens

● Future Scalability

● Maintenance and Support

● Conclusion

● FAQ

>> 1. What is SMT?

>> 2. How do I determine my production volume needs?

>> 3. What is a pick-and-place machine?

>> 4. Why is accuracy important in SMT assembly?

>> 5. How can I ensure my SMT line is scalable?

Selecting the appropriate equipment for a Surface Mount Technology (SMT) production line is a critical decision that can significantly impact the efficiency, quality, and cost-effectiveness of your manufacturing process. This guide will provide a comprehensive overview of the factors to consider when choosing SMT equipment, including types of machines, production needs, and future scalability.

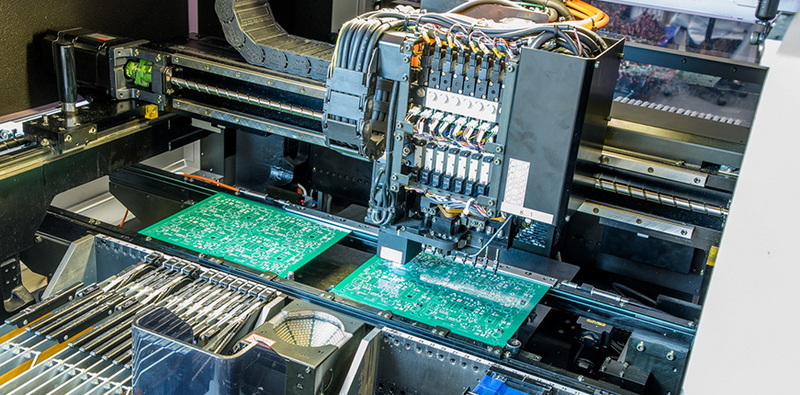

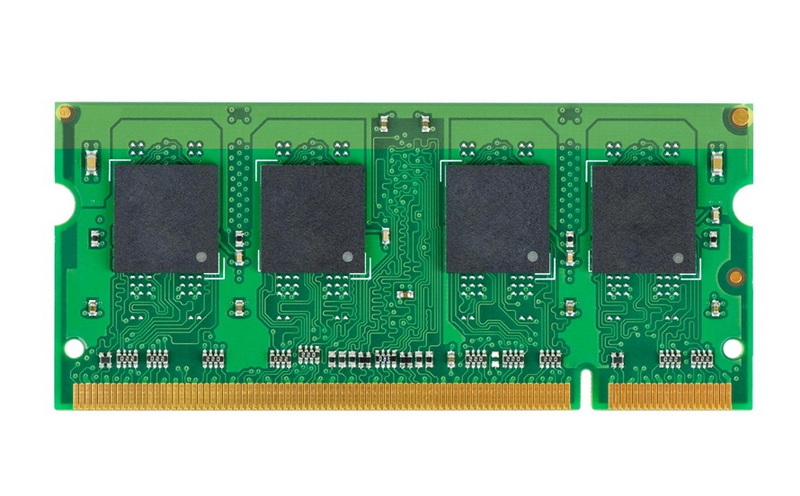

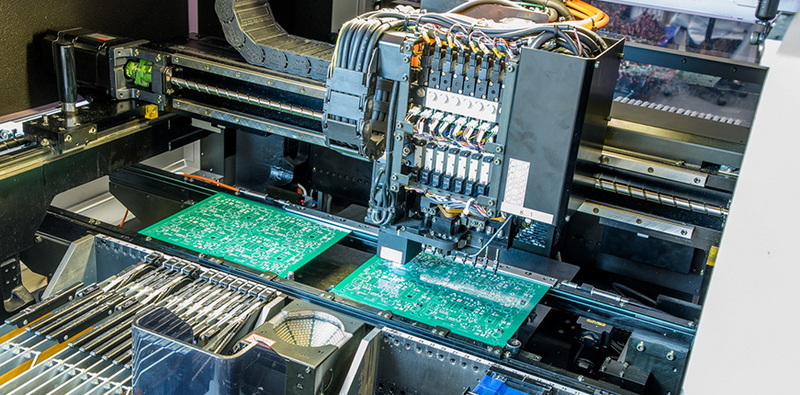

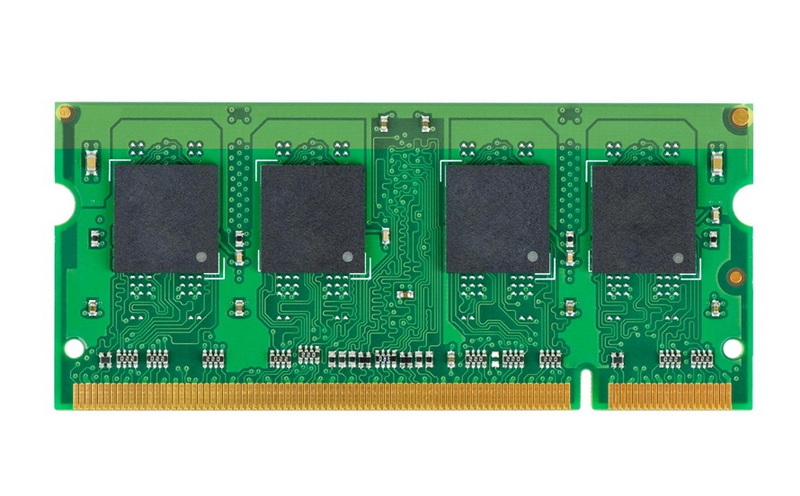

Understanding SMT Production Lines

SMT production lines are designed to assemble electronic components onto printed circuit boards (PCBs) using various machines. The main equipment typically includes:

- Pick and Place Machines: Responsible for placing surface mount devices (SMDs) onto PCBs.

- Solder Paste Printers: Apply solder paste to the PCB pads before component placement.

- Reflow Ovens: Melt solder paste to secure components to the PCB.

- Automated Optical Inspection (AOI): Check for defects in the assembled boards.

- Conveyors: Transport PCBs between different stages of assembly.

Key Factors in Choosing SMT Equipment

Choosing the right equipment involves several crucial considerations:

1. Production Volume and Flexibility

Assessing your current and projected production volumes is essential. High-volume production may necessitate faster, more automated equipment, while lower volumes might benefit from flexible, multi-purpose machines. Consider:

- Throughput Rates: The speed at which components can be placed on PCBs.

- Changeover Time: The time required to switch between different product runs.

- Component Variety: The ability of the machine to handle various component sizes and types.

For example, if your production line is expected to handle a diverse range of products with varying demand, investing in flexible equipment that can quickly adapt to changes will be beneficial. Machines with quick changeover capabilities can significantly reduce downtime during transitions between different product runs.

2. PCB Complexity and Component Mix

Evaluate the complexity of your PCBs and the variety of components used. Considerations include:

- Component Sizes: From large ICs to tiny 01005 components.

- Mixed Technology Requirements: Handling both through-hole and surface mount components.

- Fine-Pitch Components: Machines must be capable of placing fine-pitch and ultra-fine-pitch components accurately.

The complexity of your PCB design directly affects the choice of equipment. For instance, if your designs frequently incorporate fine-pitch components or require precise alignment, investing in high-end pick-and-place machines with advanced vision systems will ensure quality assembly.

3. Accuracy and Quality

Precision is paramount in SMT assembly. Look for equipment that offers:

- High Placement Accuracy: Ideally ±0.05mm or better for fine-pitch components.

- Advanced Vision Systems: For component recognition and alignment.

- Closed-loop Feedback Systems: To ensure continuous accuracy improvement.

Quality assurance should also extend beyond placement accuracy. Implementing automated optical inspection (AOI) systems can help detect defects early in the process, minimizing waste and rework costs.

4. Software Integration

Modern SMT equipment should integrate seamlessly with existing systems, including:

- Manufacturing Execution Systems (MES): For real-time monitoring and management.

- Data Collection Capabilities: To analyze production efficiency.

- Industry 4.0 Compatibility: Support for smart factory initiatives.

Choosing equipment that supports data analytics can provide insights into operational efficiency, helping you make informed decisions about process improvements and resource allocation.

5. Equipment Types

Different types of SMT machines serve specific purposes:

- Manual Pick-and-Place Machines: Suitable for prototyping or small-scale production.

- Semi-Automatic Pick-and-Place Machines: Offer partial automation for medium-scale operations.

- Automatic Pick-and-Place Machines: Fully automated machines used in high-speed, high-volume PCB assembly.

When selecting between these options, consider not only your current production needs but also potential future requirements as your business grows.

Choosing Specific Equipment

Pick and Place Machines

When selecting a pick-and-place machine, consider:

1. Production Volume: High-speed machines for large volumes; smaller machines for low-volume runs.

2. Component Type and Size: Ensure compatibility with your most frequently used components.

3. Speed vs. Cost: Determine the optimal speed needed without over-investing in unnecessary capabilities.

4. Versatility: The machine should handle various types of components to adapt to changing market demands.

5. Ease of Use: User-friendly interfaces can reduce setup times and training costs.

6. Support Services: Choose a manufacturer that offers reliable technical support and service.

Investing in a high-quality pick-and-place machine can dramatically enhance productivity by reducing cycle times while maintaining accuracy across diverse product lines.

Solder Paste Printers

These are critical for applying solder paste accurately onto PCB pads. Key considerations include:

- Printing Speed and Accuracy: Ensure that the printer can meet your production demands without compromising quality.

- Stencil Quality: High-quality stencils lead to better paste application.

The choice of solder paste printer can influence overall solder joint quality; therefore, consider models that offer adjustable parameters for different paste types or thicknesses.

Reflow Ovens

Reflow ovens are essential for melting solder paste after component placement. Factors to consider include:

- Temperature Profiles: Ensure that the oven can accommodate the specific temperature profiles required by your components.

- Throughput Capacity: Match the oven's capacity with your production line's speed.

Understanding the thermal characteristics of your components is vital when selecting a reflow oven; improper profiles can lead to defects such as tombstoning or cold solder joints.

Future Scalability

When planning your SMT production line, consider future growth and scalability:

- Assess potential increases in production volume and complexity over time.

- Choose equipment that allows for easy upgrades or expansions as your production needs grow without significant additional investment.

Investing in modular systems can provide flexibility; these systems allow you to add or upgrade individual machines without overhauling the entire line, ensuring longevity in your investment.

Maintenance and Support

Another important aspect to consider when choosing SMT equipment is maintenance and support:

- Regular maintenance protocols should be established to ensure optimal performance over time.

- Evaluate the manufacturer's support services; prompt assistance can minimize downtime during unforeseen issues.

Establishing a relationship with a reliable service provider can enhance machine longevity and maintain production efficiency through timely repairs and updates.

Conclusion

Choosing the right equipment for your SMT production line is a complex process that requires careful consideration of multiple factors including production volume, PCB complexity, accuracy requirements, software integration capabilities, maintenance support, and future scalability needs. By understanding these elements thoroughly, manufacturers can optimize their operations, improve product quality, reduce waste, and maintain competitiveness in a rapidly evolving market landscape.

FAQ

1. What is SMT?

SMT stands for Surface Mount Technology, a method used in electronics manufacturing where components are mounted directly onto the surface of PCBs rather than being inserted into holes.

2. How do I determine my production volume needs?

Assess your current output levels, expected growth rates, and market demand forecasts to estimate your production volume needs accurately.

3. What is a pick-and-place machine?

A pick-and-place machine is an automated device used in SMT lines to place SMDs onto PCBs with high precision and speed.

4. Why is accuracy important in SMT assembly?

Accuracy ensures that components are correctly placed on PCBs, reducing defects and rework while improving overall product quality.

5. How can I ensure my SMT line is scalable?

Choose modular equipment that allows easy upgrades or additions as your production needs grow, ensuring flexibility without extensive re-investment.