Content Menu

● What is Wholesale PCB SMT Assembly?

● The Complete Wholesale PCB SMT Assembly Process

>> 1. PCB Design and Fabrication

>> 2. Material Procurement and Preparation

>> 3. Solder Paste Application

>> 4. Component Placement (Pick and Place)

>> 5. Reflow Soldering

>> 6. Inspection and Quality Control

>> 7. Through-Hole Component Insertion and Wave Soldering (If Needed)

>> 8. Final Testing and Functional Verification

● Advantages of Wholesale PCB SMT Assembly

● Technology and Equipment in Wholesale PCB SMT Assembly

● Best Practices for Successful Wholesale PCB SMT Assembly

● Conclusion

● FAQ

>> 1. What is the difference between SMT and through-hole assembly?

>> 2. How does solder paste application impact PCB assembly quality?

>> 3. Why is automated inspection important in wholesale PCB SMT assembly?

>> 4. Can wholesale PCB SMT assembly handle complex and small components?

>> 5. What factors influence the cost of wholesale PCB SMT assembly?

The wholesale PCB SMT assembly process is a critical method in modern electronics manufacturing, enabling the efficient production of printed circuit boards (PCBs) with surface mount technology (SMT) components. This process transforms bare PCBs into fully functional electronic assemblies by mounting and soldering components directly onto the board's surface. Understanding how this process works in detail is essential for manufacturers, engineers, and buyers who seek high-quality, cost-effective PCB assemblies at scale.

This article provides a comprehensive overview of the wholesale PCB SMT assembly process, covering each step from design to final testing, highlighting the advantages of wholesale production lines, and addressing common questions.

What is Wholesale PCB SMT Assembly?

Wholesale PCB SMT assembly refers to the large-scale production of PCBs using surface mount technology. SMT involves placing electronic components directly onto the surface of PCBs rather than inserting component leads through holes (as in through-hole technology). Wholesale production implies high-volume manufacturing, often using automated machine lines that streamline the process for speed, efficiency, and quality control.

Wholesale PCB SMT assembly is widely used across industries such as consumer electronics, automotive, telecommunications, medical devices, and industrial equipment. The ability to produce thousands or even millions of assembled PCBs rapidly and consistently makes wholesale SMT assembly indispensable in today's electronics supply chain.

The Complete Wholesale PCB SMT Assembly Process

1. PCB Design and Fabrication

The process begins with the design of the PCB. Engineers use computer-aided design (CAD) software to create the schematic and layout, defining the electrical connections and component placements. The design must consider factors such as signal integrity, thermal management, and manufacturability to ensure optimal performance and assembly yield.

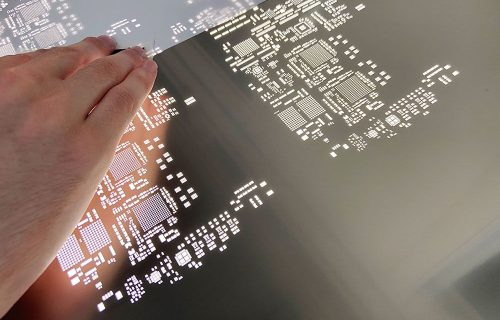

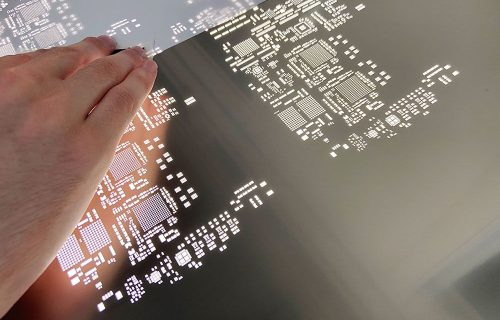

Once the design is finalized, it is sent for fabrication, where the bare PCB is manufactured with copper traces, solder mask, silkscreen, and insulating layers according to the specifications. The fabrication quality directly impacts the assembly process, as issues like incorrect pad sizes or poor surface finish can lead to assembly defects.

2. Material Procurement and Preparation

Before assembly, all required materials are sourced and prepared:

- Components: Resistors, capacitors, integrated circuits, connectors, and other SMT parts are procured from qualified suppliers. Components must be carefully inspected for authenticity and quality to prevent counterfeit parts, which can cause failures.

- Solder Paste: A mixture of tiny solder particles and flux, which will be applied to the PCB pads. The paste's composition and shelf life are critical factors affecting solder joint reliability.

- Stencils: Laser-cut metal sheets that match the PCB layout for precise solder paste application. Stencils are designed to deposit the exact amount of solder paste needed for each pad, considering component size and pitch.

Proper storage and handling of materials are essential to maintain their integrity. For example, moisture-sensitive components require baking or controlled environments to prevent damage during assembly.

3. Solder Paste Application

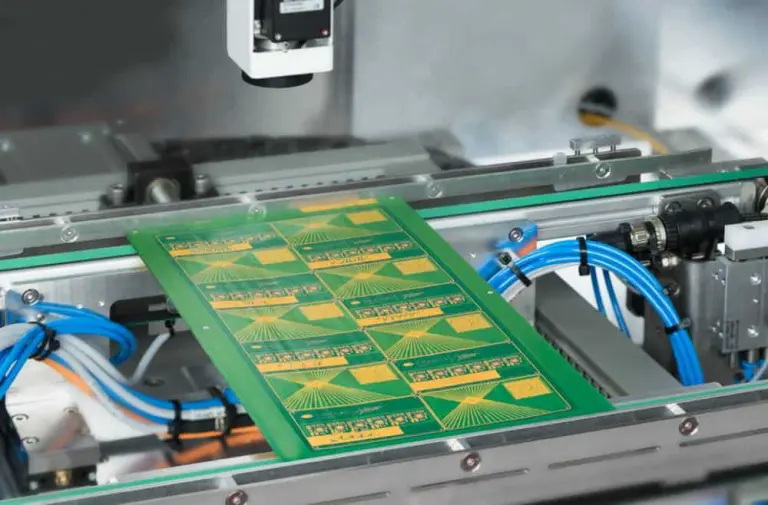

Using a stencil printer, solder paste is applied to the PCB pads where components will be mounted. The stencil aligns perfectly with the PCB, and a squeegee spreads the paste evenly, depositing it only on the designated pads. This step is critical because the quantity and placement of solder paste directly affect solder joint quality.

The solder paste printing process must be tightly controlled. Factors such as squeegee pressure, speed, and stencil cleanliness influence the paste deposition. Defects at this stage, such as insufficient or excessive paste, can cause solder bridging, tombstoning, or weak joints.

4. Component Placement (Pick and Place)

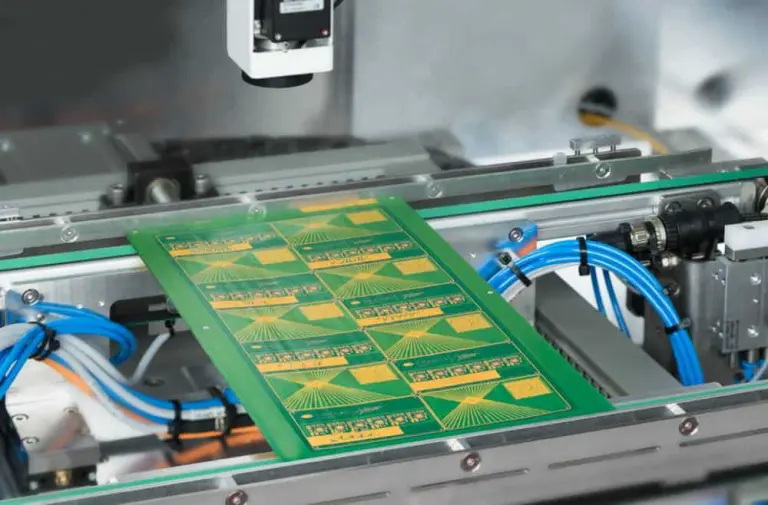

Automated pick-and-place machines then position SMT components onto the solder-pasted PCB. These machines use precise robotic arms and vision systems to place thousands of tiny components rapidly and accurately according to the design layout.

The pick-and-place process involves several sub-steps:

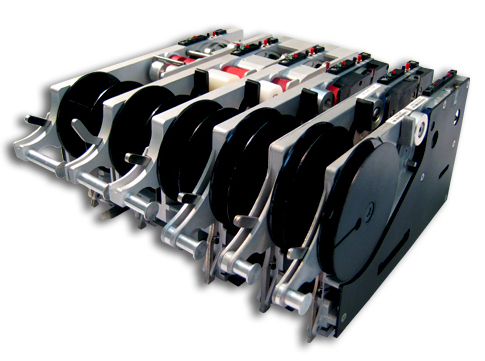

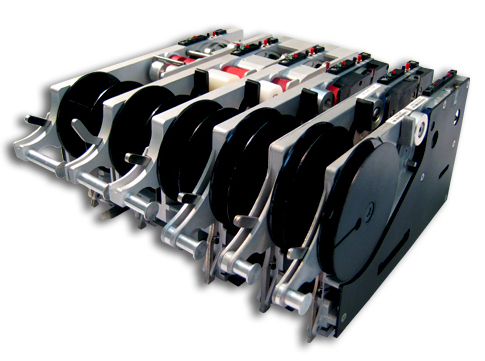

- Feeding Components: Components are loaded into feeders or trays, which supply the machine.

- Vision Alignment: Cameras verify component orientation and position before placement.

- Placement: Robotic nozzles pick components and place them onto the PCB pads with micron-level accuracy.

This automation is key to handling complex boards with high component density in wholesale production. Modern machines can place components ranging from large connectors to tiny passive devices in fractions of a second.

5. Reflow Soldering

Once components are placed, the PCB moves into a reflow oven. The oven heats the board gradually to a temperature that melts the solder paste, forming strong electrical and mechanical connections between components and the PCB pads.

The reflow soldering process follows a carefully controlled temperature profile, including preheat, soak, reflow, and cooling zones. This profile ensures the solder melts and solidifies correctly without damaging components or the PCB substrate.

Different solder paste types (lead-free or leaded) require specific reflow profiles to comply with environmental and reliability standards. The reflow oven may use convection, infrared, or vapor phase heating technologies.

6. Inspection and Quality Control

After soldering, the assembled PCBs undergo inspection to detect defects such as misaligned components, solder bridges, or cold joints. Automated Optical Inspection (AOI) systems use cameras and software to scan the boards, while X-ray inspection can check hidden solder joints under components like BGAs (Ball Grid Arrays).

Inspection is essential for maintaining high quality in wholesale production. Defective boards are either reworked or scrapped, depending on the severity of the issue. Some manufacturers also employ manual visual inspection and functional testing to complement automated methods.

7. Through-Hole Component Insertion and Wave Soldering (If Needed)

If the design includes through-hole components, these are inserted manually or by machines after SMT assembly. The PCB then passes through wave soldering, where molten solder contacts the exposed leads to form joints.

Wave soldering is less common in pure SMT boards but still relevant for mixed technology assemblies that combine SMT and through-hole components. Proper coordination between SMT and through-hole processes is necessary to avoid thermal damage or solder defects.

8. Final Testing and Functional Verification

The last step involves electrical testing to verify that the PCB assembly functions as intended. Tests may include:

- In-Circuit Testing (ICT): Checks individual components and connections for shorts, opens, and correct values.

- Functional Testing: Simulates the board's operation under real conditions to ensure performance.

- Burn-In Testing: Subjects boards to elevated temperatures and voltages over time to identify early failures.

Only boards that pass all tests proceed to packaging and delivery. This ensures that customers receive reliable products that meet their specifications.

Advantages of Wholesale PCB SMT Assembly

Wholesale PCB SMT assembly offers numerous advantages that make it the preferred choice for mass electronics production:

- High Efficiency: Automated machines and streamlined workflows reduce production time and labor costs.

- Improved Quality: Consistent solder paste application, precise component placement, and rigorous inspection ensure reliable assemblies.

- Scalability: Production lines can be scaled up or down to meet demand fluctuations without compromising quality.

- Flexibility: Modern lines can handle diverse PCB designs and component types, supporting complex electronics manufacturing.

- Cost-Effectiveness: Bulk production lowers per-unit costs, making wholesale SMT assembly ideal for mass-market electronics.

- Reduced Lead Times: Automation and optimized processes shorten turnaround times from design to delivery.

- Better Supply Chain Integration: Wholesale manufacturers often manage component sourcing and inventory, reducing supply risks.

These benefits contribute to the widespread adoption of wholesale PCB SMT assembly in industries requiring high-volume, high-quality electronic products.

Technology and Equipment in Wholesale PCB SMT Assembly

Wholesale PCB SMT assembly relies on advanced machinery and technology to achieve precision and speed:

- Solder Paste Printers: For precise paste application, these printers use stencils and controlled squeegee mechanisms.

- Pick-and-Place Machines: High-speed, accurate placement of components using robotic arms and vision systems.

- Reflow Ovens: Controlled heating zones ensure proper solder melting and solidification.

- Inspection Systems: AOI and X-ray machines detect defects and verify solder joint integrity.

- Conveyors and Automation: Efficient material handling between process stages reduces manual intervention.

- Software Systems: Manufacturing Execution Systems (MES) and automated programming optimize production scheduling, traceability, and quality control.

The integration of these technologies enables wholesale PCB SMT assembly lines to produce complex boards with minimal errors and high throughput.

Best Practices for Successful Wholesale PCB SMT Assembly

To maximize the benefits of wholesale PCB SMT assembly, manufacturers and designers should follow best practices:

- Design for Manufacturability (DFM): Collaborate with assembly partners early to optimize PCB layout for SMT processes.

- Component Selection: Use standard, readily available components to avoid supply delays.

- Material Handling: Store and handle components and PCBs properly to prevent contamination and damage.

- Process Control: Monitor critical parameters such as solder paste printing, placement accuracy, and reflow profiles.

- Quality Assurance: Implement rigorous inspection and testing protocols throughout production.

- Communication: Maintain clear communication between design, procurement, and manufacturing teams to address issues promptly.

Adhering to these practices helps ensure smooth production runs and high-quality assemblies in wholesale SMT manufacturing.

Conclusion

The wholesale PCB SMT assembly process is a sophisticated, highly automated manufacturing method that enables the mass production of reliable, high-performance electronic assemblies. From initial PCB design and material procurement to solder paste application, component placement, reflow soldering, inspection, and final testing, each step is optimized for efficiency and quality.

Wholesale SMT assembly lines leverage advanced equipment and automation to meet the demands of modern electronics manufacturing, delivering cost-effective solutions for a wide range of industries. By understanding this process and following best practices, businesses can better select manufacturing partners and optimize their product development cycles, ensuring successful outcomes in their electronics projects.

FAQ

1. What is the difference between SMT and through-hole assembly?

SMT mounts components directly onto the PCB surface without drilling holes, allowing for smaller, denser designs, while through-hole assembly requires component leads to be inserted into holes and soldered, typically used for larger or mechanically stressed parts.

2. How does solder paste application impact PCB assembly quality?

Proper solder paste application ensures the right amount of solder is deposited on pads, which is critical for forming strong, reliable solder joints. Inaccurate paste application can cause defects like solder bridges or cold joints.

3. Why is automated inspection important in wholesale PCB SMT assembly?

Automated inspection systems quickly and accurately detect assembly defects, reducing human error, minimizing rework, and ensuring consistent product quality in high-volume production.

4. Can wholesale PCB SMT assembly handle complex and small components?

Yes, advanced pick-and-place machines and precise solder paste printing enable the assembly of very small and complex components, including BGAs and fine-pitch devices, making it suitable for modern electronics.

5. What factors influence the cost of wholesale PCB SMT assembly?

Cost factors include PCB complexity, component types and quantities, production volume, inspection requirements, and lead times. High-volume wholesale assembly typically reduces per-unit costs due to economies of scale.