Content Menu

● Understanding SMT PCB Assembly

>> Key Steps in SMT PCB Assembly

● SMT PCB How Many Hours Does Each Step Take?

>> Detailed Time Considerations

● Factors Affecting SMT PCB Assembly Time

>> 1. Design Complexity

>> 2. Batch Size

>> 3. Equipment and Automation Level

>> 4. Component Types

>> 5. Material Availability and Preparation

● Additional Considerations in SMT PCB Assembly Time

>> Setup and Programming Time

>> Rework and Repair

>> Environmental and Process Controls

● Typical Timeframes for SMT PCB Assembly

● Summary Table: SMT PCB How Many Hours?

● Conclusion

● FAQ

>> 1. How long does solder paste printing take in SMT PCB assembly?

>> 2. What affects the pick-and-place time in SMT assembly?

>> 3. How long is the reflow soldering process?

>> 4. Can SMT PCB assembly be completed within 24 hours?

>> 5. Does double-sided SMT assembly take twice as long?

Surface Mount Technology (SMT) PCB assembly is a critical process in modern electronics manufacturing, enabling the placement of tiny components on printed circuit boards (PCBs) with high precision and efficiency. A common question in the industry is: SMT PCB how many hours does it take to complete the assembly? The answer depends on multiple factors including design complexity, production volume, equipment used, and process steps. This article provides a comprehensive overview of the SMT PCB assembly process, the time each step typically requires, and factors influencing the total assembly time.

Understanding SMT PCB Assembly

SMT PCB assembly involves mounting surface mount components (SMCs or SMDs) directly onto the surface of a PCB. Unlike through-hole technology, SMT does not require drilling holes for component leads, allowing for smaller, lighter, and more densely packed boards.

Key Steps in SMT PCB Assembly

1. PCB and Component Preparation

Before assembly, bare PCBs and components are inspected and prepared. Components are sorted into kits based on the Bill of Materials (BOM) and organized for efficient placement.

2. Solder Paste Application

Solder paste is applied to the PCB pads using a stencil printer. This step is critical as the paste acts as both adhesive and solder material.

3. Solder Paste Inspection (SPI)

After printing, the solder paste is inspected using automated optical or 3D inspection machines to ensure correct volume and placement.

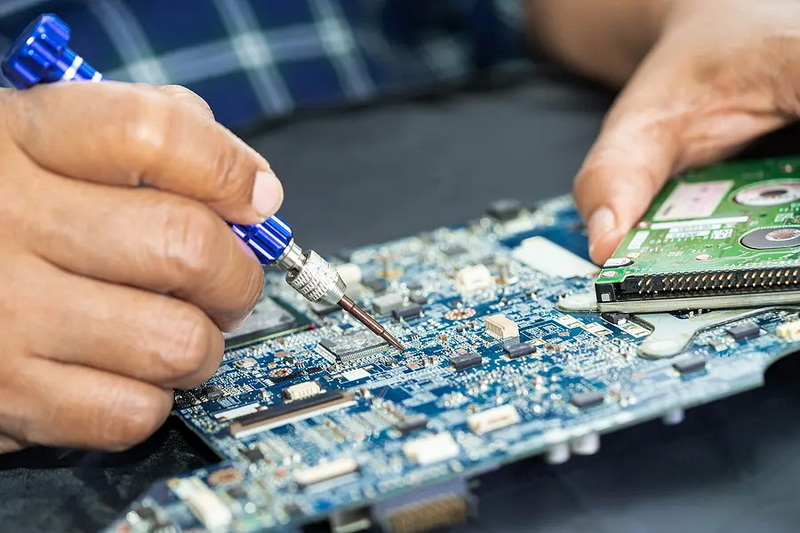

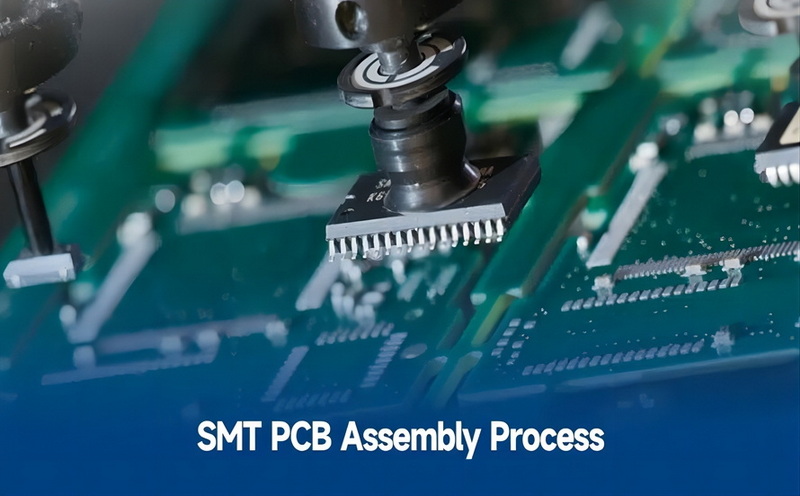

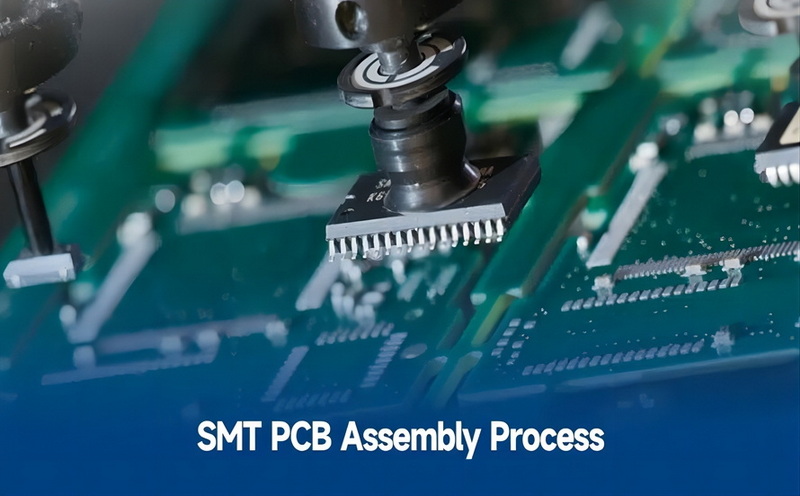

4. Pick and Place Component Mounting

Automated pick-and-place machines place components onto the solder-pasted pads with high speed and accuracy.

5. Reflow Soldering

The PCB passes through a reflow oven where the solder paste melts and solidifies, permanently attaching components.

6. Post-Reflow Inspection

Automated Optical Inspection (AOI) and sometimes X-ray inspection (for BGAs) verify solder joint quality and component placement.

7. Testing and Quality Control

Functional testing, in-circuit testing, and final inspections ensure the assembled PCB meets specifications.

SMT PCB How Many Hours Does Each Step Take?

The total time to complete SMT PCB assembly varies widely depending on the factors below. However, typical time ranges for each step in a standard automated SMT line are:

| SMT Assembly Step | Typical Time per PCB or Batch |

| PCB and Component Preparation | Hours to a day (depends on batch size and complexity) |

| Solder Paste Printing | Seconds to a few minutes per PCB |

| Solder Paste Inspection | Seconds per PCB |

| Pick and Place Mounting | Minutes to hours (depends on component count and machine speed) |

| Reflow Soldering | 10 to 20 minutes per batch |

| Post-Reflow Inspection | Minutes per PCB |

| Testing and Quality Control | Minutes to hours (depends on test complexity) |

Detailed Time Considerations

- Solder Paste Printing: This is a fast process, typically taking less than a minute per PCB. The stencil printer applies solder paste precisely and quickly.

- Pick and Place: This is often the most time-consuming step. The speed depends on the number of components, their sizes, and the pick-and-place machine's capability. High-speed machines can place thousands of components per hour, but complex boards with many components can take several hours.

- Reflow Soldering: The reflow oven cycle usually lasts between 10 to 20 minutes, depending on the oven type and solder paste profile.

- Inspection and Testing: Automated inspections are fast, but manual inspections or functional testing can add significant time, especially for complex or prototype boards.

Factors Affecting SMT PCB Assembly Time

1. Design Complexity

- Boards with a high component count or multiple component types require longer pick-and-place times.

- Double-sided SMT assembly doubles the process time as both sides need solder paste application, component placement, and reflow.

2. Batch Size

- Small prototype batches may take longer per unit due to setup and programming time.

- Large volume production benefits from automation and parallel processing, reducing per-unit assembly time.

3. Equipment and Automation Level

- Advanced pick-and-place machines with multiple heads and feeders increase speed.

- Automated inspection and testing reduce manual labor and errors, speeding up the process.

4. Component Types

- Smaller components like 0201 resistors are harder and slower to place.

- Complex components like BGAs require additional inspection steps (X-ray), adding time.

5. Material Availability and Preparation

- Delays in component kitting or PCB preparation can extend total assembly time.

Additional Considerations in SMT PCB Assembly Time

Setup and Programming Time

Before production begins, machines must be programmed with the PCB layout and component placement data. This setup phase can take several hours, especially for new or complex designs. For prototype runs, setup time can be a significant portion of total assembly time. In contrast, for high-volume production, setup time is amortized over many units, reducing its impact on per-unit assembly time.

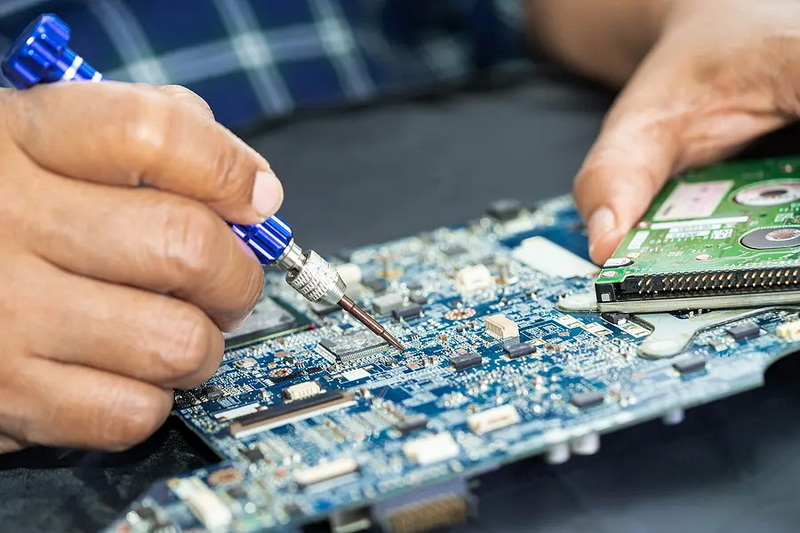

Rework and Repair

Defects detected during inspection may require rework, which adds to total assembly time. The complexity of rework depends on the defect type and component accessibility. For example, replacing a small resistor is quicker than reworking a fine-pitch BGA. Minimizing defects through process control reduces rework time and improves overall throughput.

Environmental and Process Controls

Maintaining optimal environmental conditions such as temperature and humidity is essential for consistent solder paste performance and component placement accuracy. Variations can cause defects, leading to longer assembly times due to troubleshooting and rework.

Typical Timeframes for SMT PCB Assembly

- Prototype or Small Batch:

Assembly can take from several hours to a few days, including setup, programming, and manual inspections.

- Medium to Large Volume Production:

Automated lines can assemble PCBs in a matter of hours or less per batch, with turnaround times as fast as 24 to 72 hours for full turnkey assembly.

- Expedited Services:

Some manufacturers offer rapid SMT assembly with turnaround times as short as 24 to 48 hours, depending on complexity and volume.

Summary Table: SMT PCB How Many Hours?

| Production Scale | Typical SMT PCB Assembly Time |

| Prototype (1-10 pcs) | 8 to 48 hours (including setup) |

| Small Batch (10-100 pcs) | 1 to 3 days |

| Medium Batch (100-1000 pcs) | 1 to 2 days |

| Large Volume (>1000 pcs) | Hours to 1 day (high automation) |

Conclusion

The question "SMT PCB how many hours does it take to complete assembly?" does not have a one-size-fits-all answer. The total assembly time depends on design complexity, batch size, equipment, and process steps. Generally, solder paste printing and inspection take minutes, pick-and-place can range from minutes to hours, and reflow soldering takes about 10-20 minutes per batch. For prototypes, the entire process may take up to 48 hours or more, while high-volume automated production can complete assembly in a few hours. Understanding these factors helps manufacturers and designers plan production schedules effectively, optimize costs, and meet delivery deadlines.

FAQ

1. How long does solder paste printing take in SMT PCB assembly?

Solder paste printing typically takes less than a minute per PCB, as the stencil printer quickly applies paste to all pads simultaneously.

2. What affects the pick-and-place time in SMT assembly?

Pick-and-place time depends on the number of components, their sizes, machine speed, and whether the board is single or double-sided.

3. How long is the reflow soldering process?

Reflow soldering usually takes between 10 to 20 minutes per batch, depending on the oven and solder paste profile.

4. Can SMT PCB assembly be completed within 24 hours?

Yes, with advanced automation and streamlined processes, some manufacturers can complete full turnkey SMT PCB assembly within 24 hours for small to medium batches.

5. Does double-sided SMT assembly take twice as long?

Double-sided assembly requires repeating solder paste printing, placement, and reflow for the second side, which can roughly double the assembly time compared to single-sided boards.