Content Menu

● Introduction to SMT Stencil Aperture Design

>> Key Factors in SMT Stencil Aperture Design

● Impact of SMT Stencil Aperture Size on PCB Assembly Quality

● Challenges and Solutions in SMT Stencil Aperture Design

>> Challenges

>> Solutions

● Best Practices for SMT Stencil Aperture Design

● Emerging Technologies in SMT Stencil Design

● Conclusion

● FAQs

>> 1. What is the purpose of the "half pitch rule" in SMT stencil aperture design?

>> 2. How does the aspect ratio affect solder paste release from the stencil?

>> 3. What is the significance of the area ratio in SMT stencil aperture design?

>> 4. How do stepped stencils address the challenge of varying component sizes on a PCB?

>> 5. What materials are commonly used for SMT stencils, and why?

● Citations:

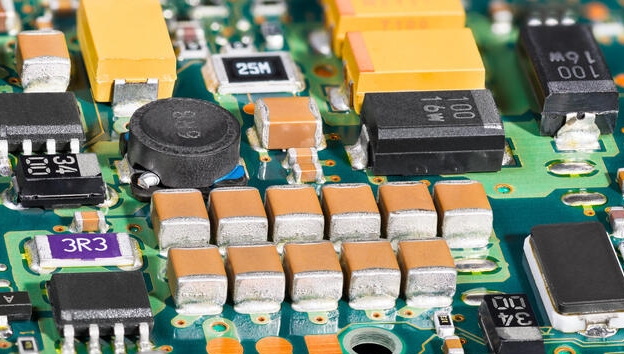

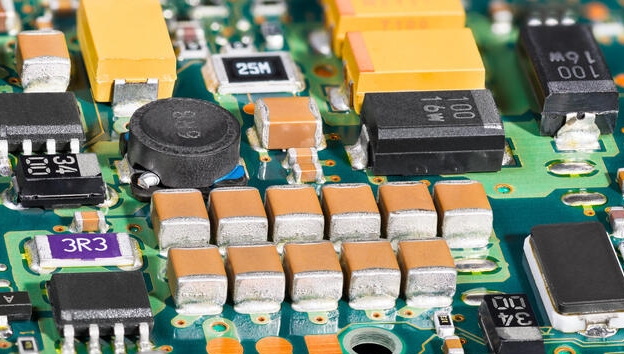

The quality of PCB (Printed Circuit Board) assembly is heavily influenced by several factors, with the SMT (Surface Mount Technology) stencil aperture size being one of the most critical. The SMT stencil is a crucial tool in the PCB assembly process, as it determines the amount and precision of solder paste applied to the PCB pads. In this article, we will delve into the importance of SMT stencil aperture design and its impact on PCB assembly quality.

Introduction to SMT Stencil Aperture Design

SMT stencil aperture design involves creating precise openings in a stencil to deposit solder paste onto PCB pads. The size and shape of these apertures are tailored to match the specific requirements of the components being assembled. Proper aperture design ensures that the right amount of solder paste is applied, which is essential for achieving reliable and robust solder joints.

Key Factors in SMT Stencil Aperture Design

1. Aperture Size and Shape: The aperture size should be carefully selected to ensure that the correct amount of solder paste is applied. Oversized apertures can lead to excessive solder paste, causing solder bridging, while undersized apertures may result in insufficient solder paste, leading to weak solder joints or solder voids[2]. Common aperture shapes include rectangles, circles, and home plates, each designed to optimize solder paste deposition for specific components[1][5].

2. Aspect Ratio: The aspect ratio, which is the ratio of the aperture width to the stencil thickness, should be greater than 1.5 to ensure smooth solder paste release[4]. This is particularly important for fine-pitch components where precise paste deposition is critical.

3. Area Ratio: The area ratio, which compares the surface area of the aperture opening to the surface area of the aperture walls, should be greater than 0.66 for optimal solder paste transfer efficiency[4]. This ensures that solder paste is efficiently released onto the PCB pads without sticking to the stencil walls.

4. Component Pitch and Type: The stencil aperture width is often reduced based on component pitch and type. For example, for components with a pitch of 0.5 mm, the aperture width might be reduced to 0.25 mm to prevent solder bridging.

5. PCB Pad Size and Surface Finish: The size of the PCB pads and the surface finish can affect the seal between the stencil and PCB, impacting solder paste application. A good seal is essential for preventing solder paste from spreading beyond the pad boundaries.

Impact of SMT Stencil Aperture Size on PCB Assembly Quality

The size of the SMT stencil aperture directly affects several aspects of PCB assembly quality:

- Solder Paste Distribution: Proper aperture size ensures that the correct volume of solder paste is applied to each pad, preventing issues like solder bridging or insufficient solder joints[2]. This is crucial for maintaining the spacing between components and ensuring reliable solder joints.

- Reflow Soldering Quality: The aperture size influences the quality of reflow soldering by ensuring that components receive the appropriate amount of solder paste, which is crucial for achieving reliable solder joints[2].

- Ease of Solder Paste Release: The aperture size and shape affect how easily solder paste releases from the stencil during printing. A well-designed aperture ensures smooth release, reducing the risk of solder paste collapse or bridging[2].

Challenges and Solutions in SMT Stencil Aperture Design

Challenges

1. Miniaturization: As components become smaller, achieving precise solder paste application becomes more challenging. Smaller apertures are required, which can lead to issues with solder paste release if not properly designed.

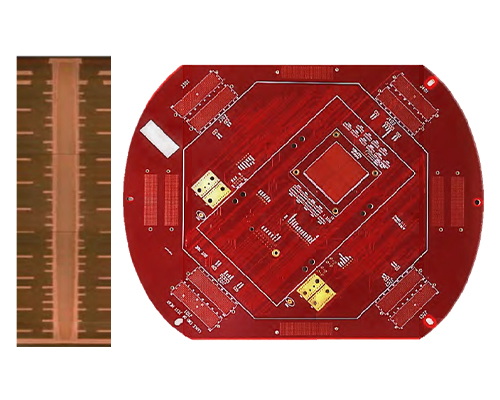

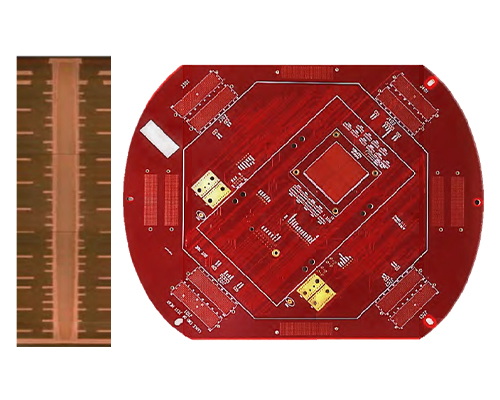

2. Variety of Component Sizes: PCBs often contain a mix of large and small components, requiring different solder paste volumes. This can be addressed using stepped stencils, which allow for varying thicknesses to accommodate different component types.

Solutions

1. Stepped Stencils: These stencils have varying thicknesses to accommodate components requiring different solder paste volumes. This approach is particularly useful for PCBs with a mix of large and small components, ensuring that each component receives the appropriate amount of solder paste.

2. Specialized Aperture Designs: Techniques like the "home plate" design can reduce mid-chip solder beads by depositing less paste on the inner edge of components[5]. This design is especially beneficial for components prone to mid-chip solder balls.

3. Advanced Materials and Coatings: Using materials like nickel or applying coatings can improve solder paste release from the stencil, enhancing overall assembly quality. For example, nano-coatings can enhance the hydrophobic properties of the stencil, making it easier for solder paste to separate from the aperture walls[1].

4. Laser Cutting and Chemical Etching: Laser cutting is the most precise method for creating stencil apertures, ideal for fine-pitch components. Chemical etching is an alternative, cost-effective process for larger apertures or thicker stencils[1].

Best Practices for SMT Stencil Aperture Design

To ensure high-quality PCB assembly, consider the following best practices:

- Optimize Aperture Size Based on Component Pitch: Use guidelines like the "half pitch rule" for fine-pitch components to minimize solder bridging.

- Consider PCB Pad Size and Surface Finish: Ensure that the stencil aperture size complements the PCB pad size and surface finish to maintain a good seal during printing.

- Use Appropriate Stencil Thickness: Select stencil thickness based on component density and spacing. Thinner stencils are preferred for fine-pitch components but may struggle with sufficient paste volume, while thicker stencils can provide robust deposits but may hinder paste release[1].

- Implement Quality Control Measures: Regularly inspect stencils for wear and ensure that they are properly cleaned and maintained to prevent defects.

Emerging Technologies in SMT Stencil Design

Recent advancements in SMT stencil technology include the introduction of BluPrint PVD Stencils by StenTech Inc. These stencils offer superior precision, durability, and cost-efficiency, reducing cleaning cycles and enhancing solder paste deposition efficiency[3]. Additionally, additive manufacturing techniques are being explored for creating complex, multi-level stencils that can accommodate a wide range of component types and sizes on a single PCB[1].

Conclusion

The SMT stencil aperture size plays a pivotal role in determining the quality of PCB assembly. Proper aperture design ensures that the right amount of solder paste is applied to each pad, which is crucial for achieving reliable solder joints. By understanding the factors that influence aperture design and implementing best practices, manufacturers can significantly improve the quality and reliability of their PCB assemblies.

FAQs

1. What is the purpose of the "half pitch rule" in SMT stencil aperture design?

The "half pitch rule" is used to determine the optimal aperture width for fine-pitch components. It suggests setting the aperture width to half of the component pitch or 1:1 with the copper pad size, whichever is smaller, to minimize solder bridging and ensure reliable solder joints.

2. How does the aspect ratio affect solder paste release from the stencil?

The aspect ratio, which is the ratio of the aperture width to the stencil thickness, should be greater than 1.5 to ensure smooth solder paste release. A higher aspect ratio reduces the likelihood of solder paste sticking to the stencil walls instead of the PCB pad.

3. What is the significance of the area ratio in SMT stencil aperture design?

The area ratio compares the surface area of the aperture opening to the surface area of the aperture walls. An area ratio greater than 0.66 ensures optimal solder paste transfer efficiency, reducing the risk of incomplete deposits.

4. How do stepped stencils address the challenge of varying component sizes on a PCB?

Stepped stencils allow for different thicknesses in various areas, accommodating components that require different solder paste volumes. This approach is particularly useful for PCBs with a mix of large and small components, ensuring that each component receives the appropriate amount of solder paste.

5. What materials are commonly used for SMT stencils, and why?

SMT stencils are commonly made from stainless steel due to its durability and precision. Nickel is also used, especially for fine-pitch devices, although it is more expensive. Coatings like nano-coatings can be applied to improve solder paste release from the stencil.

Citations:

[1] https://pcbpit.com/smt-stencil-a-comprehensive-guide/

[2] https://silmantech.com/the-importance-of-smt-stencil-thickness-and-aperture-size-in-pcb-assembly/

[3] https://www.precedenceresearch.com/news/stentech-launches-bluprint-pvd-stencils-for-smt-production-in-us

[4] https://www.7pcb.com/blog/design-principles-stencil-aperatures

[5] https://www.circuitsassembly.com/ca/editorial/menu-features/32317-comparison-of-aperture-designs-solder-pastes-nanocoatings-and-print-inspection-systems.html

[6] https://www.surfacemountprocess.com/a-guide-to-effective-stencil-design.html

[7] https://blueringstencils.com/top-5-smt-industry-trends-for-2019/

[8] https://www.circuitinsight.com/pdf/Effect_Area_Shape_Area_Ratio_Solder_Paste_Printing_Performance_smta.pdf