Content Menu

● Introduction

● Understanding THT PCB Assembly

>> What is THT PCB Assembly?

>> The THT PCB Assembly Process

● THT vs. SMT: A Comparative Analysis

>> Surface Mount Technology (SMT)

>> Key Differences

● Impact of THT PCB Assembly on Circuit Performance

>> Mechanical Strength

>> Thermal Management

>> Electrical Performance

>> Reliability and Longevity

● Applications Where THT PCB Assembly Excels

>> High-Power Electronics

>> Prototyping and Low-Volume Production

>> Harsh Environment Applications

>> Mixed Technology Boards

● Challenges and Considerations in THT PCB Assembly

>> Space Constraints

>> Assembly Time and Cost

>> Component Availability

>> Automated Assembly Limitations

● Future Trends and Innovations in THT PCB Assembly

>> Hybrid Assembly Techniques

>> Improved Automation

>> Enhanced Materials and Components

>> Sustainability and Recyclability

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main differences between THT and SMT PCB assembly?

>> 2. When should I choose THT PCB assembly over SMT?

>> 3. How does THT PCB assembly affect the thermal management of a circuit?

>> 4. Can THT and SMT components be used on the same PCB?

>> 5. What are the future trends in THT PCB assembly?

Introduction

In the ever-evolving world of electronics, Printed Circuit Boards (PCBs) serve as the backbone of countless devices. Among the various assembly techniques, Through-Hole Technology (THT) PCB assembly has been a stalwart method for decades. This article delves into the intricacies of THT PCB assembly and its impact on circuit performance, comparing it with other techniques like Surface Mount Technology (SMT) and exploring its relevance in the age of miniaturization.

Understanding THT PCB Assembly

What is THT PCB Assembly?

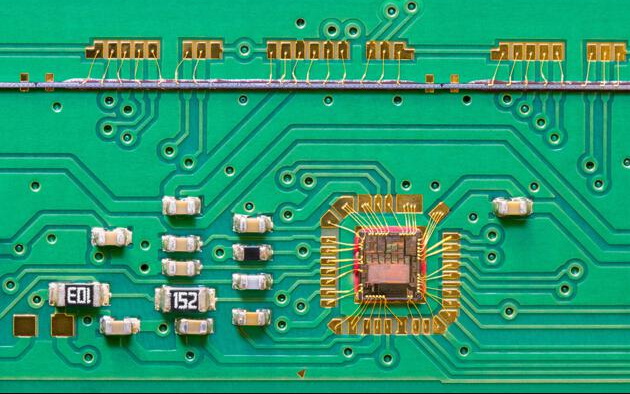

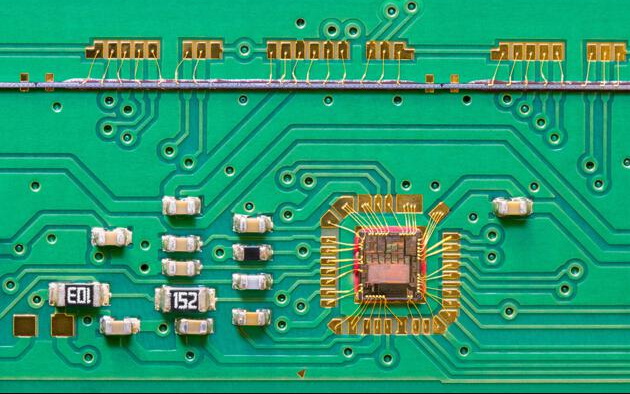

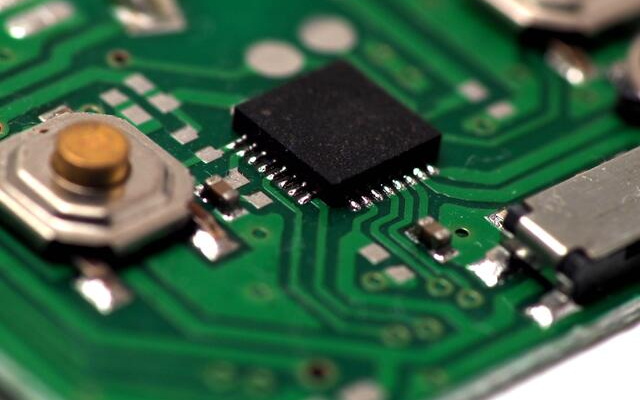

Through-Hole Technology (THT) PCB assembly is a method of mounting electronic components on a printed circuit board by inserting their leads through pre-drilled holes in the board and soldering them on the opposite side. This technique has been used since the early days of electronics manufacturing and continues to play a crucial role in certain applications today.

The THT PCB Assembly Process

1. Hole Drilling: Precise holes are drilled in the PCB at designated locations.

2. Component Insertion: Electronic components are manually or automatically inserted into the holes.

3. Wave Soldering: The board is passed over a wave of molten solder, securing the components.

4. Inspection and Cleaning: The assembled board is inspected for quality and cleaned of excess flux.

THT vs. SMT: A Comparative Analysis

Surface Mount Technology (SMT)

SMT is a more recent PCB assembly technique where components are mounted directly onto the surface of the board. It has gained popularity due to its ability to accommodate higher component densities and smaller form factors.

Key Differences

1. Component Size: THT components are generally larger than their SMT counterparts.

2. Board Real Estate: SMT allows for higher component density, while THT requires more board space.

3. Assembly Process: THT typically involves more manual labor, whereas SMT is more automated.

4. Reliability: THT connections are often considered more robust, especially in high-stress environments.

Impact of THT PCB Assembly on Circuit Performance

Mechanical Strength

One of the primary advantages of THT PCB assembly is the superior mechanical strength it offers. The through-hole connections provide a stronger physical bond between the component and the board, making THT assemblies more resistant to shock and vibration. This characteristic is particularly valuable in applications such as automotive electronics, aerospace, and industrial machinery where devices are subjected to harsh environmental conditions.

Thermal Management

THT components often have better thermal characteristics compared to their SMT counterparts. The larger size of THT components allows for better heat dissipation, which can be crucial in high-power applications. Additionally, the through-hole connections themselves can act as heat sinks, helping to distribute heat more effectively across the board.

Electrical Performance

The impact of THT PCB assembly on electrical performance is multifaceted:

1. Signal Integrity: THT connections can provide better signal integrity in certain high-frequency applications due to their robust nature and lower parasitic capacitance.

2. Power Handling: THT components are generally better suited for high-power applications due to their larger size and better heat dissipation capabilities.

3. Impedance Control: While SMT allows for more precise impedance control in high-speed circuits, THT can still be effective in many applications where extreme precision is not required.

Reliability and Longevity

THT PCB assemblies are known for their long-term reliability. The stronger mechanical connections make them less susceptible to issues like thermal cycling and mechanical stress. This reliability factor is crucial in applications where long-term performance is paramount, such as in medical devices, critical infrastructure, and military equipment.

Applications Where THT PCB Assembly Excels

High-Power Electronics

In applications requiring high power handling, such as power supplies, amplifiers, and motor controllers, THT PCB assembly often remains the preferred choice. The ability to use larger components and the superior heat dissipation characteristics make THT ideal for managing high currents and voltages.

Prototyping and Low-Volume Production

THT PCB assembly is particularly well-suited for prototyping and low-volume production runs. The ease of manual assembly and the ability to easily replace components make THT an excellent choice for experimental designs and small-scale manufacturing.

Harsh Environment Applications

In environments where devices are subjected to extreme temperatures, vibrations, or mechanical stress, THT PCB assemblies often outperform their SMT counterparts. Industries such as automotive, aerospace, and industrial automation frequently rely on THT for critical components.

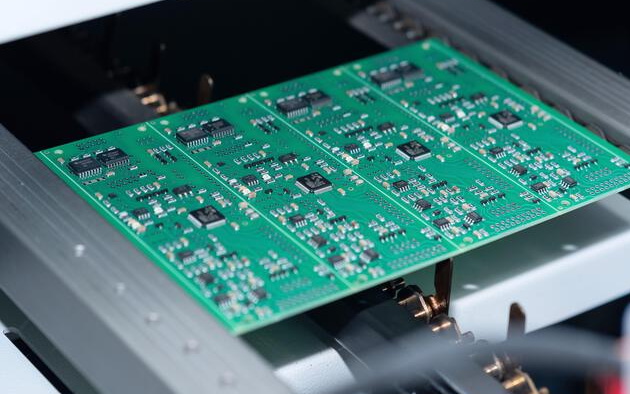

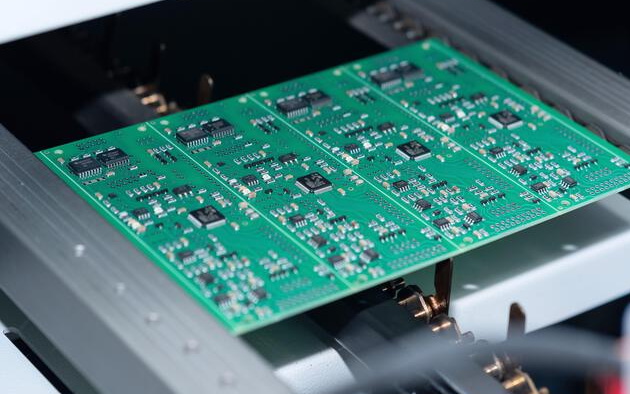

Mixed Technology Boards

Many modern PCB designs incorporate both THT and SMT components, leveraging the strengths of each technology. This hybrid approach allows designers to use THT for high-power or high-reliability components while taking advantage of SMT for high-density, low-power sections of the circuit.

Challenges and Considerations in THT PCB Assembly

Space Constraints

One of the primary challenges with THT PCB assembly is the larger footprint required for components. As electronic devices continue to shrink, fitting THT components into compact designs becomes increasingly difficult. This limitation has led to the widespread adoption of SMT in consumer electronics and portable devices.

Assembly Time and Cost

THT PCB assembly often requires more manual labor compared to highly automated SMT processes. This can lead to increased assembly time and higher production costs, especially for high-volume manufacturing. However, for low-volume production or prototyping, the initial setup costs for THT can be lower than those for SMT.

Component Availability

As the electronics industry increasingly shifts towards SMT, the availability of certain THT components may become limited. Designers must consider long-term component availability when choosing THT for new designs, especially for products with long lifecycles.

Automated Assembly Limitations

While automated insertion machines exist for THT components, they are generally less flexible and efficient compared to SMT pick-and-place machines. This can limit the speed and scalability of THT PCB assembly in high-volume production environments.

Future Trends and Innovations in THT PCB Assembly

Hybrid Assembly Techniques

The future of PCB assembly likely lies in the continued development of hybrid techniques that combine the strengths of both THT and SMT. Advanced manufacturing processes are being developed to seamlessly integrate these technologies, allowing designers to optimize their circuits for both performance and manufacturability.

Improved Automation

Efforts are ongoing to enhance automation in THT PCB assembly. New machines and techniques are being developed to increase the speed and efficiency of through-hole component insertion and soldering, potentially narrowing the gap with SMT in terms of production efficiency.

Enhanced Materials and Components

Research into new materials and component designs may lead to THT components that offer improved performance while addressing some of the current limitations. This could include smaller THT components with better thermal properties or new board materials that enhance the electrical characteristics of through-hole connections.

Sustainability and Recyclability

As environmental concerns become increasingly important, the electronics industry is exploring ways to make PCB assembly more sustainable. THT PCB assembly may have advantages in terms of repairability and component replacement, potentially extending the lifespan of electronic devices and reducing electronic waste.

Conclusion

Through-Hole Technology (THT) PCB assembly continues to play a vital role in the electronics industry, offering unique advantages in terms of mechanical strength, thermal management, and reliability. While Surface Mount Technology (SMT) has become dominant in many areas due to its ability to accommodate higher component densities, THT remains the preferred choice for certain applications, particularly those involving high power, harsh environments, or where long-term reliability is critical.

The impact of THT PCB assembly on circuit performance is significant, affecting aspects such as signal integrity, power handling, and overall reliability. As the electronics industry continues to evolve, the future of PCB assembly likely lies in hybrid approaches that leverage the strengths of both THT and SMT technologies.

Designers and engineers must carefully consider the specific requirements of their applications when choosing between THT and SMT, or when implementing a hybrid approach. By understanding the strengths and limitations of each technology, it's possible to create optimized circuit designs that meet the demands of modern electronic devices while ensuring long-term performance and reliability.

Frequently Asked Questions (FAQ)

1. What are the main differences between THT and SMT PCB assembly?

THT (Through-Hole Technology) and SMT (Surface Mount Technology) are two primary methods of PCB assembly. The main differences include:

- Component Size: THT components are generally larger than SMT components.

- Assembly Process: THT involves inserting component leads through holes in the PCB, while SMT components are placed directly on the board's surface.

- Board Real Estate: SMT allows for higher component density, while THT requires more board space.

- Reliability: THT connections are often considered more robust, especially in high-stress environments.

- Automation: SMT is more conducive to automated assembly, while THT often requires more manual labor.

2. When should I choose THT PCB assembly over SMT?

THT PCB assembly is often preferred in the following situations:

- High-power applications requiring better heat dissipation

- Designs subjected to high mechanical stress or vibration

- Prototyping and low-volume production runs

- Applications requiring extremely high reliability (e.g., aerospace, military)

- When using larger components that are not available in SMT packages

Consider THT when these factors outweigh the need for miniaturization or high-volume production efficiency.

3. How does THT PCB assembly affect the thermal management of a circuit?

THT PCB assembly can positively impact thermal management in several ways:

- Larger Component Size: THT components are generally larger, providing more surface area for heat dissipation.

- Through-Hole Connections: The metal-lined holes can act as heat sinks, helping to distribute heat across the board.

- Better Air Flow: The spacing between THT components often allows for better air circulation.

- Thermal Vias: Through-holes can be used to create thermal vias, enhancing heat transfer between board layers.

These factors make THT PCB assembly particularly suitable for high-power applications where effective heat management is crucial.

4. Can THT and SMT components be used on the same PCB?

Yes, it's common to use both THT and SMT components on the same PCB, known as a mixed-technology or hybrid board. This approach allows designers to:

- Use THT for components requiring high mechanical strength or power handling

- Implement SMT for high-density, low-power sections of the circuit

- Optimize the overall design for performance, size, and cost

- Overcome component availability issues by having flexibility in component choices

However, mixed-technology boards may require more complex assembly processes and careful design consideration to ensure compatibility between the two technologies.

5. What are the future trends in THT PCB assembly?

Several trends are shaping the future of THT PCB assembly:

- Hybrid Assembly Techniques: Continued development of methods to efficiently combine THT and SMT on a single board.

- Improved Automation: Advancements in automated THT component insertion and soldering to increase efficiency.

- Enhanced Materials: Research into new board materials and component designs to improve THT performance and reduce size.

- Sustainability Focus: Exploration of THT's potential advantages in terms of repairability and component replacement for extended product lifecycles.

- Specialized Applications: Continued use and refinement of THT for niche applications where its strengths are particularly valuable.

These trends suggest that while SMT will continue to dominate in many areas, THT will remain an important technology in specific sectors of the electronics industry.