Content Menu

● Introduction to Wave Soldering

>> Key Steps in Wave Soldering

● Applications of Wave Soldering

>> Challenges in Wave Soldering for SMT Components

● Advantages of Wave Soldering

● Limitations of Wave Soldering

● Comparison with Reflow Soldering

>> Key Differences Between Wave and Reflow Soldering

● Innovations and Trends in Wave Soldering

>> Future of Wave Soldering

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary use of wave soldering in PCB assembly?

>> 2. Can wave soldering be used for SMT components?

>> 3. What are the advantages of wave soldering over reflow soldering?

>> 4. What are the limitations of wave soldering?

>> 5. How does wave soldering compare to selective soldering?

● Citations:

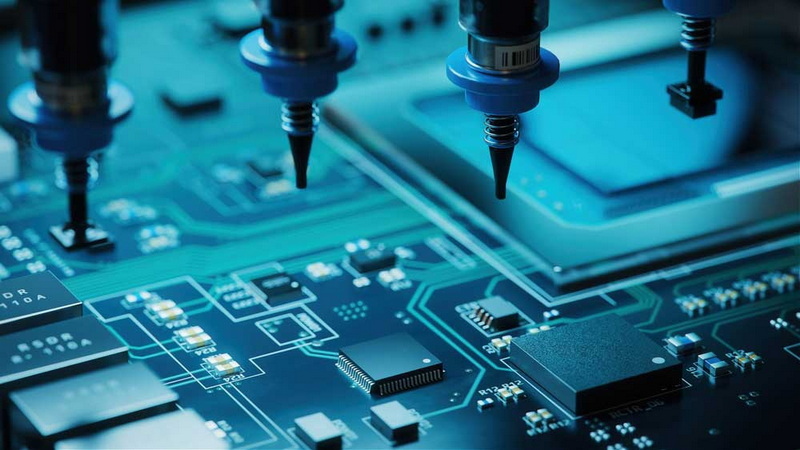

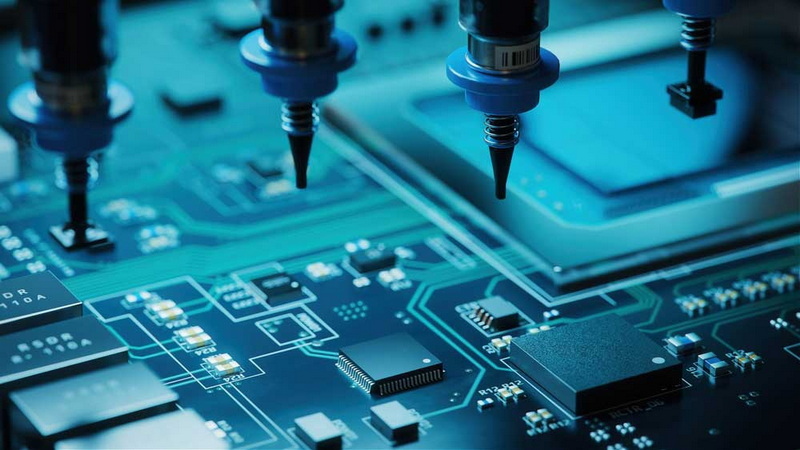

Wave soldering is a widely used technique in the assembly of printed circuit boards (PCBs), particularly for through-hole components. This method involves passing the PCB over a wave of molten solder to create robust connections between components and the board. In this article, we will delve into the process of wave soldering, its applications, advantages, and limitations, as well as compare it with other soldering techniques like reflow soldering.

Introduction to Wave Soldering

Wave soldering was developed in the mid-20th century as a response to the need for efficient mass soldering of electronic components onto PCBs. Before its introduction, most soldering was done manually, which was time-consuming and prone to errors. The wave soldering process involves several key steps: applying flux, preheating the PCB, passing the board over a wave of molten solder, and cooling the assembly to solidify the solder joints.

Key Steps in Wave Soldering

1. Flux Application: The first step involves applying a layer of solder flux to the bottom side of the PCB. Flux is a chemical agent that helps remove oxidation from the metal surfaces, ensuring better solder flow and adhesion. It is typically applied using a sprayer or foam applicator to evenly coat the solder pads and component leads.

2. Preheating: After flux application, the PCB is preheated to a temperature between 80°C and 100°C. This step is crucial for evaporating the solvents in the flux and activating its properties. Preheating also helps prevent thermal shock when the PCB comes into contact with the molten solder.

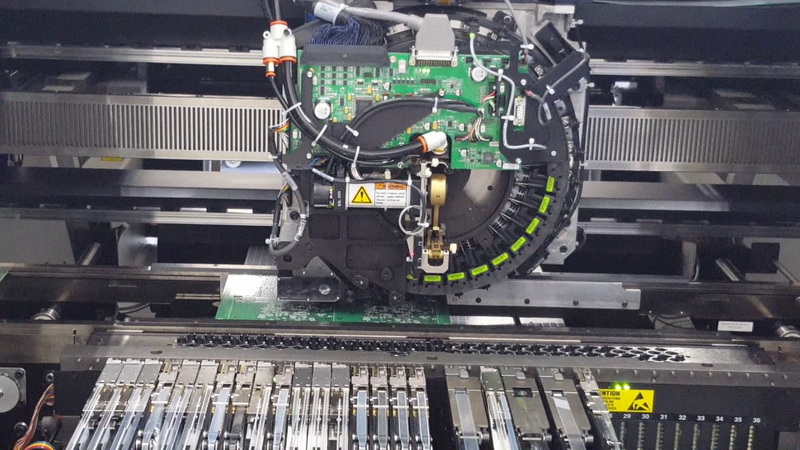

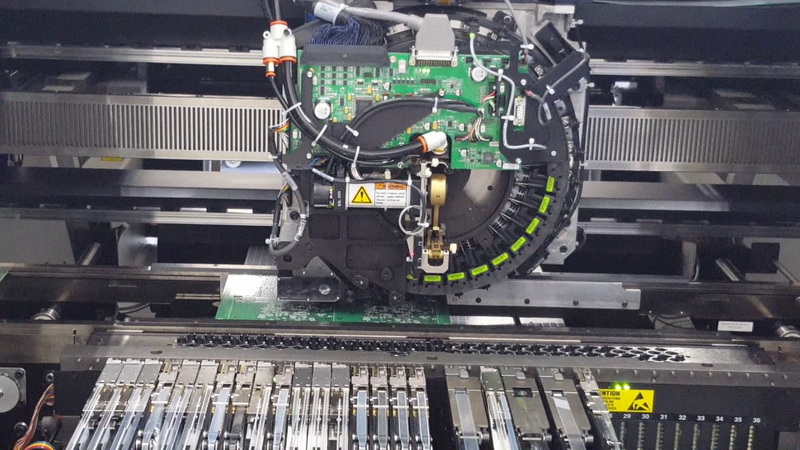

3. Wave Soldering: The PCB is then passed over a wave of molten solder, which is maintained at a temperature around 250°C. The solder wave is created by a pump submerged in the solder bath, and it flows under the PCB, soldering the component leads to the board.

4. Cooling: Finally, the PCB is cooled gradually to solidify the solder joints. This cooling process is important to prevent sudden temperature changes that could cause stress on the PCB or components.

Applications of Wave Soldering

Wave soldering is primarily used for through-hole technology (THT) components, which have leads that pass through holes in the PCB. This method is effective for mass-producing PCBs with THT components because it can solder multiple connections simultaneously, ensuring efficiency and consistency.

However, wave soldering can also be used for surface mount technology (SMT) components under certain conditions. For SMT components, a technique called SMT wave soldering is used, where components are glued to the PCB before soldering. This method is less common due to the risk of overheating and solder bridging. Specialized equipment and techniques, such as using inert environments and hot nitrogen knives, can help mitigate these issues by reducing oxidation and preventing solder bridging[7].

Challenges in Wave Soldering for SMT Components

- Component Density: With the increasing density of components on PCBs, wave soldering requires precise adjustments in soldering parameters to ensure each joint is fully melted without causing damage[3].

- Surface Treatment: Proper surface treatment is crucial to ensure good solderability. This includes chemical cleaning and mechanical polishing to remove contaminants and oxides[3].

Advantages of Wave Soldering

- Efficiency: Wave soldering allows for the simultaneous soldering of multiple components, making it highly efficient for mass production.

- Cost-Effectiveness: Compared to other soldering techniques, wave soldering can be more cost-effective, especially for large-scale production.

- No Masking Required: Unlike some other methods, wave soldering does not require masking off areas of the PCB that do not need soldering, saving time and resources.

Limitations of Wave Soldering

- Limited Applicability to SMT: Wave soldering is not ideal for fine-pitch SMT components due to the risk of solder bridging and component overheating.

- Potential Component Damage: Sensitive components can be damaged by the high temperatures involved in wave soldering.

- Dominance of SMT: As electronics continue to miniaturize, SMT components are becoming more prevalent, reducing the demand for wave soldering.

Comparison with Reflow Soldering

Reflow soldering is another common technique used in PCB assembly, particularly for SMT components. It involves applying solder paste to the PCB pads, placing components, and then heating the assembly in an oven to melt the solder. Reflow soldering is more suitable for SMT components due to its ability to handle fine-pitch parts and its lower risk of overheating components.

Key Differences Between Wave and Reflow Soldering

| Feature | Wave Soldering | Reflow Soldering |

| Components | Primarily THT, can be used for SMT under specific conditions | Primarily SMT, can be used for THT |

| Process | PCB passes over a wave of molten solder | Solder paste is melted in an oven |

| Temperature Control | Molten solder at around 250°C | Oven temperature controlled to melt solder paste |

| Efficiency | Efficient for mass production of THT components | Efficient for SMT components |

| Cost | Generally more cost-effective for THT | More expensive than wave soldering for THT |

Innovations and Trends in Wave Soldering

Recent innovations in wave soldering include the use of inert environments to improve solderability and reduce oxidation. Techniques like using hot nitrogen knives help prevent solder bridging by removing excess solder from the joints[7]. Additionally, there is a growing focus on automation and precision in PCB assembly processes, with advancements in machine learning and AI being integrated to optimize workflows and detect defects[4].

Future of Wave Soldering

As the electronics industry continues to evolve, wave soldering will remain relevant for specific applications, particularly in industries where through-hole components are still prevalent. However, the trend towards miniaturization and the increasing use of SMT components mean that reflow soldering will continue to dominate in many sectors.

Conclusion

Wave soldering remains a vital technique in PCB assembly, particularly for through-hole components. Its efficiency and cost-effectiveness make it suitable for mass production. However, its limitations with fine-pitch SMT components and potential for component damage mean that reflow soldering is often preferred for surface mount technology. As technology advances, the choice between wave and reflow soldering will depend on the specific requirements of the PCB design and the components involved.

Frequently Asked Questions

1. What is the primary use of wave soldering in PCB assembly?

Wave soldering is primarily used for soldering through-hole components onto PCBs. It is highly efficient for mass-producing PCBs with THT components.

2. Can wave soldering be used for SMT components?

Yes, wave soldering can be used for SMT components, but it is less common due to the risk of overheating and solder bridging. Special techniques like gluing components to the PCB are used in such cases.

3. What are the advantages of wave soldering over reflow soldering?

Wave soldering is more cost-effective for large-scale production of THT components and does not require masking off areas of the PCB. It also allows for simultaneous soldering of multiple connections.

4. What are the limitations of wave soldering?

Wave soldering is not ideal for fine-pitch SMT components due to the risk of solder bridging and component overheating. It also has limited applicability to sensitive components.

5. How does wave soldering compare to selective soldering?

Wave soldering is a batch process suitable for mass production, whereas selective soldering is more precise and can target specific areas on the PCB. Selective soldering offers better control and is useful for mixed assemblies with both THT and SMT components.

Citations:

[1] https://riversideintegratedsolutions.com/n/pcba-soldering-techniques/

[2] https://iconnect007.com/index.php/article/51691/continuous-improvement-approaches-for-wave-soldering/51694?skin=smt

[3] https://www.neodensmt.com/news/problems-and-solutions-of-wave-soldering-78252912.html

[4] https://rootsems.com/future-of-electronics-manufacturing-emerging-trends-in-2025/

[5] https://pcb-copy.com/wave-soldering-the-ultimate-guide-to-effective-soldering/

[6] https://www.odyssey-oei.com/pcb-assembly-process/wave-solder-selective-solder.html

[7] https://www.airproducts.com/-/media/files/en/450/450-10-023-glb-optimizing-inert-wave-soldering-process-hot-nitrogen-knives.pdf

[8] https://www.mclpcb.com/blog/wave-soldering-issues/

[9] https://unitedpacificinc.com/articles/future-of-pcb-manufacturing-2024/

[10] https://www.vexos.com/2018/07/31/best-practices-in-manufacturing-wave-soldering/

[11] https://www.ipc.org/system/files/technical_resource/E18&S17-3.pdf

[12] https://jlcpcb.com/blog/how-to-solve-common-wave-soldering-defects

[13] https://www.aimsolder.com/wp-content/uploads/legacy-files/documents/wave_ts.pdf

[14] https://www.pcbpower.us/blog/top-trends-pcb-assembly

[15] https://www.vse.com/blog/2023/10/25/wave-soldering-placement-guidelines/

[16] https://blog.picamfg.com/advanced-soldering-techniques-for-printed-circuit-board-assembly

[17] https://shop.isixsigma.com/products/wave-solder-process-improvement-project-example

[18] https://www.epectec.com/pcb/wave-soldering-defects/

[19] https://www.linkedin.com/pulse/wave-soldering-system-market-future-trends-2024-size-mp0cc/

[20] https://www.ourpcb.com/wave-soldering.html