Content Menu

● What is SMT?

● The SMT Line: A Definition

● Key Components of an SMT Line

● The SMT Assembly Process

● Advantages of Using an SMT Line for PCB Assembly

● Challenges Associated with SMT Lines

● Innovations in SMT Technology

● The Role of Quality Control in SMT Lines

● Environmental Considerations

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does an SMT line improve PCB assembly?

>> 3. What are some key advantages of using an SMT line?

>> 4. What challenges might arise when using an SMT line?

>> 5. Can both SMT and through-hole components be used on the same PCB?

● Citations:

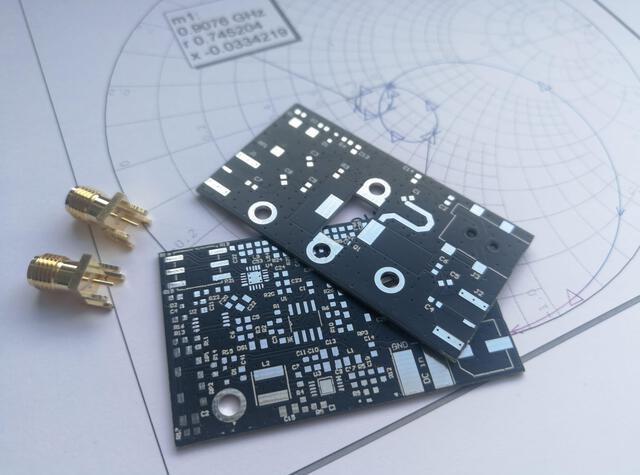

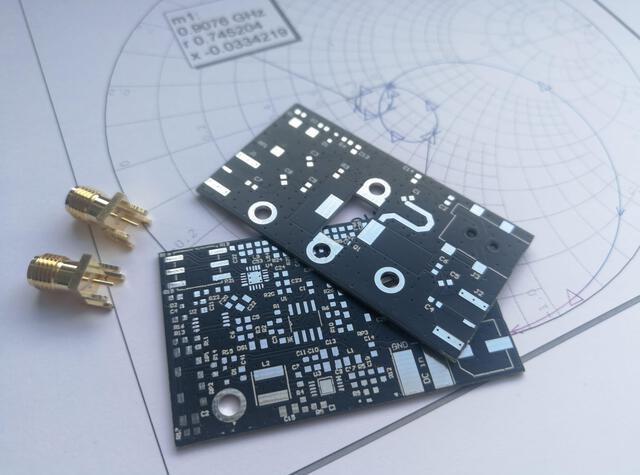

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, particularly in the realm of Printed Circuit Board (PCB) assembly. Understanding the full form of SMT and its implications for PCB assembly is crucial for anyone involved in electronics design or manufacturing. This article delves into the intricacies of SMT lines, their components, processes, advantages, challenges, and how they relate to PCB assembly.

What is SMT?

SMT stands for Surface Mount Technology, a method that allows electronic components to be mounted directly onto the surface of PCBs. Unlike traditional through-hole technology, which requires components to be inserted into drilled holes on the board, SMT uses solder paste to attach components directly to the surface. This innovation has significantly enhanced production efficiency and component density on PCBs.

The SMT Line: A Definition

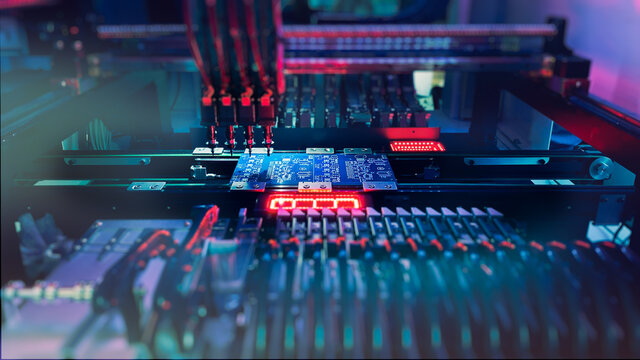

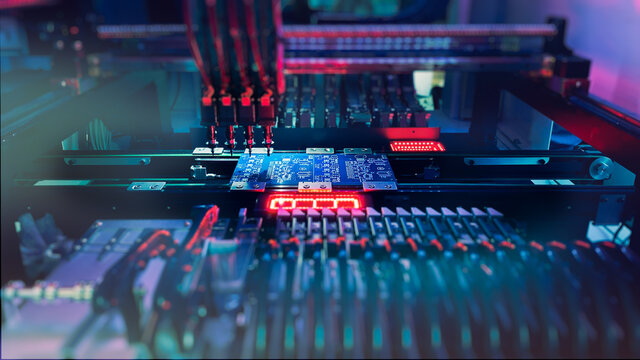

An SMT line refers to a series of interconnected machines and equipment designed for the automated assembly of electronic components onto PCBs using surface mount technology. The process involves several stages, each facilitated by specialized machinery that ensures precision and speed in manufacturing.

Key Components of an SMT Line

Understanding the components of an SMT line is essential to grasp how it relates to PCB assembly. The typical SMT line includes:

- SMT Loader: This machine automatically feeds bare PCBs into the assembly line.

- Stencil Printer: It applies solder paste onto designated areas of the PCB using a stencil, ensuring that paste is deposited only where components will be placed.

- Pick and Place Machine: This robotic system picks up surface mount components from feeders and accurately places them onto the solder-pasted PCBs.

- Reflow Oven: After placement, PCBs pass through a reflow oven where solder paste is melted, creating strong electrical connections between the components and the PCB.

- SMT Unloader: This machine removes completed PCBs from the line for inspection or further processing.

The SMT Assembly Process

The SMT assembly process can be broken down into several key stages:

1. PCB Preparation: The process begins with preparing the PCB layout using CAD software, ensuring that all necessary components are accounted for.

2. Solder Paste Printing: Solder paste is applied to specific locations on the PCB using a stencil printer. This step is critical as it ensures proper adhesion of components during soldering.

3. Component Placement: Using pick and place machines, components are positioned accurately on the solder-pasted areas of the PCB.

4. Reflow Soldering: The assembled boards are then heated in a reflow oven where solder paste melts and solidifies, forming permanent connections between components and pads on the PCB.

5. Inspection and Testing: After cooling, boards undergo inspection using Automated Optical Inspection (AOI) systems to ensure quality and functionality before they are sent for further processing or packaging.

Advantages of Using an SMT Line for PCB Assembly

The adoption of SMT lines offers numerous advantages over traditional assembly methods:

- Higher Component Density: SMT allows for more compact designs as components can be placed on both sides of the PCB without drilling holes.

- Reduced Manufacturing Costs: Fewer holes mean lower processing costs and less material waste, making it economically favorable for high-volume production.

- Increased Production Speed: Automated processes significantly reduce assembly time compared to manual methods, allowing manufacturers to produce large quantities quickly.

- Improved Reliability: The precision of automated machines minimizes human error during assembly, resulting in higher quality products.

- Flexibility in Design: Engineers can create smaller, more complex circuits without being constrained by through-hole limitations.

Challenges Associated with SMT Lines

While SMT lines provide many benefits, there are challenges that manufacturers must consider:

- Component Fragility: Surface mount devices (SMDs) are often smaller and more fragile than their through-hole counterparts, requiring careful handling during assembly.

- Higher Initial Setup Costs: Although operational costs may be lower in the long run, setting up an SMT line can require significant initial investment in machinery and training.

- Limited Repairability: Once assembled, repairing SMDs can be more difficult than through-hole components due to their size and placement on the board.

Innovations in SMT Technology

Recent advancements in SMT technology have further enhanced its application in PCB assembly:

- Finer Pitch Components: Manufacturers have developed smaller component sizes that allow for greater density on PCBs. This miniaturization enables more functionality within limited space.

- Improved Soldering Techniques: New methods such as selective soldering and advanced reflow techniques have improved joint reliability while reducing defects like cold joints or solder bridges[1].

- Automation and Robotics Integration: The integration of robotics has streamlined processes within SMT lines. Automated systems not only increase speed but also enhance accuracy while reducing labor costs[3].

- Artificial Intelligence (AI): AI technologies are being utilized to monitor production processes continuously. By analyzing data from various stages of manufacturing, AI can predict failures before they occur and suggest adjustments to improve yield rates[6].

The Role of Quality Control in SMT Lines

Quality control is paramount in maintaining high standards throughout the SMT assembly process:

- Automated Optical Inspection (AOI): AOI systems are employed post-reflow to identify defects such as missing components or poor solder joints. This step is crucial for ensuring product reliability before shipping[9].

- Process Monitoring Tools: Continuous monitoring tools help detect issues early in production. By tracking parameters such as temperature profiles during reflow soldering, manufacturers can make real-time adjustments[6].

- Training Programs for Operators: Ensuring that operators are well-trained in handling machinery and understanding quality standards contributes significantly to reducing errors during assembly[3].

Environmental Considerations

With growing concerns about environmental sustainability, many manufacturers are adopting eco-friendly practices within their SMT lines:

- Lead-Free Soldering: The transition from lead-based solders to lead-free alternatives not only meets regulatory requirements but also aligns with global sustainability goals[8].

- Waste Reduction Initiatives: Manufacturers are increasingly focused on minimizing waste generated during production processes by optimizing material usage and recycling scrap materials[10].

Conclusion

The full form of SMT—Surface Mount Technology—plays a pivotal role in modern PCB assembly processes. By utilizing automated systems within an SMT line, manufacturers can achieve greater efficiency, higher quality products, and reduced costs. As technology continues to evolve with innovations such as AI integration and advancements in component design, understanding these processes becomes essential for anyone involved in electronics design or manufacturing.

The benefits offered by SMT lines extend beyond mere production efficiency; they contribute significantly to product reliability and environmental sustainability. As industries demand increasingly compact and efficient electronic devices, mastering Surface Mount Technology will remain crucial for manufacturers aiming to stay competitive in this rapidly evolving market.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs and automated assembly processes.

2. How does an SMT line improve PCB assembly?

An SMT line improves PCB assembly by automating key processes such as solder paste application, component placement, and soldering, which enhances speed, accuracy, and reduces labor costs compared to manual methods.

3. What are some key advantages of using an SMT line?

Key advantages include higher component density on PCBs, reduced manufacturing costs due to fewer drilled holes, increased production speed through automation, improved reliability from reduced human error, and flexibility in design capabilities.

4. What challenges might arise when using an SMT line?

Challenges include handling fragile surface mount devices (SMDs), higher initial setup costs for machinery and training, and difficulties in repairing SMDs once they are assembled onto PCBs.

5. Can both SMT and through-hole components be used on the same PCB?

Yes, both SMT and through-hole components can coexist on the same PCB design; however, careful consideration must be given to layout and manufacturing processes to ensure compatibility.

Citations:

[1] https://www.wevolver.com/article/smt-process

[2] https://www.pcbgogo.com/Article/Innovations_in_printed_circuit_board_assembly__trends_and_techniques.html

[3] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[4] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[5] https://www.rs-online.com/designspark/latest-pcb-technology-and-industry-trends

[6] https://quality-line.com/smt-quality/

[7] https://www.viasion.com/blog/common-challenges-in-smt-assembly-and-solutions/

[8] https://www.raypcb.com/surface-mount-technology/

[9] https://blog.matric.com/smt-production-for-pcbs-matric

[10] https://www.hayawin.com/resources/smt-line-an-efficient-and-cost-effective-production-line.html