Content Menu

● Introduction

● Understanding Surface Mount Technology

● The Reflow Soldering Process

>> Preparation of the PCB

>> Component Placement

>> Preheating Phase

>> Soaking Phase

>> Reflow Phase

>> Cooling Phase

● Advantages of Reflow Soldering in SMT

● Challenges in Reflow Soldering

● Best Practices for Successful Reflow Soldering

● Conclusion

● Related Questions

>> 1. What Are Common Defects Associated with Reflow Soldering?

>> 2. How Can I Optimize My Reflow Profile?

>> 3. What Types of Solder Paste Are Available?

>> 4. How Do I Choose Between Wave Soldering and Reflow Soldering?

>> 5. What Role Does Flux Play in Reflow Soldering?

Introduction

Reflow soldering is a critical process in surface mount technology (SMT) that has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). This method allows for the efficient and reliable connection of surface-mounted devices (SMDs) to PCBs, enabling the production of compact and high-performance electronic products. In this article, we will explore the intricacies of the reflow soldering process, its advantages, challenges, and best practices, while incorporating relevant keywords related to soldering and surface mount technology.

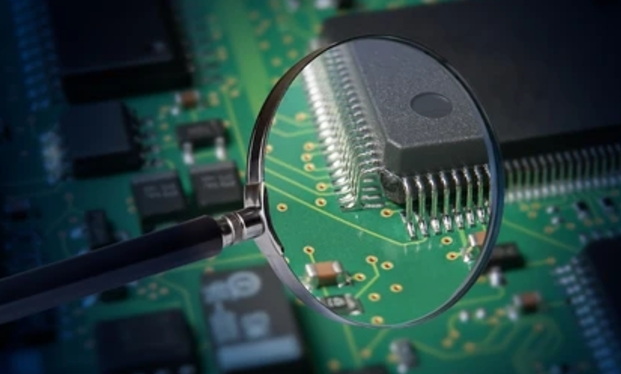

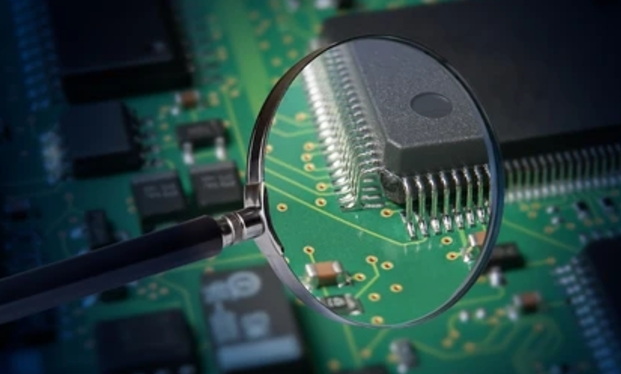

Understanding Surface Mount Technology

Surface mount technology is a method where electronic components are mounted directly onto the surface of PCBs. Unlike through-hole technology, where components are inserted into holes drilled in the PCB, SMT allows for a more compact design, which is essential in today's electronics that demand miniaturization. The advantages of SMT include:

- Reduced Size: Components can be placed closer together, allowing for smaller PCBs.

- Improved Performance: Shorter electrical paths lead to better performance and reduced signal interference.

- Automated Assembly: SMT is compatible with automated assembly processes, increasing production efficiency.

The Reflow Soldering Process

Preparation of the PCB

The reflow soldering process begins with the preparation of the PCB. This involves applying a solder paste to the pads where SMDs will be placed. Solder paste is a mixture of tiny solder spheres and flux, which helps to clean the surfaces and promote adhesion during soldering.

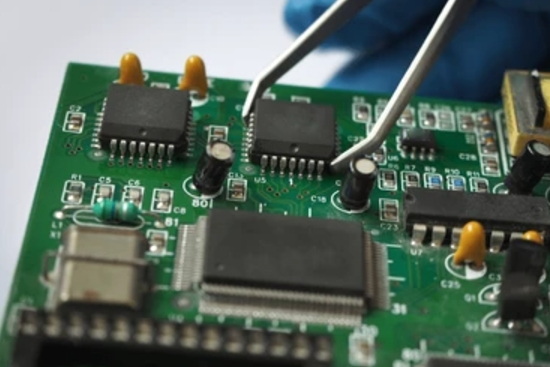

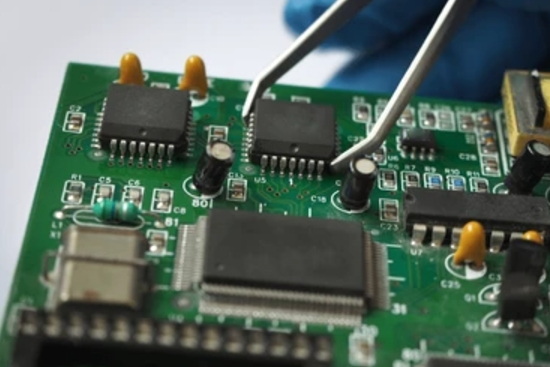

Component Placement

Once the solder paste is applied, SMDs are accurately placed onto the PCB using pick-and-place machines. These machines utilize vision systems to ensure precise placement of components on the solder paste-covered pads.

Preheating Phase

After component placement, the PCB enters the reflow oven. The first stage in the oven is preheating, where the temperature gradually increases to prepare both the PCB and components for soldering. This phase typically lasts about 60 to 120 seconds and serves several purposes:

Reduces thermal shock to components.

Activates flux in the solder paste.

Evaporates solvents present in the paste.

Soaking Phase

Following preheating, the PCB enters a soaking phase where it maintains a stable temperature for a brief period. This allows for uniform heating of all components, ensuring that they reach an optimal temperature before melting occurs.

Reflow Phase

The heart of reflow soldering lies in the reflow phase. During this stage, temperatures rise rapidly to melt the solder paste. The typical peak temperature ranges from 220°C to 260°C (428°F to 500°F), depending on the type of solder used (lead-free or leaded).

As the solder melts, it flows around the component leads and pads, creating a strong mechanical and electrical bond once it cools and solidifies. The reflow phase usually lasts between 30 seconds to a few minutes.

Cooling Phase

After reflowing, PCBs must cool down gradually to solidify the solder joints properly. Rapid cooling can lead to defects such as thermal shock or poor joint formation. Controlled cooling rates help achieve reliable connections.

Advantages of Reflow Soldering in SMT

Reflow soldering offers numerous advantages that make it a preferred choice in surface mount technology:

High Throughput: Automated processes allow for rapid production rates.

Consistent Quality: The controlled environment of reflow ovens ensures uniform heating and cooling, leading to consistent solder joints.

Flexibility: Reflow soldering can accommodate various component types and sizes.

Reduced Labor Costs: Automation reduces manual labor requirements, lowering overall production costs.

Challenges in Reflow Soldering

Despite its advantages, reflow soldering also presents challenges that manufacturers must address:

Temperature Control: Precise temperature management is crucial; too high can damage components while too low may result in cold joints.

Solder Paste Quality: The quality of solder paste affects joint reliability; expired or improperly stored paste can lead to defects.

Component Variability: Different components have varying thermal characteristics which can complicate uniform heating.

Best Practices for Successful Reflow Soldering

To achieve optimal results during reflow soldering, manufacturers should adhere to best practices:

Regular Equipment Calibration: Ensure that reflow ovens are properly calibrated for accurate temperature control.

Quality Control of Materials: Use high-quality solder paste and components from reputable suppliers.

Process Monitoring: Implement monitoring systems to track temperatures throughout each phase of reflow soldering.

Training Personnel: Ensure that staff are well-trained in handling equipment and understanding process parameters.

Conclusion

Reflow soldering is an essential process within surface mount technology that enables efficient assembly of electronic devices. By understanding each phase of this process—from preparation through cooling—manufacturers can optimize their production lines for better quality and performance. As technology continues to evolve, staying informed about advancements in reflow techniques will be crucial for maintaining competitiveness in electronics manufacturing.

Related Questions

1. What Are Common Defects Associated with Reflow Soldering?

Common defects include cold joints, bridging, tombstoning, and insufficient wetting. These issues often arise from improper temperature profiles or poor quality materials.

2. How Can I Optimize My Reflow Profile?

To optimize your reflow profile, conduct experiments adjusting preheat times and peak temperatures while monitoring joint quality through testing methods like X-ray inspection.

3. What Types of Solder Paste Are Available?

There are several types of solder paste available including leaded (SnPb) and lead-free options (like SAC305). Each has different melting points and properties suitable for various applications.

4. How Do I Choose Between Wave Soldering and Reflow Soldering?

Choosing between wave and reflow soldering depends on your specific application needs; wave soldering is often used for through-hole components while reflow is ideal for SMT applications.

5. What Role Does Flux Play in Reflow Soldering?

Flux cleans oxides from surfaces during heating, promotes wetting by lowering surface tension, and helps ensure strong bonds between components and pads after cooling.