Content Menu

● Introduction to SMT

● Advantages of SMT in PCB Assembly

● Integration with BGA Assembly

● BGA Assembly Process

● Improving SMT Efficiency

● Recent Advancements in SMT Technology

● Future Trends in SMT Machines

● Applications of SMT and BGA Assembly

● Challenges and Future Developments

● Role of Automation in SMT Assembly

● Impact of SMT on the Electronics Industry

● Environmental Considerations

● Conclusion

● FAQs

>> 1. What are the primary benefits of using SMT over through-hole technology?

>> 2. How does BGA assembly enhance PCB performance?

>> 3. What are some common defects encountered during SMT assembly?

>> 4. How can manufacturers improve the efficiency of SMT mounters?

>> 5. What role does automation play in SMT assembly?

● Citations:

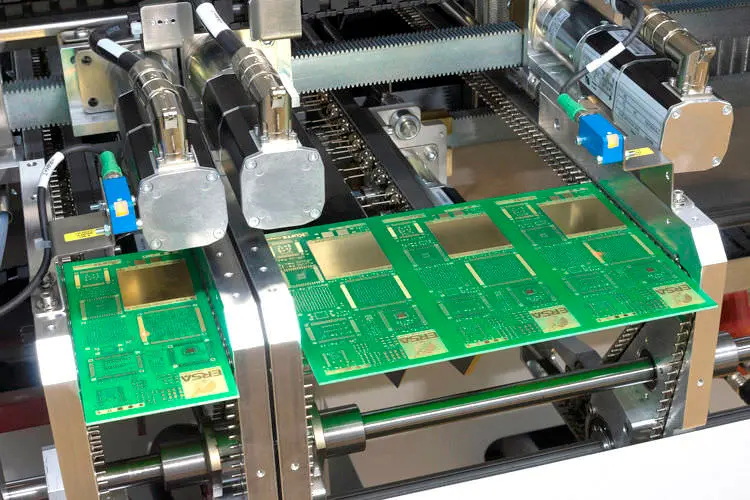

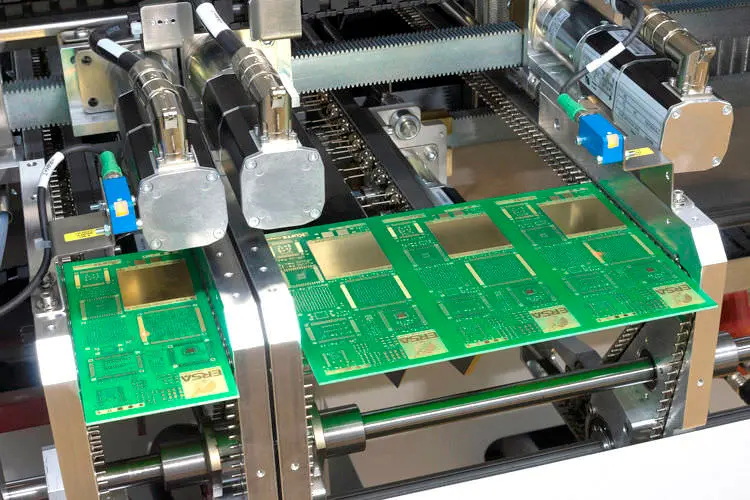

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by significantly improving the efficiency of Printed Circuit Board Assembly (PCBA). This technology involves mounting components directly onto the surface of a PCB, offering numerous advantages over traditional through-hole technology. In this article, we will explore how SMT enhances PCBA efficiency, its applications, and its integration with other technologies like Ball Grid Array (BGA) assembly.

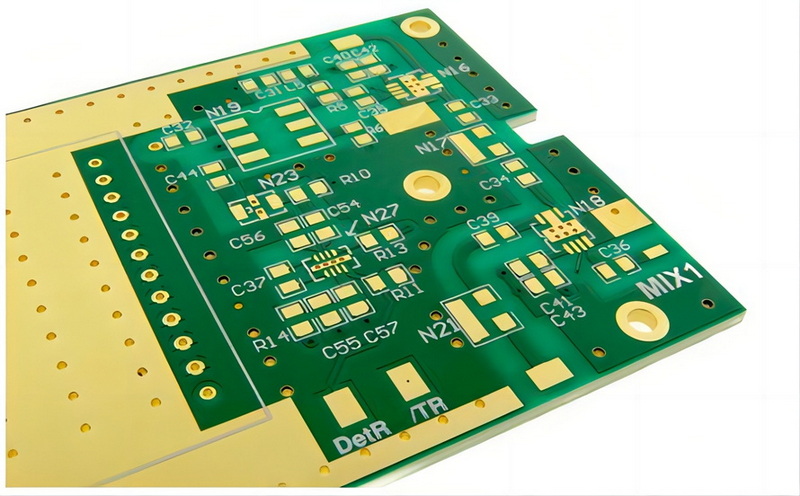

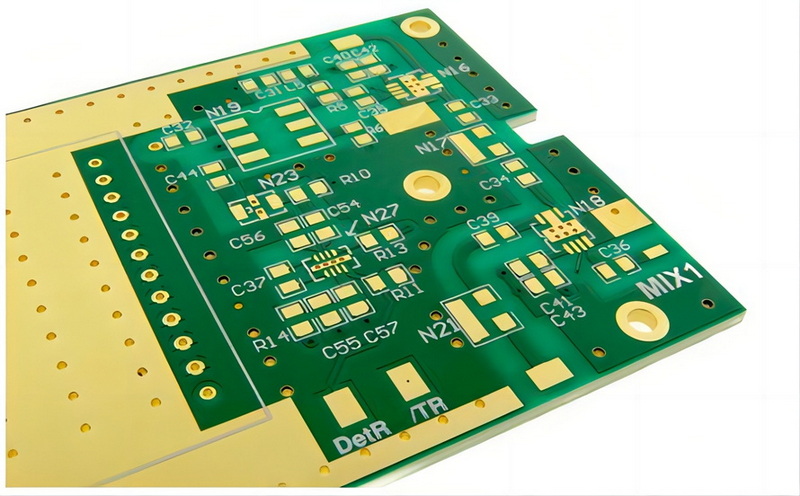

Introduction to SMT

SMT is a method of assembling electronic components onto a PCB by mounting them directly onto the board's surface. This approach allows for compact designs, faster assembly, and improved electrical performance compared to through-hole technology. SMT components are smaller and lighter, enabling higher component density on PCBs, which is crucial for modern electronic devices such as smartphones and laptops.

Advantages of SMT in PCB Assembly

1. Higher Component Density: SMT allows for more components to be placed on a smaller area of the PCB, increasing the overall functionality of the board while reducing its size and weight. This miniaturization is essential for portable and compact electronic devices.

2. Improved Electrical Performance: The shorter leads in SMT components reduce signal distortion and improve signal integrity, making them ideal for high-frequency applications.

3. Cost-Effectiveness: SMT reduces production costs by minimizing manual labor through automation. This automation also decreases human error, leading to higher quality and consistency in production.

4. Enhanced Reliability: SMT solder joints are more reliable than those in through-hole technology, offering better resistance to thermal stress and mechanical vibrations.

5. Faster Assembly: SMT supports high-speed automated assembly, allowing thousands of components to be placed per hour, significantly reducing production time compared to through-hole technology.

Integration with BGA Assembly

BGA assembly is another critical technology used in PCBA, particularly for high-density and high-performance applications. BGA components have solder balls on their underside that connect to the PCB during the reflow soldering process. The integration of SMT with BGA assembly enhances the efficiency and reliability of PCBs by allowing for more complex designs and higher component densities.

BGA Assembly Process

The BGA assembly process involves several key steps:

- PCB Preparation: The PCB is cleaned and prepared with solder paste applied to designated pad areas using a stencil.

- Component Placement: A pick-and-place machine accurately positions the BGA component onto the PCB.

- Reflow Soldering: The PCB is heated in a reflow oven to melt the solder balls, forming solid solder joints.

- Inspection and Quality Control: Advanced inspection techniques like X-ray imaging are used to verify solder joint integrity.

Improving SMT Efficiency

To further enhance SMT efficiency, manufacturers can implement several strategies:

- Invest in High-Speed Placement Machines: These machines can mount components faster, increasing production output and reducing assembly time.

- Optimize the SMT Process: This includes optimizing machine setup, selecting the right component feeders, and using appropriate solder paste.

- Implement Inline Inspection Systems: These systems detect defects early in the production process, reducing rework and improving quality control.

- Automate Material Handling: Automating material transport and feeder changeovers reduces manual intervention and increases material uptime.

Recent Advancements in SMT Technology

Recent advancements in SMT technology have significantly transformed the landscape of PCB assembly. Innovations such as the integration of artificial intelligence (AI) and machine learning enable real-time monitoring and adaptive learning within production lines. These technologies facilitate predictive maintenance and quicker response times to anomalies, enhancing overall assembly efficiency[1]. Additionally, advanced solder materials have improved reliability while reducing defects in assembled boards[1].

Automated optical inspection (AOI) systems are another key innovation, detecting errors at various stages of assembly and ensuring that discrepancies are logged and addressed promptly[1]. Modular equipment has also enabled greater flexibility in production setups, allowing for rapid changeovers between different SMT assembly configurations without significant downtime[1].

Future Trends in SMT Machines

Future SMT machines will become more intelligent and automated, incorporating AI, machine learning, and Internet of Things (IoT) technologies. These advancements will enable self-learning, optimize production processes, allow for remote monitoring, and conduct predictive maintenance, thereby improving production efficiency and product quality[2].

SMT machines will also focus on achieving higher precision and speed, adopting advanced visual recognition systems and precision mechanical structures to meet the demands of miniaturization and high-density assembly[2]. Multifunctionality and high integration will be key features, enabling machines to handle various types of components with different package forms, such as BGA, CSP, and FC[2].

Applications of SMT and BGA Assembly

SMT and BGA assembly technologies are widely used in various industries:

- Consumer Electronics: Smartphones, tablets, and laptops rely heavily on SMT and BGA for compact and high-performance designs.

- Automotive Electronics: Modern vehicles utilize SMT and BGA components for reliability and performance in control systems.

- Medical Devices: Compact and efficient designs are crucial for advanced medical equipment, benefiting from SMT and BGA technologies.

Challenges and Future Developments

Despite the advantages, SMT and BGA assembly face challenges such as component fragility and the need for advanced soldering technology. Future developments focus on improving process automation, reducing defects, and enhancing component reliability.

Role of Automation in SMT Assembly

Automation plays a critical role in SMT assembly by reducing human error and increasing throughput. Advanced pick-and-place machines equipped with sophisticated software can place thousands of components per hour with remarkable precision, tailored for various shapes and sizes[1]. The integration of AI and machine learning further enhances automation by optimizing production processes and enabling predictive maintenance[2].

Impact of SMT on the Electronics Industry

The SMT market is expected to grow significantly due to its superior performance in miniaturization and high-volume production. The development of advanced automation and robotics is emerging as a key opportunity for the SMT market, addressing the need for faster production cycles and higher precision[5].

Environmental Considerations

As the electronics industry continues to evolve, environmental considerations are becoming increasingly important. Future SMT machines will focus on green production and environmental protection technologies, such as using environmentally friendly materials, reducing energy consumption, and minimizing waste emissions[2].

Conclusion

SMT technology has significantly improved the efficiency of PCB assembly by offering higher component density, improved electrical performance, and cost-effectiveness. Its integration with BGA assembly further enhances the reliability and performance of electronic devices. As the electronics industry continues to evolve, optimizing SMT processes and investing in advanced technologies will remain crucial for manufacturers seeking to improve production efficiency and product quality.

FAQs

1. What are the primary benefits of using SMT over through-hole technology?

- SMT offers smaller component sizes, faster automated assembly, improved electrical performance, and greater design flexibility compared to through-hole technology.

2. How does BGA assembly enhance PCB performance?

- BGA assembly provides better electrical performance due to shorter signal paths and is ideal for high-density applications, enhancing overall PCB reliability and functionality.

3. What are some common defects encountered during SMT assembly?

- Common defects include solder bridging, tombstoning, insufficient solder, misaligned components, and voids in solder joints, often mitigated through precise inspection and process control.

4. How can manufacturers improve the efficiency of SMT mounters?

- Efficiency can be improved by investing in high-speed placement machines, optimizing the SMT process, implementing inline inspection systems, automating material handling, and training operators effectively.

5. What role does automation play in SMT assembly?

- Automation in SMT assembly significantly reduces labor costs and increases production efficiency by allowing for high-speed component placement and minimizing human error, contributing to higher product quality and consistency.

Citations:

[1] https://www.andwinpcb.com/advancements-in-smt-assembly-technology-for-modern-electronics/

[2] https://www.hwgcsmt.com/news/new-technological-trends-in-the-smt-machine-in-84515003.html

[3] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[4] https://www.andwinpcb.com/innovations-in-smt-assembly-for-enhanced-circuit-board-production/

[5] https://www.cognitivemarketresearch.com/articles/surface-mount-technology-smt-market-trends-and-future-opportunities

[6] https://www.pcbpower.us/blog/unveiling-the-advantages-and-disadvantages-of-surface-mount-technology

[7] https://www.linkedin.com/pulse/latest-advancements-pcb-assembly-technologies-whats-new-2024-xo2qf

[8] https://blog.tbrc.info/2025/02/surface-mount-technology-equipment-market/

[9] https://arkcircuits.com/blog/impact-of-smt-on-modern-pcb-design/

[10] https://novaenginc.com/future-of-circuit-board-assembly/

[11] https://www.mordorintelligence.com/industry-reports/surface-mount-technology-market

[12] https://jlcpcb.com/blog/the-characteristics-of-surface-mount-technology

[13] https://www.unmannedsystemstechnology.com/feature/mpl-explains-the-evolution-of-smt-technology/

[14] https://www.neodentech.com/newsinfo/1008374.html

[15] https://www.ultralibrarian.com/2021/08/10/the-impact-of-smt-components-on-pcb-assembly-ulc

[16] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[17] https://www.wicz.com/story/52475077/surface-mount-technology-smt-equipment-market-demands-and-projected-outlook-for-2025-2033

[18] https://www.linkedin.com/pulse/impact-smt-printing-pcb-assembly-quality-0c0mc

[19] https://www.pcbgogo.com/Article/Innovations_in_printed_circuit_board_assembly__trends_and_techniques.html

[20] https://smtcorp.com/semiconductor-chip-industry-trends/