Content Menu

● Introduction

● What is Surface Mount Technology?

● The Evolution of PCB Manufacturing

● Advantages of Surface Mount Technology

>> 1. Increased Component Density

>> 2. Enhanced Performance

>> 3. Cost-Effectiveness

>> 4. Improved Reliability

>> 5. Flexibility in Design

● The SMT Process

>> 1. Design and Layout

>> 2. Solder Paste Application

>> 3. Component Placement

>> 4. Reflow Soldering

>> 5. Inspection and Testing

● Impact of Surface Mount Technology on Industries

● Future Trends in Surface Mount Technology

● Challenges Facing Surface Mount Technology

>> 1. Complexity in Design

>> 2. Equipment Costs

>> 3. Component Availability

>> 4. Training Requirements

● Conclusion

● Related Questions

>> 1. What are the main differences between Surface Mount Technology and Through-Hole Technology?

>> 2. How does automation impact Surface Mount Technology?

>> 3. What types of products commonly use Surface Mount Technology?

>> 4. What challenges do manufacturers face when implementing Surface Mount Technology?

>> 5. How does Surface Mount Technology contribute to product reliability?

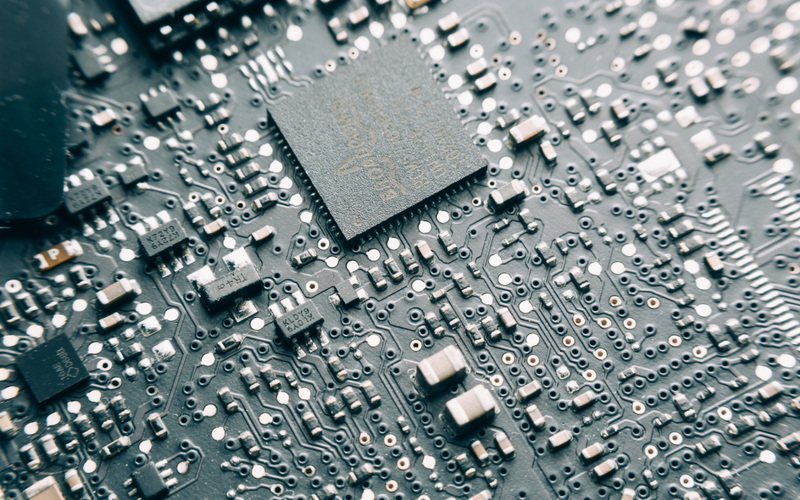

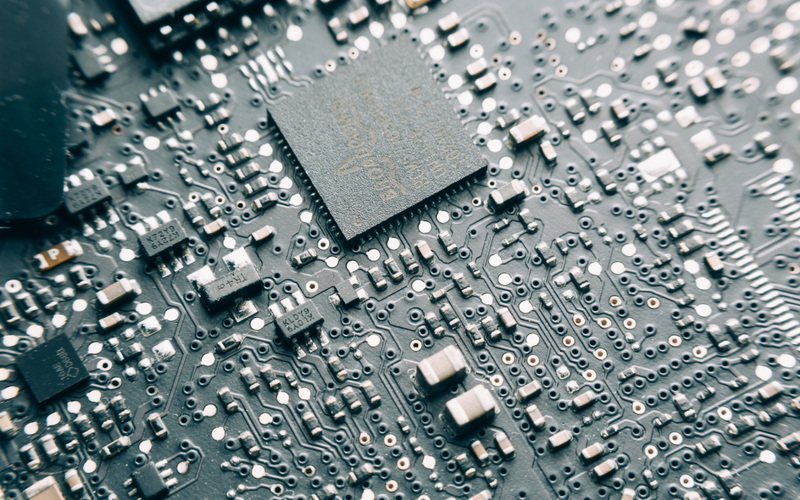

Introduction

In the ever-evolving landscape of electronics, the demand for efficient, compact, and high-performance devices has propelled the development of various manufacturing technologies. Among these, Surface Mount Technology (SMT) has emerged as a game-changer in the realm of Printed Circuit Board (PCB) manufacturing. This article explores how SMT revolutionizes PCB manufacturing, its advantages over traditional methods, and its impact on the electronics industry.

What is Surface Mount Technology?

Surface Mount Technology refers to a method of mounting electronic components directly onto the surface of PCBs. Unlike traditional through-hole technology, where components are inserted into holes on the board and soldered from the opposite side, SMT allows for components to be placed on both sides of the PCB. This leads to a more compact design and improved performance characteristics.

The Evolution of PCB Manufacturing

Historically, PCB manufacturing relied heavily on through-hole technology. While this method was effective for early electronic devices, it presented several limitations:

- Size Constraints: Through-hole components require significant space on PCBs, limiting design flexibility.

- Manual Labor: The assembly process was labor-intensive, leading to higher production costs and longer lead times.

- Performance Issues: The mechanical stress of soldering through holes could lead to reliability issues in high-frequency applications.

With the advent of SMT in the 1980s, these challenges began to be addressed. SMT allowed manufacturers to create smaller, more complex circuits that could operate at higher frequencies with greater reliability.

Advantages of Surface Mount Technology

1. Increased Component Density

One of the primary benefits of SMT is its ability to accommodate a higher density of components on a PCB. This is particularly important as electronic devices continue to shrink in size while increasing in functionality. By utilizing smaller components that can be mounted directly onto the surface, designers can maximize space efficiency.

2. Enhanced Performance

SMT enables shorter electrical paths between components, reducing signal loss and improving overall performance. This is crucial for high-speed applications where delays can affect functionality. Additionally, SMT components are generally lighter and have lower profiles, which further enhances performance characteristics.

3. Cost-Effectiveness

While the initial setup cost for SMT may be higher due to specialized equipment and training, the long-term savings can be significant. Automated assembly processes reduce labor costs and increase production speed, leading to lower overall manufacturing costs per unit.

4. Improved Reliability

SMT offers enhanced reliability compared to traditional methods. The solder joints formed during the SMT process are typically stronger and more resistant to mechanical stress. This is particularly beneficial in applications subject to vibration or thermal cycling.

5. Flexibility in Design

The flexibility offered by SMT allows engineers to experiment with innovative designs without being constrained by component size or placement limitations. This encourages creativity and leads to more advanced electronic products.

The SMT Process

The SMT process involves several key steps:

1. Design and Layout

The first step is designing the PCB layout using specialized software that accommodates SMT components. Engineers must consider factors such as component placement, trace routing, and thermal management.

2. Solder Paste Application

Solder paste is applied to the PCB using a stencil or a printing process. This paste contains tiny solder balls that will melt during reflow soldering.

3. Component Placement

Automated pick-and-place machines are used to accurately position SMT components onto the solder paste-covered pads on the PCB.

4. Reflow Soldering

Once all components are placed, the PCB undergoes reflow soldering in an oven where heat melts the solder paste, creating strong electrical connections between components and pads.

5. Inspection and Testing

After soldering, PCBs are inspected using automated optical inspection (AOI) systems or X-ray machines to ensure quality and reliability before they are sent for final testing.

Impact of Surface Mount Technology on Industries

The influence of SMT extends beyond just electronics manufacturing; it has transformed various industries:

- Consumer Electronics: Devices like smartphones and tablets benefit from compact designs made possible by SMT.

- Automotive: Modern vehicles incorporate advanced electronics for safety and performance features that rely on high-density PCBs.

- Medical Devices: The miniaturization enabled by SMT allows for more sophisticated medical equipment that can fit within smaller enclosures while maintaining functionality.

- Telecommunications: High-speed communication devices leverage SMT for improved signal integrity and reduced latency.

- Aerospace: In aerospace applications, where reliability is paramount, SMT provides robust solutions for navigation systems, communication devices, and other critical electronics.

Future Trends in Surface Mount Technology

As technology continues to advance, several trends are emerging within SMT:

- Miniaturization: As devices become smaller, manufacturers are developing even tinier components that can be used with SMT. This trend is driven by consumer demand for portable devices with enhanced capabilities.

- Smart Manufacturing: The integration of IoT technologies into manufacturing processes enhances efficiency and quality control in SMT assembly lines. Smart factories utilize real-time data analytics to optimize production workflows and reduce waste.

- Sustainability: There is a growing focus on environmentally friendly materials and processes within SMT practices. Manufacturers are exploring lead-free soldering options and eco-friendly packaging solutions to minimize their environmental impact.

- Advanced Materials: Research into new materials for PCBs is ongoing, with innovations such as flexible circuits gaining traction in industries requiring lightweight and adaptable solutions.

Challenges Facing Surface Mount Technology

Despite its many advantages, Surface Mount Technology does face some challenges:

1. Complexity in Design

As component density increases, so does design complexity. Engineers must carefully plan layouts to avoid issues such as signal interference or thermal management problems caused by closely packed components.

2. Equipment Costs

The initial investment required for specialized SMT equipment can be significant for manufacturers transitioning from traditional methods. However, this cost is often offset by long-term savings through increased efficiency.

3. Component Availability

As technology evolves rapidly, ensuring a steady supply of advanced SMT components can be challenging. Manufacturers must maintain relationships with suppliers to secure necessary parts while also adapting to changing market demands.

4. Training Requirements

Implementing SMT requires skilled personnel who understand both the technology itself and how to operate complex machinery effectively. Continuous training programs are essential for keeping staff updated on best practices and new developments in SMT processes.

Conclusion

Surface Mount Technology has undeniably revolutionized PCB manufacturing by enhancing component density, improving performance, reducing costs, increasing reliability, and providing design flexibility. As industries continue to evolve towards smarter and more compact electronic solutions, SMT will remain at the forefront of innovation in electronics manufacturing.

With its numerous advantages and ongoing advancements—including miniaturization trends, smart manufacturing practices, sustainable approaches, and advanced materials—Surface Mount Technology is set to play a pivotal role in shaping the future of electronics across various sectors.

In summary, as we look ahead at the future landscape of electronics manufacturing driven by Surface Mount Technology Corp innovations, it becomes clear that this method will continue to influence how we design, produce, and utilize electronic devices in our daily lives.

Related Questions

1. What are the main differences between Surface Mount Technology and Through-Hole Technology?

Surface Mount Technology allows for mounting components directly onto the surface of PCBs without requiring holes, leading to higher component density and improved performance compared to Through-Hole Technology which requires inserting components into holes on the board.

2. How does automation impact Surface Mount Technology?

Automation significantly enhances efficiency in Surface Mount Technology by reducing labor costs and increasing production speed through automated placement machines and reflow ovens.

3. What types of products commonly use Surface Mount Technology?

Common products that utilize Surface Mount Technology include smartphones, tablets, computers, automotive electronics, medical devices, and telecommunications equipment.

4. What challenges do manufacturers face when implementing Surface Mount Technology?

Manufacturers may face challenges such as initial setup costs for specialized equipment, training requirements for staff, ensuring quality control during production, and managing component supply chains effectively.

5. How does Surface Mount Technology contribute to product reliability?

Surface Mount Technology contributes to product reliability through stronger solder joints formed during reflow soldering processes which are less prone to mechanical stress compared to traditional methods.