Content Menu

● Understanding SMT Technology

>> Benefits of SMT Lines

● Cost Breakdown of Setting Up an SMT Line in Noida

>> 1. Equipment Costs

>> 2. Installation and Setup Costs

>> 3. Operational Costs

>> 4. Regulatory and Compliance Costs

>> 5. Facility Costs

● Factors Influencing the Cost of SMT Lines in Noida

>> 1. Production Volume

>> 2. Technology Level

>> 3. Customization Needs

>> 4. Location and Infrastructure

>> 5. Market Conditions

● The Importance of Choosing the Right Equipment

● Conclusion

● FAQs

>> 1. What is the average cost of setting up an SMT line in Noida?

>> 2. What are the main components of an SMT line?

>> 3. How long does it take to set up an SMT line?

>> 4. Are there any ongoing costs after setting up an SMT line?

>> 5. What are the benefits of using SMT technology?

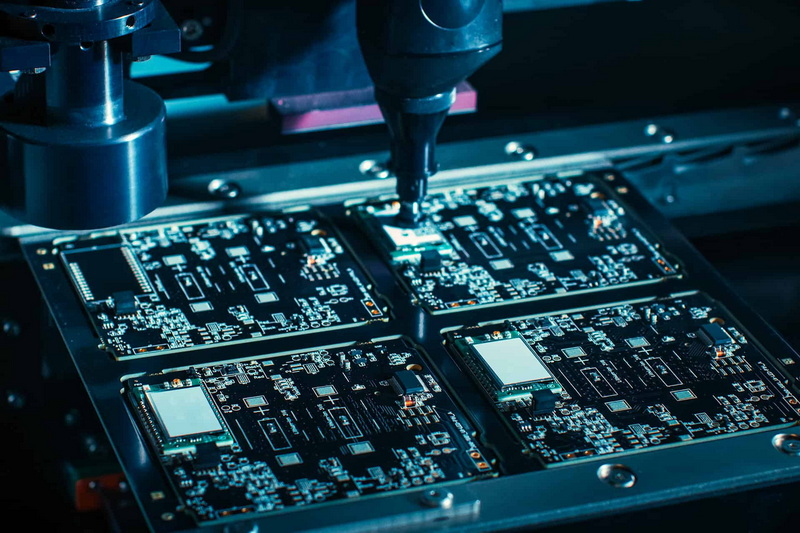

Setting up a Surface Mount Technology (SMT) line in Noida can be a significant investment for businesses looking to enhance their manufacturing capabilities. This article will explore the costs associated with establishing an SMT line, the factors influencing these costs, and the overall benefits of investing in such technology.

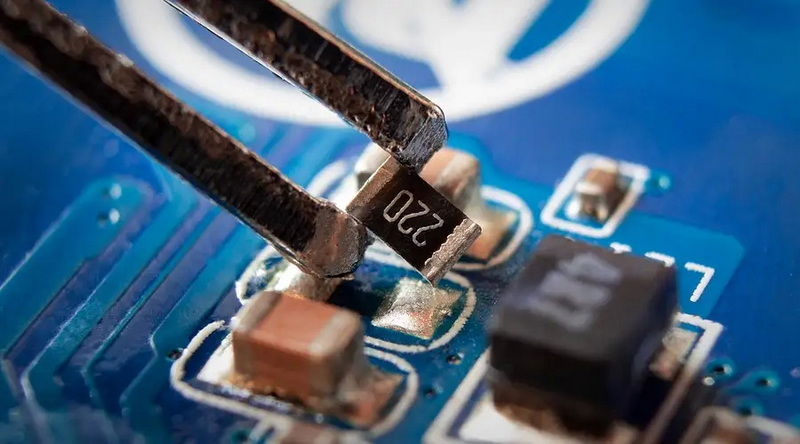

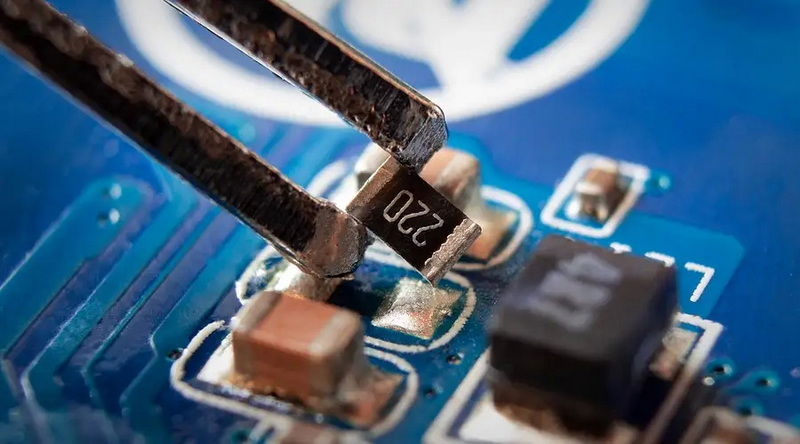

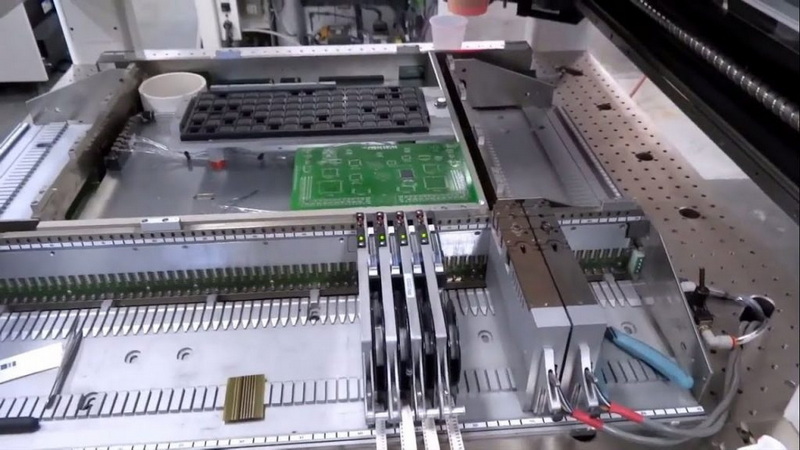

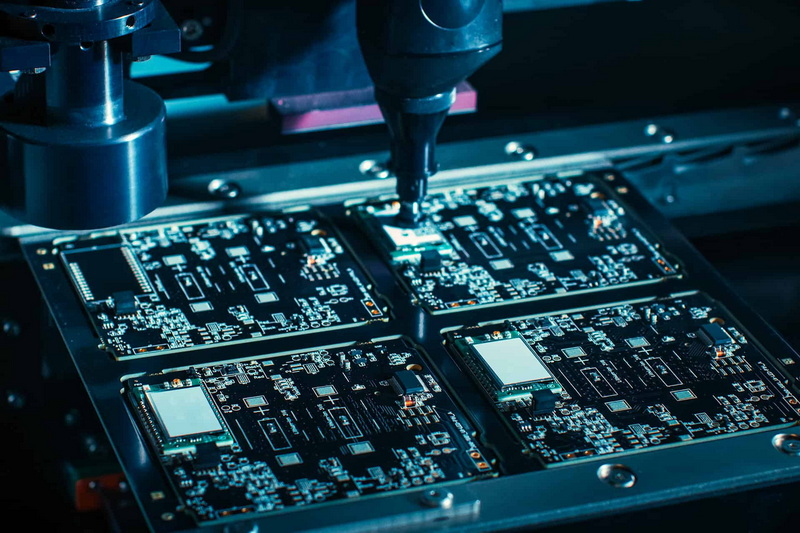

Understanding SMT Technology

Surface Mount Technology (SMT) is a method used to produce electronic circuits in which components are mounted directly onto the surface of printed circuit boards (PCBs). This technology has revolutionized the electronics manufacturing industry by allowing for smaller, more efficient designs and faster production times.

Benefits of SMT Lines

1. Higher Efficiency: SMT lines can produce more units in less time compared to traditional through-hole technology.

2. Reduced Size and Weight: SMT components are generally smaller and lighter, allowing for more compact designs.

3. Cost-Effectiveness: Although the initial setup cost can be high, the long-term savings in labor and materials can offset these expenses.

4. Improved Reliability: SMT components are less prone to mechanical stress and damage, leading to higher reliability in electronic devices.

5. Flexibility in Design: SMT allows for more complex circuit designs, enabling manufacturers to innovate and create advanced electronic products.

Cost Breakdown of Setting Up an SMT Line in Noida

The cost of setting up an SMT line in Noida can vary widely based on several factors, including the complexity of the line, the type of equipment used, and the scale of production. Here's a detailed breakdown:

1. Equipment Costs

The primary expense in setting up an SMT line is the equipment. The cost can range from $100,000 to $8 million depending on the specifications and capabilities of the machines. Here are some key components:

- Solder Paste Printer: $20,000 - $100,000

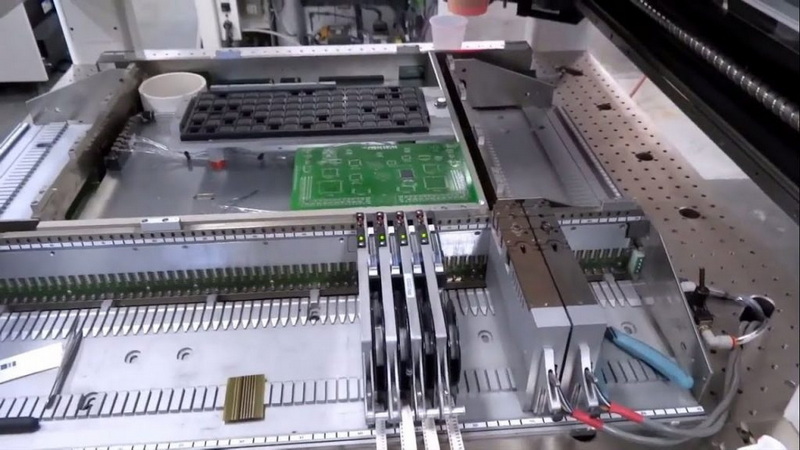

- Pick and Place Machine: $50,000 - $500,000

- Reflow Oven: $30,000 - $200,000

- Inspection Equipment: $10,000 - $100,000

- Conveyor Systems: $10,000 - $50,000

Each of these components plays a crucial role in the SMT process, and the choice of equipment can significantly impact the overall cost and efficiency of the line.

2. Installation and Setup Costs

Once the equipment is purchased, installation and setup costs must be considered. This can include:

- Site Preparation: Ensuring the facility meets the necessary standards for an SMT line, including proper ventilation, temperature control, and cleanliness.

- Installation Fees: Hiring professionals to install and calibrate the equipment, which can range from $5,000 to $50,000 depending on the complexity of the setup.

- Training Costs: Training staff to operate the new machinery effectively, which can cost between $1,000 and $10,000 depending on the number of employees and the depth of training required.

3. Operational Costs

After the SMT line is set up, ongoing operational costs will include:

- Labor Costs: Wages for operators and technicians, which can vary based on the skill level required. In Noida, skilled labor costs can range from $300 to $1,000 per month per employee.

- Maintenance Costs: Regular maintenance to keep the machines running efficiently, typically around 5-10% of the initial equipment cost annually.

- Material Costs: Costs for components and PCBs, which can fluctuate based on market conditions and supplier agreements.

4. Regulatory and Compliance Costs

In India, businesses must comply with various regulations, which can add to the overall cost. This includes obtaining necessary licenses and ensuring that the facility meets environmental and safety standards. Compliance costs can range from $1,000 to $10,000 depending on the specific requirements.

5. Facility Costs

The cost of real estate in Noida can also impact the overall investment. Renting or purchasing a facility suitable for an SMT line can range from $5,000 to $20,000 per month, depending on the location and size of the facility. Additionally, utilities such as electricity, water, and waste management must be factored into the operational budget.

Factors Influencing the Cost of SMT Lines in Noida

Several factors can influence the total cost of setting up an SMT line:

1. Production Volume

Higher production volumes typically require more advanced and expensive equipment. A line designed for high-volume production will have a higher initial cost but can lead to lower per-unit costs. Businesses must analyze their expected production needs to determine the appropriate scale of investment.

2. Technology Level

The level of technology used in the SMT line can significantly impact costs. Advanced machines with automation capabilities will be more expensive but can improve efficiency and reduce labor costs. For instance, fully automated pick and place machines can increase production speed and accuracy, justifying their higher price.

3. Customization Needs

If a business requires customized solutions for specific products, this can increase costs. Customization may involve additional engineering and design work, which can add thousands of dollars to the initial investment. Companies should assess their product lines to determine if customization is necessary.

4. Location and Infrastructure

The cost of real estate and infrastructure in Noida can also affect the overall investment. A well-located facility may have higher rental or purchase costs but can provide better access to suppliers and customers. Proximity to transportation hubs can also reduce logistics costs.

5. Market Conditions

Fluctuations in the electronics market can impact the cost of components and materials. Businesses should stay informed about market trends and potential supply chain disruptions that could affect their operational costs.

The Importance of Choosing the Right Equipment

Selecting the right equipment for an SMT line is crucial for maximizing efficiency and minimizing costs. Businesses should consider the following when choosing equipment:

- Compatibility: Ensure that all equipment is compatible with each other and can handle the specific components being used.

- Scalability: Choose equipment that can be scaled up or down based on changing production needs.

- Supplier Reputation: Work with reputable suppliers who offer reliable equipment and support services.

Investing time in research and consultation can lead to better decision-making and ultimately save costs in the long run.

Conclusion

Setting up an SMT line in Noida is a substantial investment that can yield significant returns in efficiency and production capacity. While the initial costs can be high, the long-term benefits often justify the expenditure. Businesses must carefully consider their specific needs, production volumes, and the technology they wish to implement to make informed decisions. By understanding the various costs involved and the factors that influence them, companies can better prepare for the financial commitment required to establish a successful SMT line.

FAQs

1. What is the average cost of setting up an SMT line in Noida?

The average cost can range from $100,000 to $8 million, depending on the complexity and scale of the line.

2. What are the main components of an SMT line?

Key components include a solder paste printer, pick and place machine, reflow oven, inspection equipment, and conveyor systems.

3. How long does it take to set up an SMT line?

The setup time can vary but typically ranges from a few weeks to several months, depending on the complexity of the line and the availability of equipment.

4. Are there any ongoing costs after setting up an SMT line?

Yes, ongoing costs include labor, maintenance, and material costs.

5. What are the benefits of using SMT technology?

Benefits include higher efficiency, reduced size and weight of components, improved reliability, and flexibility in design.