Content Menu

● Understanding SMT Production Lines

>> Key Components of an SMT Production Line

● Benefits of SMT Production Lines in Radiator Manufacturing

>> 1. Increased Efficiency

>> 2. Higher Component Density

>> 3. Improved Quality Control

>> 4. Cost Reduction

>> 5. Flexibility and Scalability

● The Role of Reflow Soldering in Radiator Manufacturing

● Challenges Addressed by SMT Production Lines

>> 1. Complexity of Designs

>> 2. Miniaturization Trends

>> 3. Demand for Customization

● Environmental Considerations

● Future Trends in Radiator Manufacturing with SMT

>> 1. Integration with IoT

>> 2. Smart Manufacturing Technologies

>> 3. Enhanced Collaboration Across Supply Chains

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does an SMT production line improve efficiency?

>> 3. What are the main components of an SMT production line?

>> 4. Why is reflow soldering important in radiator manufacturing?

>> 5. How does SMT contribute to environmental sustainability?

Surface Mount Technology (SMT) has revolutionized the manufacturing processes across various industries, including the production of radiators. The integration of SMT production lines into radiator manufacturing enhances efficiency, reduces costs, and improves product quality. This article explores the mechanisms through which SMT production lines transform radiator manufacturing, detailing the technological advancements and benefits they bring.

Understanding SMT Production Lines

SMT is a method where electronic components are mounted directly onto the surface of printed circuit boards (PCBs). This contrasts with traditional through-hole technology, where components are inserted into holes in the PCB. SMT has gained prominence due to its advantages in automation, efficiency, and miniaturization.

Key Components of an SMT Production Line

An SMT production line typically consists of several interconnected machines that work collaboratively to assemble electronic components onto PCBs. The main components include:

- Solder Paste Printer: Applies solder paste to designated pads on the PCB.

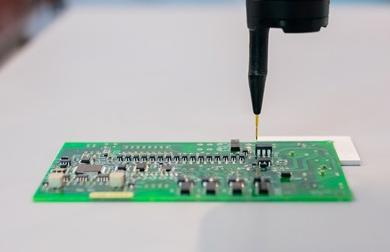

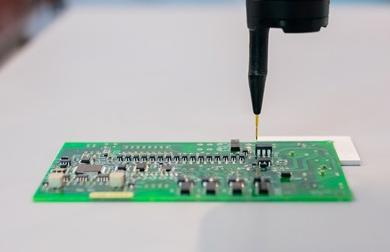

- Pick and Place Machine: Automatically places surface-mount devices (SMDs) onto the solder paste.

- Reflow Oven: Melts the solder paste to create permanent electrical connections between the components and the PCB.

- Automated Optical Inspection (AOI): Inspects for defects in component placement and solder joints.

- Cleaning Machine: Removes any residues from the PCB after assembly.

Benefits of SMT Production Lines in Radiator Manufacturing

The application of SMT in radiator manufacturing offers several advantages:

1. Increased Efficiency

SMT production lines significantly enhance manufacturing efficiency. The automation involved allows for faster assembly times compared to manual processes. For instance, pick-and-place machines can place thousands of components per hour, drastically reducing lead times for radiator production. This rapid assembly capability is essential in meeting market demands where speed is crucial.

Moreover, the streamlined workflow minimizes downtime between different stages of production. Automated systems can work continuously, allowing manufacturers to operate at higher capacities without sacrificing quality.

2. Higher Component Density

SMT allows for a higher density of components on PCBs due to the smaller size of SMDs. This is particularly beneficial for radiators that require compact designs to fit within limited spaces. The ability to mount components on both sides of a PCB further maximizes space utilization.

Higher component density not only optimizes space but also enhances functionality. Radiators can incorporate more advanced features, such as integrated sensors or control units, which improve their performance and adaptability in various applications.

3. Improved Quality Control

With automated processes, SMT production lines reduce human error associated with manual assembly. The use of AOI systems ensures that any defects in component placement or solder joints are identified early in the process, leading to higher quality radiators.

Additionally, implementing real-time monitoring systems can track various parameters during production. This data-driven approach enables manufacturers to make informed decisions quickly, addressing any issues before they escalate into significant problems.

4. Cost Reduction

The automation inherent in SMT reduces labor costs and minimizes material waste. Additionally, because SMT components are often smaller and lighter than their through-hole counterparts, transportation and handling costs are also reduced.

Furthermore, the reduction in defects means fewer reworks and returns, leading to significant cost savings over time. By investing in an SMT production line, manufacturers can achieve a quicker return on investment through enhanced productivity and lower operational costs.

5. Flexibility and Scalability

SMT production lines can be easily reconfigured to accommodate different designs or changes in production volume. This flexibility is crucial for radiator manufacturers who may need to adapt quickly to market demands or new technologies.

The ability to switch between different products without extensive downtime allows manufacturers to respond rapidly to customer needs and market trends. This adaptability is especially important in industries like automotive or consumer electronics, where design changes occur frequently.

The Role of Reflow Soldering in Radiator Manufacturing

Reflow soldering is a critical process within SMT that permanently attaches components to PCBs. The process involves several stages:

1. Preheat Zone: Gradually raises the temperature of the PCB and components to prevent thermal shock.

2. Soaking Zone: Maintains a steady temperature to allow moisture to escape from the components.

3. Reflow Zone: The temperature peaks at around 210-230°C, melting the solder paste.

4. Cooling Zone: Rapidly cools down the PCB, solidifying the solder joints.

This controlled heating process is essential for ensuring reliable connections between components and PCBs used in radiators, which often experience significant thermal stress during operation.

Challenges Addressed by SMT Production Lines

While SMT offers numerous advantages, it also addresses several challenges faced by traditional radiator manufacturing processes:

1. Complexity of Designs

Modern radiators often incorporate sophisticated electronic controls and sensors that require intricate designs. SMT's ability to handle complex layouts allows manufacturers to innovate without being constrained by traditional assembly methods.

2. Miniaturization Trends

As devices become smaller and more compact, traditional methods struggle to keep up with miniaturization trends. SMT's capacity for high-density assembly makes it ideal for producing smaller radiators that meet contemporary design requirements while maintaining performance standards.

3. Demand for Customization

With increasing consumer demand for customized products, manufacturers must be agile enough to produce small batches efficiently without incurring high costs. SMT production lines facilitate this by allowing quick changes in setup between different product runs.

Environmental Considerations

SMT production lines are generally more environmentally friendly than traditional methods due to reduced material waste and lower energy consumption during manufacturing processes. The precise application of solder paste minimizes excess use, contributing to a more sustainable manufacturing approach.

Additionally, many modern SMT processes utilize lead-free solder materials that comply with environmental regulations such as RoHS (Restriction of Hazardous Substances). This not only reduces environmental impact but also enhances product safety for consumers.

Future Trends in Radiator Manufacturing with SMT

As technology continues to evolve, several trends are likely to shape the future of radiator manufacturing using SMT:

1. Integration with IoT

The Internet of Things (IoT) is transforming how devices communicate and operate within their environments. Radiators equipped with IoT capabilities can monitor performance metrics in real-time and adjust their operation based on external conditions or user preferences.

SMT will play a crucial role in integrating these advanced features into compact designs while maintaining reliability and performance standards.

2. Smart Manufacturing Technologies

The rise of smart manufacturing technologies will further enhance the capabilities of SMT production lines. Implementing artificial intelligence (AI) and machine learning can optimize production processes by predicting maintenance needs or identifying inefficiencies before they impact output.

These technologies will enable manufacturers to achieve greater levels of automation while maintaining high quality standards throughout their operations.

3. Enhanced Collaboration Across Supply Chains

As industries become more interconnected, collaboration across supply chains will be essential for success. Manufacturers will need robust systems that facilitate communication among suppliers, distributors, and customers.

SMT production lines can integrate seamlessly with these systems, providing real-time data on inventory levels and production status that enhances overall supply chain efficiency.

Conclusion

The integration of SMT production lines into radiator manufacturing represents a significant advancement in electronics assembly technology. By enhancing efficiency, improving quality control, reducing costs, and offering flexibility, SMT not only streamlines radiator production but also meets modern demands for compact and reliable electronic devices. As industries continue to evolve towards automation and precision engineering, the role of SMT will undoubtedly expand further.

FAQ

1. What is Surface Mount Technology (SMT)?

SMT is a method used for mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs compared to traditional through-hole technology.

2. How does an SMT production line improve efficiency?

An SMT production line automates many assembly processes, allowing for faster component placement and reduced lead times compared to manual methods.

3. What are the main components of an SMT production line?

Key components include solder paste printers, pick-and-place machines, reflow ovens, automated optical inspection systems, and cleaning machines.

4. Why is reflow soldering important in radiator manufacturing?

Reflow soldering creates permanent electrical connections between components and PCBs using controlled heating processes that ensure reliability under thermal stress conditions.

5. How does SMT contribute to environmental sustainability?

SMT reduces material waste through precise solder paste application and lowers energy consumption during manufacturing processes compared to traditional methods.