Content Menu

● Introduction

● Understanding Surface Mount Technology

>> The Evolution of Surface Mount Assembly Equipment

● Key Benefits of Surface Mount Technology

>> Increased Component Density

>> Enhanced Production Speed

>> Improved Reliability and Quality

>> Cost Efficiency

>> Flexibility in Design

● The Role of Automation in SMT

>> Automated Pick-and-Place Machines

>> Soldering Techniques

>> Integrated Testing and Inspection

● Challenges in Surface Mount Assembly

>> Component Handling

>> Thermal Management

>> Design Complexity

● Future Trends in Surface Mount Technology

>> Miniaturization of Components

>> Smart Manufacturing

>> Sustainable Practices

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does SMT improve production speed?

>> 3. What are the advantages of using surface mount assembly equipment?

>> 4. What challenges are associated with surface mount assembly?

>> 5. What future trends are influencing surface mount technology?

Introduction

In the fast-paced world of electronics manufacturing, efficiency is paramount. As the demand for smaller, more powerful devices continues to rise, manufacturers are increasingly turning to Surface Mount Technology (SMT) as a solution to enhance their assembly processes. This article explores how surface mount assembly equipment revolutionizes electronic assembly, improving efficiency, reducing costs, and ensuring high-quality production.

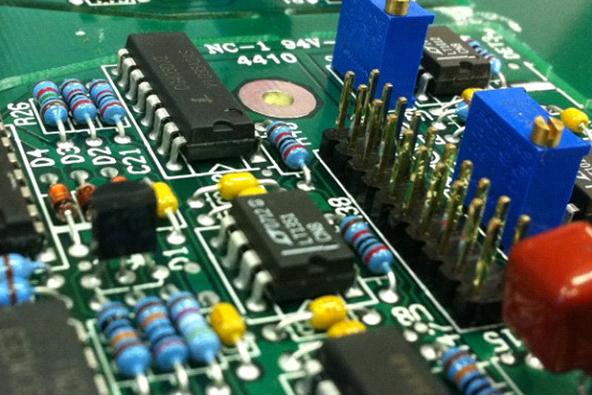

Understanding Surface Mount Technology

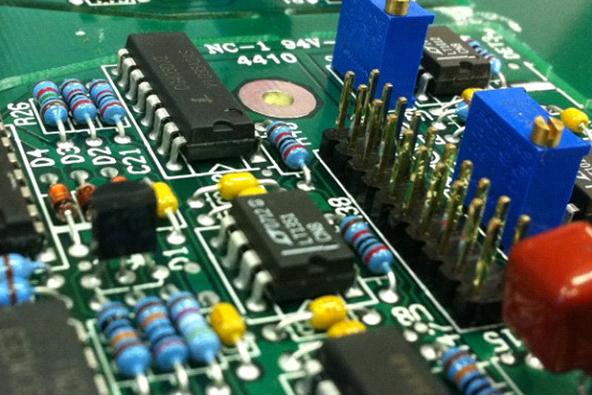

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, where components are inserted into holes drilled in the PCB, SMT allows for a more compact design and a higher density of components. This technology has become the standard in the electronics industry due to its numerous advantages.

The Evolution of Surface Mount Assembly Equipment

The development of surface mount assembly equipment has been a game-changer for manufacturers. Early SMT machines were limited in capability and speed, but advancements in technology have led to the creation of sophisticated equipment that can handle a wide range of components and assembly processes. Modern SMT machines are equipped with features such as automated pick-and-place systems, advanced vision systems for component alignment, and integrated testing capabilities.

Key Benefits of Surface Mount Technology

Increased Component Density

One of the primary advantages of SMT is the ability to place more components on a PCB in a smaller area. This increased component density allows for the design of more compact and lightweight electronic devices, which is essential in today's market where portability is crucial. Surface mount assembly equipment facilitates this by enabling precise placement of components, even in tight spaces.

Enhanced Production Speed

Surface mount assembly equipment significantly speeds up the assembly process. Automated pick-and-place machines can place thousands of components per hour, far surpassing the capabilities of manual assembly. This increased speed not only reduces production time but also allows manufacturers to meet tight deadlines and respond quickly to market demands.

Improved Reliability and Quality

The precision offered by surface mount technology leads to improved reliability and quality of electronic assemblies. SMT components are less prone to mechanical stress and damage during the assembly process, resulting in fewer defects. Additionally, the use of automated inspection systems integrated into SMT equipment ensures that any issues are detected early, further enhancing product quality.

Cost Efficiency

While the initial investment in surface mount assembly equipment can be significant, the long-term cost savings are substantial. The increased speed and efficiency of SMT reduce labor costs and minimize material waste. Furthermore, the ability to produce high-quality products with fewer defects lowers the costs associated with returns and repairs.

Flexibility in Design

Surface mount technology allows for greater flexibility in PCB design. Designers can incorporate a wider variety of components, including smaller and more complex parts, without worrying about the limitations of through-hole technology. This flexibility enables the development of innovative products that can meet diverse consumer needs.

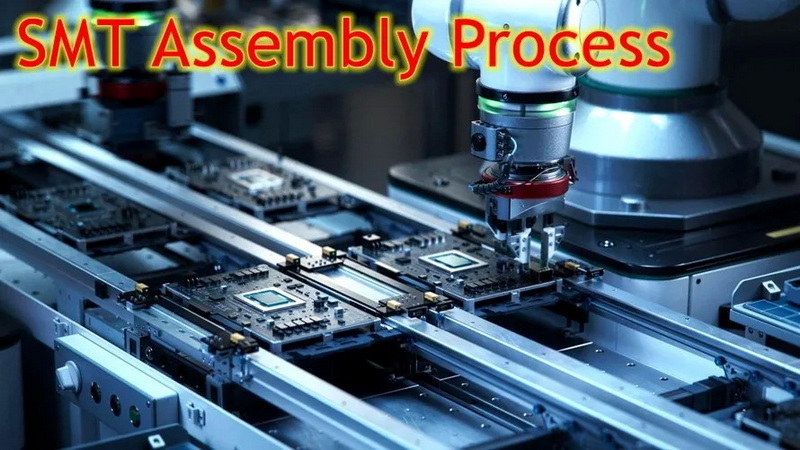

The Role of Automation in SMT

Automation plays a crucial role in the efficiency of surface mount assembly. Automated systems streamline the entire assembly process, from component placement to soldering and inspection. Here are some key aspects of automation in SMT:

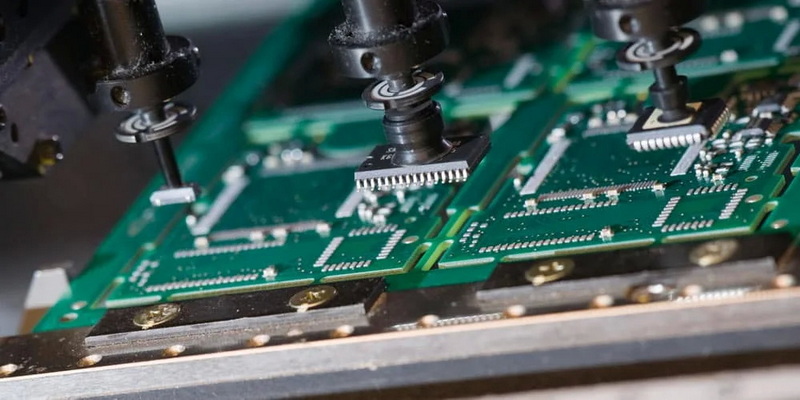

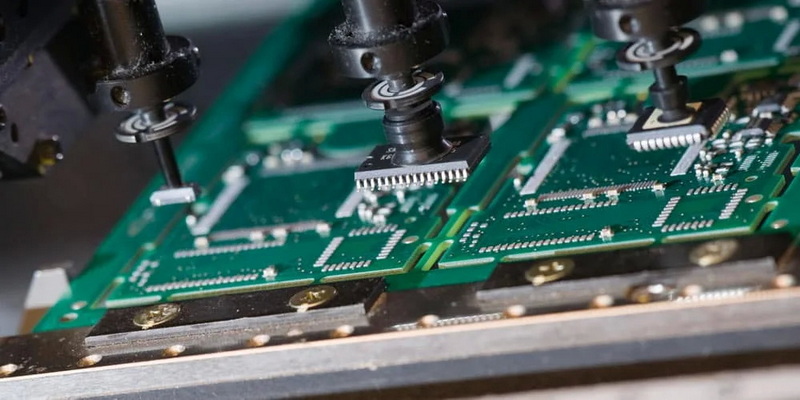

Automated Pick-and-Place Machines

These machines are designed to quickly and accurately place components onto PCBs. They use advanced robotics and vision systems to identify and position components with high precision. This automation reduces the risk of human error and increases the overall speed of the assembly process.

Soldering Techniques

Modern surface mount assembly equipment often includes automated soldering solutions, such as reflow ovens and selective soldering machines. These technologies ensure that solder is applied consistently and accurately, which is critical for the reliability of the final product.

Integrated Testing and Inspection

Quality control is essential in electronics manufacturing. Many SMT machines come equipped with integrated testing and inspection capabilities, allowing for real-time monitoring of the assembly process. Automated optical inspection (AOI) systems can detect defects such as misaligned components or insufficient solder joints, ensuring that only high-quality products reach the market.

Challenges in Surface Mount Assembly

Despite its many advantages, surface mount technology is not without challenges. Manufacturers must navigate several issues to fully leverage the benefits of SMT:

Component Handling

SMT components are often smaller and more delicate than their through-hole counterparts, making handling and placement more challenging. Manufacturers must invest in high-quality surface mount assembly equipment that can handle these components without causing damage.

Thermal Management

As electronic devices become more compact, managing heat dissipation becomes increasingly important. SMT designs must consider thermal management solutions to prevent overheating and ensure the longevity of the product.

Design Complexity

While SMT allows for greater design flexibility, it also introduces complexity. Designers must carefully consider the layout of components to ensure optimal performance and manufacturability. This complexity can lead to longer design cycles and increased costs if not managed properly.

Future Trends in Surface Mount Technology

The landscape of surface mount technology is continually evolving. Here are some trends that are shaping the future of SMT:

Miniaturization of Components

As consumer demand for smaller devices grows, manufacturers are focusing on the miniaturization of components. This trend requires advanced surface mount assembly equipment capable of handling increasingly tiny parts without compromising quality.

Smart Manufacturing

The integration of smart technologies into SMT processes is on the rise. Manufacturers are adopting Industry 4.0 principles, utilizing data analytics and IoT devices to optimize production processes and improve efficiency.

Sustainable Practices

Sustainability is becoming a key consideration in electronics manufacturing. Companies are exploring eco-friendly materials and processes, including lead-free solder and energy-efficient SMT equipment, to reduce their environmental impact.

Conclusion

Surface Mount Technology has transformed the landscape of electronic assembly, offering numerous benefits that enhance efficiency, reduce costs, and improve product quality. As manufacturers continue to adopt advanced surface mount assembly equipment, they can meet the growing demands of the market while maintaining high standards of reliability and performance. The future of SMT looks promising, with ongoing innovations and trends that will further drive efficiency and sustainability in the electronics industry.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for higher component density and improved assembly efficiency.

2. How does SMT improve production speed?

SMT improves production speed through the use of automated pick-and-place machines that can place thousands of components per hour, significantly reducing assembly time compared to manual methods.

3. What are the advantages of using surface mount assembly equipment?

The advantages include increased component density, enhanced production speed, improved reliability and quality, cost efficiency, and greater design flexibility.

4. What challenges are associated with surface mount assembly?

Challenges include handling delicate components, managing thermal issues, and navigating the complexity of PCB design.

5. What future trends are influencing surface mount technology?

Future trends include the miniaturization of components, the adoption of smart manufacturing practices, and a focus on sustainable manufacturing processes.