Content Menu

● Understanding Surface Mount Technology

>> Advantages of SMT

● The Role of SMT Equipment in PCB Assembly

>> 1. Pick-and-Place Machines

>>> Benefits:

>> 2. Solder Paste Printers

>>> Benefits:

>> 3. Reflow Ovens

>>> Benefits:

>> 4. Inspection Equipment

>>> Benefits:

● Impact on PCB Assembly Efficiency

>> Increased Production Speed

>> Enhanced Quality Control

>> Cost Reduction

>> Flexibility in Production

● Challenges in Implementing SMT Equipment

>> High Initial Investment

>> Technical Expertise Required

>> Maintenance Requirements

● Future Trends in Surface Mount Technology Equipment Market

>> Miniaturization of Components

>> Smart Manufacturing Technologies

>> Sustainable Practices

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology?

>> 2. How does pick-and-place machinery improve efficiency?

>> 3. What are common types of SMT equipment?

>> 4. What challenges do manufacturers face when implementing SMT?

>> 5. How does automation impact labor costs in PCB assembly?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, particularly in the realm of Printed Circuit Board (PCB) assembly. As demand for smaller, more efficient electronic devices grows, the SMT equipment market has expanded significantly. This article explores how SMT equipment influences PCB assembly efficiency, delves into the various types of equipment available, and discusses the benefits and challenges associated with their implementation.

Understanding Surface Mount Technology

Surface Mount Technology is a method for producing electronic circuits where components are mounted directly onto the surface of PCBs. Unlike traditional through-hole technology, where components are inserted into holes on the PCB and soldered from the other side, SMT allows for a more compact design and higher component density.

Advantages of SMT

- Reduced Size: SMT components are generally smaller than their through-hole counterparts, allowing for more compact circuit designs.

- Higher Component Density: More components can fit on a single PCB, enhancing functionality without increasing size.

- Improved Performance: Shorter electrical paths reduce resistance and inductance, improving signal integrity.

- Automated Assembly: SMT is highly compatible with automated assembly processes, increasing production speed and reducing labor costs.

The Role of SMT Equipment in PCB Assembly

The efficiency of PCB assembly is heavily influenced by the type and quality of SMT equipment used. Here are some key pieces of equipment that play a vital role in this process:

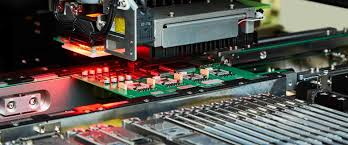

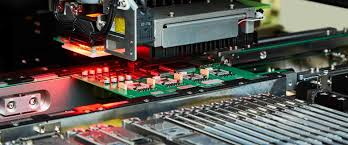

1. Pick-and-Place Machines

Pick-and-place machines are essential for SMT assembly as they automate the process of placing components onto PCBs. These machines use robotic arms to pick up components from a feeder and place them accurately on the board.

Benefits:

- Speed: Modern pick-and-place machines can place thousands of components per hour.

- Precision: High accuracy reduces the risk of misplacement, which can lead to assembly defects.

- Flexibility: Many machines can handle various component sizes and types, making them adaptable to different production needs.

2. Solder Paste Printers

Solder paste printers apply solder paste to the PCB pads before components are placed. The quality of solder paste application is critical for ensuring reliable solder joints.

Benefits:

- Uniform Application: Advanced printers ensure consistent solder paste thickness, reducing defects.

- Speed: Automated printing processes significantly increase throughput compared to manual methods.

3. Reflow Ovens

Reflow ovens are used to melt solder paste after components are placed on the PCB. The process involves heating the entire board to a specific temperature profile to ensure proper soldering.

Benefits:

- Controlled Environment: Precise temperature control minimizes thermal stress on components.

- High Throughput: Reflow ovens can process multiple boards simultaneously, enhancing production efficiency.

4. Inspection Equipment

Inspection equipment, such as Automated Optical Inspection (AOI) systems, ensures that PCBs are assembled correctly before they move to the next stage.

Benefits:

- Defect Detection: Early detection of defects reduces rework costs and improves overall quality.

- Data Collection: Inspection systems can provide valuable data for process improvement.

Impact on PCB Assembly Efficiency

The integration of advanced SMT equipment significantly impacts PCB assembly efficiency in several ways:

Increased Production Speed

With automated processes like pick-and-place and solder paste printing, manufacturers can achieve higher production rates compared to manual assembly methods. This speed is crucial in meeting market demands for rapid product development cycles.

Enhanced Quality Control

SMT equipment often comes with built-in quality control features that help detect errors early in the assembly process. This capability reduces waste and rework, leading to more efficient operations overall.

Cost Reduction

Although initial investments in high-quality SMT equipment can be substantial, the long-term cost savings from increased efficiency and reduced defect rates often outweigh these costs. Automated processes also lower labor costs by minimizing manual intervention.

Flexibility in Production

Modern SMT equipment is designed to handle various component types and sizes, allowing manufacturers to quickly switch between different products. This flexibility is essential in today's fast-paced electronics market where product lifecycles are short.

Challenges in Implementing SMT Equipment

Despite its advantages, implementing SMT equipment comes with challenges:

High Initial Investment

The cost of purchasing advanced SMT machinery can be prohibitive for smaller manufacturers. However, many find that this investment pays off over time through increased efficiency and reduced labor costs.

Technical Expertise Required

Operating sophisticated SMT equipment requires skilled personnel who understand both the technology and the nuances of PCB assembly processes. Training staff can be time-consuming and costly.

Maintenance Requirements

Regular maintenance is essential to keep SMT equipment running smoothly. Downtime due to maintenance can impact production schedules and efficiency if not managed properly.

Future Trends in Surface Mount Technology Equipment Market

As technology continues to evolve, several trends are shaping the future of the SMT equipment market:

Miniaturization of Components

As electronic devices become smaller, there is a growing demand for even more compact SMT equipment capable of handling miniature components without compromising performance or quality.

Smart Manufacturing Technologies

The integration of IoT (Internet of Things) technologies into SMT equipment allows for real-time monitoring and data collection, enabling manufacturers to optimize their processes continuously.

Sustainable Practices

There is an increasing focus on sustainability within manufacturing processes. Companies are looking for ways to reduce waste and energy consumption associated with PCB assembly through innovative technologies and practices.

Conclusion

In conclusion, surface mount technology equipment plays a crucial role in enhancing PCB assembly efficiency. By automating key processes such as component placement, soldering, and inspection, manufacturers can achieve higher production speeds, improved quality control, and significant cost savings over time. While there are challenges associated with implementing this technology—such as high initial investments and technical expertise requirements—the long-term benefits often outweigh these hurdles. As trends like miniaturization and smart manufacturing continue to shape the industry, it is clear that advancements in SMT equipment will remain pivotal in meeting future demands within the electronics sector.

FAQ

1. What is Surface Mount Technology?

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of PCBs instead of being inserted into holes. This technique allows for smaller devices with higher component density.

2. How does pick-and-place machinery improve efficiency?

Pick-and-place machinery automates the placement of components onto PCBs at high speeds with precision. This reduces manual labor time significantly while increasing production rates and minimizing errors during assembly.

3. What are common types of SMT equipment?

Common types of SMT equipment include pick-and-place machines, solder paste printers, reflow ovens, and inspection systems like Automated Optical Inspection (AOI).

4. What challenges do manufacturers face when implementing SMT?

Manufacturers may face challenges such as high initial investments in advanced machinery, the need for skilled operators familiar with complex systems, and regular maintenance requirements that can lead to downtime if not managed effectively.

5. How does automation impact labor costs in PCB assembly?

Automation reduces reliance on manual labor by streamlining processes such as component placement and soldering. This leads to lower labor costs over time as fewer workers are needed for assembly operations while maintaining or increasing production capacity.