Content Menu

● Understanding Flex PCB and SMT

● The Flex PCB SMT Process

● Advantages of Flex PCB SMT Assembly

>> Enhanced Flexibility and Durability

>> Improved Space Utilization

>> Weight Reduction

>> Enhanced Signal Integrity

>> Improved Thermal Management

● Impact on Manufacturing Efficiency

>> Streamlined Production Process

>> Reduced Production Costs

>> Increased Component Density

● Applications of Flex PCB SMT in Various Industries

>> Aerospace Industry

>> Medical Devices

>> Consumer Electronics

● Challenges and Considerations in Flex PCB SMT Assembly

>> Material Selection

>> Design Complexity

>> Assembly Precision

>> Testing and Quality Control

● Future Trends in Flex PCB SMT Technology

>> Increased Automation

>> Miniaturization

>> Integration of Advanced Materials

>> 3D Printing and Additive Manufacturing

● Conclusion

● FAQ

>> 1. What are the main advantages of the flex PCB SMT process?

>> 2. How does the flex PCB SMT process contribute to manufacturing efficiency?

>> 3. What industries benefit most from flex PCB SMT technology?

>> 4. What are the main challenges in implementing flex PCB SMT assembly?

>> 5. What future trends are expected in flex PCB SMT technology?

● Citations:

The flex PCB SMT process has revolutionized the electronics manufacturing industry, offering significant improvements in circuit board performance, reliability, and efficiency. This article explores the various aspects of the flex PCB SMT process and its impact on modern electronics.

Understanding Flex PCB and SMT

Flexible Printed Circuit Boards (Flex PCBs) are thin, lightweight, and bendable circuit boards that can conform to various shapes and spaces. Surface Mount Technology (SMT) is an advanced method of mounting electronic components directly onto the surface of PCBs. When combined, these technologies create a powerful synergy that enhances circuit board performance in numerous ways.

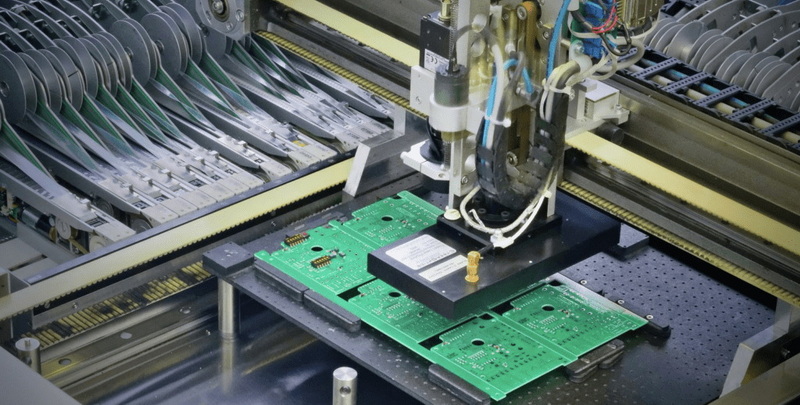

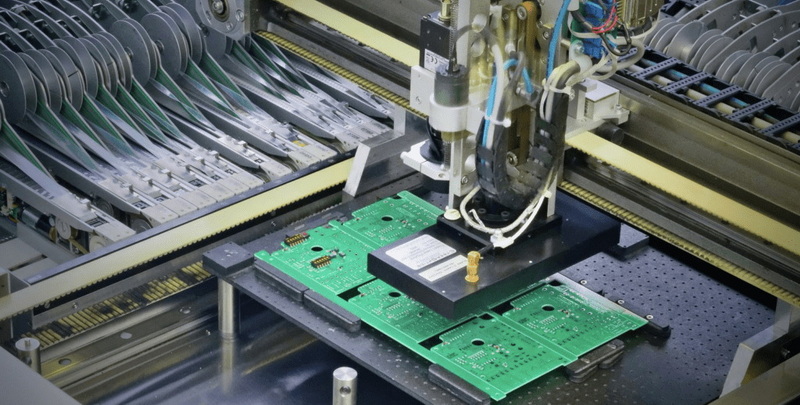

The Flex PCB SMT Process

The flex PCB SMT process involves several key steps:

1. Design and fabrication of the flexible PCB

2. Application of solder paste to the PCB

3. Placement of components using automated pick-and-place machines

4. Reflow soldering to secure components

5. Inspection and testing

Each step in this process contributes to the overall improvement of circuit board performance[1].

Advantages of Flex PCB SMT Assembly

Enhanced Flexibility and Durability

The flex PCB SMT process allows for the creation of highly flexible and durable circuit boards. These boards can withstand bending, twisting, and folding without compromising their electrical integrity. This flexibility enables designers to create innovative product designs that were previously impossible with rigid PCBs[7].

Improved Space Utilization

One of the most significant advantages of the flex PCB SMT process is its ability to maximize space utilization. Flex PCBs can be bent and folded to fit into tight or irregularly shaped spaces, allowing for more compact and efficient product designs. This is particularly beneficial in industries such as aerospace, medical devices, and consumer electronics, where space is at a premium[7].

Weight Reduction

Flex PCBs assembled using SMT are significantly lighter than their rigid counterparts. In fact, they typically weigh only about 10% of traditional wired solutions. This weight reduction is crucial in applications where every gram matters, such as in aerospace and portable electronic devices[7].

Enhanced Signal Integrity

The flex PCB SMT process contributes to improved signal integrity in several ways:

1. Consistent impedance: Flex materials have low dielectric constants (DK: 3.2 to 3.4), ensuring consistent impedance across the board.

2. Reduced signal loss: The homogeneous composition of flex materials eliminates variations seen in rigid materials due to glass weave, resulting in lower signal loss.

3. Shorter signal paths: The ability to bend and fold flex PCBs allows for shorter signal paths, reducing signal degradation[7].

Improved Thermal Management

The flex PCB SMT process allows for better thermal management in electronic devices. The thin profile of flex PCBs enables more efficient heat dissipation, reducing the risk of component failure due to overheating. Additionally, flex PCBs can be designed with specific thermal management features, such as copper planes or heat-dissipating layers[1].

Impact on Manufacturing Efficiency

Streamlined Production Process

The flex PCB SMT process significantly streamlines the production process compared to traditional through-hole technology. The use of automated pick-and-place machines and reflow soldering techniques increases production speed and reduces the likelihood of human error[5].

Reduced Production Costs

While the initial investment in SMT equipment may be higher, the flex PCB SMT process ultimately leads to reduced production costs. This is due to:

1. Faster assembly times

2. Lower material costs

3. Reduced labor requirements

4. Fewer errors and rework needed[5]

Increased Component Density

The flex PCB SMT process allows for higher component density on circuit boards. Surface mount components are typically smaller than their through-hole counterparts, enabling more components to be placed in a given area. This increased density contributes to more compact and feature-rich electronic devices[4].

Applications of Flex PCB SMT in Various Industries

Aerospace Industry

In the aerospace industry, the flex PCB SMT process offers several key benefits:

1. Weight reduction: Lighter circuit boards contribute to overall weight savings in aircraft and spacecraft.

2. Space efficiency: Flex PCBs can be designed to fit into tight spaces within aerospace equipment.

3. Vibration resistance: The flexibility of these boards makes them more resistant to vibration and shock, crucial in aerospace applications[7].

Medical Devices

The medical industry has embraced flex PCB SMT technology for various reasons:

1. Miniaturization: Enables the creation of smaller, less invasive medical devices.

2. Reliability: The reduced number of interconnections in flex PCBs increases the reliability of medical equipment.

3. Flexibility: Allows for the design of wearable medical devices that can conform to the human body[7].

Consumer Electronics

In consumer electronics, the flex PCB SMT process has enabled:

1. Thinner and lighter devices: Smartphones, tablets, and wearables benefit from the space and weight savings.

2. Innovative designs: Flex PCBs allow for unique form factors and foldable devices.

3. Improved durability: The flexibility of these boards increases the overall durability of consumer devices[1].

Challenges and Considerations in Flex PCB SMT Assembly

While the flex PCB SMT process offers numerous advantages, it also presents some challenges that manufacturers must address:

Material Selection

Choosing the right materials for flex PCBs is crucial. The materials must be able to withstand repeated bending and flexing without compromising electrical performance. Common materials include polyimide and polyester, each with its own set of properties and limitations[1].

Design Complexity

Designing flex PCBs for SMT assembly requires careful consideration of factors such as bend radii, component placement, and stress relief. Engineers must ensure that the design accommodates the flexibility of the board while maintaining the integrity of the electrical connections[3].

Assembly Precision

The flex PCB SMT process requires high precision during component placement and soldering. Even small misalignments can lead to connection failures or poor performance. Advanced pick-and-place machines and reflow ovens are essential for achieving the necessary precision[2].

Testing and Quality Control

Testing flex PCBs assembled with SMT can be more challenging than testing rigid boards. Specialized fixtures and testing procedures may be required to ensure the functionality and reliability of the finished product[6].

Future Trends in Flex PCB SMT Technology

As technology continues to advance, several trends are emerging in the field of flex PCB SMT:

Increased Automation

The future of flex PCB SMT assembly lies in increased automation. Advanced robotics and artificial intelligence will play a larger role in component placement, soldering, and quality control, further improving efficiency and reducing errors[6].

Miniaturization

The trend towards smaller, more powerful electronic devices will drive further miniaturization in flex PCB SMT technology. This will include the development of even smaller components and more precise assembly techniques[4].

Integration of Advanced Materials

Research into new materials for flex PCBs and SMT components will continue, with a focus on improving flexibility, durability, and electrical performance. This may include the integration of nanomaterials or advanced polymers[1].

3D Printing and Additive Manufacturing

The integration of 3D printing technologies with flex PCB SMT assembly could revolutionize the manufacturing process, allowing for even more complex and customized circuit designs[3].

Conclusion

The flex PCB SMT process has significantly improved circuit board performance across various dimensions. From enhanced flexibility and space utilization to improved signal integrity and thermal management, this technology has enabled the creation of more compact, efficient, and reliable electronic devices. As the electronics industry continues to evolve, the flex PCB SMT process will play an increasingly crucial role in meeting the demands for smaller, lighter, and more powerful devices across multiple industries.

While challenges exist in design, material selection, and assembly precision, ongoing advancements in automation, materials science, and manufacturing techniques are addressing these issues. The future of flex PCB SMT technology looks promising, with trends towards increased automation, further miniaturization, and the integration of advanced materials set to drive innovation in electronic device design and manufacturing.

As we move forward, the flex PCB SMT process will continue to be a key enabler of technological progress, pushing the boundaries of what's possible in electronics and opening up new possibilities for product design and functionality.

FAQ

1. What are the main advantages of the flex PCB SMT process?

The main advantages of the flex PCB SMT process include:

- Enhanced flexibility and durability of circuit boards

- Improved space utilization in electronic devices

- Significant weight reduction compared to traditional PCBs

- Better signal integrity due to consistent impedance and shorter signal paths

- Improved thermal management capabilities

2. How does the flex PCB SMT process contribute to manufacturing efficiency?

The flex PCB SMT process contributes to manufacturing efficiency by:

- Streamlining the production process through automation

- Reducing production costs through faster assembly times and lower material costs

- Enabling higher component density on circuit boards

- Minimizing errors and the need for rework

3. What industries benefit most from flex PCB SMT technology?

Industries that benefit significantly from flex PCB SMT technology include:

- Aerospace: for weight reduction and space efficiency in aircraft and spacecraft

- Medical devices: for miniaturization and the creation of wearable devices

- Consumer electronics: for thinner, lighter devices with innovative designs

- Automotive: for reliable electronics in harsh environments

- Military and defense: for durable and compact electronic systems

4. What are the main challenges in implementing flex PCB SMT assembly?

The main challenges in implementing flex PCB SMT assembly include:

- Selecting appropriate materials that can withstand repeated flexing

- Managing the complexity of designing flex PCBs for SMT assembly

- Ensuring high precision during component placement and soldering

- Developing effective testing and quality control procedures for flexible boards

5. What future trends are expected in flex PCB SMT technology?

Future trends in flex PCB SMT technology include:

- Increased automation in the assembly process

- Further miniaturization of components and circuit designs

- Integration of advanced materials for improved performance

- Potential incorporation of 3D printing and additive manufacturing techniques

- Development of more environmentally friendly manufacturing processes

Citations:

[1] https://swimbi.com/flex-pcb-smt-assembly-everything-you-need-to-know/

[2] https://patents.google.com/patent/CN112040669B/zh

[3] https://www.andwinpcb.com/advancements-in-flex-pcb-smt-assembly-techniques-and-benefits/

[4] https://www.medicaldesignbriefs.com/component/content/article/46458-surface-mount-technology-for-pcb-assembly-use-case-and-smt-in-healthcare-systems

[5] https://www.pcbgogo.com/Article/Why_SMT_Technology_Benefit_PCB_Assembly_.html

[6] https://www.techtarget.com/iotagenda/blog/IoT-Agenda/3-key-steps-for-IoT-PCB-SMT-and-microelectronics-assembly

[7] https://www.epectec.com/flex/benefits/

[8] https://www.wevolver.com/article/smt-process