Content Menu

● Introduction to SMT PCB Assembly

>> Key Benefits of SMT PCB Assembly

● Challenges in SMT PCB Assembly

● Impact on Product Quality

>> Component Quality

>> PCB Design and Quality

>> Solder Paste Application

>> Component Placement

>> Reflow Soldering

● SMT PCB Assembly Equipment

● Process Optimization Techniques

>> Design for Manufacturability (DFM)

>> Statistical Process Control (SPC)

>> Poka-Yoke (Error-Proofing)

● Advanced Technologies in SMT Assembly

>> Machine Learning in SMT

>> IoT Sensors for Real-Time Monitoring

● Conclusion

● FAQ

>> 1. What are the primary benefits of using SMT PCB assembly equipment?

>> 2. What are the key challenges in SMT PCB assembly?

>> 3. How does SMT PCB assembly equipment impact product quality?

>> 4. What types of SMT PCB assembly equipment are commonly used?

>> 5. How can manufacturers optimize SMT assembly processes for better quality?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the production of smaller, more complex, and reliable electronic devices. SMT PCB assembly involves mounting components directly onto the surface of printed circuit boards (PCBs), which offers numerous advantages over traditional through-hole technology. However, the impact of SMT PCB assembly on product quality and reliability is multifaceted and requires careful consideration of various factors.

Introduction to SMT PCB Assembly

SMT PCB assembly is a method of producing electronic circuits where components are mounted directly onto the surface of PCBs. This technique has largely replaced through-hole technology in modern electronics manufacturing due to its numerous advantages, including increased component density, smaller overall product size, improved electrical performance, higher production speeds, and lower manufacturing costs.

Key Benefits of SMT PCB Assembly

1. Higher Component Density: SMT allows for much higher component densities compared to through-hole mounting techniques, enabling miniaturization and weight reduction of electronic products.

2. Smaller and Lighter Assemblies: The finished circuit board assemblies can be made much smaller and lighter, which is especially beneficial for mobile and portable electronic devices.

3. Improved Automation Potential: The SMT assembly process is highly amenable to automation, reducing reliance on manual labor and improving consistency and quality.

4. Higher Reliability and Longevity: SMT assembled PCBs generally have improved reliability and longer lifespans due to robust solder joints and reduced thermal stress.

Challenges in SMT PCB Assembly

Despite its advantages, SMT PCB assembly also presents several challenges:

1. High Initial Investment Costs: Transitioning to SMT requires significant upfront investment in specialized equipment like pick-and-place machines and reflow ovens.

2. Challenges with Fine Pitch Components: Assembling fine-pitch components requires advanced skills and precise equipment, increasing the complexity of the assembly process.

3. Difficult Rework and Modifications: Reworking or modifying assembled SMT PCBs can be extremely difficult due to the compact nature of the components.

Impact on Product Quality

The quality of SMT PCB assemblies is influenced by several factors:

Component Quality

The quality of individual components used in SMT assembly plays a crucial role in the final product's performance and reliability. Proper storage, handling, and supplier quality management are essential. Components must be stored in controlled environments to prevent moisture absorption and oxidation, which can lead to soldering issues during assembly.

PCB Design and Quality

The design and quality of the PCB itself significantly affect the success of SMT assembly. Factors such as PCB material selection, trace width and spacing, pad design, and thermal management features are critical. High-quality PCBs ensure reliable electrical connections and mechanical stability, which are essential for maintaining product performance under various environmental conditions.

Solder Paste Application

Proper solder paste application is vital for creating reliable solder joints. Stencil design, solder paste composition, and printing conditions must be carefully controlled. The solder paste must be applied evenly and in the correct amount to ensure consistent soldering quality.

Component Placement

Accurate and consistent component placement is essential for high-quality SMT assemblies. This involves precise pick-and-place machines and well-maintained component feeders. Misplaced components can lead to electrical failures and reduce product reliability.

Reflow Soldering

The reflow soldering process is critical for forming strong and reliable solder joints. Factors such as oven profile design, temperature uniformity, and atmosphere control are important. A well-controlled reflow process ensures that solder melts evenly and solidifies without defects, contributing to the overall reliability of the assembly.

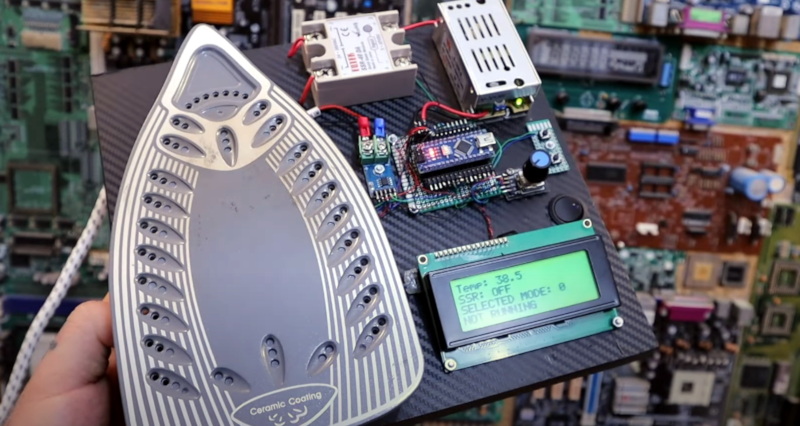

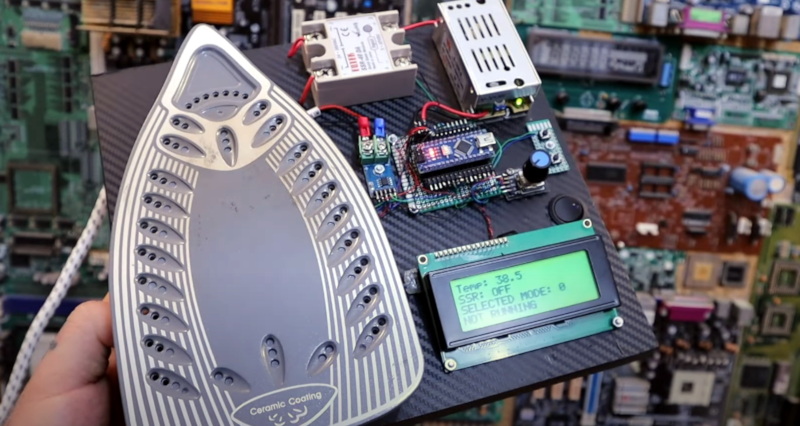

SMT PCB Assembly Equipment

SMT PCB assembly involves a range of specialized equipment to ensure high-quality and efficient production:

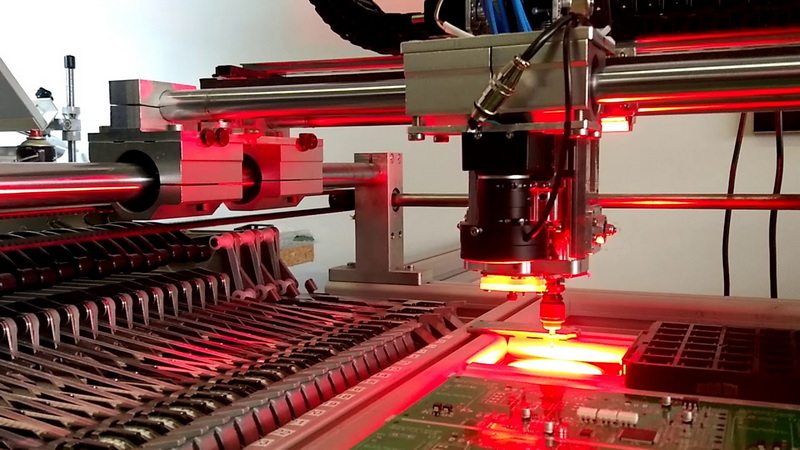

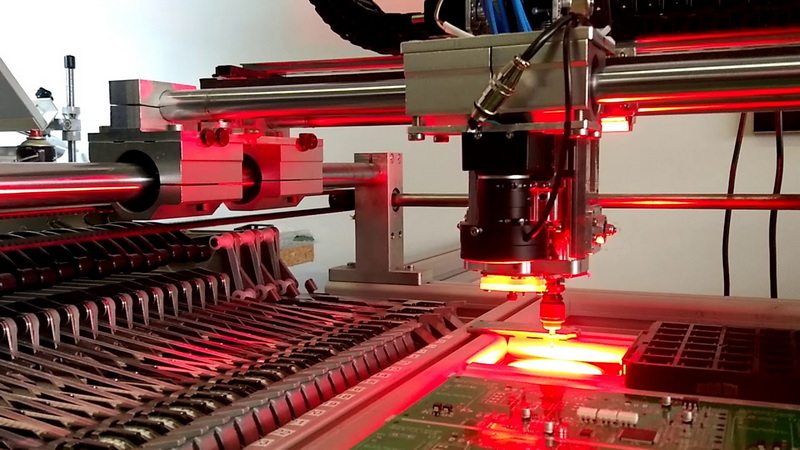

1. Pick-and-Place Machines: These machines are crucial for accurately placing SMDs onto PCBs. They come in manual, semi-automatic, and fully automatic versions, each suited to different production needs. Advanced pick-and-place machines can handle a wide range of components, from small resistors to large BGAs.

2. Solder Paste Printing Machines: These machines apply solder paste to PCB pads before component placement. Stencil printing is preferred for its accuracy and ability to handle fine-pitch components. The quality of the stencil directly affects the solder paste application, so it must be carefully designed and maintained.

3. Reflow Ovens: These ovens melt the solder paste to form permanent bonds between components and PCBs. Long heating zone ovens provide better temperature control, ensuring consistent soldering quality across the board. The oven's temperature profile must be carefully optimized to match the specific solder paste used.

4. Solder Paste Inspection (SPI) Machines: These machines inspect the solder paste application to ensure correct volume and distribution, preventing soldering issues. SPI machines help detect defects early in the assembly process, reducing the need for costly rework.

5. Automated Optical Inspection (AOI) Machines: These machines inspect PCBs for component placement and soldering defects, enhancing quality control. AOI systems can detect issues such as misaligned components, insufficient solder, or solder bridges, allowing for immediate correction.

Process Optimization Techniques

To improve SMT assembly quality, several process optimization techniques can be employed:

Design for Manufacturability (DFM)

Implementing DFM principles early in the product development cycle can significantly improve SMT assembly quality by optimizing component selection and placement. DFM ensures that PCB designs are compatible with SMT assembly processes, reducing production challenges and improving yield rates.

Statistical Process Control (SPC)

SPC techniques help identify and address process variations before they lead to quality issues, ensuring stable and reliable production. By monitoring key parameters such as solder paste application and reflow oven temperatures, manufacturers can maintain consistent quality levels.

Poka-Yoke (Error-Proofing)

Implementing error-proofing mechanisms can prevent common assembly mistakes, such as using barcode scanning for component verification. Poka-yoke systems ensure that only the correct components are used in each assembly step, reducing the risk of human error.

Advanced Technologies in SMT Assembly

Recent advancements in SMT assembly include the integration of Industry 4.0 technologies, such as machine learning and IoT sensors. These technologies enable real-time monitoring and optimization of the assembly process, further enhancing quality and efficiency.

Machine Learning in SMT

Machine learning algorithms can analyze production data to predict potential quality issues and optimize process parameters. For example, predictive models can identify trends in solder paste application that may lead to defects, allowing for proactive adjustments.

IoT Sensors for Real-Time Monitoring

IoT sensors can monitor environmental conditions, equipment performance, and production metrics in real-time. This data can be used to adjust assembly processes dynamically, ensuring optimal conditions for high-quality production.

Conclusion

SMT PCB assembly significantly impacts product quality and reliability by offering higher component densities, improved automation, and enhanced electrical performance. However, it also presents challenges such as high initial investment costs and difficulties with rework. By understanding these factors and optimizing the assembly process with the right equipment and techniques, manufacturers can produce high-quality, reliable electronic products efficiently.

FAQ

1. What are the primary benefits of using SMT PCB assembly equipment?

- The primary benefits include higher component density, smaller and lighter assemblies, improved automation potential, and higher reliability and longevity of the final products.

2. What are the key challenges in SMT PCB assembly?

- Key challenges include high initial investment costs, difficulties with fine-pitch components, and the complexity of reworking or modifying assembled PCBs.

3. How does SMT PCB assembly equipment impact product quality?

- SMT equipment impacts product quality by enabling precise component placement, accurate solder paste application, and robust solder joints, all of which contribute to improved reliability and performance.

4. What types of SMT PCB assembly equipment are commonly used?

- Commonly used equipment includes pick-and-place machines, solder paste printing machines, reflow ovens, SPI machines, and AOI machines.

5. How can manufacturers optimize SMT assembly processes for better quality?

- Manufacturers can optimize processes by implementing DFM principles, using SPC techniques, and incorporating error-proofing mechanisms to ensure consistent and reliable production.