Content Menu

● Understanding Copper Universal PCB Boards

>> The Role of Copper in PCB Manufacturing

● Key Considerations for Choosing Copper Universal PCB Boards

>> Copper Thickness

>> Board Material

>> Layer Count

>> Surface Finish

● Design Considerations for SMT Applications

>> Component Placement

>> Trace Width and Spacing

>> Thermal Management

● Manufacturing Process Considerations

>> Etching and Plating

>> Solder Mask Application

>> Surface Mount Assembly

● Quality Control and Testing

>> Electrical Testing

>> Visual Inspection

>> X-ray Inspection

● Advanced Technologies for Copper Universal PCB Boards

>> High-Density Interconnect (HDI) Technology

>> Embedded Components

>> Flexible and Rigid-Flex PCBs

● Environmental Considerations

>> RoHS Compliance

>> Recyclability

● Cost Considerations

>> Material Costs

>> Manufacturing Complexity

>> Volume Production

● Conclusion

● FAQs

>> 1. What is the ideal copper thickness for SMT applications?

>> 2. How does the choice of PCB material affect SMT assembly?

>> 3. What are the advantages of using HDI technology in copper universal PCB boards for SMT?

>> 4. How can I ensure proper thermal management in my SMT design?

>> 5. What are the key factors to consider when choosing a surface finish for SMT applications?

● Citations:

Selecting the right copper universal PCB board for Surface Mount Technology (SMT) applications is crucial for ensuring optimal performance and reliability in electronic devices. This comprehensive guide will walk you through the key factors to consider when choosing the best copper universal PCB board for your SMT projects, helping you make informed decisions that will enhance your manufacturing process and end-product quality.

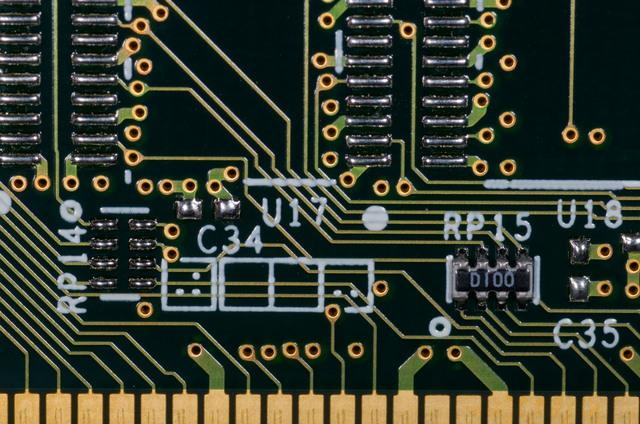

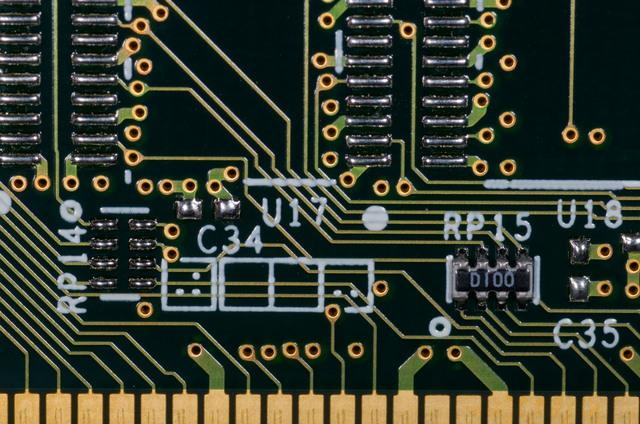

Understanding Copper Universal PCB Boards

Copper universal PCB boards are the foundation of modern electronics, providing the necessary platform for mounting and interconnecting electronic components. These boards are characterized by their versatility and ability to accommodate a wide range of SMT components, making them ideal for various applications across industries.

The Role of Copper in PCB Manufacturing

Copper plays a pivotal role in PCB manufacturing due to its excellent electrical conductivity and thermal properties. In universal PCB boards designed for SMT applications, copper layers are essential for creating the intricate pathways that allow electrical signals to flow between components[1]. The thickness and quality of copper used can significantly impact the board's performance, especially in high-frequency applications.

Key Considerations for Choosing Copper Universal PCB Boards

When selecting a copper universal PCB board for SMT applications, several factors must be taken into account to ensure compatibility with your specific requirements and manufacturing processes.

Copper Thickness

The thickness of the copper layer is a critical factor in determining the current-carrying capacity and impedance characteristics of the PCB. For SMT applications, common copper thicknesses range from 0.5 oz to 2 oz per square foot. Thicker copper layers may be necessary for high-power applications or when improved thermal management is required[6].

Board Material

The choice of board material affects the overall performance and reliability of the PCB. FR-4 is a popular choice for many SMT applications due to its balance of cost and performance. However, for high-frequency or high-temperature applications, specialized materials such as Rogers or polyimide may be more suitable[7].

Layer Count

The number of layers in a PCB can range from single-layer to multi-layer designs. For complex SMT applications, multi-layer boards offer greater design flexibility and improved signal integrity. When choosing the layer count, consider the complexity of your circuit, space constraints, and signal routing requirements[3].

Surface Finish

The surface finish of a copper universal PCB board is crucial for ensuring proper solderability and protection of the copper traces. Common surface finishes for SMT applications include:

- HASL (Hot Air Solder Leveling)

- ENIG (Electroless Nickel Immersion Gold)

- OSP (Organic Solderability Preservative)

- Immersion Tin or Silver

Each finish has its advantages and is suited to different types of SMT applications. ENIG, for example, offers excellent flatness and is well-suited for fine-pitch components[1].

Design Considerations for SMT Applications

Optimizing your copper universal PCB board design for SMT applications is essential for achieving the best results in terms of manufacturability and performance.

Component Placement

Proper component placement is critical for successful SMT assembly. Consider the following guidelines:

- Maintain adequate spacing between components to allow for pick-and-place machine tolerances.

- Group similar components together to optimize the assembly process.

- Ensure sufficient clearance for reflow soldering and inspection[8].

Trace Width and Spacing

The width and spacing of copper traces on your PCB affect both electrical performance and manufacturability. For SMT applications, consider the following:

- Use appropriate trace widths based on current requirements and impedance control needs.

- Maintain consistent trace widths and spacing throughout the board to improve signal integrity.

- Adhere to minimum trace width and spacing requirements specified by your PCB manufacturer[3].

Thermal Management

Effective thermal management is crucial for the reliability of SMT assemblies. Consider incorporating the following features in your copper universal PCB board design:

- Thermal vias to dissipate heat from power components.

- Copper pours or planes for improved heat distribution.

- Strategic placement of heat-generating components to optimize thermal performance[6].

Manufacturing Process Considerations

Understanding the manufacturing process for copper universal PCB boards is essential for ensuring that your design is optimized for production.

Etching and Plating

The etching process removes unwanted copper from the board, leaving only the desired copper traces. For SMT applications, consider the following:

- Design your traces and pads to accommodate the etching process tolerances.

- Specify the appropriate copper thickness to ensure proper etching results.

- Consider the use of advanced etching techniques for fine-pitch SMT components[7].

Solder Mask Application

The solder mask protects the copper traces and defines the areas where solder can be applied. For SMT applications:

- Ensure proper solder mask clearance around SMT pads to prevent solder bridging.

- Consider using laser-defined solder masks for improved accuracy in fine-pitch applications.

- Choose a solder mask color that provides good contrast for automated optical inspection[3].

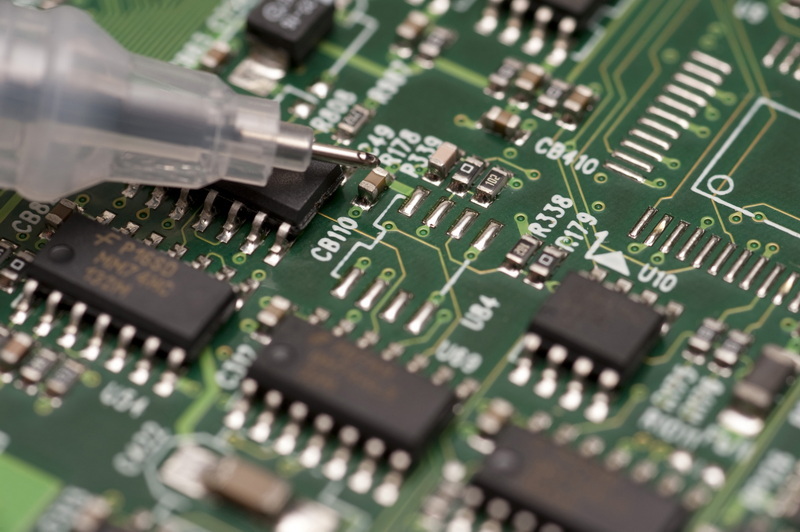

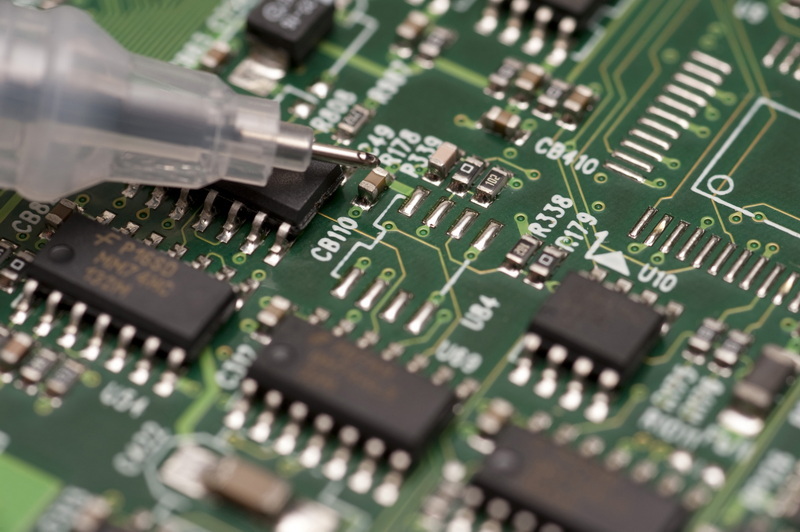

Surface Mount Assembly

The final step in the manufacturing process is the assembly of SMT components onto the copper universal PCB board. To optimize this process:

- Provide clear assembly documentation, including component placement diagrams.

- Consider using fiducial markers to aid in automated component placement.

- Specify appropriate solder paste stencil thickness for optimal solder joint formation[1].

Quality Control and Testing

Implementing robust quality control measures is essential for ensuring the reliability of your copper universal PCB boards in SMT applications.

Electrical Testing

Electrical testing verifies the integrity of the copper traces and ensures proper connectivity. Common testing methods include:

- Continuity testing to check for open circuits.

- Isolation testing to detect short circuits.

- Impedance testing for high-frequency applications[7].

Visual Inspection

Visual inspection is crucial for identifying defects that may not be detected through electrical testing. This includes:

- Checking for proper solder joint formation.

- Verifying component placement and orientation.

- Identifying any visible damage or contamination on the board surface[8].

X-ray Inspection

For complex SMT assemblies, X-ray inspection can be invaluable for detecting hidden defects, such as:

- Solder voids in BGA (Ball Grid Array) connections.

- Insufficient solder in hidden joints.

- Component misalignment or tombstoning[1].

Advanced Technologies for Copper Universal PCB Boards

As SMT technology continues to evolve, new advancements in copper universal PCB board manufacturing are emerging to meet the demands of increasingly complex electronic designs.

High-Density Interconnect (HDI) Technology

HDI technology allows for higher component density and improved signal integrity in SMT applications. Key features include:

- Microvias for increased routing density.

- Finer line widths and spacings.

- Improved signal performance for high-speed applications[6].

Embedded Components

Embedding passive components within the PCB layers can offer several advantages for SMT designs:

- Reduced board size and improved space utilization.

- Enhanced electrical performance due to shorter signal paths.

- Improved reliability by protecting components from environmental factors[3].

Flexible and Rigid-Flex PCBs

For applications requiring flexibility or unique form factors, consider using flexible or rigid-flex copper universal PCB boards:

- Flexible PCBs allow for dynamic bending and folding.

- Rigid-flex PCBs combine the benefits of rigid and flexible boards in a single assembly.

- These technologies can enable more compact and innovative product designs[1].

Environmental Considerations

When choosing copper universal PCB boards for SMT applications, it's important to consider the environmental impact of your selection.

RoHS Compliance

Ensure that the PCB materials and manufacturing processes comply with RoHS (Restriction of Hazardous Substances) regulations:

- Choose lead-free surface finishes.

- Verify that all components and materials used are RoHS compliant.

- Consider the environmental impact of the entire product lifecycle[7].

Recyclability

Consider the recyclability of your copper universal PCB boards:

- Use materials that can be easily recycled at the end of the product's life.

- Design for disassembly to facilitate easier recycling of components and materials.

- Work with PCB manufacturers that have environmentally responsible recycling programs[3].

Cost Considerations

While performance is crucial, it's also important to consider the cost implications of your copper universal PCB board choices for SMT applications.

Material Costs

The choice of materials can significantly impact the overall cost of your PCB:

- Standard FR-4 is generally the most cost-effective option for many applications.

- High-performance materials like Rogers or polyimide can increase costs but may be necessary for specific requirements.

- Consider the trade-offs between material cost and performance benefits[6].

Manufacturing Complexity

The complexity of your design can affect manufacturing costs:

- Simpler designs with fewer layers are generally less expensive to produce.

- Advanced features like HDI or embedded components may increase costs but can offer overall system-level savings.

- Consider the total cost of ownership, including assembly and potential rework costs[1].

Volume Production

Consider how your production volume affects the choice of copper universal PCB board:

- Higher volumes can justify more expensive tooling or setup costs if they result in lower per-unit costs.

- For low-volume or prototype runs, consider using more standard manufacturing processes to keep costs down.

- Discuss volume pricing with your PCB manufacturer to optimize costs[8].

Conclusion

Choosing the best copper universal PCB board for SMT applications requires careful consideration of numerous factors, including copper thickness, board material, layer count, surface finish, and manufacturing processes. By understanding these key elements and how they impact the performance, reliability, and cost of your PCB, you can make informed decisions that will optimize your SMT projects.

Remember to consider the specific requirements of your application, such as electrical performance, thermal management, and environmental conditions. Additionally, stay informed about emerging technologies and manufacturing techniques that can enhance the capabilities of your copper universal PCB boards.

Ultimately, the best choice will balance performance, manufacturability, cost, and environmental considerations. By carefully evaluating these factors and working closely with your PCB manufacturer, you can select the ideal copper universal PCB board that will ensure the success of your SMT applications and drive innovation in your electronic designs.

FAQs

1. What is the ideal copper thickness for SMT applications?

The ideal copper thickness for SMT applications typically ranges from 0.5 oz to 2 oz per square foot. The choice depends on factors such as current requirements, thermal management needs, and signal integrity considerations. For most standard SMT applications, 1 oz copper thickness is commonly used as it provides a good balance between performance and manufacturability. However, high-power or high-frequency applications may require thicker copper layers to handle increased current or improve signal performance.

2. How does the choice of PCB material affect SMT assembly?

The choice of PCB material can significantly impact SMT assembly in several ways:

- Thermal stability: Materials with higher glass transition temperatures (Tg) are better suited for lead-free soldering processes, which require higher temperatures.

- Dimensional stability: Some materials are more prone to warping or expansion during the reflow process, which can affect component placement accuracy.

- Electrical properties: Different materials have varying dielectric constants and loss tangents, which can impact signal integrity, especially in high-frequency applications.

- Moisture absorption: Materials with lower moisture absorption rates are generally preferred for SMT assembly, as moisture can lead to issues during the reflow process.

3. What are the advantages of using HDI technology in copper universal PCB boards for SMT?

High-Density Interconnect (HDI) technology offers several advantages for SMT applications:

- Increased routing density: HDI allows for more traces and vias in a given area, enabling more complex designs in smaller form factors.

- Improved signal integrity: Shorter signal paths and reduced via stubs lead to better electrical performance, especially for high-speed signals.

- Enhanced component placement: HDI enables finer pitch component placement, allowing for more compact designs.

- Reduced layer count: In some cases, HDI can reduce the overall layer count of a PCB while maintaining the same functionality, potentially reducing costs.

- Improved reliability: Smaller vias and more robust connections can lead to improved long-term reliability of the PCB.

4. How can I ensure proper thermal management in my SMT design?

To ensure proper thermal management in your SMT design:

- Use thermal vias: Place vias under heat-generating components to help dissipate heat to other layers or a ground plane.

- Implement copper pours: Large copper areas can help distribute heat more evenly across the board.

- Consider component placement: Place heat-generating components away from heat-sensitive components and near the edges of the board for better heat dissipation.

- Use thicker copper: For high-power applications, consider using thicker copper layers to improve heat distribution.

- Incorporate heat sinks: For components that generate significant heat, design in mounting points for heat sinks or use PCB materials with better thermal conductivity.

5. What are the key factors to consider when choosing a surface finish for SMT applications?

When selecting a surface finish for SMT applications, consider the following factors:

- Solderability: Choose a finish that provides excellent solderability and is compatible with your soldering process.

- Shelf life: Some finishes have longer shelf lives than others, which can be important for inventory management.

- Flatness: Finishes like ENIG provide excellent flatness, which is crucial for fine-pitch components.

- Environmental considerations: Some finishes are more environmentally friendly than others, which may be important for RoHS compliance.

- Cost: Different finishes vary in cost, so consider your budget constraints.

- Reliability: Some finishes offer better long-term reliability, especially in harsh environments.

- Compatibility with components: Ensure the chosen finish is compatible with all components in your design, including those that may be press-fit or require specific surface properties.

Citations:

[1] https://www.andwinpcb.com/understanding-smt-pcb-board-technology-and-its-applications/

[2] https://www.viasion.com/blog/heavy-copper-pcb-construction-properties-and-applications/

[3] https://www.candorind.com/blog/pcb-manufacturing-process/

[4] https://smtnet.com/library/index.cfm?fuseaction=browse_articles&start_at=601

[5] https://www.ittcannon.com/universal-contacts-pcb-contact-system

[6] https://www.elepcb.com/pcb-products/ele-copper-pcb-board/

[7] https://www.mclpcb.com/blog/pcb-manufacturing-process/

[8] https://www.smthelp.com/pcb-design-guideline.html

[9] https://www.elepcb.com/pcb-manufacturing-process-and-services/