Understanding SMT Line Production

SMT line production refers to the systematic process of assembling electronic components onto PCBs using surface mount technology. This method is characterized by several key stages:

1. Solder Paste Printing

2. Component Placement

3. Reflow Soldering

4. Inspection and Cleaning

Each stage is essential for ensuring that the final product meets quality standards and operates effectively.

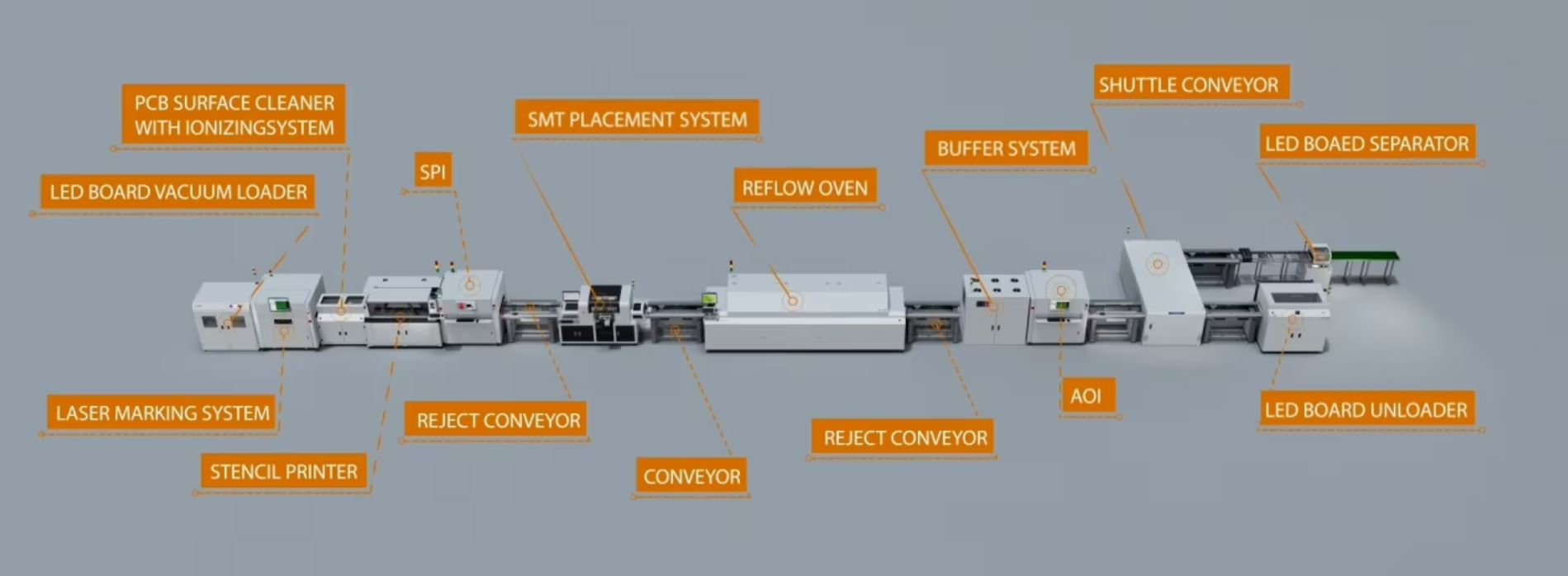

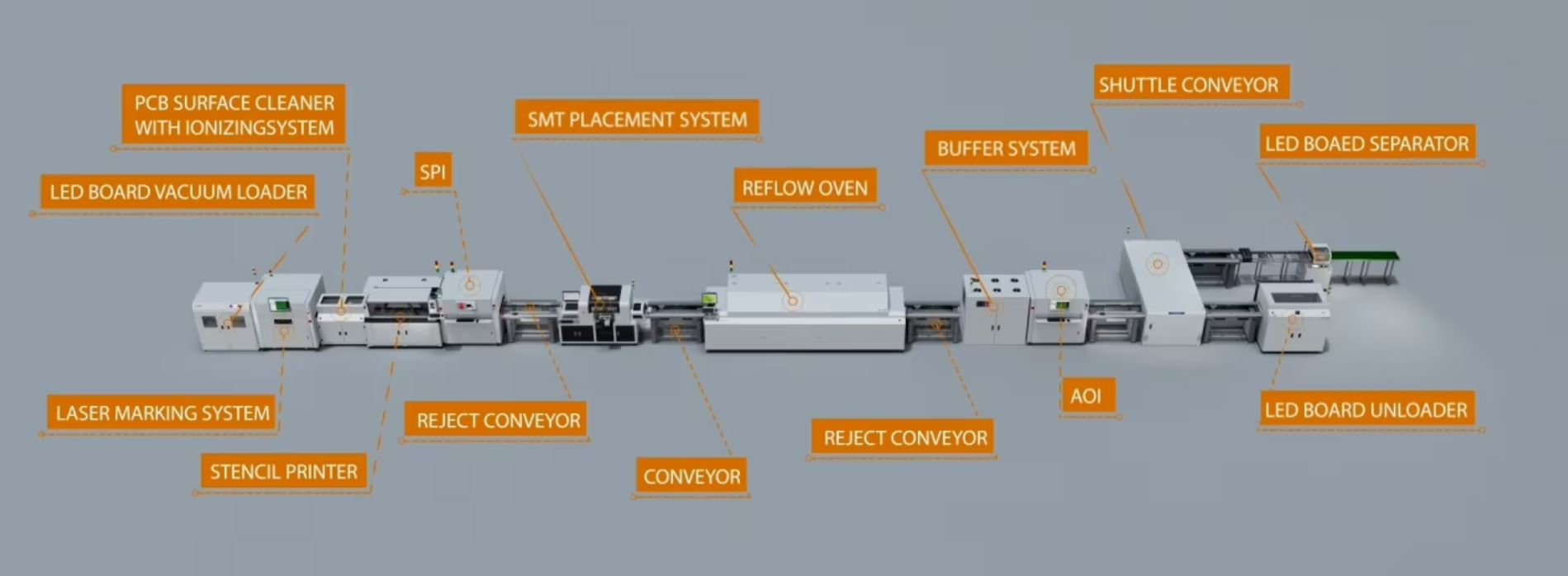

Key Components of an SMT Line

A typical SMT line consists of interconnected machines that work together seamlessly. Here are the primary components involved in SMT line production:

1. Solder Paste Printer

The solder paste printer applies solder paste to the PCB using a stencil. This process is crucial as it prepares the board for component placement.

Solder Paste Printer

2. Pick-and-Place Machine

This machine accurately places surface mount devices (SMDs) onto the PCB. Equipped with advanced vision systems, it ensures precise component placement.

Pick-and-Place Machine

3. Reflow Oven

The reflow oven melts the solder paste to create reliable electrical connections between the components and the PCB. It operates through a controlled heating process that includes several temperature zones.

Reflow Oven

4. Automatic Optical Inspection (AOI)

After soldering, AOI machines inspect the boards for defects or misalignments in component placement, ensuring quality control.

AOI Machine

5. Cleaning Machine

This machine removes excess flux and debris from the PCB, preparing it for final assembly or packaging.

Cleaning Machine

The SMT Line Production Process

The SMT line production process can be broken down into several detailed steps:

Step 1: Material Preparation

Before production begins, materials such as PCBs and components are inspected for quality. This step ensures that only defect-free materials enter the production line.

Step 2: Solder Paste Printing

Using a stencil printer, solder paste is applied to designated areas on the PCB. The precision of this step is vital for effective soldering later on.

Step 3: Component Placement

The pick-and-place machine retrieves components from reels or trays and places them onto the solder paste on the PCB. This step requires high accuracy to ensure proper alignment.

Step 4: Reflow Soldering

Once all components are placed, the PCB moves through a reflow oven where heat is applied in a controlled manner to melt the solder paste, creating strong electrical connections.

Step 5: Inspection

After reflow soldering, AOI machines check for any defects in component placement and solder joints. This step is crucial for maintaining high-quality standards.

Step 6: Cleaning

Finally, any residual flux or contaminants are removed using a cleaning machine, ensuring that the PCB is ready for further processing or packaging.

Benefits of SMT Line Production

The adoption of SMT line production offers numerous advantages:

- Increased Efficiency: Automated processes reduce manual labor and speed up production cycles.

- Higher Precision: Advanced machines ensure accurate component placement, minimizing defects.

- Cost Savings: Reduced labor costs and material wastage contribute to overall savings.

- Flexibility: SMT lines can accommodate various component sizes and types, making them versatile for different products.

Future Trends in SMT Line Production

As technology advances, SMT line production continues to evolve. Some emerging trends include:

- AI Integration: Artificial intelligence is being used to optimize production processes by analyzing data in real-time.

- Industry 4.0: The integration of IoT devices allows for better monitoring and control of manufacturing processes.

- Sustainability Practices: Companies are increasingly focusing on eco-friendly materials and processes to reduce their environmental impact.

Frequently Asked Questions (FAQs)

1. What is an SMT line?

- An SMT line is a series of interconnected machines used for assembling electronic components onto printed circuit boards using surface mount technology.

2. What are the main components of an SMT line?

- Key components include solder paste printers, pick-and-place machines, reflow ovens, AOI machines, and cleaning machines.

3. How does an AOI machine work?

- AOI machines use cameras and software to inspect PCBs for defects after soldering, ensuring quality control in production.

4. What benefits does SMT line production offer?

- Benefits include increased efficiency, higher precision, cost savings, and flexibility in handling various component types.

5. What future trends are expected in SMT line production?

- Emerging trends include AI integration, Industry 4.0 advancements, and a focus on sustainability practices.

Conclusion

SMT line production plays a crucial role in modern electronics manufacturing by enhancing efficiency and precision in assembling electronic components onto PCBs. As technology continues to advance, these production lines will become even more sophisticated, driving further innovations in the industry.