Content Menu

● What is an SMT PCB Socket?

● Advantages of SMT PCB Socket in PCB Design and Performance

>> 1. Enhanced Electrical Performance

>> 2. Increased Component Density and Compactness

>> 3. Improved Manufacturing Efficiency and Cost Reduction

>> 4. Ease of Maintenance and Upgradability

>> 5. Mechanical Reliability and Vibration Resistance

>> 6. Thermal Management Considerations

● Applications of SMT PCB Sockets

● Design Considerations for SMT PCB Sockets

>> Socket Size and Pitch

>> Thermal Management

>> Mechanical Stress and Environmental Factors

>> Soldering Process

>> Testing and Inspection

● Future Trends in SMT PCB Socket Technology

● Conclusion

● FAQ

>> 1. What is the main difference between SMT PCB sockets and through-hole sockets?

>> 2. Can SMT PCB sockets be used for high-power applications?

>> 3. How do SMT PCB sockets improve signal integrity?

>> 4. Are SMT PCB sockets easy to replace or upgrade?

>> 5. What are the challenges of using SMT PCB sockets?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling compact, efficient, and high-performance printed circuit boards (PCBs). Among the critical components that leverage SMT are SMT PCB sockets, which play an essential role in enhancing the functionality, reliability, and serviceability of PCBs. This article explores how SMT PCB sockets improve your PCB's performance, highlighting their benefits, applications, and design considerations in detail.

What is an SMT PCB Socket?

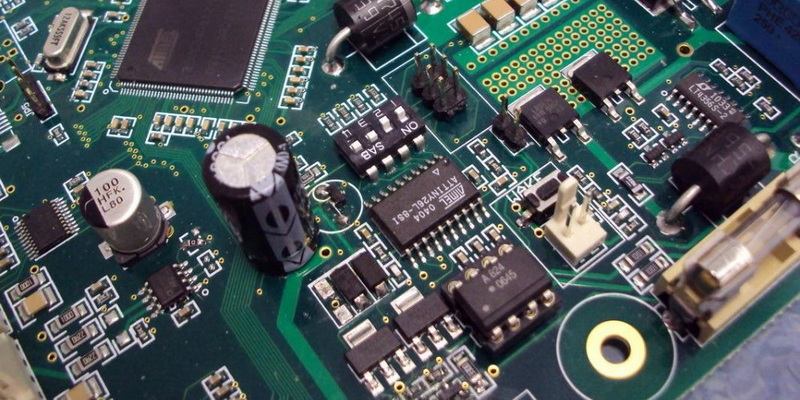

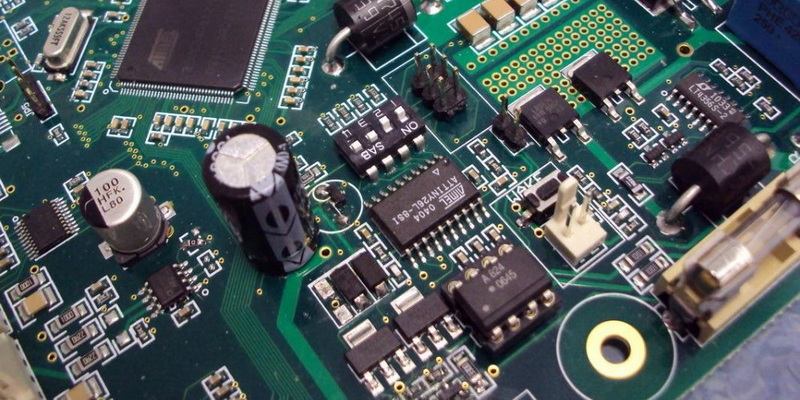

An SMT PCB socket is a surface-mount device designed to provide a removable interface between an integrated circuit (IC) or other electronic components and the PCB. Unlike traditional through-hole sockets, SMT sockets are soldered directly onto the surface of the PCB, enabling a more compact design and higher component density. These sockets facilitate easy installation, replacement, and testing of ICs without permanent soldering, making them invaluable in modern electronics manufacturing.

The SMT PCB socket acts as a bridge that connects the IC pins to the PCB pads, allowing for secure electrical contact while maintaining the flexibility to remove or replace the component. This flexibility is especially important in applications where frequent upgrades, repairs, or testing are required.

Advantages of SMT PCB Socket in PCB Design and Performance

1. Enhanced Electrical Performance

One of the most significant ways SMT PCB sockets improve PCB performance is by enhancing electrical characteristics. Because SMT sockets reduce the lead length between the IC and the PCB, they help minimize parasitic inductance and resistance. This is crucial for high-frequency and high-speed circuits where signal integrity is vital.

Parasitic inductance and capacitance can cause signal degradation, timing errors, and electromagnetic interference (EMI). SMT PCB sockets, by virtue of their design, provide shorter and more direct electrical paths, which reduce these parasitic effects. This results in cleaner signal transmission, reduced noise, and better overall circuit performance.

Moreover, SMT PCB sockets support controlled impedance designs, which are essential in RF and microwave applications. By maintaining consistent impedance, these sockets help prevent signal reflections and losses, ensuring reliable data transmission.

2. Increased Component Density and Compactness

The SMT PCB socket enables designers to maximize the use of available PCB space. Since SMT sockets are mounted on the PCB surface without requiring holes, they allow for a higher packing density of components. This means more components can be placed on both sides of the PCB, enabling smaller, lighter, and more compact electronic devices.

In industries such as consumer electronics, aerospace, and medical devices, where size and weight are critical constraints, the compactness enabled by SMT PCB sockets is a significant advantage. For example, smartphones and wearable devices benefit greatly from the space-saving features of SMT sockets, allowing manufacturers to incorporate more features without increasing device size.

3. Improved Manufacturing Efficiency and Cost Reduction

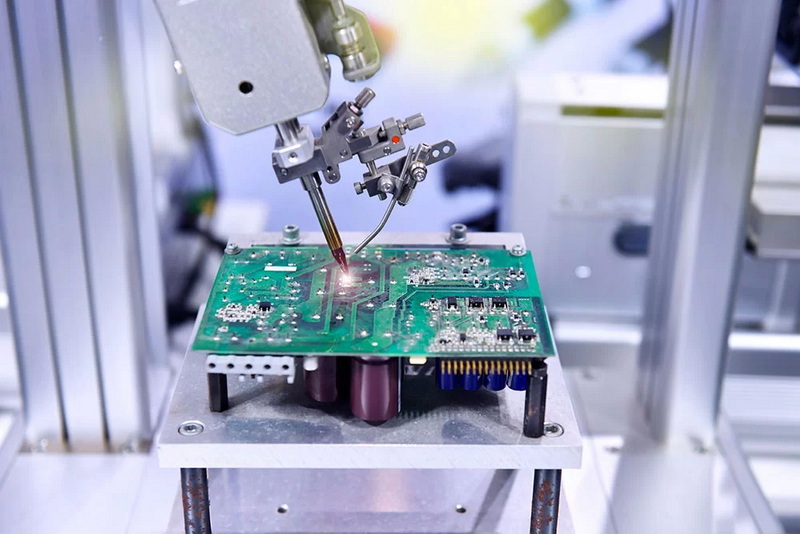

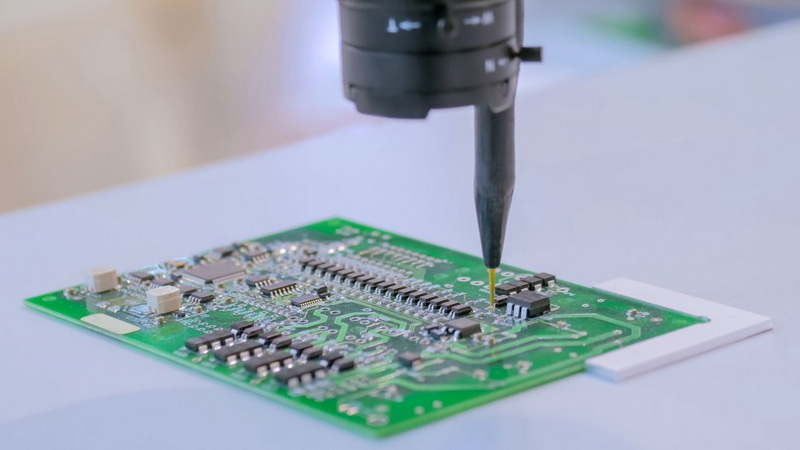

SMT PCB sockets enhance manufacturing efficiency by supporting automated assembly processes. Automated pick-and-place machines can quickly and accurately position SMT sockets on the PCB, followed by reflow soldering to secure them in place. This automation reduces labor costs and production time while improving consistency and yield.

Additionally, SMT sockets eliminate the need for drilling holes for socket leads, which simplifies PCB fabrication and reduces material costs. Fewer drilling operations mean less wear on manufacturing equipment and faster turnaround times.

The ability to use SMT sockets also reduces the risk of soldering defects associated with manual soldering, such as cold joints or solder bridges. This leads to improved product reliability and lower failure rates.

4. Ease of Maintenance and Upgradability

A standout benefit of SMT PCB sockets is their facilitation of easy maintenance and upgrades. During prototyping, testing, or repair, ICs can be plugged into or removed from the socket without the need for desoldering. This reduces the risk of damage to the PCB or components, saving time and cost.

For products that require frequent firmware or hardware upgrades, SMT sockets provide a convenient interface for swapping out ICs. This is particularly valuable in computing and networking equipment, where technology evolves rapidly.

In addition, SMT sockets enable quick troubleshooting by allowing faulty ICs to be replaced swiftly, minimizing downtime and improving serviceability.

5. Mechanical Reliability and Vibration Resistance

While SMT components generally have weaker mechanical strength compared to through-hole components, SMT PCB sockets offer sufficient mechanical stability for most applications. Their reduced mass and compact form factor contribute to better resistance to shock and vibration.

This makes SMT sockets suitable for use in automotive, aerospace, and industrial electronics, where devices are exposed to mechanical stress. Proper socket design and PCB layout can further enhance mechanical reliability, such as using sockets with locking mechanisms or reinforced contacts.

6. Thermal Management Considerations

Although SMT PCB sockets provide many advantages, thermal management is a critical consideration. SMT sockets have less thermal mass and fewer heat dissipation paths compared to through-hole sockets. This can lead to localized heating under high-power conditions.

Designers must ensure adequate heat sinking, thermal vias, and proper PCB layout to dissipate heat effectively. Selecting SMT sockets made from materials with good thermal conductivity and designing the PCB to spread heat away from the socket area can prevent thermal damage and ensure long-term reliability.

Applications of SMT PCB Sockets

SMT PCB sockets are widely used across various sectors due to their versatility and performance benefits:

- Computing Devices: CPUs, memory modules, and other ICs that require frequent replacement or upgrades often use SMT PCB sockets to facilitate easy swapping and testing.

- Telecommunications: Network switches, routers, and communication modules benefit from SMT sockets' ability to maintain signal integrity at high frequencies.

- Consumer Electronics: Compact devices like smartphones, tablets, and wearables use SMT sockets to maximize space and allow for modular component replacement.

- Test and Measurement Equipment: SMT sockets enable rapid IC swapping during testing and calibration, improving efficiency.

- Automotive and Industrial Electronics: SMT sockets provide reliable connections in harsh environments with vibration and thermal stress.

Design Considerations for SMT PCB Sockets

To fully leverage the benefits of SMT PCB sockets, careful design and planning are essential:

Socket Size and Pitch

Selecting the correct socket size and pin pitch is crucial for compatibility with the IC package. Mismatched pitch can cause poor contact or damage to the IC pins. Standard pitch sizes include 0.5 mm, 0.65 mm, and 1.27 mm, among others. Precision in socket selection ensures reliable electrical connections and ease of assembly.

Thermal Management

As mentioned earlier, SMT sockets require adequate thermal design. Incorporating thermal vias, heat sinks, and copper pours near the socket area helps dissipate heat. In some cases, active cooling solutions might be necessary for high-power applications.

Mechanical Stress and Environmental Factors

Consider the operational environment when selecting SMT PCB sockets. In high-vibration or shock-prone settings, choose sockets with robust mechanical retention features. Additionally, ensure the PCB material and solder mask can withstand environmental stresses such as humidity, temperature cycling, and corrosion.

Soldering Process

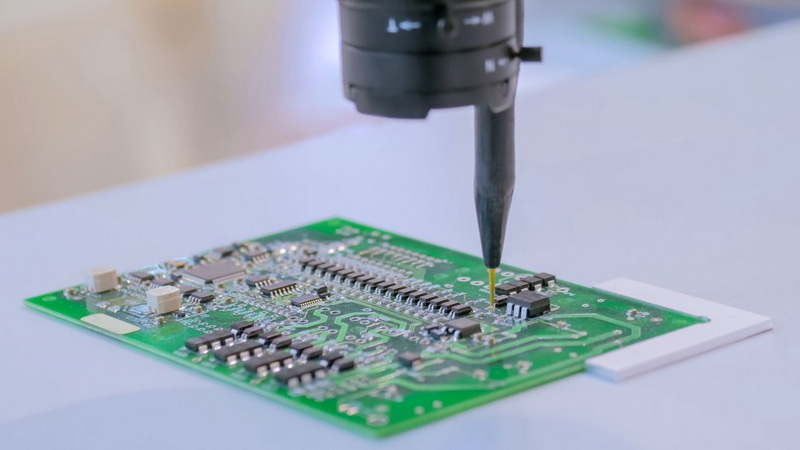

SMT sockets are typically soldered using reflow soldering processes. It is vital to follow manufacturer-recommended temperature profiles to avoid damaging the socket or PCB. Proper solder paste application and stencil design contribute to consistent solder joints.

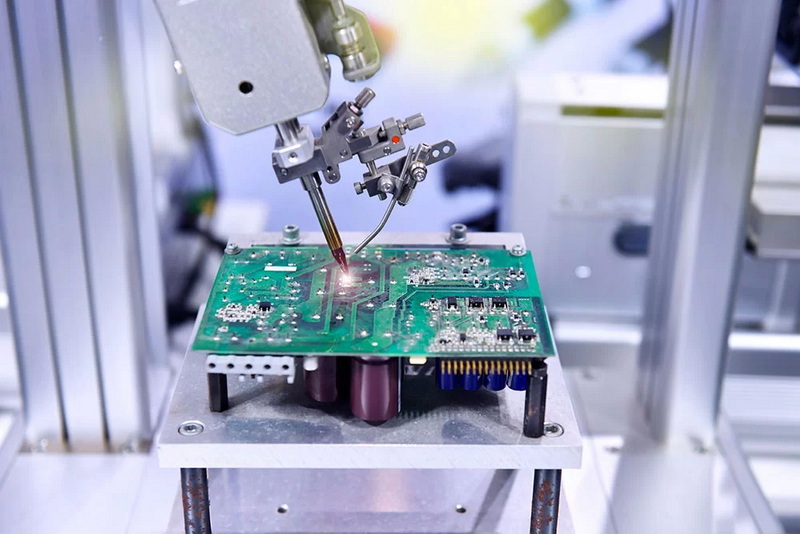

Testing and Inspection

Automated Optical Inspection (AOI) and X-ray inspection are recommended to verify solder joint quality and socket placement. These inspection methods help detect defects early, reducing the risk of field failures.

Future Trends in SMT PCB Socket Technology

As electronics continue to evolve, SMT PCB sockets are also advancing. Emerging trends include:

- Miniaturization: Development of ultra-fine pitch SMT sockets to accommodate smaller IC packages.

- High-Speed Data Transmission: Sockets designed for even lower parasitic inductance and capacitance to support next-generation communication standards.

- Improved Materials: Use of advanced alloys and polymers to enhance thermal and mechanical performance.

- Integration with Flexible PCBs: SMT sockets compatible with flexible and rigid-flex PCBs for wearable and foldable devices.

- Smart Sockets: Incorporation of diagnostic features within sockets to monitor connection integrity and component health in real-time.

These innovations will further enhance the role of SMT PCB sockets in delivering high-performance, reliable, and serviceable electronic systems.

Conclusion

SMT PCB sockets significantly enhance PCB performance by improving electrical characteristics, enabling higher component density, reducing manufacturing costs, and facilitating easy maintenance and upgrades. Their compatibility with automated assembly processes and suitability for compact designs make them indispensable in modern electronics manufacturing. While they have some limitations in mechanical strength compared to through-hole sockets, careful design and application ensure their reliability across various industries.

By integrating SMT PCB sockets into your PCB design, you can achieve superior signal integrity, faster manufacturing, and greater flexibility in product development and servicing. As technology advances, SMT PCB sockets will continue to play a pivotal role in optimizing PCB performance and meeting the demands of increasingly sophisticated electronic devices.

FAQ

1. What is the main difference between SMT PCB sockets and through-hole sockets?

SMT PCB sockets are mounted directly on the PCB surface without the need for drilled holes, allowing for higher component density and automated assembly, whereas through-hole sockets require leads inserted into holes, which can limit design compactness and increase manufacturing complexity.

2. Can SMT PCB sockets be used for high-power applications?

Generally, SMT PCB sockets are better suited for low to moderate power applications due to their limited heat dissipation capabilities. Through-hole sockets are preferred for high-power or high-heat environments.

3. How do SMT PCB sockets improve signal integrity?

By reducing lead lengths and parasitic inductance, SMT sockets minimize signal loss and electromagnetic interference, which is crucial for high-frequency and high-speed circuits.

4. Are SMT PCB sockets easy to replace or upgrade?

Yes, one of the key advantages of SMT PCB sockets is that they allow easy installation and removal of ICs without soldering, facilitating maintenance, upgrades, and testing.

5. What are the challenges of using SMT PCB sockets?

Challenges include weaker solder joints compared to through-hole sockets, sensitivity to mechanical stress in harsh environments, and the need for precise soldering and inspection techniques to ensure reliability.