Content Menu

● Understanding Surface Mount Assembly

● Factors Influencing Surface Mount Assembly Costs

>> Component Type and Quantity

>> Complexity of the PCB Design

>> Production Volume

>> Assembly Process

>> Quality Control and Testing

● Cost Breakdown of Surface Mount Assembly in 2024

>> Example Cost Scenarios

● The Future of Surface Mount Assembly Costs

● Conclusion

● FAQ

>> 1. What is surface mount assembly?

>> 2. How does the complexity of a PCB design affect assembly costs?

>> 3. What are the average costs for surface mount assembly in 2024?

>> 4. How does production volume impact costs?

>> 5. What role does quality control play in assembly costs?

Surface mount assembly (SMA) is a crucial process in the electronics manufacturing industry, allowing for the efficient production of printed circuit boards (PCBs). As technology advances, the costs associated with surface mount assembly continue to evolve. In this article, we will explore the various factors influencing surface mount assembly costs in 2024, provide insights into the assembly process, and offer a comprehensive overview of what businesses can expect when budgeting for these services.

Understanding Surface Mount Assembly

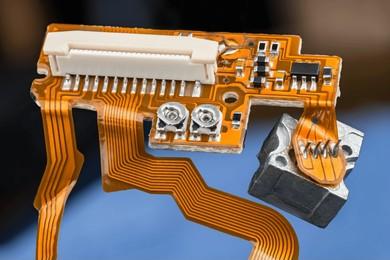

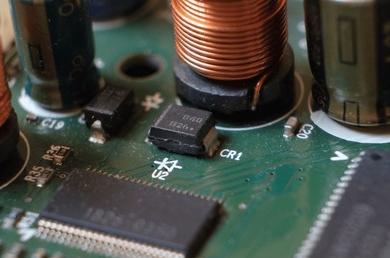

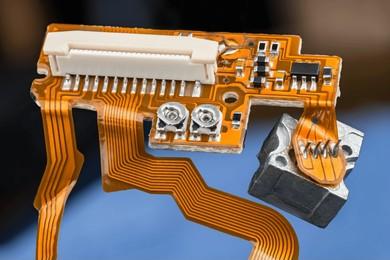

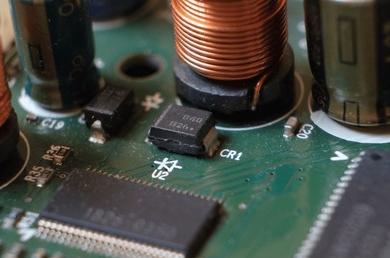

Surface mount assembly involves placing electronic components directly onto the surface of a PCB. This method contrasts with traditional through-hole technology, where components are inserted into holes in the board. The advantages of surface mount technology (SMT) include:

- Higher Component Density: SMT allows for more components to be placed on a smaller area, which is essential for modern electronic devices.

- Automated Assembly: The process is highly automated, reducing labor costs and increasing production speed.

- Improved Performance: SMT components typically have better electrical performance due to shorter lead lengths.

Factors Influencing Surface Mount Assembly Costs

Component Type and Quantity

The type and quantity of components used in a PCB design significantly impact assembly costs. Surface mount devices (SMDs) are generally more expensive to assemble than through-hole components due to the additional equipment and processes required. For instance, specialized components or those requiring unique handling can increase costs.

Complexity of the PCB Design

More complex designs with intricate layouts or a higher number of components will naturally incur higher assembly costs. The need for advanced machinery and skilled labor to handle these complexities can add to the overall expense.

Production Volume

The volume of production plays a critical role in determining costs. Higher production volumes typically lead to lower per-unit costs due to economies of scale. Conversely, low-volume production runs may result in higher costs per unit.

Assembly Process

The specific assembly process used can also affect costs. Automated processes, such as pick-and-place machines, are generally more cost-effective for high-volume production. However, if manual assembly is required for certain components, this can increase labor costs.

Quality Control and Testing

Quality assurance is vital in electronics manufacturing. The costs associated with testing and inspection processes can vary significantly based on the complexity of the product and the level of quality assurance required.

Cost Breakdown of Surface Mount Assembly in 2024

In 2024, the average cost of surface mount assembly can vary widely based on the factors mentioned above. Here's a general breakdown of costs:

- Setup Costs: These can range from $500 to $5,000, depending on the complexity of the assembly and the equipment required.

- Per-Unit Costs: For low-volume production, costs can range from $0.10 to $1.00 per component. For high-volume runs, this can drop to $0.05 or less per component.

- Testing and Quality Control: This can add an additional $0.01 to $0.10 per unit, depending on the testing methods used.

Example Cost Scenarios

1. Low-Volume Production: A small batch of 100 units with a simple design might cost around $1,500 to $2,000 for assembly.

2. Medium-Volume Production: A run of 1,000 units with moderate complexity could range from $5,000 to $10,000.

3. High-Volume Production: For 10,000 units with a straightforward design, costs might drop to $20,000 or less.

The Future of Surface Mount Assembly Costs

As technology continues to advance, the costs associated with surface mount assembly are expected to evolve. Innovations in automation, materials, and processes will likely lead to further reductions in costs, particularly for high-volume production. Additionally, the growing demand for smaller, more complex electronic devices will drive the need for efficient assembly solutions.

Conclusion

In summary, the costs associated with surface mount assembly in 2024 are influenced by various factors, including component type, PCB complexity, production volume, and quality control measures. Businesses looking to budget for surface mount assembly should consider these factors carefully to ensure they are prepared for the financial implications of their manufacturing needs.

As the industry continues to evolve, staying informed about trends and advancements in surface mount technology will be crucial for companies aiming to remain competitive in the electronics market.

FAQ

1. What is surface mount assembly?

Surface mount assembly is a method of placing electronic components directly onto the surface of a printed circuit board (PCB), allowing for higher component density and automated production.

2. How does the complexity of a PCB design affect assembly costs?

More complex PCB designs require advanced machinery and skilled labor, leading to higher assembly costs compared to simpler designs.

3. What are the average costs for surface mount assembly in 2024?

Costs can vary widely, with setup costs ranging from $500 to $5,000 and per-unit costs from $0.05 to $1.00, depending on production volume and complexity.

4. How does production volume impact costs?

Higher production volumes typically lead to lower per-unit costs due to economies of scale, while low-volume runs may incur higher costs per unit.

5. What role does quality control play in assembly costs?

Quality control is essential in electronics manufacturing and can add an additional $0.01 to $0.10 per unit, depending on the testing methods used.