Content Menu

● Introduction to Solder Paste

>> Composition of Solder Paste

● Role of Solder Paste in PCB Assembly

>> Impact on Solder Joint Formation

>> Influence on Manufacturing Yield

● Solder Paste Application Techniques

>> 1. Stencil Printing

>> 2. Jet Printing

>> 3. Manual Dispensing

● Factors Affecting Solder Paste Performance

● Impact of Solder Paste Quality on PCB Assembly Outcomes

>> Effects on Electrical Performance

>> Influence on Mechanical Strength

● Best Practices for SMT Printing

● Circuit Board Printing Machines and SMT Assembly

>> Future Developments in Solder Paste Technology

● Challenges in Solder Paste Application

● Overcoming Challenges with Advanced Technologies

● Conclusion

● FAQ

>> 1. What is the primary role of solder paste in PCB assembly?

>> 2. How does stencil printing affect solder paste application?

>> 3. What are the common defects associated with poor solder paste application?

>> 4. How does the composition of solder paste impact its performance?

>> 5. What are the best practices for handling solder paste?

Solder paste is a crucial component in the Surface Mount Technology (SMT) assembly process for printed circuit boards (PCBs). It plays a pivotal role in creating reliable electrical and mechanical connections between components and the PCB pads. The quality of solder paste significantly impacts the outcome of PCB assembly, affecting factors such as solder joint integrity, electrical performance, and manufacturing yield. In this article, we will delve into the importance of solder paste quality, its composition, application methods, and how it influences PCB assembly outcomes.

Introduction to Solder Paste

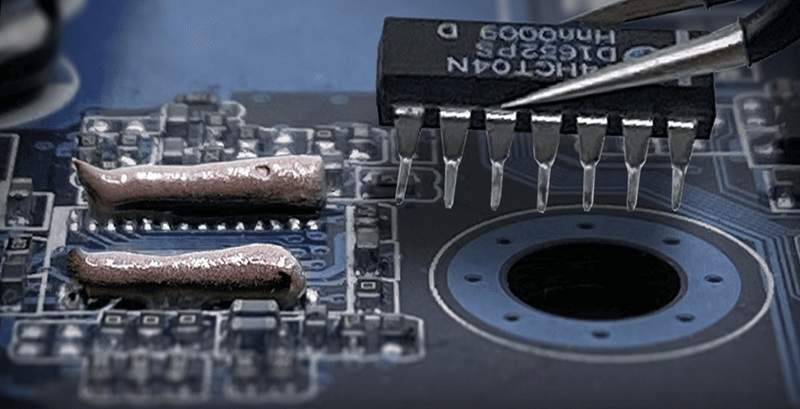

Solder paste is a mixture of finely powdered solder alloy and flux, which acts as a temporary adhesive to hold components in place before the reflow soldering process. The solder alloy melts during reflow, forming solid connections, while the flux removes oxidation from metal surfaces, ensuring proper wetting and adhesion of the solder.

Composition of Solder Paste

The composition of solder paste includes:

- Solder Alloy: Common alloys are Sn63/Pb37 (tin-lead) and SAC305 (tin-silver-copper) for lead-free applications. The choice of alloy depends on the specific requirements of the PCB, such as operating temperature and environmental conditions.

- Flux: Removes oxides and ensures proper wetting of the solder. Fluxes can be classified into different types based on their activity level and residue characteristics.

- Rheology Modifiers: Maintain viscosity and stability during printing and placement. These additives ensure that the solder paste flows smoothly under pressure but retains its shape once applied.

Role of Solder Paste in PCB Assembly

Solder paste is essential for creating reliable solder joints, which are critical for the electrical and mechanical integrity of PCBs. It acts as a glue that holds components in place during assembly and facilitates the formation of strong electrical connections during the reflow process.

Impact on Solder Joint Formation

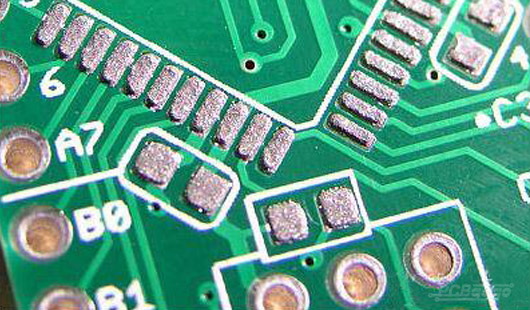

The quality and consistency of solder paste application directly affect solder joint formation. Insufficient or excessive solder paste can lead to weak and unreliable joints, prone to electrical failures due to high resistance and poor mechanical strength. Proper solder paste application ensures robust joints, reducing the risk of premature failures or intermittent connections.

Influence on Manufacturing Yield

The quality of solder paste also impacts manufacturing yield. Defects such as bridging, tombstoning, and cold solder joints can significantly reduce yield, leading to increased production costs and delays. High-quality solder paste minimizes these defects, ensuring a higher percentage of defect-free assemblies.

Solder Paste Application Techniques

There are several methods for applying solder paste to PCBs, each with its advantages and best practices:

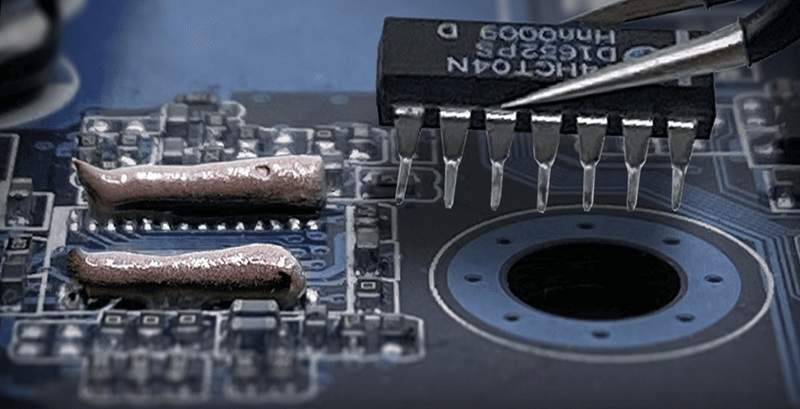

1. Stencil Printing

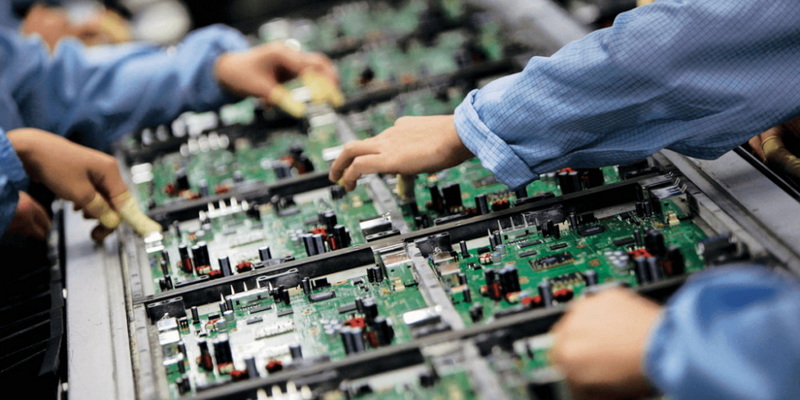

Stencil printing is the most widely used technique, involving a laser-cut stainless steel stencil aligned over the PCB. A squeegee blade spreads solder paste evenly across the openings, ensuring a controlled amount of paste deposition for optimal reflow soldering. This method is ideal for high-volume production due to its precision and repeatability.

2. Jet Printing

Jet printing is an advanced technique where solder paste is dispensed in precise droplets without a stencil. It is suitable for prototyping and low-volume production, especially for complex PCB layouts with varying pad sizes. Jet printing offers flexibility and reduces material waste compared to traditional stencil methods.

3. Manual Dispensing

Manual dispensing involves using syringes to apply solder paste directly onto PCB pads. This method is typically used for repair work and low-volume assemblies but lacks the precision of stencil and jet printing. It requires skilled operators to ensure consistent application.

Factors Affecting Solder Paste Performance

Several factors must be controlled to ensure defect-free assembly:

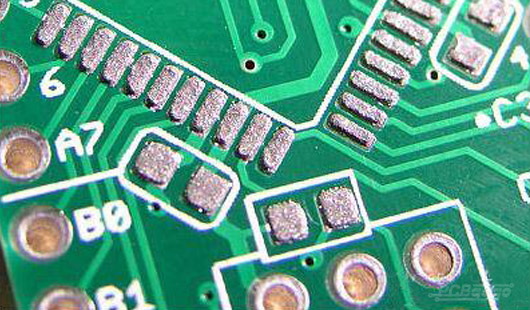

- Viscosity and Thixotropy: Solder paste must maintain the right viscosity to flow smoothly yet retain its shape on PCB pads. Thixotropic behavior ensures that paste spreads under pressure but retains structure once applied.

- Particle Size and Distribution: The size of solder particles affects print resolution and reflow behavior. Common classifications include Type 3, Type 4, and Type 5 for different applications. Smaller particles offer better print resolution but may require more precise control during application.

- Storage and Handling: Solder paste requires refrigerated storage to prevent premature oxidation and degradation. Before use, it should be brought to room temperature to avoid condensation issues that could affect paste consistency.

Impact of Solder Paste Quality on PCB Assembly Outcomes

The quality of solder paste significantly affects the reliability and performance of PCB assemblies. Poor solder paste application can lead to defects such as tombstoning, bridging, and cold solder joints, which compromise circuit reliability. High-quality solder paste ensures robust solder joints, reducing the risk of premature failures and improving manufacturing yield.

Effects on Electrical Performance

Solder paste quality also impacts the electrical performance of PCBs. Reliable solder joints ensure low resistance and stable connections, which are critical for high-speed digital circuits and sensitive analog circuits. Poor solder joints can lead to signal degradation and noise, affecting overall system performance.

Influence on Mechanical Strength

Mechanical strength of solder joints is equally important, especially in applications where PCBs are subjected to vibration, thermal cycling, or mechanical stress. High-quality solder paste ensures joints that can withstand these stresses without compromising electrical integrity.

Best Practices for SMT Printing

To ensure reliable and high-quality SMT assembly, adhering to best practices is crucial:

- Use High-Quality Solder Paste: Ensure the solder paste is fresh and stored properly to maintain its performance.

- Optimize Stencil Design: Ensure the stencil is accurately aligned with PCB pads to prevent misregistration.

- Maintain Cleanliness: Keep the PCB surface clean and free of contaminants to ensure proper solder wetting.

- Monitor Environmental Conditions: Control temperature and humidity during assembly to prevent paste degradation and ensure consistent application.

Circuit Board Printing Machines and SMT Assembly

Circuit board printing machines, such as those using inkjet technology, are revolutionizing PCB manufacturing by enabling on-demand production of multi-layer PCBs. However, traditional SMT assembly still relies heavily on solder paste for component attachment and electrical connection formation. The integration of advanced printing technologies with SMT processes may offer future improvements in efficiency and quality.

Future Developments in Solder Paste Technology

Advancements in solder paste technology are focused on improving printability, reducing defects, and enhancing environmental sustainability. Lead-free solder pastes are becoming more prevalent due to regulatory requirements, and research into new alloys aims to improve thermal stability and reduce costs.

Challenges in Solder Paste Application

Despite its importance, solder paste application poses several challenges:

- Stencil Design Complexity: Ensuring accurate alignment and optimal aperture design can be complex, especially for dense PCB layouts.

- Paste Consistency: Maintaining consistent paste viscosity and particle distribution is crucial for reliable application.

- Environmental Factors: Temperature and humidity control are essential to prevent paste degradation and ensure consistent performance.

Overcoming Challenges with Advanced Technologies

Advanced technologies are being developed to address these challenges:

- Automated Inspection Systems: These systems help detect defects early in the assembly process, reducing rework and improving yield.

- Advanced Stencil Materials: New materials offer improved durability and precision, reducing the need for frequent stencil replacements.

- Smart Factory Integration: Implementing Industry 4.0 concepts allows for real-time monitoring and optimization of assembly processes, enhancing efficiency and quality.

Conclusion

In conclusion, the quality of solder paste is paramount in achieving reliable and high-quality PCB assemblies. Proper application techniques, such as stencil printing and jet printing, combined with best practices in handling and storage, are essential for minimizing defects and ensuring robust solder joints. As electronics continue to evolve with more complex and miniaturized designs, the role of solder paste in SMT assembly will remain critical.

FAQ

1. What is the primary role of solder paste in PCB assembly?

Solder paste acts as a temporary adhesive to hold components in place and facilitates the formation of strong electrical connections during the reflow process by melting into solder joints.

2. How does stencil printing affect solder paste application?

Stencil printing ensures uniform and precise application of solder paste across multiple PCB pads, which is crucial for achieving reliable solder joints and minimizing defects.

3. What are the common defects associated with poor solder paste application?

Common defects include tombstoning, bridging, and cold solder joints, which can lead to electrical failures and compromise circuit reliability.

4. How does the composition of solder paste impact its performance?

The composition, including solder alloy, flux, and rheology modifiers, affects the solder paste's ability to form reliable solder joints and maintain viscosity during application.

5. What are the best practices for handling solder paste?

Best practices include storing solder paste in refrigerated conditions, allowing it to reach room temperature before use, and ensuring thorough mixing to maintain uniformity.